Patents

Literature

42 results about "Copper oxinate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting copper from organic silicon chemical waste residue leaching liquid of chloride and mixed salts containing copper

InactiveCN1844422AGuaranteed separation effectLow costPhotography auxillary processesCopper oxides/halidesChemical industryDecomposition

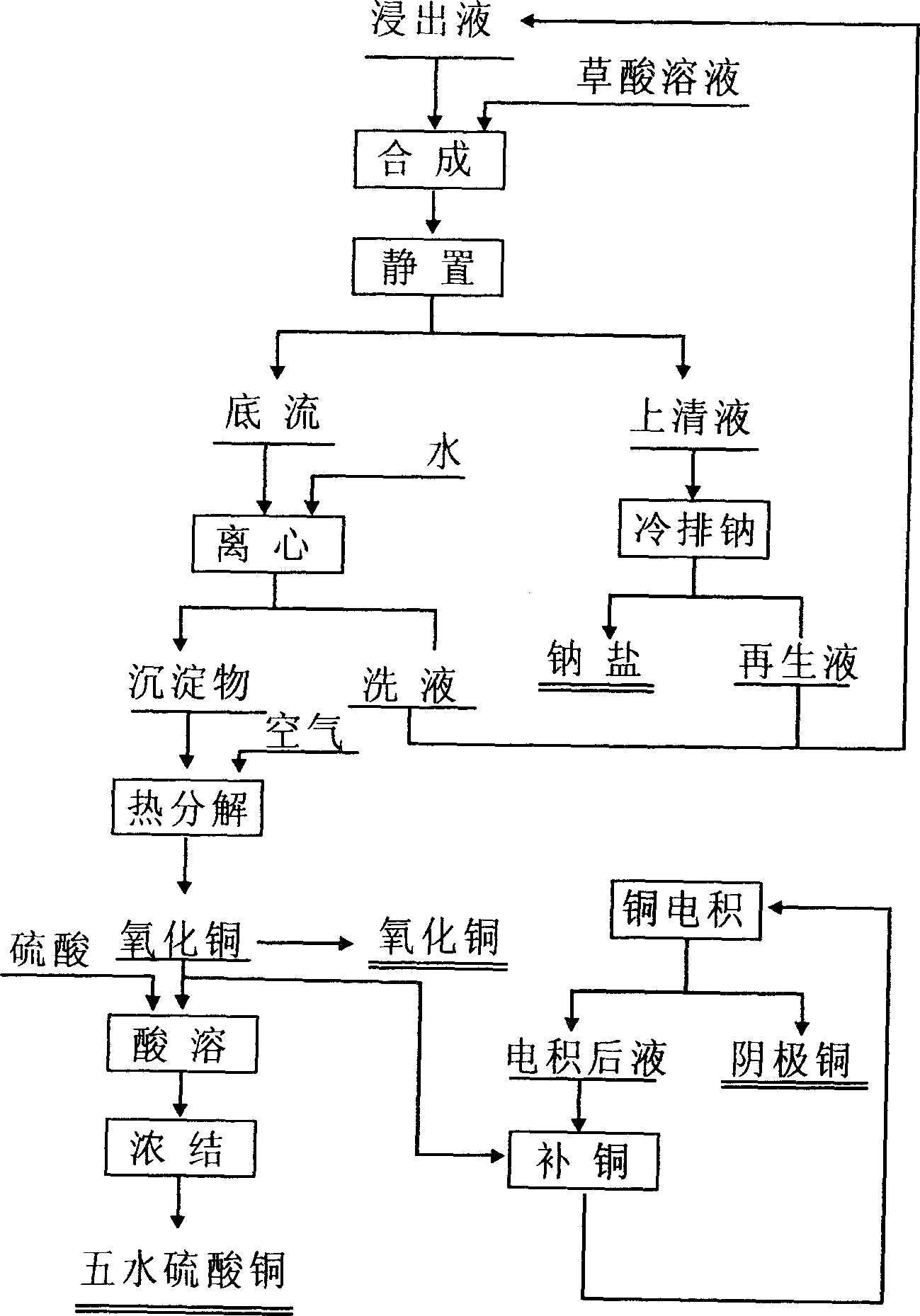

The invention selects oxalic acid solution to act as the precipitating agents of organosilicon chemical industry waste slag leachate of copper chlorate or mixture salt system, after filtering, washing and drying of the process residue of copper oxalic acid, heat decomposition in oxidizing atmosphere and at the temperature of 500~900 centigrade, the production of copper oxide is obtained by product yield cool-down. The yield acid of oxalic acid precipitation process is retuned organosilicon chemical industry waste slag leachate system to act as infusion. After the heat decomposition copper oxide dissolves in sulphuric acid, the solution can be used in electrodepositing cathode copper or regenerating copper sulphate, also can be used to produce cathode copper by copper electrodepositing solution dissolution regeneration electrodeposition, also sell as commercial copper oxide.

Owner:范有志

Preparation method and application of flaky nano copper oxide

ActiveCN110436508ASimple preparation processReduce manufacturing costNanotechnologyCopper oxides/halidesPhotocatalytic degradationCopper salt

The invention discloses a preparation method and application of flaky nano copper oxide. The preparation method of the flaky nano copper oxide mainly comprises the following steps: accurately weighingcopper salt and oxalic acid or oxalate, uniformly mixing the copper salt and the oxalic acid or the oxalate, then grinding, adding a proper amount of distilled water in the grinding process to enablethe mixture to be in a fluid state, heating, cleaning and drying after grinding to obtain a precursor copper oxalate, and calcining the precursor copper oxalate to obtain the flaky nano copper oxide.A preparation technology is simple, no organic solvent except ethanol is used in a preparation process, the preparation method is environment-friendly and safe, and prepared flaky nano copper oxide particles are uniform in size and small in particle size, and have good photocatalytic degradation performance on a methylene blue solution.

Owner:GANSU AGRI UNIV

Preparation method of nickel coated copper composite powder

The invention relates to a preparation method of nickel coated copper composite powder. The preparation method comprises the following process steps that copper salt and oxalate or carbonate take reaction to generate cupric oxalate or copper carbonate sediments, the filtering is carried out, pure water is used for flushing to be in a neutral state, and solution with the concentration being 10 to 80g / L is prepared; and nickel salt solution and the required oxalate or carbonate solution are prepared according to a proportion that the copper nickel weight ratio is 2:1 to 1:2 and are added into the cupric oxalate or copper carbonate solution for reaction to generate nickel coated copper resultants. The preparation method has the advantages that firstly, nickel salts are used for coating copper salts, then, the thermal decomposition is carried out, nickel coated copper powder is obtained, the production process is simple, the operation is easy, the production cost is low, and the industrial production can be realized. The nickel coated copper powder or alloy prepared by the method has the morphology in a spherical shape, a near-spherical shape, an irregular shape or a tree branch shape, and has the advantages that the powder dispersion is uniform, no segregation is generated, the coating effect is good, the coating is compact, the particle size is controllable, and the like. The nickel coated copper powder or alloy can be used for electromagnetic shielding materials and powder metallurgy prealloyed powder. The preparation method can be used for preparing nickel-copper alloy powder.

Owner:NAT ENG RES CENT FOR SPECIAL METAL MATERIALS OF TANTALUM & NIOBIUM

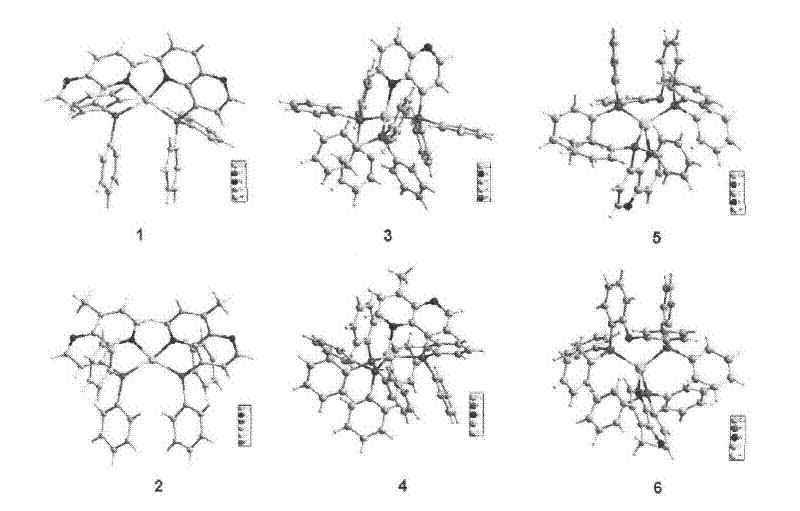

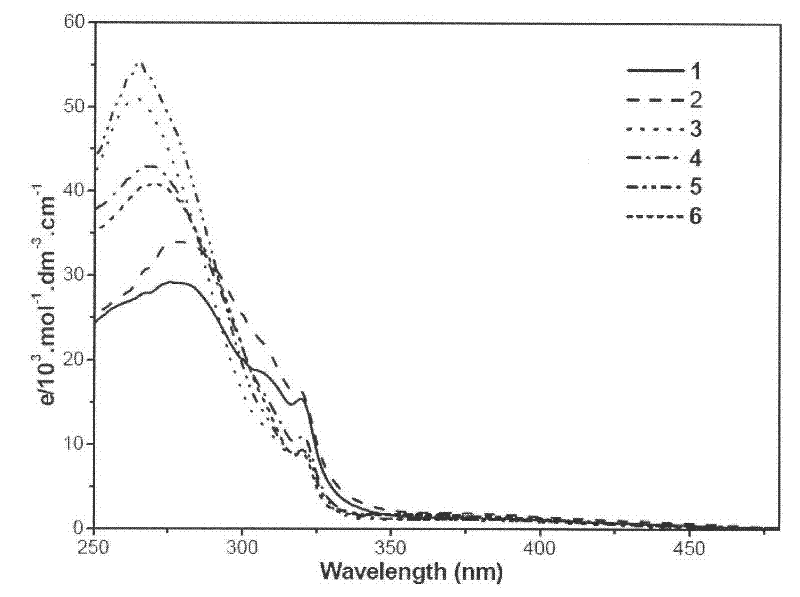

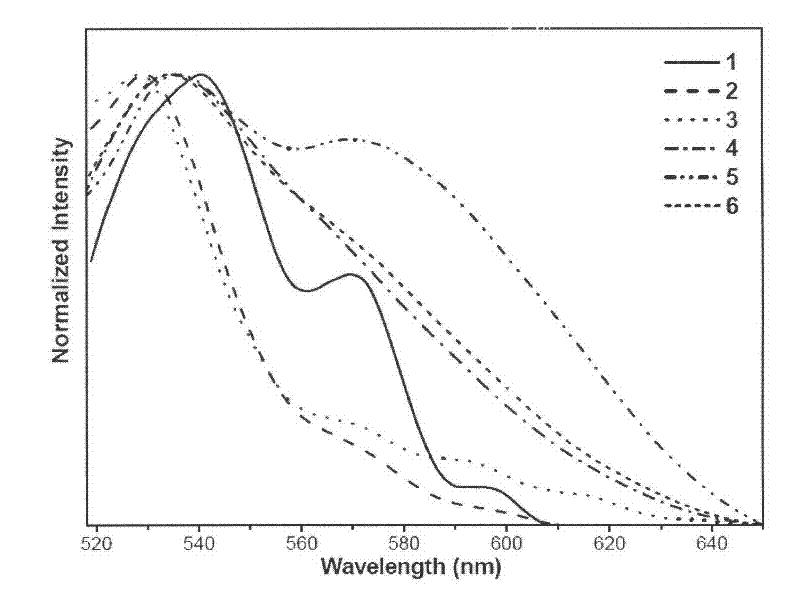

4-phosphino-1,5-naphthyridine derivative copper (i) complex luminescent material and application

The invention provides a 4-phosphino-1,5-naphthyridine derivative copper (I) complex luminescent material and application. The copper (I) complex firstly introduces 1,5-naphthyridine to asymmetrical N^P ligand, and has lower photochemical energy gap and electrochemical energy gap as compared with typical 8-phosphino-copper oxinate (I) complex. The complex can be used as the luminescent layer or electron transmission layer of organic light-emitting diodes.

Owner:NANJING UNIV OF TECH

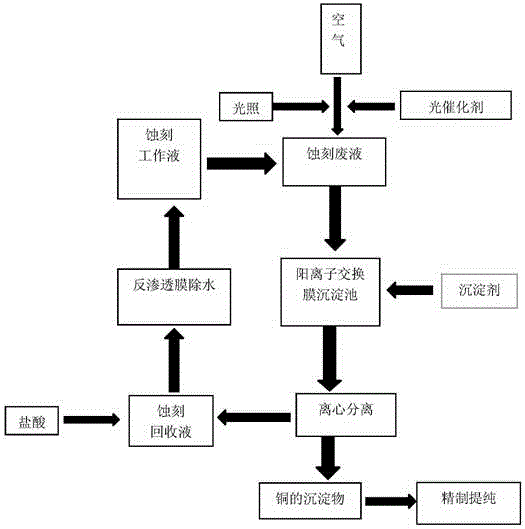

Method for recycling PCB (printed circuit board) acidic etching solution under photocatalytic actions

InactiveCN105603434APrevent escapeAchieve reusePhysical/chemical process catalystsOrganic compound preparationCopper oxidePrinted circuit board

The invention discloses a method for recycling a PCB (printed circuit board) acidic etching solution under photocatalytic actions. The method comprises the following steps: an etching waste solution overflowing from an etching cylinder on the production line flows into a waste solution collection tank; the etching waste solution flows into an oxidation reaction tank from the waste solution collection tank, and reacts by adding a photocatalyst under lighting conditions; the oxidated waste solution flows into a precipitation reaction kettle provided with a cation exchange membrane, and meanwhile, a precipitant is added to form a precipitate-containing mixed solution; the mixed solution is subjected to solid-liquid separation; part of the filter residue is refined and purified, and then is sold in the form of cupric oxalate, and the rest is decomposed into activated copper oxide for sale; the filtrate flows into a dewatering system after hydrochloric acid is supplemented, thereby removing excessive moisture; and finally, the filtrate flows into a storage tank to become the recycled solution for etching. The copper is reutilized in the technical process: the copper is extracted properly by balanced operation, and part of copper is recycled. Only a certain amount of clean water is discharged, and no waste solution is discharged, thereby implementing closed cycle production. The process is simple in equipment and convenient to control, has wide popularization prospects, and has obvious economic value and social and environmental benefits.

Owner:SOUTH CHINA UNIV OF TECH

Sound-absorbing sound-insulating composite material for automobiles

InactiveCN109553371AHigh mechanical strengthImprove corrosion resistanceCeramicwareEnvironmental resistanceBenzoic acid

The invention discloses a sound-absorbing sound-insulating composite material for automobiles, consisting of the following raw materials in parts by weight: 6-10 parts of ethylene propylene diene monomer rubber, 6-8 parts of magnesium oxide, 6-9 parts of glass fiber cotton, 0.2-0.6 part of foaming adhesive, 40-50 parts of gypsum mortar, 20-30 parts of diatom mud, 16-20 parts of wood fiber, 3-5 parts of carboxymethyl cellulose, 1-3 parts of stabilizer, 5-9 parts of foaming agent, 14-18 parts of water, 0.5-12 parts of copper oxinate, 15-25 parts of PVC resin, 2-4 parts of n-butanol, 1-3 parts ofcoalescing aid, 1-3 parts of wetting agent, 7-9 parts of zinc oxide, 1-3 parts of calcium carbonate, 4-6 parts of benzoic acid, and 6-10 parts of natural double salt. The sound-absorbing sound-insulating composite material for automobiles of the invention is improved in corrosion resistance; sound energy is gradually attenuated, so that the purpose of sound absorption is achieved, and the porouscharacteristic is used to realize sound absorption and noise reduction; and with addition of diatom mud, toxic volatile organic compounds on the surface of the composite sound-absorbing material are greatly reduced, the environmental friendliness is enhanced, the sound insulation effect is excellent, and the use prospect is better.

