Method for comprehensive recovery of rhenium and copper from waste acid of copper smelting

A technology for copper smelting and rhenium-rich slag is applied in the field of high-pressure leaching of targeted rhenium copper-rhenium-rich slag-leaching rhenium in rhenium-rich liquid to prepare potassium perrhenate, and can solve the problems of complex process, low recovery rate and processing time It can improve the precipitation rate, reduce the dosage, and improve the reaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

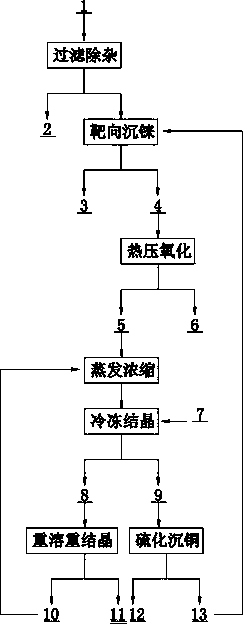

Method used

Image

Examples

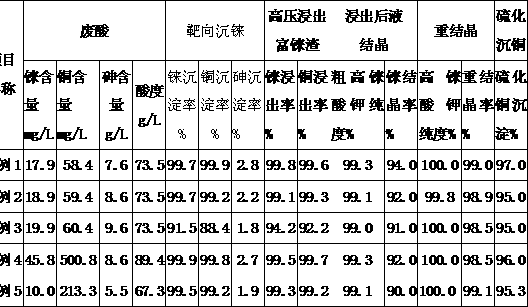

Embodiment 1

[0032] In this embodiment, the copper smelting waste acid sulfuric acid concentration is 73.48g / L, the rhenium concentration is 17.94mg / L, the arsenic concentration is 7.58g / L, and the copper concentration is 58.38mg / L. The treatment process and effects are as follows:

[0033] (1) Targeted sinking of rhenium: the waste acid from copper smelting is filtered to remove lead and then pumped to the rhenium-copper precipitation tank. 3 Add 20L of 20% sodium thiosulfate and 20g of sodium sulfide to the waste acid, heat it with steam to 70°C, and stir for 5 minutes; the obtained rhenium-rich slag consists of 2.45% rhenium, 32.22% arsenic, and 8.30% copper; the precipitation rate of rhenium is 99.7%, The arsenic precipitation rate is only 2.78%, and the copper precipitation rate is 99.9%.

[0034] (2) Hot-pressed oxidation leaching of rhenium: The rhenium-rich slag obtained in step (1) was subjected to pressurized oxygen leaching, the leaching conditions were: liquid-solid ratio 6, le...

Embodiment 2

[0039] In this example, the sulfuric acid concentration of copper smelting waste acid is 73.48g / L, the rhenium concentration is 17.94mg / L, the arsenic concentration is 7.58g / L, and the copper concentration is 58.38mg / L. The treatment process and effect are as follows: (1) Targeted rhenium sinking : Pump the waste acid after filtering and removing lead to the rhenium-copper precipitation tank, and use a metering pump at a rate of 1m 3 Add 25L of 20% sodium thiosulfate and 10g of sodium sulfide to the waste acid, heat to 65°C with steam, and stir for 15 minutes. The composition of the obtained rhenium-rich slag is 2.49% rhenium, 25.14% arsenic and 8.42% copper. The precipitation rate of rhenium is 99.7%, that of arsenic is only 2.15%, and that of copper is 99.2%. (2) Hot-pressed oxidation leaching of rhenium: The rhenium-rich slag obtained in step (1) is subjected to pressurized oxygen leaching, the leaching conditions are: liquid-solid ratio 8:1, leaching temperature 130°C, ox...

Embodiment 3

[0043] In this example, the sulfuric acid concentration of copper smelting waste acid is 73.48g / L, the rhenium concentration is 17.94mg / L, the arsenic concentration is 7.58g / L, and the copper concentration is 58.38mg / L. The treatment process and effect are as follows: (1) Targeted rhenium sinking : Pump the waste acid after filtering and removing lead to the rhenium-copper precipitation tank, and use a metering pump at a rate of 1m 3 Add 10L of 20% sodium thiosulfate and 15g of sodium sulfide to the waste acid, heat to 50°C with steam, and stir for 15 minutes. The composition of the obtained rhenium-rich slag is 3.16% rhenium, 30.36% arsenic and 9.66% copper. The precipitation rate of rhenium was 91.5%, that of arsenic was only 1.76%, and that of copper was 88.4%. (2) Hot-pressed oxidation leaching of rhenium: The rhenium-rich slag obtained in step (1) is subjected to pressurized oxygen leaching, the leaching conditions are: liquid-solid ratio 4:1, leaching temperature 150°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| crystallization time | aaaaa | aaaaa |

| crystallization time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com