A method for leaching copper from tin-copper slag

A leaching, tin-copper technology, applied in the field of leaching copper from tin-copper slag, can solve the problems of difficult copper leaching, long process flow, high cost, etc., and achieve the effects of low cost, separation and small usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

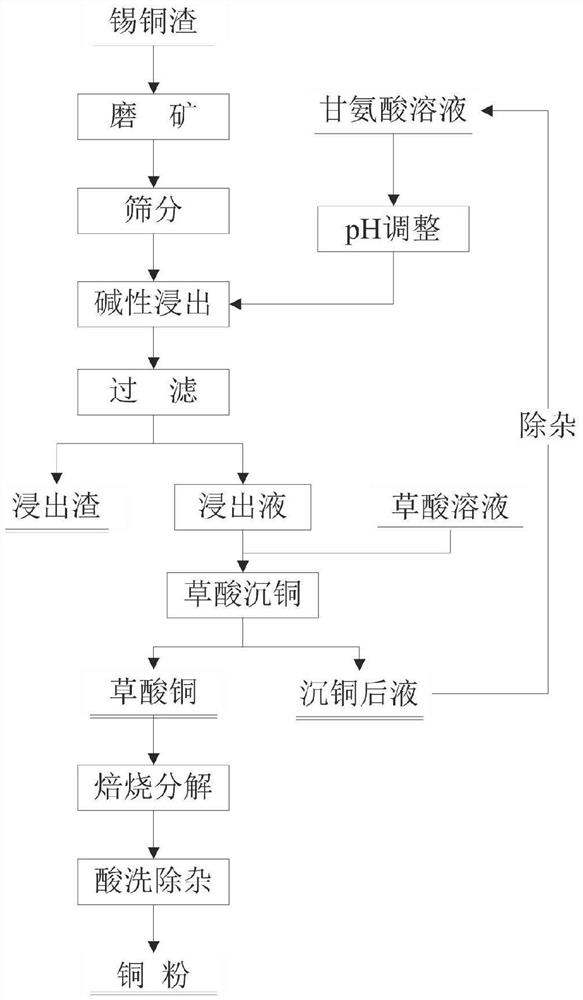

Method used

Image

Examples

Embodiment 1

[0066] The copper content in the tin-copper slag in this embodiment is 10%.

[0067] The present embodiment provides a method for leaching copper from tin-copper slag, comprising the following steps:

[0068] (1) Grinding: the tin-copper slag is crushed, ground, and sieved to a particle size of less than 0.074mm that accounts for more than 95% of the mass to obtain the slag to be treated;

[0069] (2) Alkaline leaching: The concentration of glycine leaching agent is configured to be 50g / L, and the pH of the leaching agent solution is adjusted to 10 by using sodium hydroxide solution; Heating to 40°C, leaching for 1 hour under mechanical stirring at 50 rpm, the copper leaching rate reaches 70%; the leaching pulp is filtered with a plate and frame filter device to obtain copper-containing leaching solution and leaching slag;

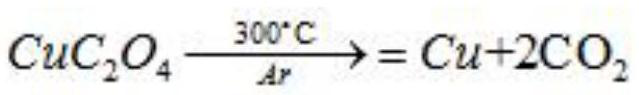

[0070] (3) oxalic acid copper precipitation: the above-mentioned copper-containing leaching solution is neutralized with 200g / L oxalic acid solution, and...

Embodiment 2

[0074] The copper content in the tin-copper slag in this embodiment is 20%.

[0075] The present embodiment provides a method for leaching copper from tin-copper slag, comprising the following steps:

[0076] (1) Grinding: crushing, grinding, and sieving the tin-copper slag to a particle size with a particle size of less than 0.074mm accounting for more than 90% of the mass to obtain the slag to be treated;

[0077] (2) Alkaline leaching: configure the concentration of glycine leaching agent to be 100g / L, and adjust the pH of the leaching agent solution to 10.5 with sodium hydroxide solution; mix the configured glycine leaching agent and the treated residue at a liquid-solid ratio of 10:1, and heat At 60°C, leaching for 5 hours under mechanical stirring at 100 rpm, the copper leaching rate reaches 80%; the leaching pulp is filtered with a plate and frame filter device to obtain copper-containing leaching solution and leaching slag;

[0078] (3) oxalic acid copper precipitatio...

Embodiment 3

[0082] The copper content in the tin-copper slag in this embodiment is 30%.

[0083] The present embodiment provides a method for leaching copper from tin-copper slag, comprising the following steps:

[0084] (1) Grinding: crushing, grinding, and sieving the tin-copper slag to a particle size with a particle size of less than 0.074mm accounting for more than 90% of the mass to obtain the slag to be treated;

[0085] (2) Alkaline leaching: the concentration of glycine leaching agent is configured to be 150g / L, and the pH of the leaching agent solution is adjusted to 11 by using sodium hydroxide solution; Heating to 75°C, leaching for 15h under mechanical stirring at 200 rpm, the copper leaching rate reaches 90%; the leaching pulp is filtered with a plate and frame filter device to obtain copper-containing leaching solution and leaching slag;

[0086] (3) oxalic acid copper precipitation: the above-mentioned copper-containing leaching solution is neutralized with 300g / L oxalic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com