Owner:LIUZHOU HAOXIANGTE SCI & TECH

High impact polystyrene (HIPS) flame-retardant plastic

InactiveCN103497477AGood flame retardant functionMechanical strength is not affectedPolymer sciencePolymer chemistry

The invention discloses high impact polystyrene (HIPS) flame-retardant plastic. The HIPS flame-retardant plastic comprises, by weight, 105-110 parts of HIPS, 10-15 parts of nano-silica, 10-15 parts of melamine cyanurate, 10-15 parts of glass fibers, 10-12 parts of sodium antimonate, 8-11 parts of styrene, 14-16 parts of alkylbenzene sulfonate, 2-3 parts of copper oxalate, 10-20 parts of triphenyl thiophosphate and 10 parts of zirconia. The HIPS flame-retardant plastic has good fire resistance and a small amount of the HIPS flame-retardant plastic can produce obvious flame retardation effects. Mechanical strength of the HIPS flame-retardant plastic is not influenced and especially, a heat deflection temperature, a kinetic temperature and electric insulation properties of a plastic product are not influenced. The HIPS flame-retardant plastic can be uniformly dispersed and has good weatherability, long action time and long-term flame resistance.

Owner:WUJIANG TIANYUAN PLASTIC

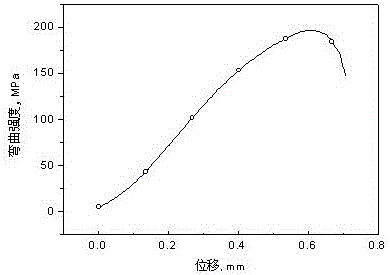

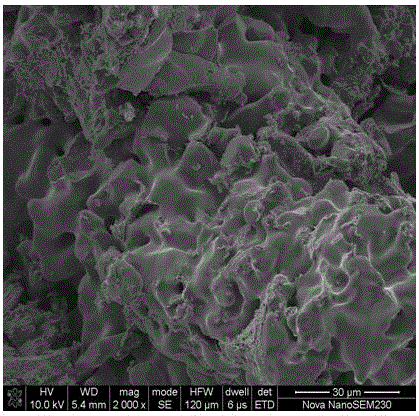

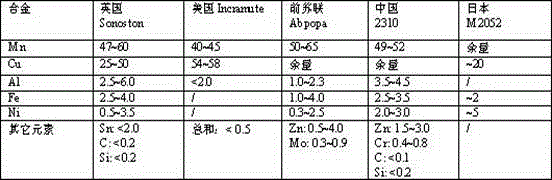

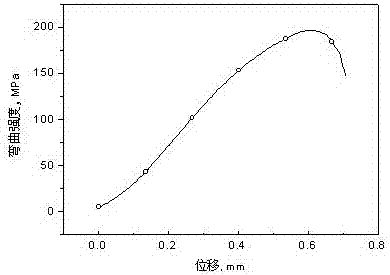

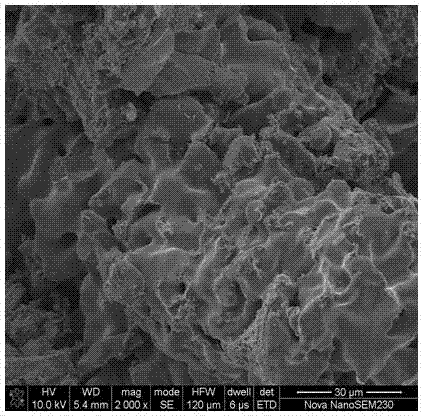

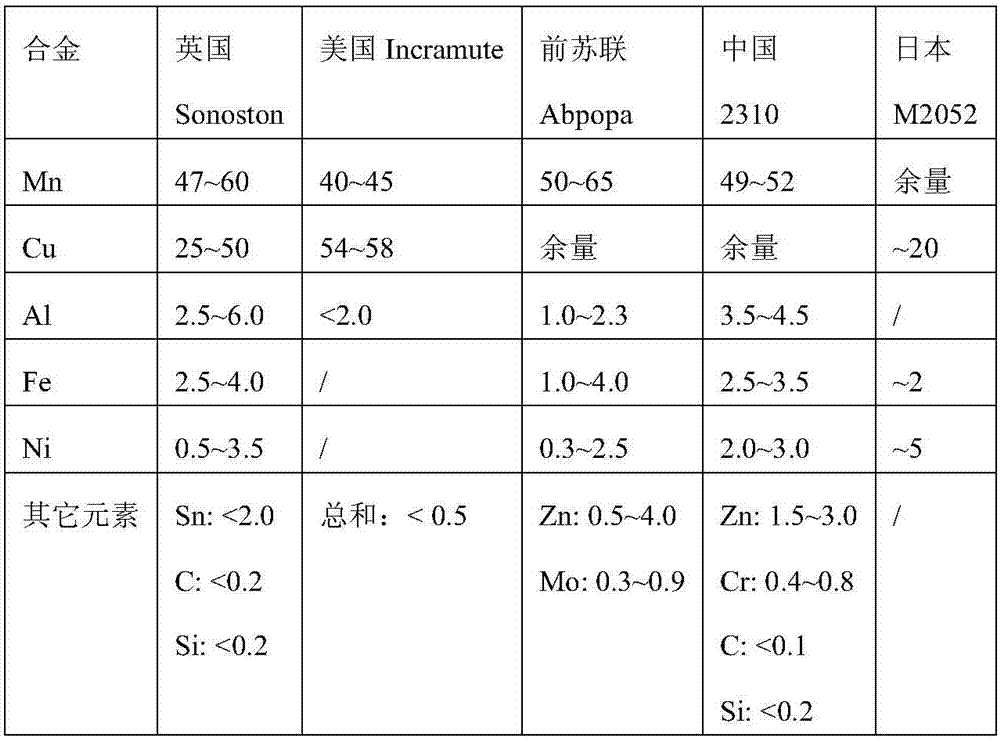

Process for improving structure and property uniformity of manganin sintered damping alloy

The invention discloses a process for improving structure and property uniformity of manganin sintered damping alloy. Decomposition products of cupric oxalate are used for replacing a part of copper powder, and then powder metallurgy manganin damping alloy is prepared. The cupric oxalate is thermally decomposed and reduced to obtain nanoscale highly active copper particles to promote sintering, released CO2 and a small amount of H2O vapor prevent a compact sealing layer from forming on the surface of a sintered blank, and then pyrolysis, presintering and sintering are carried out under the effect of H2. The pyrolysis of the cupric oxalate refers to carry out heat preservation for 1 to 4 hours at the temperature of 330 to 450 DEG C; presintering and reduction refer to carry out heat preservation for 1 to 4 hours at the temperature of 600 to 800 DEG C; the high-temperature sintering refers to carry out heat preservation for 2 to 4 hours at the temperature of 850 to 920 DEG C to complete the sintering process. For the prepared sintered alloy, the diameter is 100mm, the length is 200mm, the density is 5.10 to 5.75g / cm<3>, the hardness is 52 to 92HRF, the bending strength is within the range of 108 to 197MPa and the uniformity of a sintered body is good.

Owner:CENT SOUTH UNIV

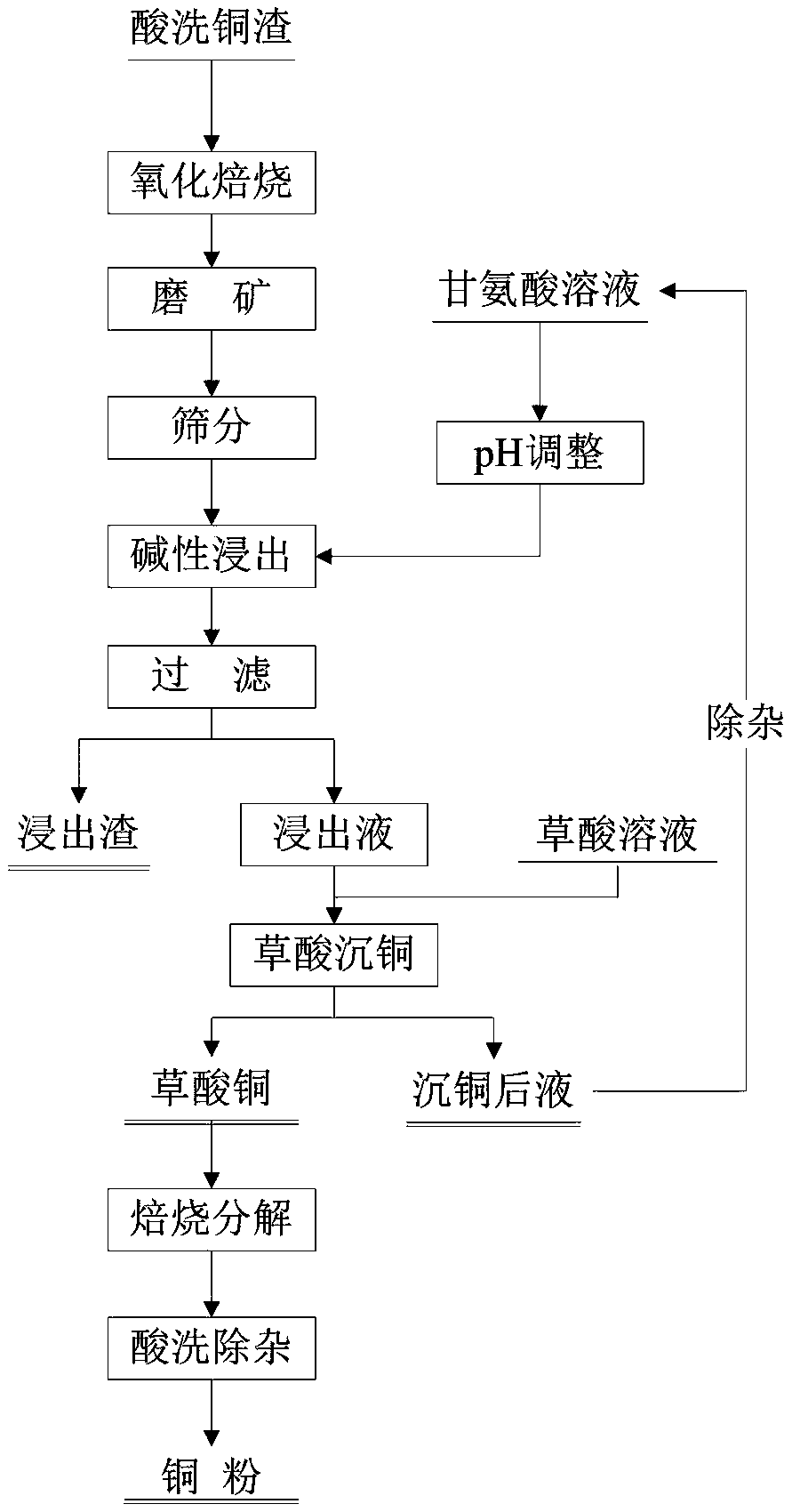

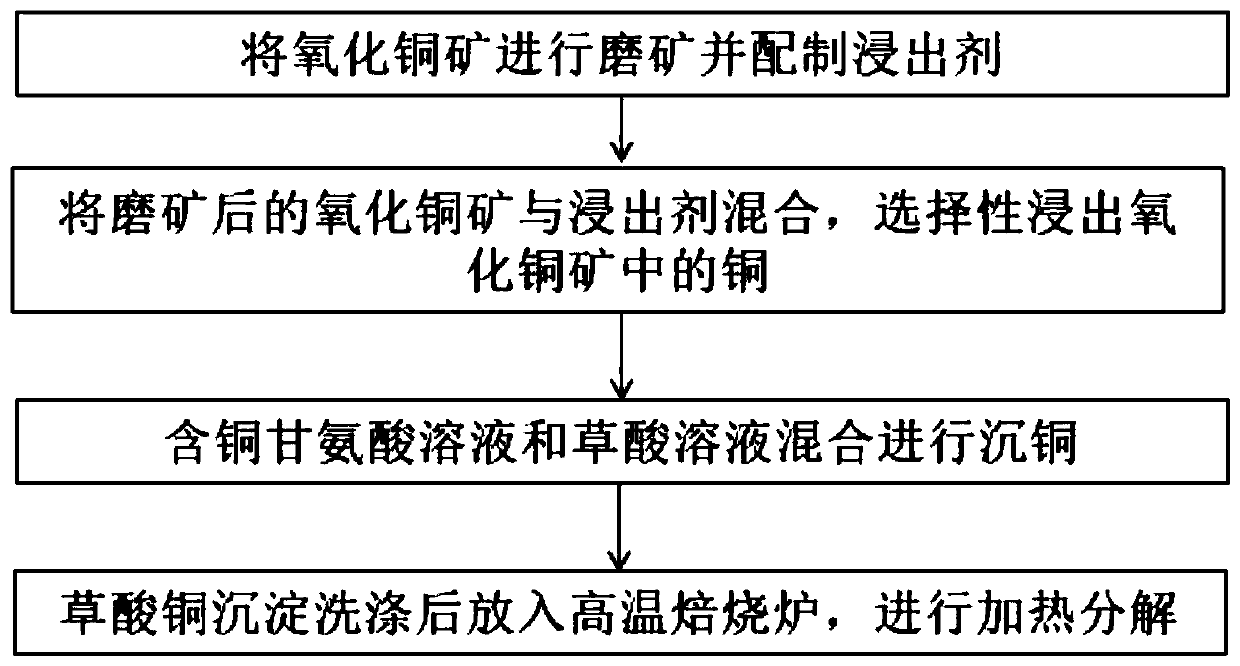

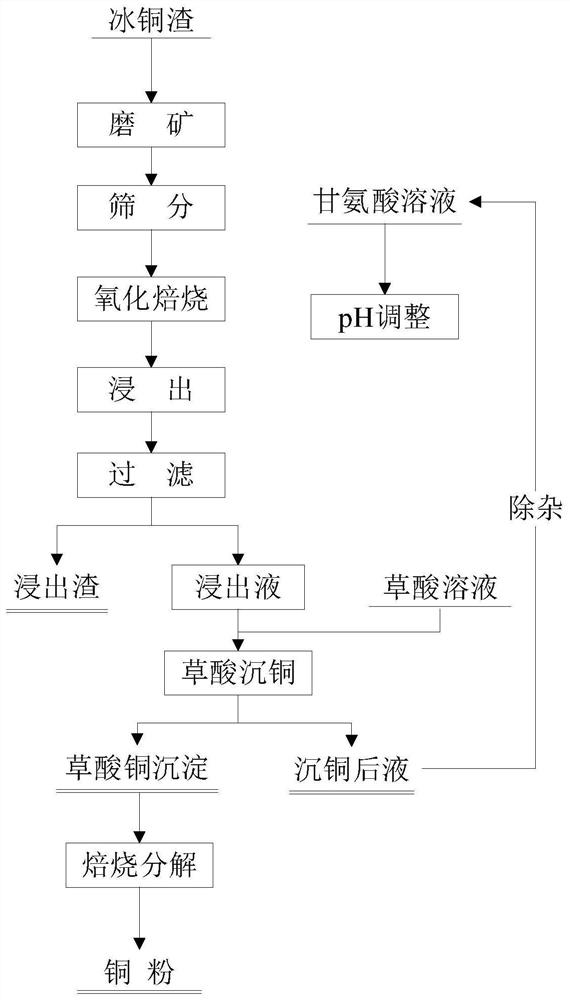

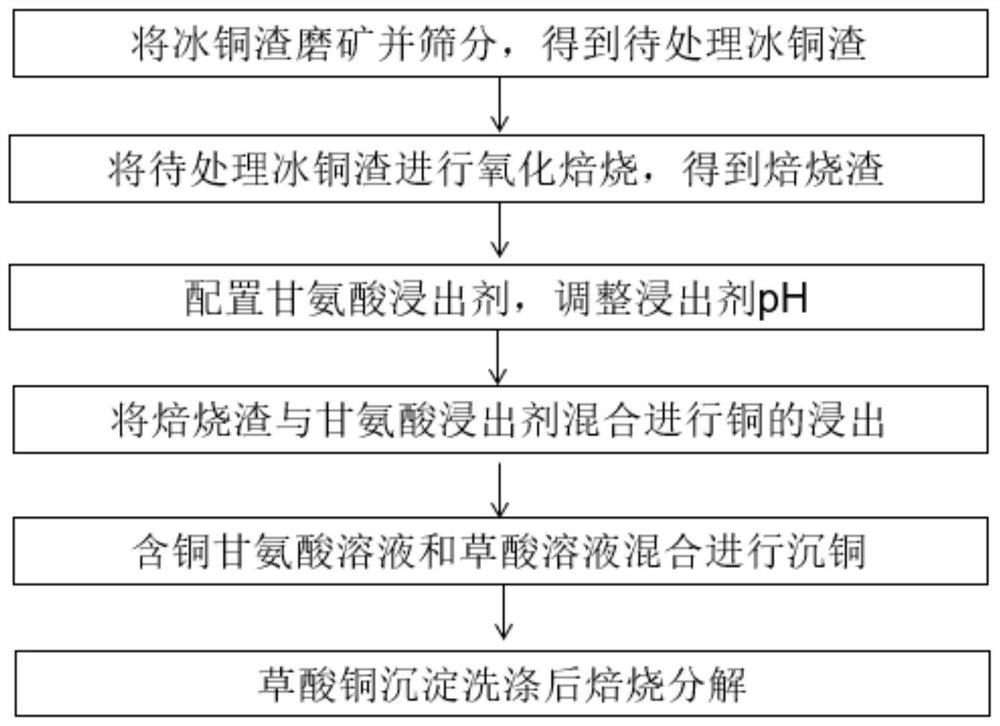

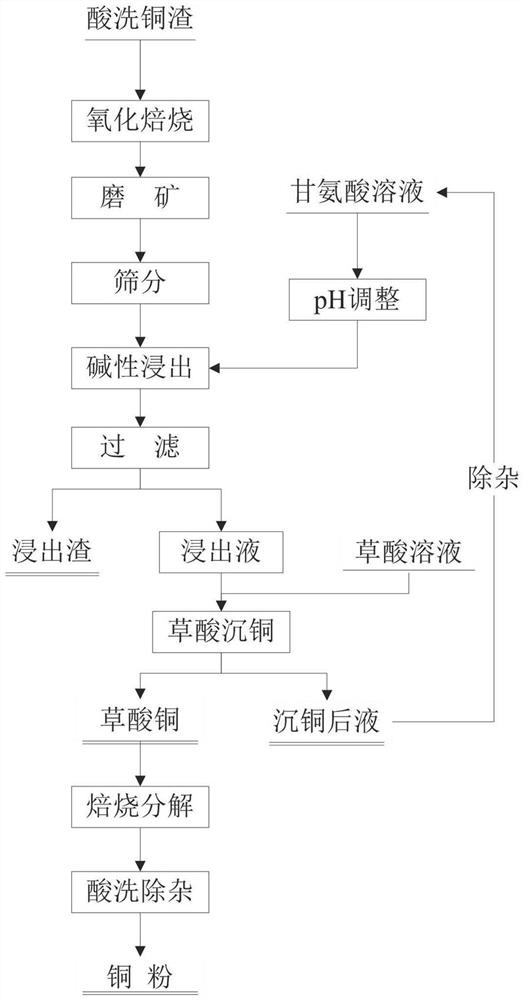

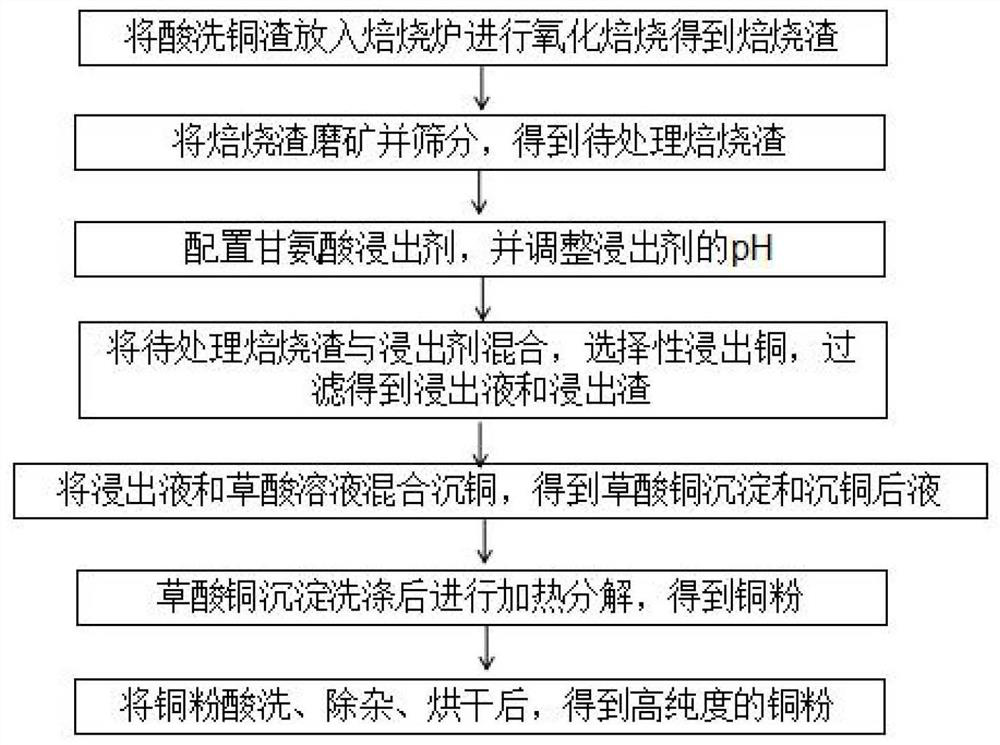

Method for leaching copper from acid pickling copper slag for zinc hydrometallurgy

ActiveCN111394587AOvercoming the Inability to Avoid ZincOvercoming disadvantages of cadmium leachingProcess efficiency improvementOXALIC ACID DIHYDRATEPregnant leach solution

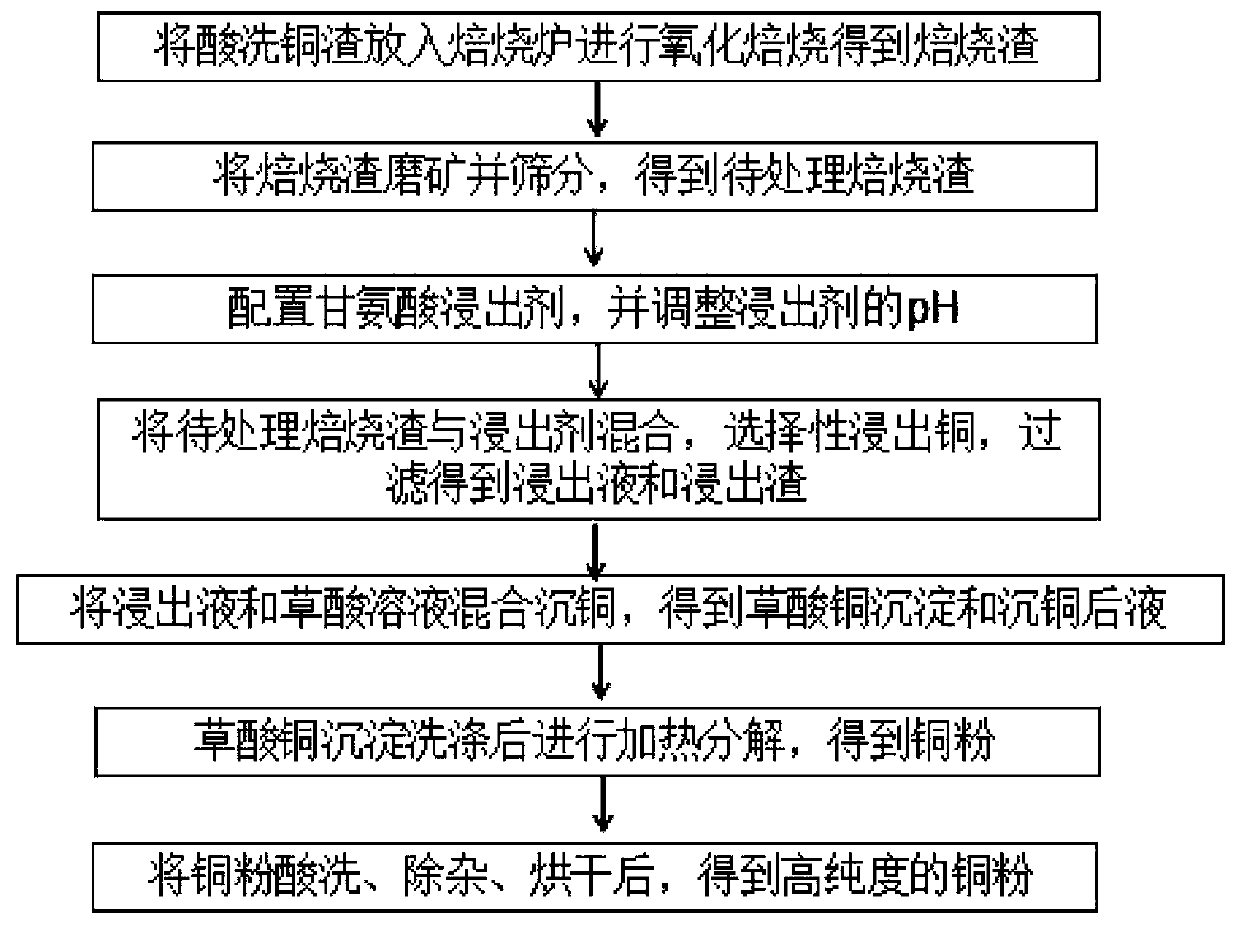

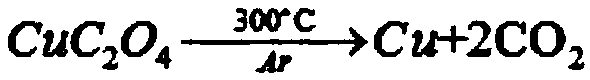

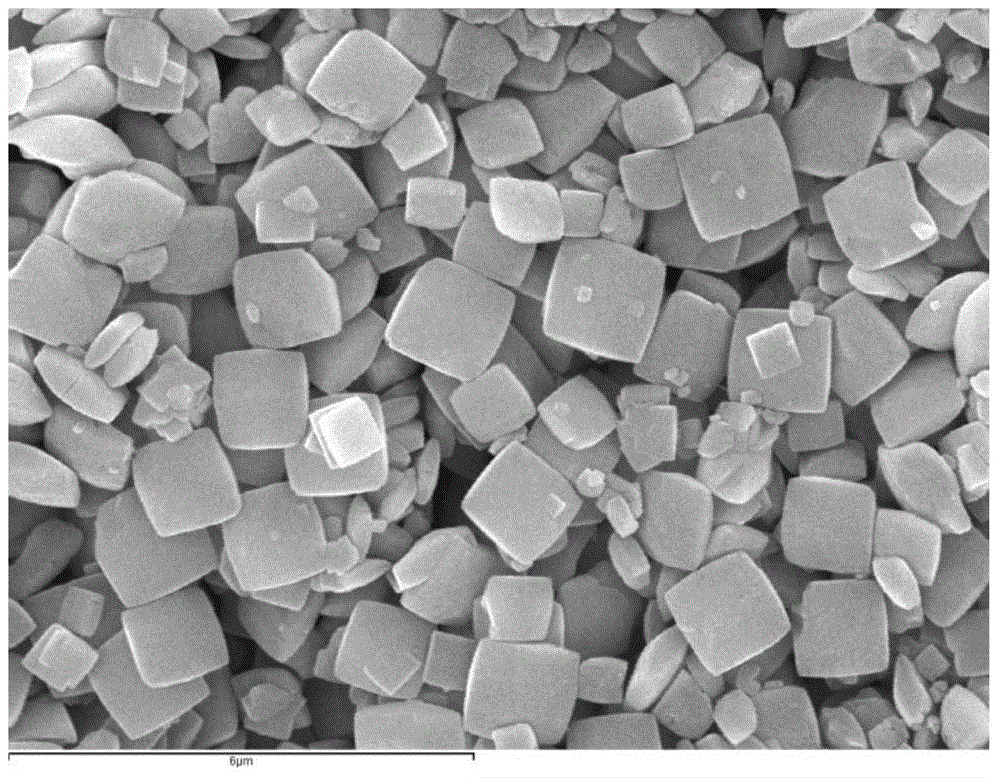

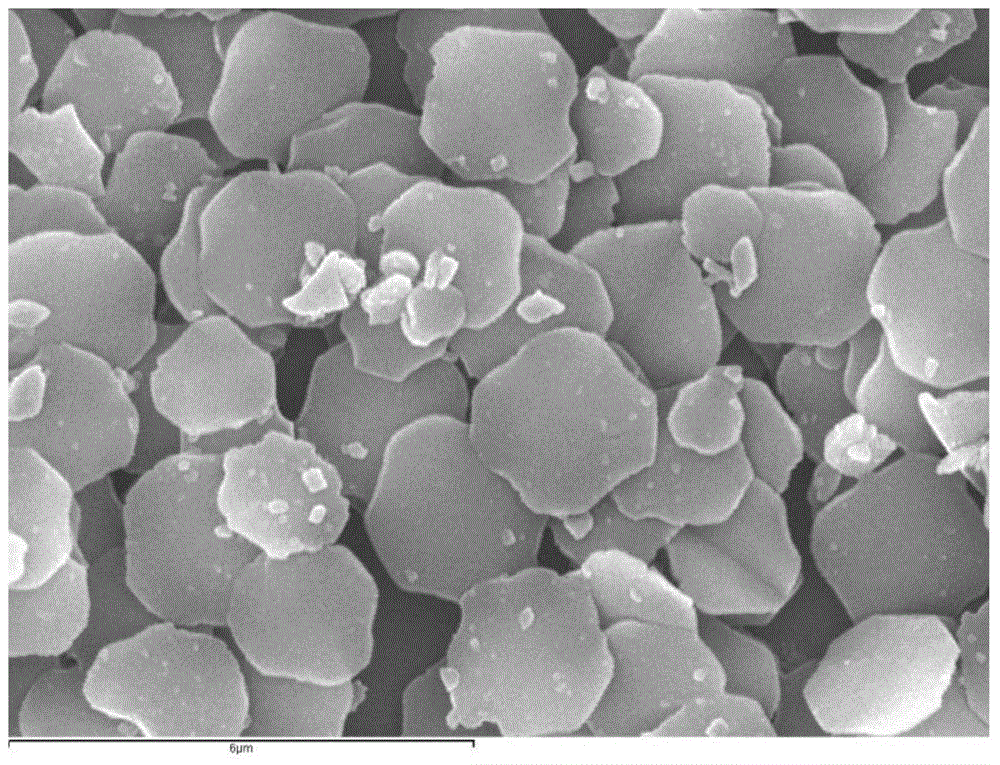

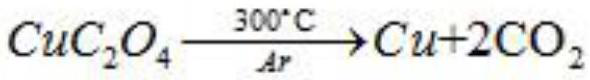

The invention discloses a method for leaching copper from acid pickling copper slag for zinc hydrometallurgy, and belongs to the technical field of copper recovery. The problems that in the prior art,the copper is difficultly leached from the acid pickling copper slag, the technological process is long, and the cost is high are solved. The method for leaching the copper from the acid pickling copper slag for zinc hydrometallurgy includes the following steps that the acid pickling copper slag is put in a calcinator to be subjected to oxidation roasting, and calcined slag is obtained; the calcined slag is ore-ground and screened, and to-be-treated calcined slag is obtained; a glycine leaching agent is prepared, and the pH value of the leaching agent is adjusted; the to-be-treated calcined slag and the leaching agent are mixed, the copper in the to-be-treated calcined slag is selectively leached, and leachate and leaching residues are obtained through filtering; the leachate and an oxalic acid solution are mixed, and copper oxalate precipitates and liquid obtained after copper precipitation are obtained through filtering; and the copper oxalate precipitates are washed and then put ina high-temperature calcinator, heating decomposition is carried out, copper powder is obtained, the copper powder is washed with dilute acid, subjected to impurity removal and dried, and then high-purity copper powder is obtained. By means of the method, the copper, zinc and cadmium are effectively separated.

Owner:ZHENGZHOU UNIV

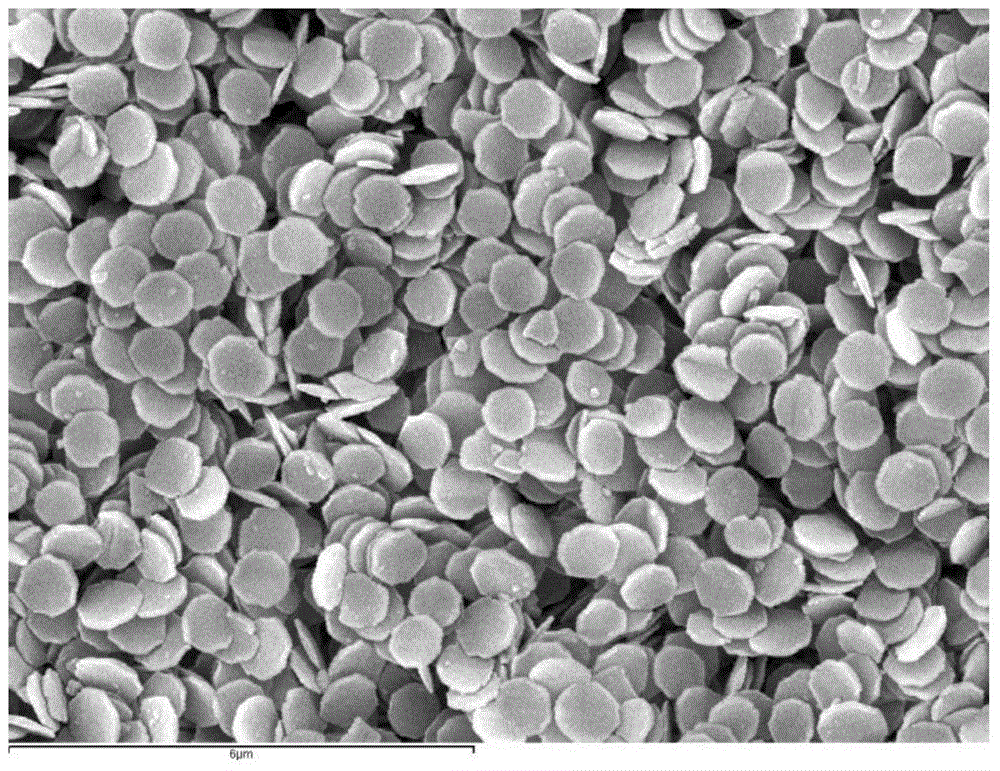

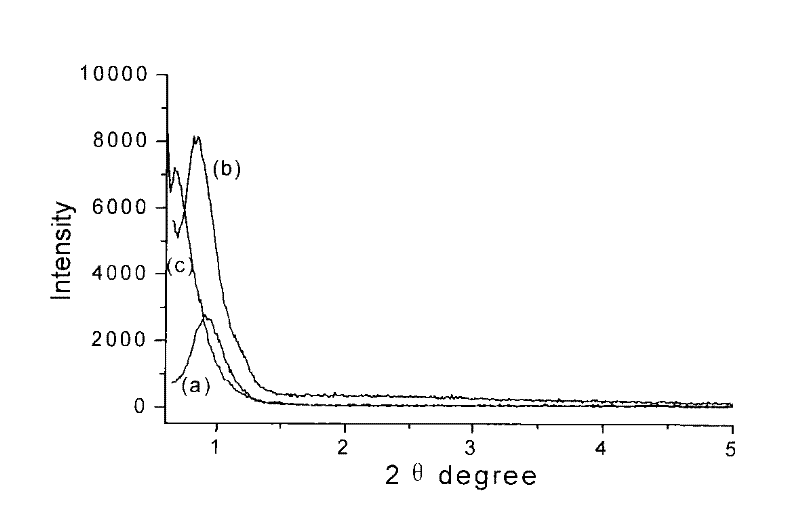

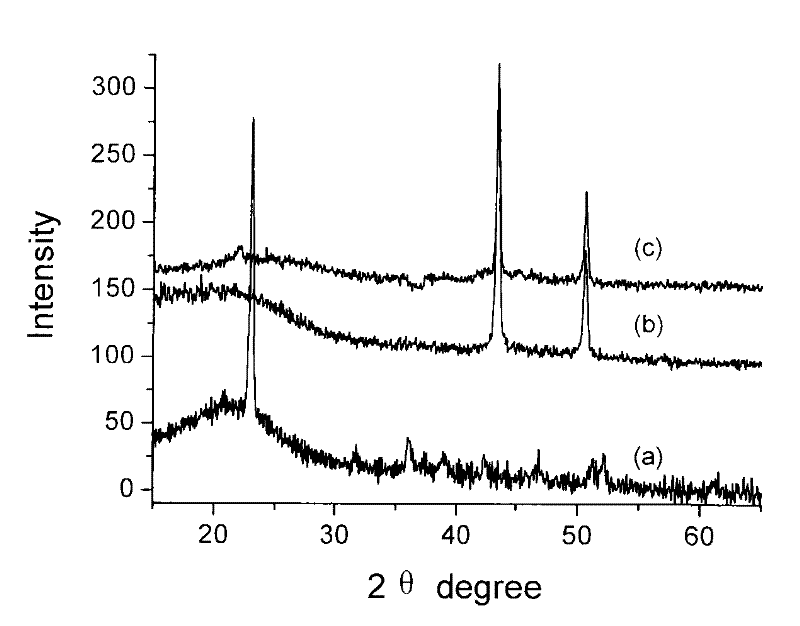

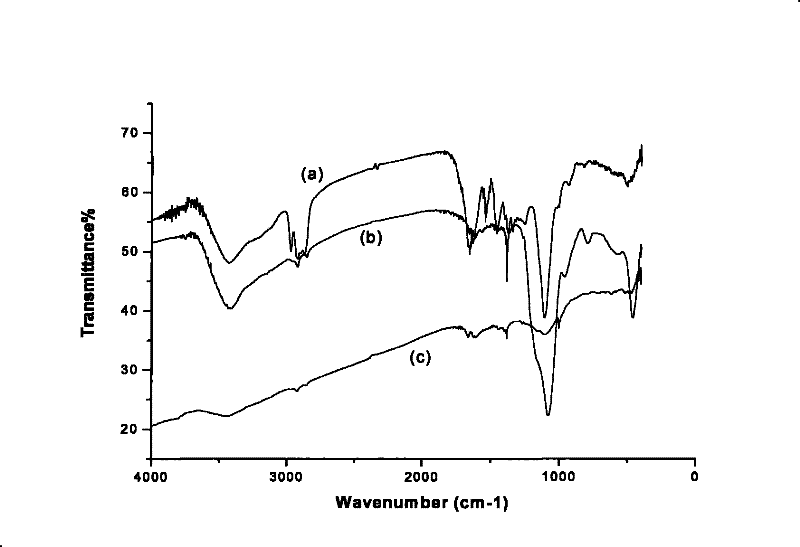

Preparation method of nano thick sheet shape copper oxalate powder possessing angle-dependent optical effect

InactiveCN104892401ASimple processThe preparation method is feasibleCarboxylic acid salt preparationSodium citrateCupric nitrate

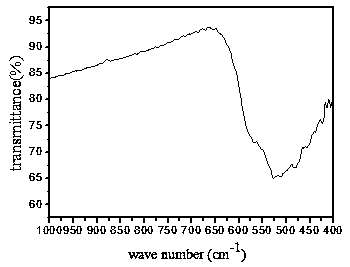

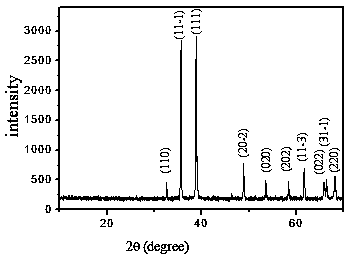

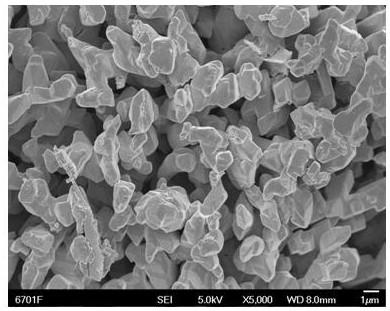

The invention relates to a preparation method of nano thick sheet shape copper oxalate powder possessing angle-dependent optical effect. The method takes cupric nitrate, sodium oxalate, sodium citrate and ionized water as raw materials, the raw materials are respectively prepared to a cupric nitrate aqueous solution and a sodium citrate aqueous solution, then mixed and uniformly stirred, a sodium oxalate aqueous solution is added and stirred for 5-120 minutes, nitric acid or a sodium hydroxide solution are added in a mixing solution for adjusting the pH value of the mixing solution to 3-6, steps of standing or stirring are carried out for 1-50 hours at room temperature being 70 DEG C to obtain a mixed liquor, and then steps of filtering, collection of precipitated powder, washing and drying are carried out to obtain the sheet shape copper oxalate powder with pearlescent color and good dispersibility. The preparation method has the beneficial effects of simple process flow, stable technological parameter, good repeatability, enforcement under normal temperature and normal pressure, low energy consumption and high yielding rate. The sheet shape copper oxalate has the advantages of uniform granularity, good dispersibility, and certain adjustability of thickness, length and width.

Owner:UNIV OF SCI & TECH BEIJING

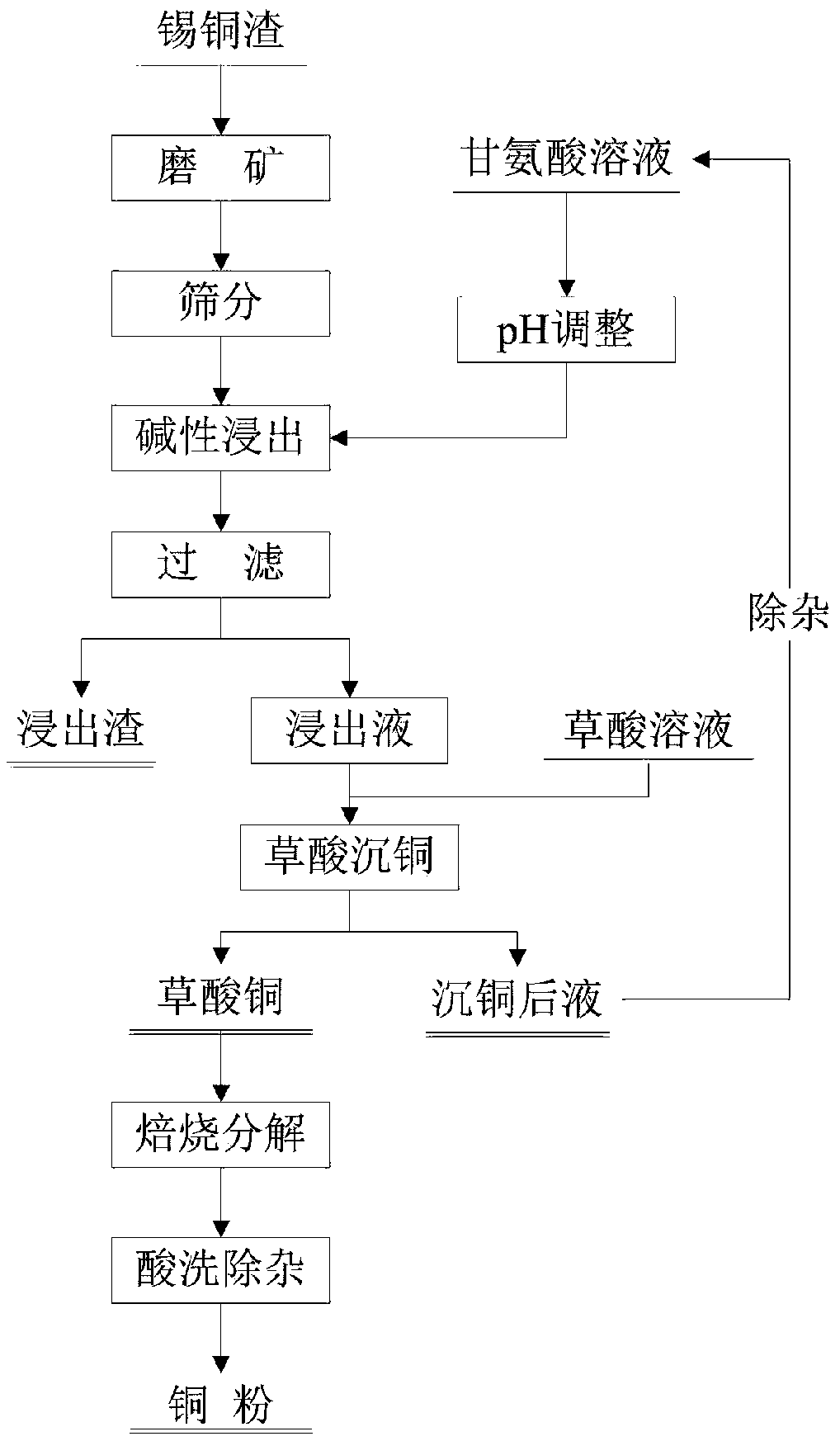

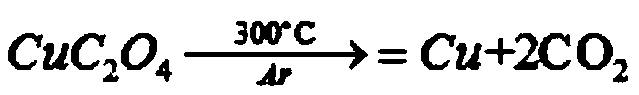

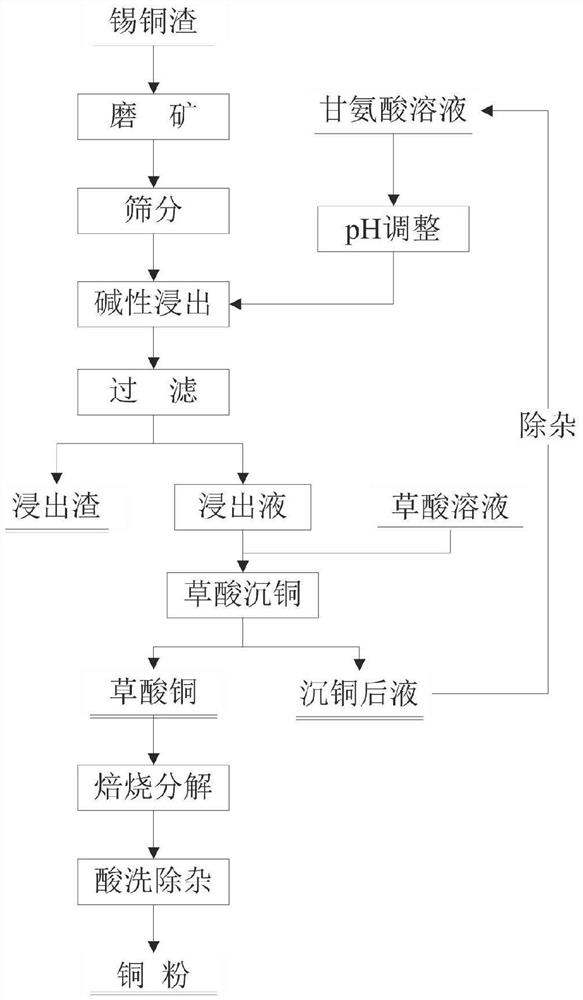

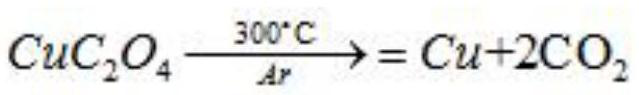

Method for leaching copper from tin-copper slag

ActiveCN111455189AAchieve value recoveryAchieve separationProcess efficiency improvementOXALIC ACID DIHYDRATEPregnant leach solution

The invention discloses a method for leaching copper from tin-copper slag, belongs to the technical field of copper recovery, and solves the existing problems that it is difficult to leach copper fromtin-copper slag, the technological process is long and the cost is high. The method for leaching copper from the tin-copper slag includes the following steps: grinding and sieving the tin-copper slagto obtain to-be-treated slag; preparing a glycine leaching agent, and regulating the pH of the leaching agent with an alkaline solution; mixing the to-be-treated slag with the leaching agent to selectively leach copper in the to-be-treated slag, and performing filtration to obtain leaching liquor and leaching slag; mixing the leaching liquor with an oxalic acid solution for copper precipitation,and performing filtration to obtain copper oxalate precipitate and post-copper-precipitation liquor; washing the copper oxalate precipitate, and putting the copper oxalate precipitate into a high-temperature roasting furnace for thermal decomposition to obtain copper powder; and washing the copper powder obtained in step 5 with dilute acid, removing impurities, and drying the copper powder to obtain high-purity copper powder. The method effectively realizes copper-tin separation and high-value recovery of copper.

Owner:ZHENGZHOU UNIV

Recycling method for acidic etching waste liquid

InactiveCN112080748ANo dischargeIncrease valueCarboxylic compound separation/purificationOil phaseEnvironmental engineering

The invention discloses a recycling method for an acidic etching waste liquid. The recycling method for the acidic etching waste liquid comprises the following steps that the pH value range of the acidic etching waste liquid is adjusted to be 1-2; extraction operations are performed on the acidic etching waste liquid by adopting an extracting agent solution, and an oil phase is obtained after still-standing layering; and back extraction operations are performed on the oil phase by adopting a solution containing oxalate ions to obtain copper oxalate. The technical scheme of the recycling methodfor the acidic etching waste liquid is low in operation cost and relatively easy to operate, no toxic waste gases are generated in the operation process, the safety is high, furthermore, no waste liquid and waste residues are discharged in the treatment process, and secondary pollution is not caused; and meanwhile, a product obtained by the recycling method for the acidic etching waste liquid isan ultrafine copper oxalate crystal, the particle size is regular and relatively uniform, the value is high, and hazardous waste transfer qualification is not needed during outward transportation.

Owner:深圳市祺鑫环保科技有限公司

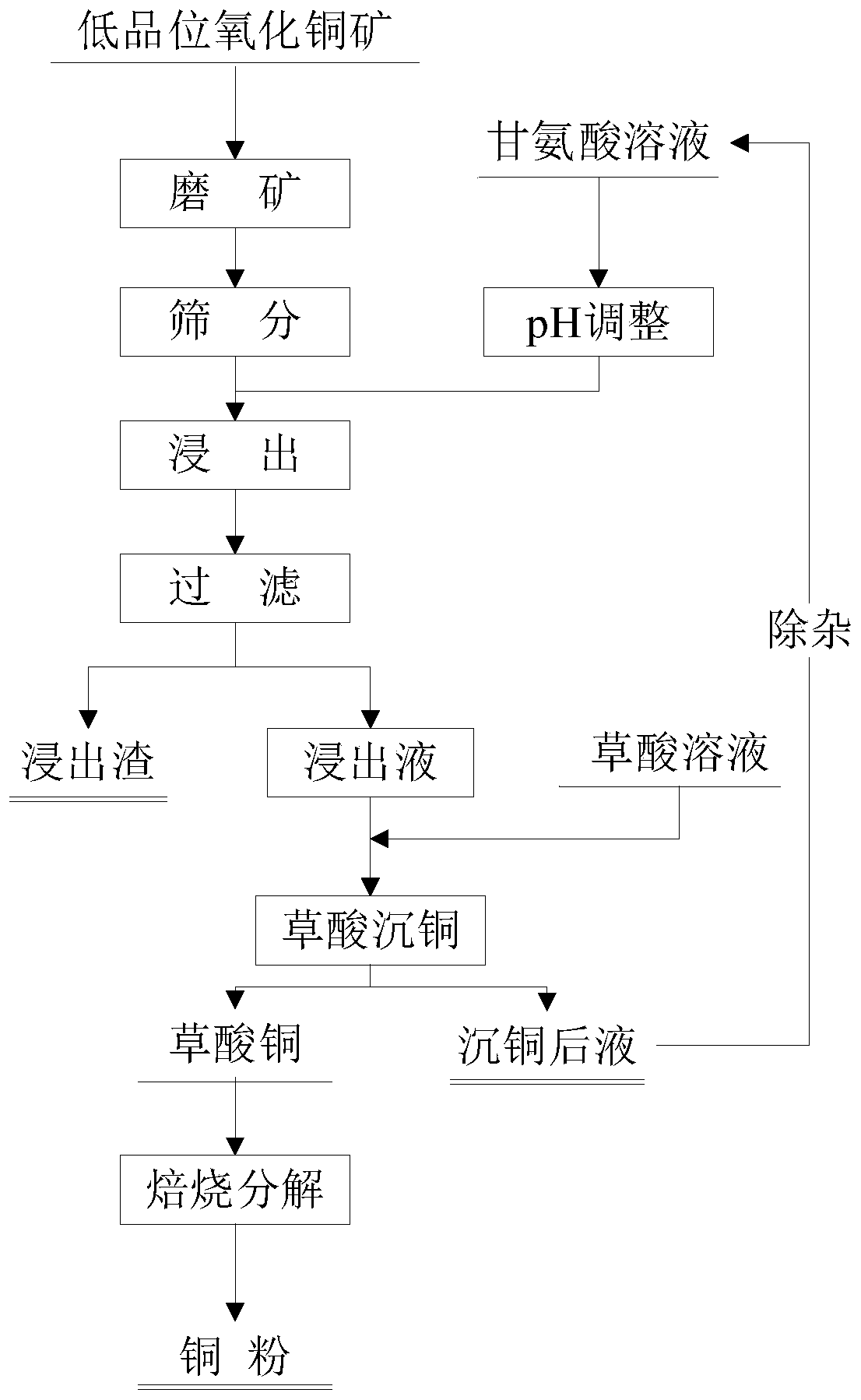

Process method for recovering copper from low-grade copper oxide ore

ActiveCN111500860AAvoid leachingImprove separation efficiencyProcess efficiency improvementOXALIC ACID DIHYDRATECalcite

The invention relates to a process method for recovering copper from low-grade copper oxide ore, belongs to the technical field of copper recovery, and solves the problems of difficulty in beneficiation and enrichment, high cost and the like of the low-grade copper oxide ore. In the process method for recovering copper, the copper grade in the low-grade copper oxide ore is 0.4-2.0 %, and the low-grade copper oxide ore contains at least one alkaline gangue mineral of quartz, dolomite, gibbsite, calcite and mica. The process method for recovering copper comprises the following steps: S1, grinding the copper oxide ore and preparing a leaching agent, wherein the leaching agent is a glycine leaching agent; S2, mixing the copper oxide ore subjected to grinding with the leaching agent, selectively leaching copper in the copper oxide ore, and carrying out filtering to obtain a copper-containing glycine solution; S3, mixing the copper-containing glycine solution and oxalic acid solution for copper deposition; and 4, washing the copper oxalate precipitate, putting the washed copper oxalate precipitate into a high-temperature roasting furnace, and carrying out heating decomposition to obtaincopper powder. The efficient selective leaching and recovering of copper in the low-grade copper oxide ore can be realized.

Owner:ZHENGZHOU UNIV

A kind of preparation method of nickel-coated copper composite powder

The invention relates to a preparation method of nickel-coated copper composite powder. The process steps include: reacting copper salt with oxalate or carbonate to form copper oxalate or copper carbonate precipitation, filtering, washing with pure water until neutral , to prepare a solution with a concentration of 10-80g / L; prepare a nickel salt solution and the required oxalate or carbonate solution according to the copper-nickel weight ratio of 2:1-1:2, and then add it to the above-mentioned copper oxalate Or react in copper carbonate solution to generate nickel-coated copper product. In the present invention, nickel salt is first used to coat copper salt, and then thermally decomposed to obtain nickel-coated copper powder. The production process is simple, easy to operate, low in production cost, and can realize industrial production. The appearance of the nickel-clad copper powder or alloy prepared by the present invention is spherical, spherical, irregular and dendritic, and has the advantages of uniform powder dispersion, no segregation, good coating effect, dense coating, controllable particle size, etc., and can be applied Used in electromagnetic shielding materials and powder metallurgy pre-alloyed powders. It can also be used to prepare nickel-copper alloy powder.

Owner:NAT ENG RES CENT FOR SPECIAL METAL MATERIALS OF TANTALUM & NIOBIUM

Polypropylene (PP) flame-retardant plastic

InactiveCN103497415ALong-term flame retardantGood flame retardant functionPolymer sciencePolypropylene

The invention discloses polypropylene (PP) flame-retardant plastic. The PP flame-retardant plastic comprises, by weight, 150-155 parts of PP, 5-10 parts of brucite, 10-20 parts of triguaiacyl phosphite, 10-15 parts of nano-montmorillonite, 10-13 parts of ferrocene, 8-11 parts of styrene, 14-16 parts of alkylbenzene sulfonate, 2-3 parts of copper oxalate, 7-9 parts of phthalic anhydride, 10-15 parts of melamine cyanurate, 10-15 parts of zinc oxide, 10 parts of dicyandiamide and 5-8 parts of organic tin. The PP flame-retardant plastic has good fire resistance and a small amount of the PP flame-retardant plastic can produce obvious flame retardation. The PP flame-retardant plastic has good compatibility with resins so that the PP flame-retardant plastic is not transferred, separated and extracted in a plastic product. In plastic, the PP flame-retardant plastic can be dispersed uniformly and has good weatherability, persistence and long-term flame resistance.

Owner:WUJIANG TIANYUAN PLASTIC

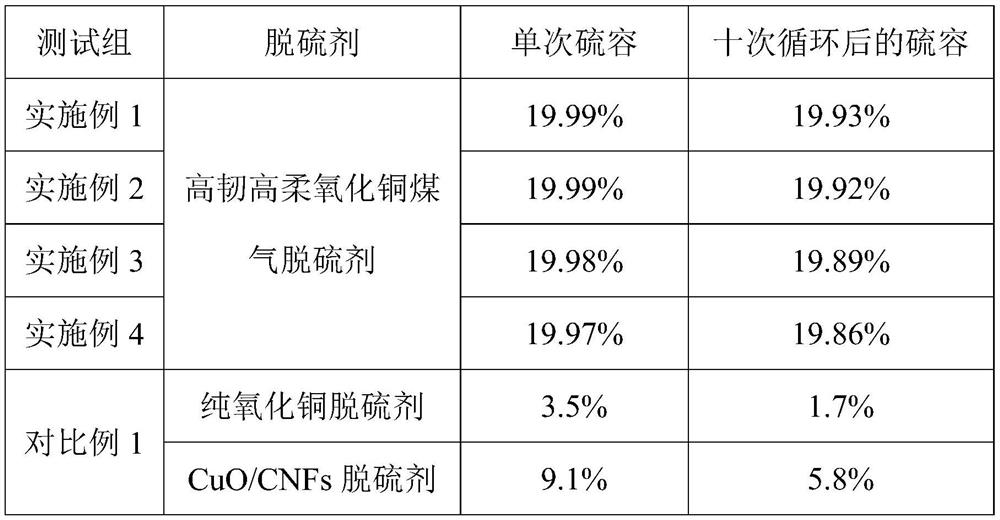

Preparation method of high-toughness and high-flexibility copper oxide gas desulfurizing agent

ActiveCN111763538AImprove adsorption capacityImprove responseGas purification with selectively adsorptive solidsGas contaminants removalFiberMetallurgy

The invention discloses a preparation method of a high-toughness and high-flexibility copper oxide gas desulfurizing agent. The preparation method comprises the following steps of: A, preparing a three-dimensional orthogonal structure prefabricated part, namely weaving fiber filaments into the three-dimensional orthogonal structure prefabricated part by adopting a three-dimensional weaving technology; B, preparing impregnation liquid, namely dissolving 1.9-7.6g of copper oxalate powder into 20mL of water to obtain the impregnation liquid; C, carrying out isopyknic impregnation, namely isopyknically impregnating the three-dimensional orthogonal structure prefabricated part obtained in the step A in the impregnation liquid obtained in the step B for 24 hours; and D, preparing a high-toughness and high-flexibility desulfurizing agent, namely performing high-temperature roasting treatment on the impregnated three-dimensional orthogonal structure prefabricated part obtained in the step C toobtain the high-toughness and high-flexibility copper oxide gas desulfurizing agent. The process is simple, and industrial production of the desulfurizing agent can be realized; and the desulfurizingagent adopts a fiber material with high flexibility and rich porosity as a carrier to construct a multistage micro-pore structure of the desulfurizing agent, so that the adsorption capacity and desulfurization reaction activity of the desulfurizing agent can be improved.

Owner:TAIYUAN UNIV OF TECH

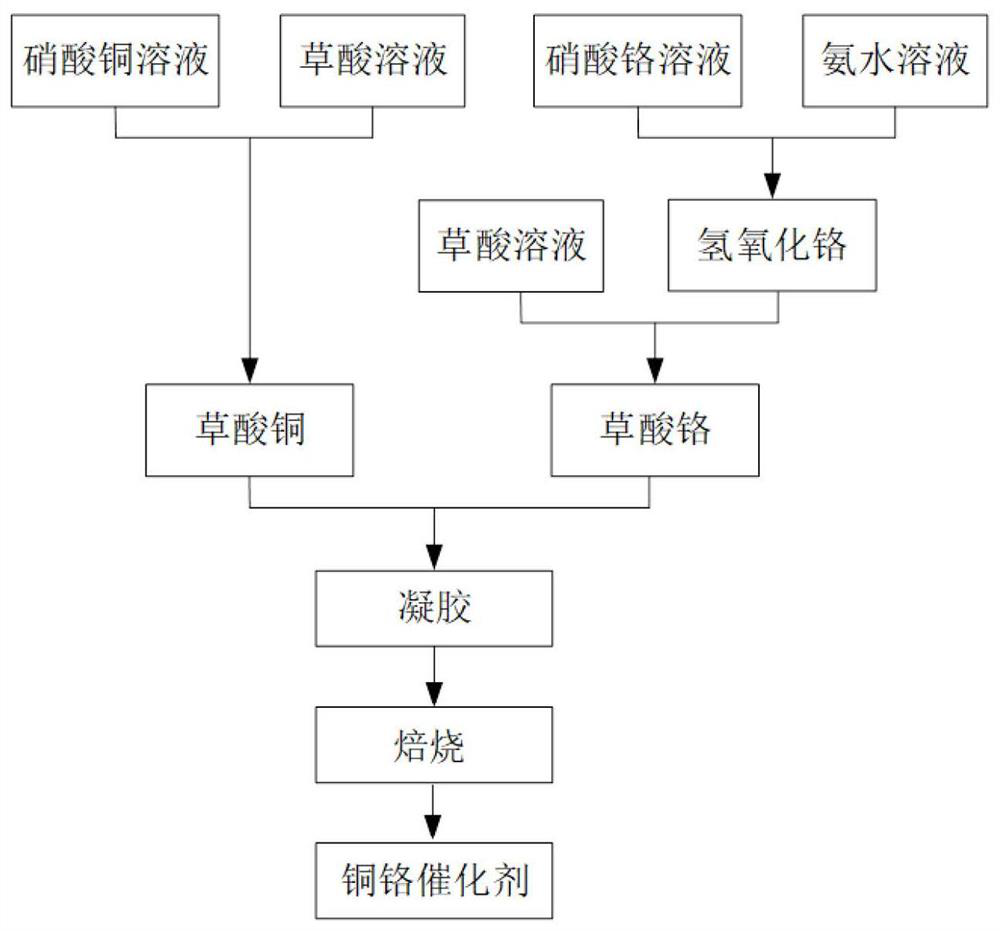

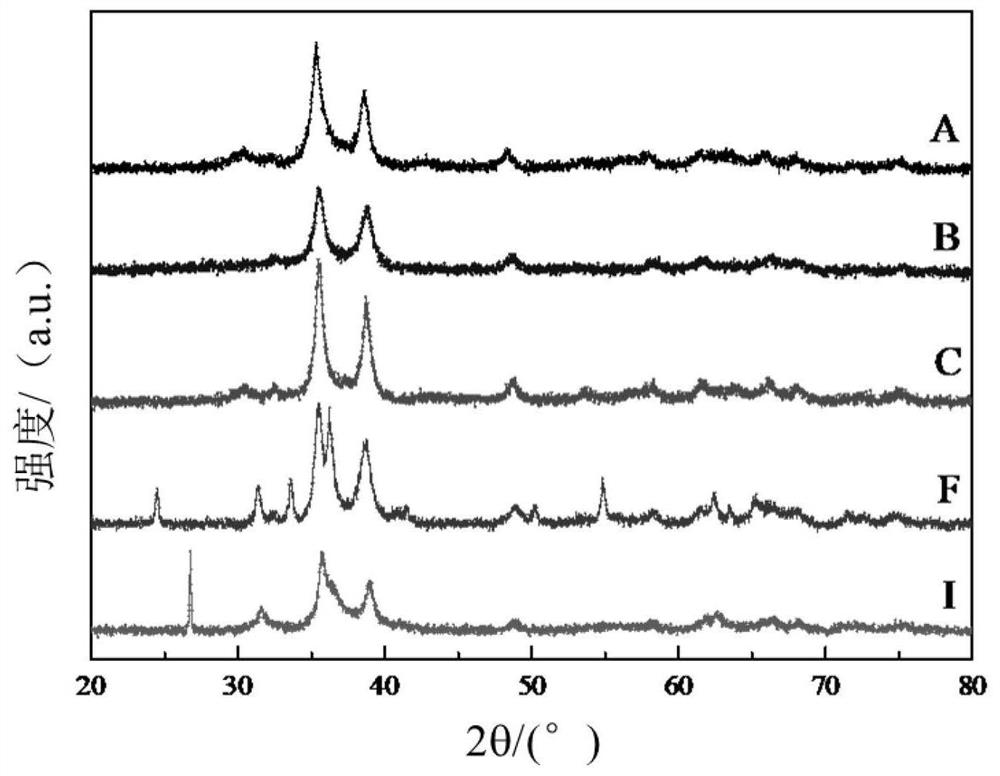

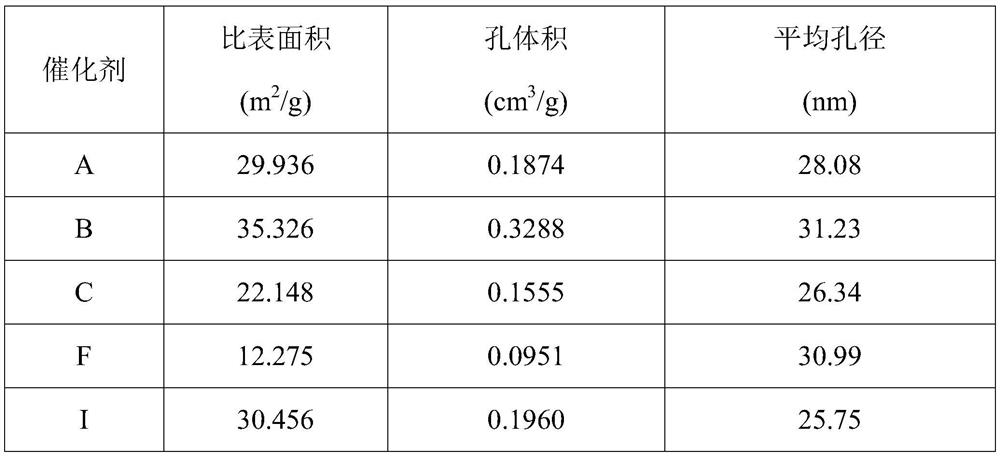

Copper-chromium catalyst as well as preparation method and application thereof

PendingCN113797933AHigh yieldReduce lossesOrganic compound preparationHydroxy compound preparationPtru catalystChromium Oxalate

The invention provides a copper-chromium catalyst and a preparation method and application thereof. The preparation method comprises the following steps: mixing cupric oxalate and chromium oxalate with water for reaction to obtain gel; and sequentially drying and roasting the obtained gel to obtain the copper-chromium catalyst. The preparation method is simple in technological process, on one hand, high yield of metal ions in the raw materials, high hydrogenation activity of the catalyst and selectivity of target hydrogenation products are guaranteed, discharge of waste liquid containing high-valence chromium ions is eliminated, and meanwhile severity of catalyst preparation operation conditions is reduced; and on the other hand, the yield of the industrial production catalyst is improved, the catalyst cost is reduced, and the method has good industrial application prospects.

Owner:CHINA NAT OFFSHORE OIL CORP +4

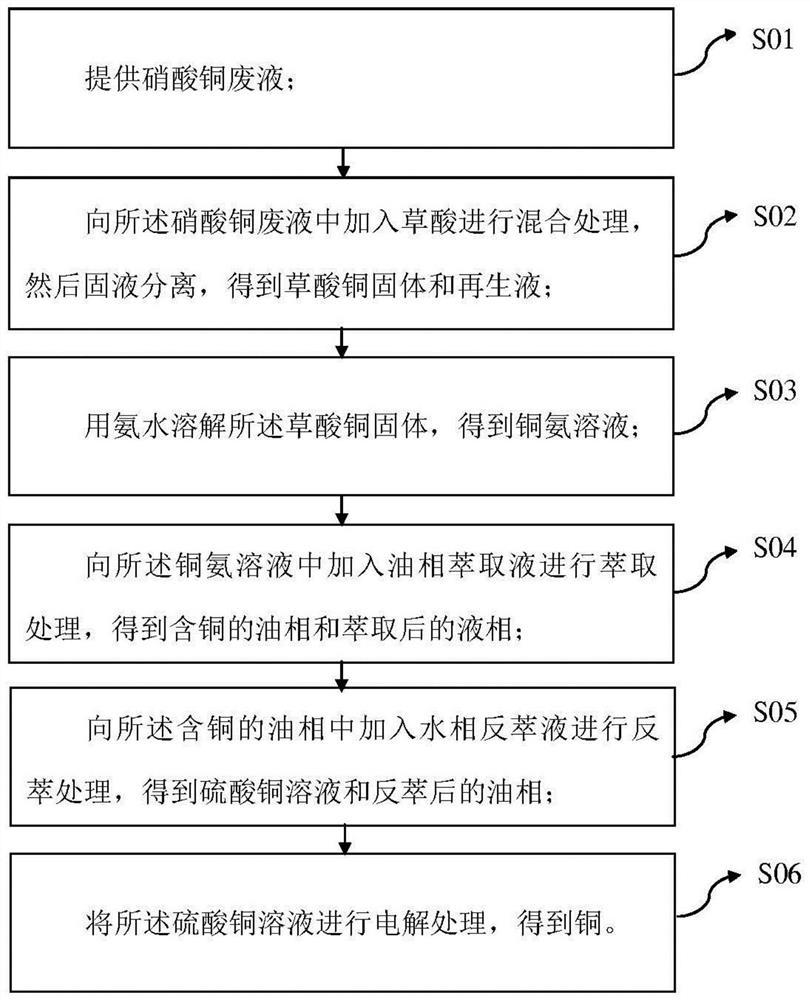

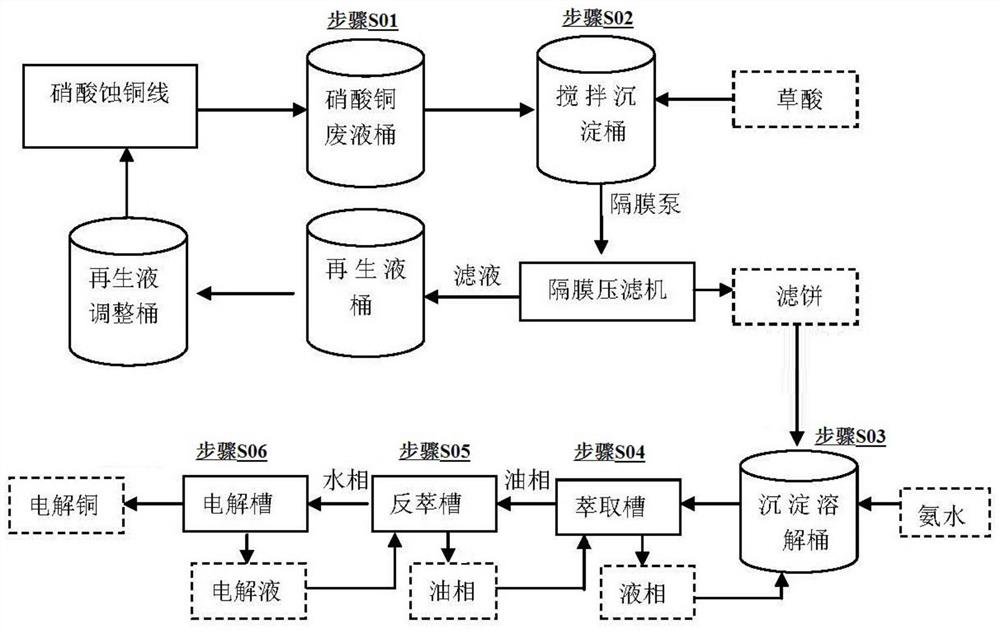

Copper recovery method

ActiveCN113136604AReduce processing costsRealize recyclingPhotography auxillary processesProcess efficiency improvementOXALIC ACID DIHYDRATEOxalate

The invention relates to the technical field of waste liquid recovery, in particular to a copper recovery method. The copper recovery method specifically comprises the following steps of providing copper nitrate waste liquid; adding oxalic acid into the copper nitrate waste liquid for mixing treatment, and then performing solid-liquid separation to obtain cupric oxalate solid and regenerated liquid; dissolving the cupric oxalate solid with ammonia water to obtain a copper ammonia solution; adding an oil phase extraction liquid into the copper ammonia solution for extraction treatment to obtain a copper-containing oil phase and an extracted water phase; adding an aqueous phase reverse extraction solution into the copper-containing oil phase for reverse extraction treatment to obtain a copper sulfate solution and a reverse-extracted aqueous phase; and performing electrolytic treatment on the copper sulfate solution to obtain copper. According to the copper recovery method, regeneration recycling can be achieved in the whole technological process, new pollutants are not prone to being generated, high-total-nitrogen waste water is not prone to being generated, the waste water treatment cost is low, electrolytic copper with extremely high purity can be recovered from the copper nitrate waste liquid, and therefore the copper recovery method has good application prospects.

Owner:深圳市祺鑫环保科技有限公司

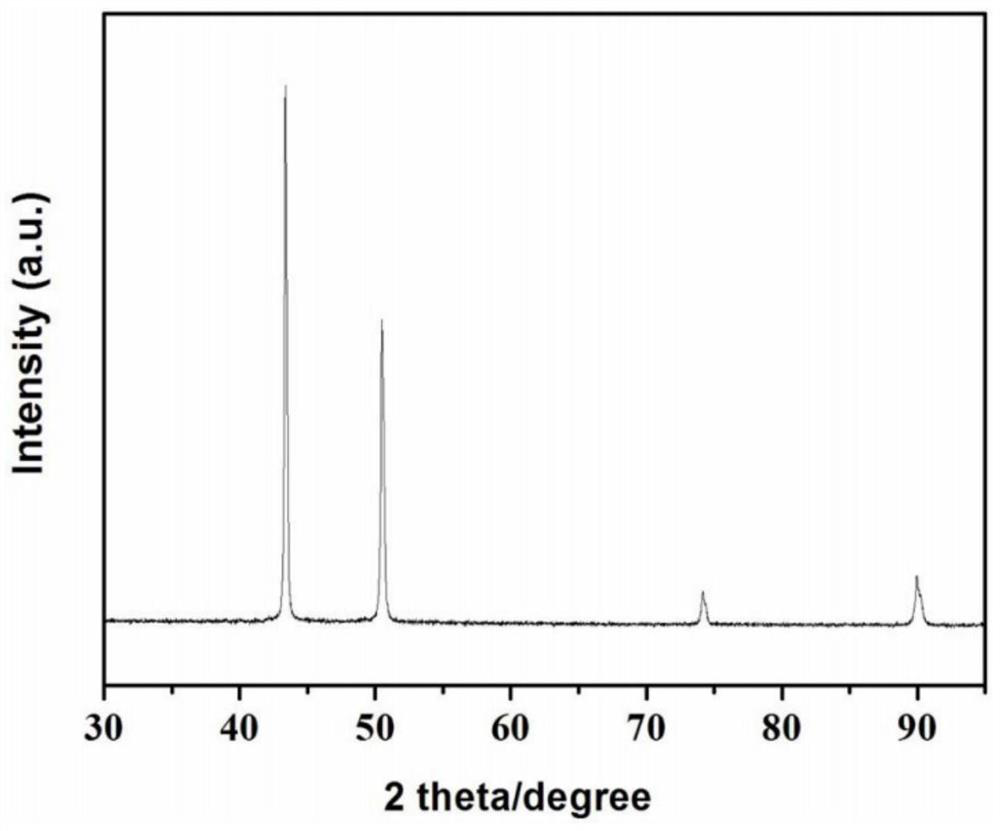

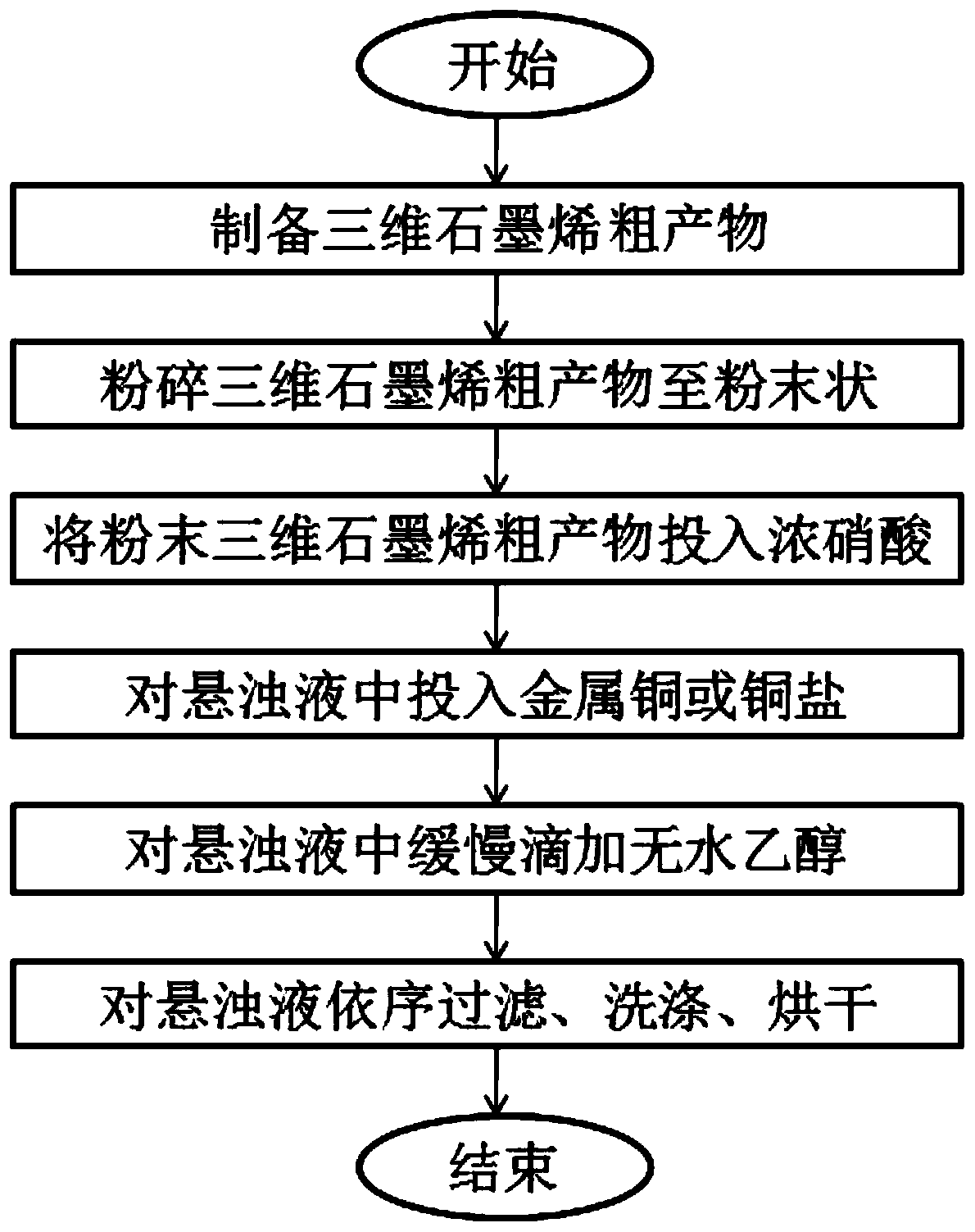

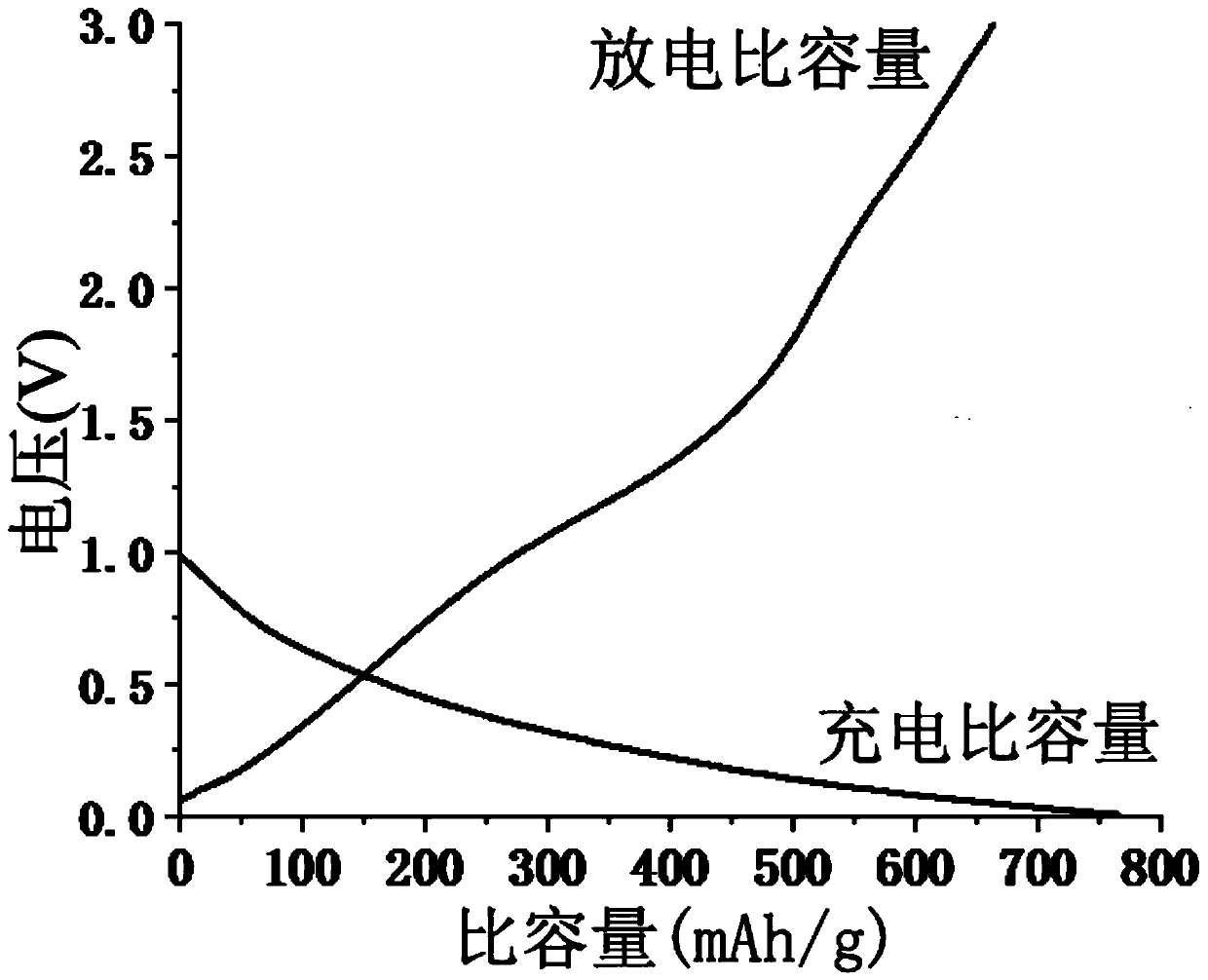

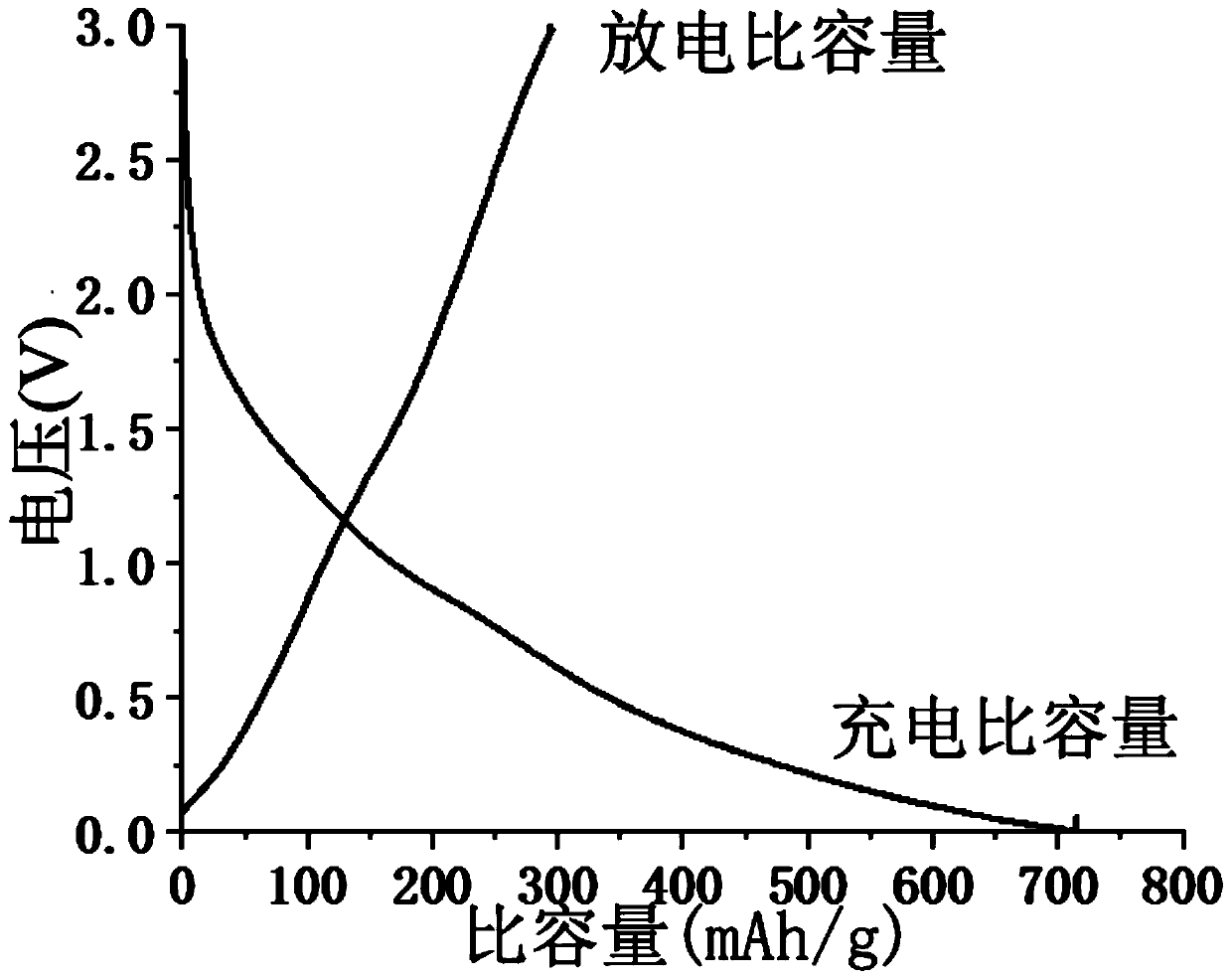

Nano copper oxalate composite three-dimensional graphene anode material as well as preparation method and application thereof

ActiveCN110931762AImprove the first Coulombic efficiencyImprove Coulombic efficiencyCarbon compoundsCell electrodesOxalateTube furnace

The invention discloses a nano copper oxalate composite three-dimensional graphene anode material as well as a preparation method and application thereof. The method comprises the following steps: S1,putting a lithium sheet into a tubular furnace, and vacuumizing the tubular furnace; and S2, introducing carbon dioxide gas into the tubular furnace, heating the tubular furnace to obtain a three-dimensional graphene crude product; S3, crushing the three-dimensional graphene crude product into powder; S4, putting the powdery three-dimensional graphene crude product into concentrated nitric acid,and continuously soaking for more than 2 hours; S5, adding metal copper powder or copper salt into the turbid liquid, and fully stirring; S6, slowly dropwise adding absolute ethyl alcohol into the turbid liquid and continuously stirring; and S7, sequentially filtering, washing and drying the product obtained in the step S6 to obtain the nano copper oxalate composite three-dimensional graphene anode material. According to the invention, nano copper oxalate is compounded on the surface of the three-dimensional graphene anode material, so that the coulombic efficiency of the obtained three-dimensional graphene anode material is greatly improved.

Owner:上海昱瓴新能源科技有限公司

Microecological preparation for improvement of allogynogenetic crucian carp water body and preparation method thereof

InactiveCN109502765AReduce COD valueGrowth inhibitionWaste water treatment from animal husbandryBiological water/sewage treatmentSucroseWater quality

The invention discloses a microecological preparation for improvement of an allogynogenetic crucian carp water body and a preparation method thereof. The preparation method comprises the following steps: (1) mixing mixed EM bacteria body fluid, sucrose, lactose, peptone and water according to a mass ratio of (5-10):(2-5):(1-5):(2-5):(80-90), transferring the mixture into a reaction bottle, and performing constant temperature fermentation at 37 DEG C for 3-5 days to obtain fermentation liquor; (2) drying and dehydrating bottom mud taken from an allogynogenetic crucian carp pond at 100-105 DEG C, crushing and sieving the bottom mud with a 40-100 mesh sieve to obtain a bottom mud powder material; (3) weighing copper oxalate and the bottom mud powder obtained in the step (2) according to a mass ratio of 1:(2-10), uniformly mixing the materials, adding water with the mass being 3-5 times the mass of the bottom mud powder, uniformly mixing the mixture, kneading the mixture into a spherical shape, drying the spherical mixture, calcining the mixture at 400-600 DEG C for 2-4 hours, and cooling the product to room temperature after the reaction; and (4) transferring the composite material obtained in the step (3) into the fermentation liquor obtained in the step (1), culturing for 5-10 days at room temperature, taking out the product, and air drying the product to obtain the microecological preparation. The microecological preparation provided by the invention can effectively improve the water quality of the allogynogenetic crucian carp water body, improve the immunity of allogynogenetic crucian carps, increase the survival rate of the allogynogenetic crucian carps, and promote the growth of the allogynogenetic crucian carps.

Owner:YANCHENG INST OF TECH

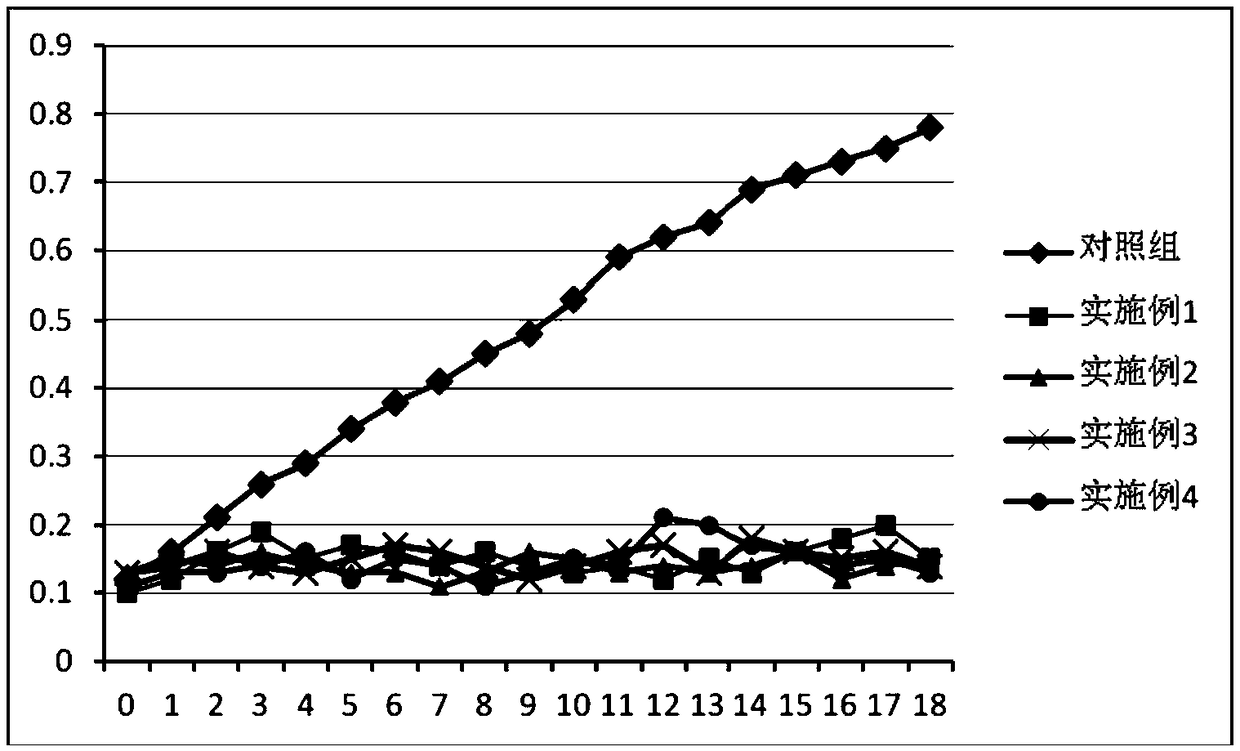

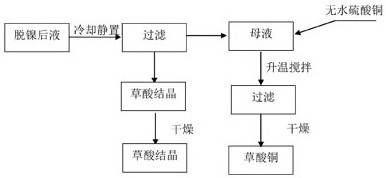

Process for deeply removing oxalic acid

PendingCN112030195AAchieve recyclingReduce contentPhotography auxillary processesElectrolysis componentsOXALIC ACID DIHYDRATEPhysical chemistry

The invention relates to a process for deeply removing oxalic acid. The process comprises the following specific steps that a, a nickel-removed solution containing oxalic acid is placed in an environment with the temperature of 5 DEG C below zero to 15 DEG C for standing for 8 to 24 hours, then is taken out and is quickly filtered, mother liquor is retained, and precipitates on filter paper are dried at the temperature of 40 to 80 DEG C to obtain an oxalic acid finished product; and b, industrial copper sulfate pentahydrate containing 23% of copper is added into the mother liquor, the molar ratio of the industrial copper sulfate pentahydrate to oxalate is 1-2: 1, the temperature is increased to 40 to 80 DEG C, a stirring reaction is conducted for 1 to 5 hours, then filtering is conducted,and light blue-green precipitates on filter paper are dried at the temperature of 40 to 80 DEG C to obtain a copper oxalate product. The process is simple and reliable, the removal rate of the oxalicacid in the solution can reach 99.7% at most, and the content of the oxalic acid in the solution can be reduced to 0.08 g / L; and the problems of toxicity and secondary pollution caused by lead are avoided, the use of a calcium-containing precipitant is also solved, the removal rate is high, and the cost is low.

Owner:HUNAN INSTITUTE OF ENGINEERING

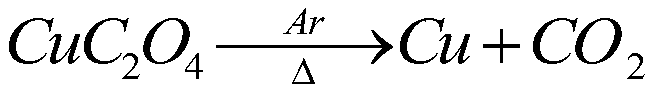

A kind of process method of alkaline wet leaching copper from matte slag

ActiveCN111455188BAvoid leachingImprove separation efficiencyProcess efficiency improvementOXALIC ACID DIHYDRATESlag

The invention relates to a process method for alkaline wet leaching of copper from matte slag, belongs to the technical field of copper recovery, and solves the problems of difficulty and high cost in recovering copper from matte slag. In the process method of the present invention, the content of copper in the matte slag is between 0.2~5wt%, comprising the following steps: step 1. grinding and sieving the matte slag to obtain the matte slag to be treated; step 2. The matte slag to be treated is oxidized and roasted to obtain roasted slag; Step 3. Configure glycine leaching agent, and use alkaline solution to adjust the pH of the leaching agent; Step 4. Leaching process: mix roasted slag and glycine leaching agent for copper leaching Step 5. Copper precipitation process: mix copper-containing glycine solution and oxalic acid solution for copper precipitation, and filter to obtain copper oxalate precipitation and glycine solution; Step 6. Roasting decomposition: put the copper oxalate precipitation into a high-temperature roaster after washing, Heating and decomposing under gas protection to obtain copper powder. The invention can realize efficient leaching and recovery of copper in matte slag.

Owner:ZHENGZHOU UNIV

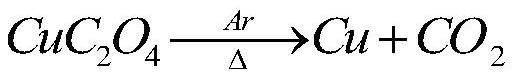

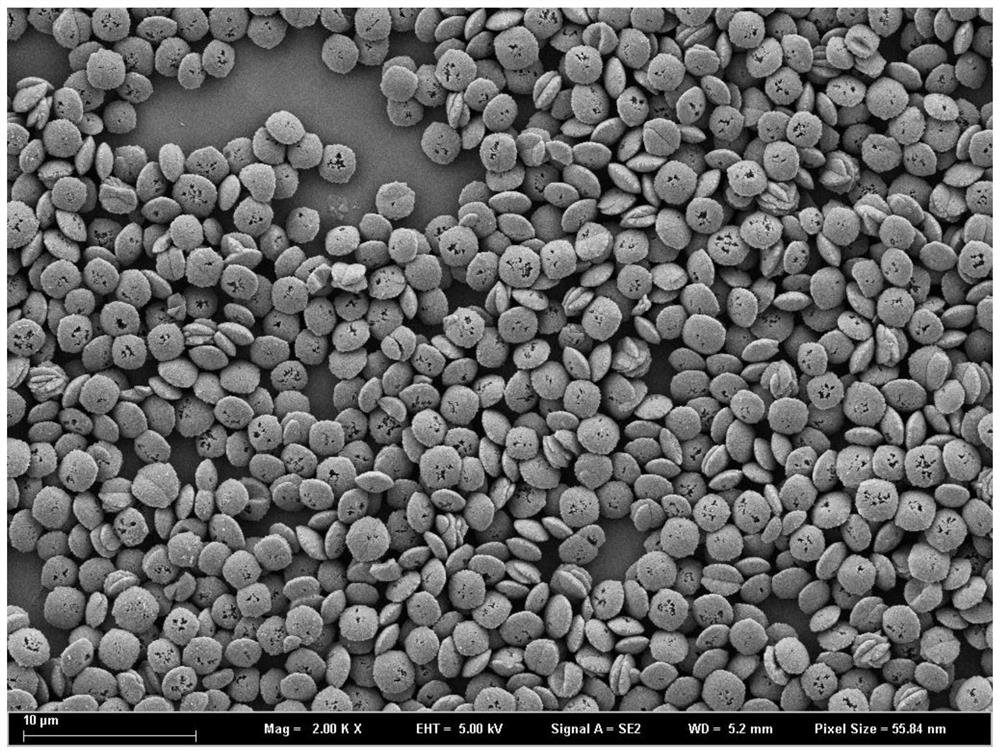

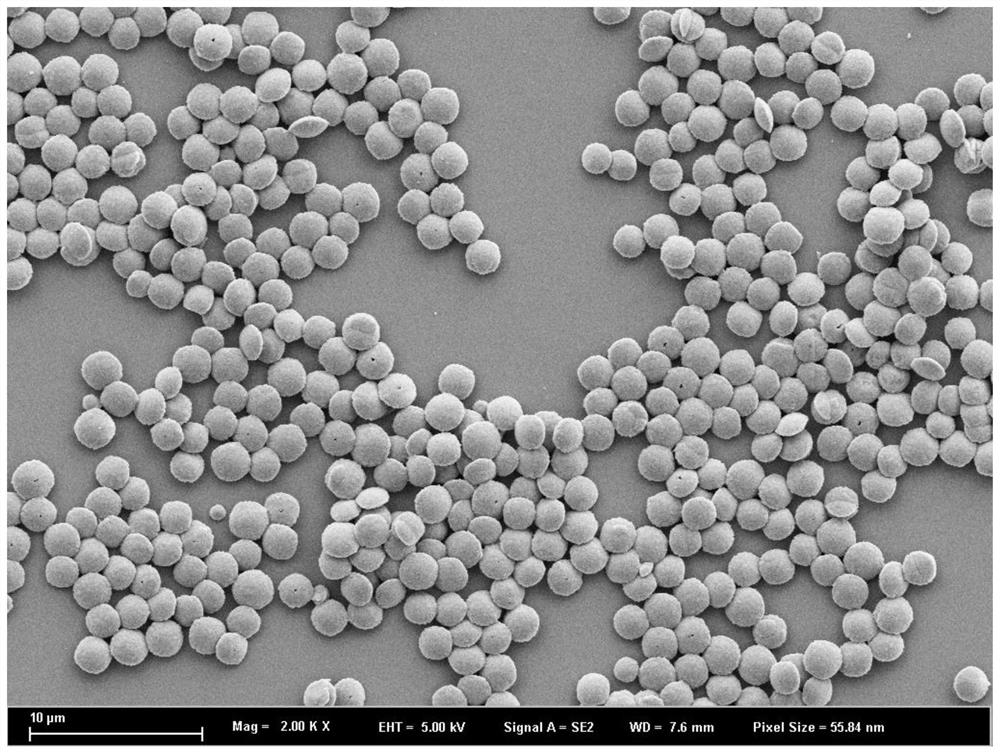

A kind of controllable preparation method of monodisperse copper oxalate powder

ActiveCN107759464BGood monodispersityEasy to operateOrganic compound preparationCarboxylic acid salt preparationSoluble oxalatePhysical chemistry

Owner:UNIV OF SCI & TECH BEIJING

A method for leaching copper from pickling copper slag in zinc hydrometallurgy

ActiveCN111394587BOvercoming the disadvantages of leachingAchieve separationProcess efficiency improvementOXALIC ACID DIHYDRATEPregnant leach solution

The invention discloses a method for leaching copper from pickling copper slag of zinc hydrometallurgy, belongs to the technical field of copper recovery, and solves the existing problems of difficulty in leaching copper from pickling copper slag, long process flow and high cost. The method for leaching copper from the pickling copper slag of zinc hydrometallurgy comprises the following steps: putting the pickling copper slag into a roasting furnace to oxidize and roast to obtain the roasting slag; grinding and screening the roasting slag to obtain the roasting slag to be treated; Glycine leaching agent, adjust the pH of the leaching agent; mix the to-be-treated roasting slag with the leaching agent, selectively leach the copper in the to-be-treated roasting slag and filter to obtain the leaching solution and leaching residue; mix the leaching solution and oxalic acid solution for copper precipitation, and filter to obtain oxalic acid Copper precipitation and copper-precipitating liquid; wash the copper oxalate precipitation and put it into a high-temperature roasting furnace for thermal decomposition to obtain copper powder. After the copper powder is washed with dilute acid, impurities are removed, and dried, high-purity copper powder is obtained. The method of the invention effectively realizes the separation of copper, zinc and cadmium.

Owner:ZHENGZHOU UNIV

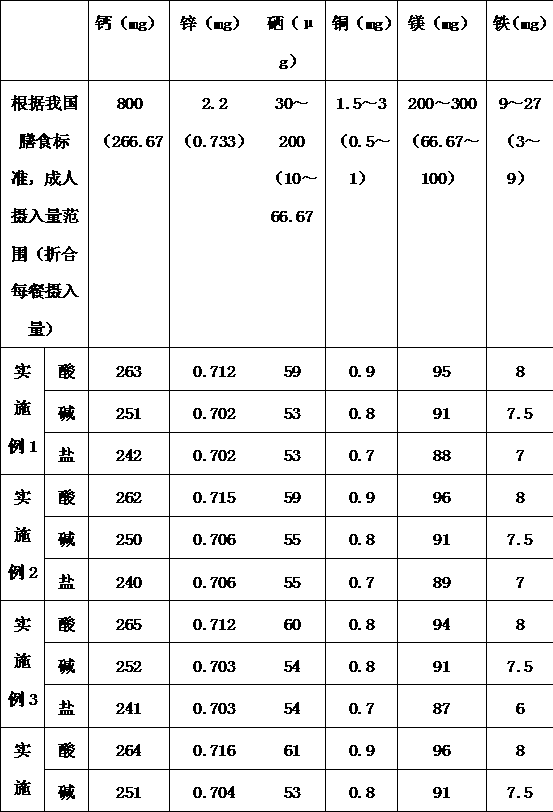

Life cultivation and health care composite and preparation method thereof

InactiveCN110055451AAvoid excessive intakeReduce manufacturing costCooking-vessel materialsWater/sewage treatment by substance additionMagnesium phosphateSodium phosphates

The invention discloses a life cultivation and health care composite and a preparation method thereof. Calcium nitrate, sodium phosphate, zinc nitrate, selenium dioxide, cupric oxalate, magnesium phosphate and high-purity iron are used as raw materials. Calcium nitrate and sodium phosphate are added into water at first and mixed, then zinc nitrate, selenium dioxide and cupric oxalate are added, still standing is conducted after primary temperature increase, coprecipitating occurs in the formation process of calcium phosphate, secondary temperature increase and stirring are conducted under inert gas shielding after drying, and a composite material is obtained; then magnesium phosphate and the composite material are added into molten iron formed by melting high-purity iron, and a high-temperature mixture is obtained; and finally, the composite product is obtained through cooling, mold forming and post-treatment. Trace elements such as calcium, zinc, selenium, copper, magnesium and iron can be precipitated during use of the product, human health is benefited, human immunity is improved, the prevalence rate of shortage of trace elements is lowered, and the good health care effect is achieved.

Owner:杭州鼎好新材料有限公司

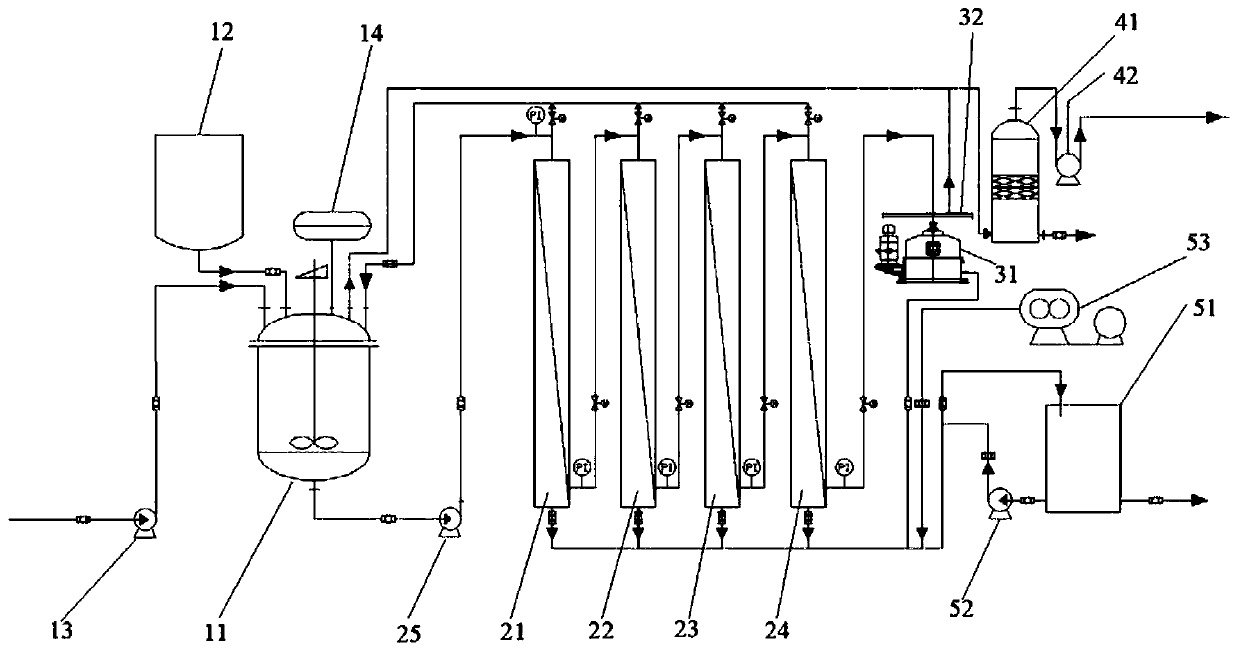

Copper separation system for strong-oxidation high-acidity copper-containing waste liquid

PendingCN110894114AAvoid the problem of easy to block filter cloth and difficult to filterPollution resistantWater/sewage treatment by centrifugal separationWater treatment parameter controlControl systemPhysical chemistry

The invention discloses a copper separation system for strong-oxidation high-acidity copper-containing waste liquid. The copper separation system comprises a PLC control system, a copper deposition reaction system connected with the PLC control system, a membrane concentration system, a centrifugal system, a waste gas recovery system and a backwashing system; the copper deposition reaction systemcomprises a precipitator feed port and a waste liquid feed port, and a reaction liquid discharge port of the copper deposition reaction system is connected with a reaction liquid feed port of the membrane concentration system; a concentrated solution discharge port of the membrane concentration system is connected with a concentrated solution feed port of the centrifugal system, and a permeate liquid discharge port of the membrane concentration system is connected with a feed port of the backwashing system; the centrifugal system further comprises a centrifugal liquid discharge port, and the centrifugal liquid discharge port is connected with the feed port of the backwashing system; a backwashing liquid outlet of the backwashing system is connected with a permeate liquid outlet of the membrane concentration system; and the copper deposition reaction system and the centrifugal system are both provided with waste discharge ports connected with the waste gas recovery system. According tothe technical scheme, efficient separation of the copper oxalate precipitate is achieved.

Owner:深圳星河环境股份有限公司

A method for leaching copper from tin-copper slag

ActiveCN111455189BAchieve value recoveryAchieve separationProcess efficiency improvementOXALIC ACID DIHYDRATEPregnant leach solution

Owner:ZHENGZHOU UNIV

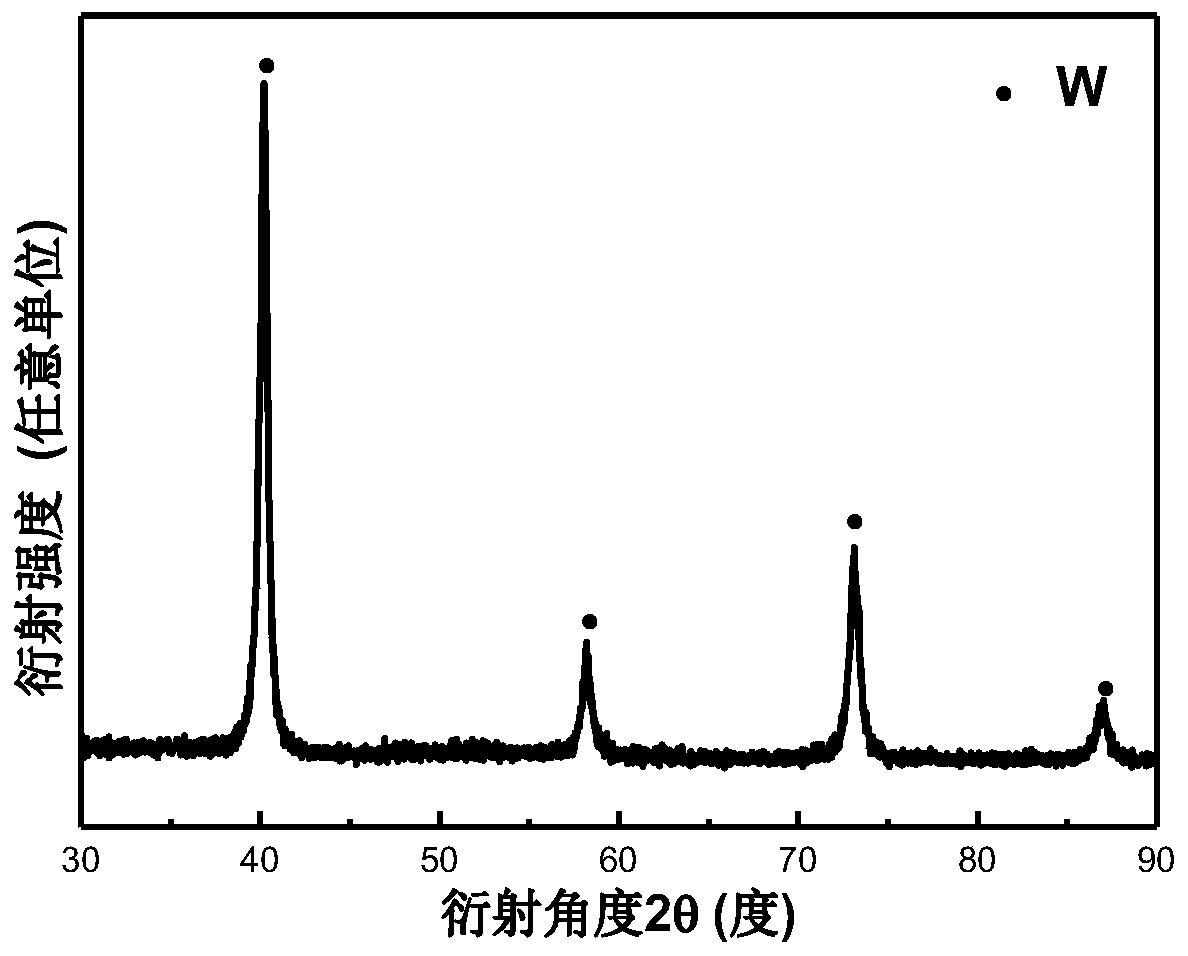

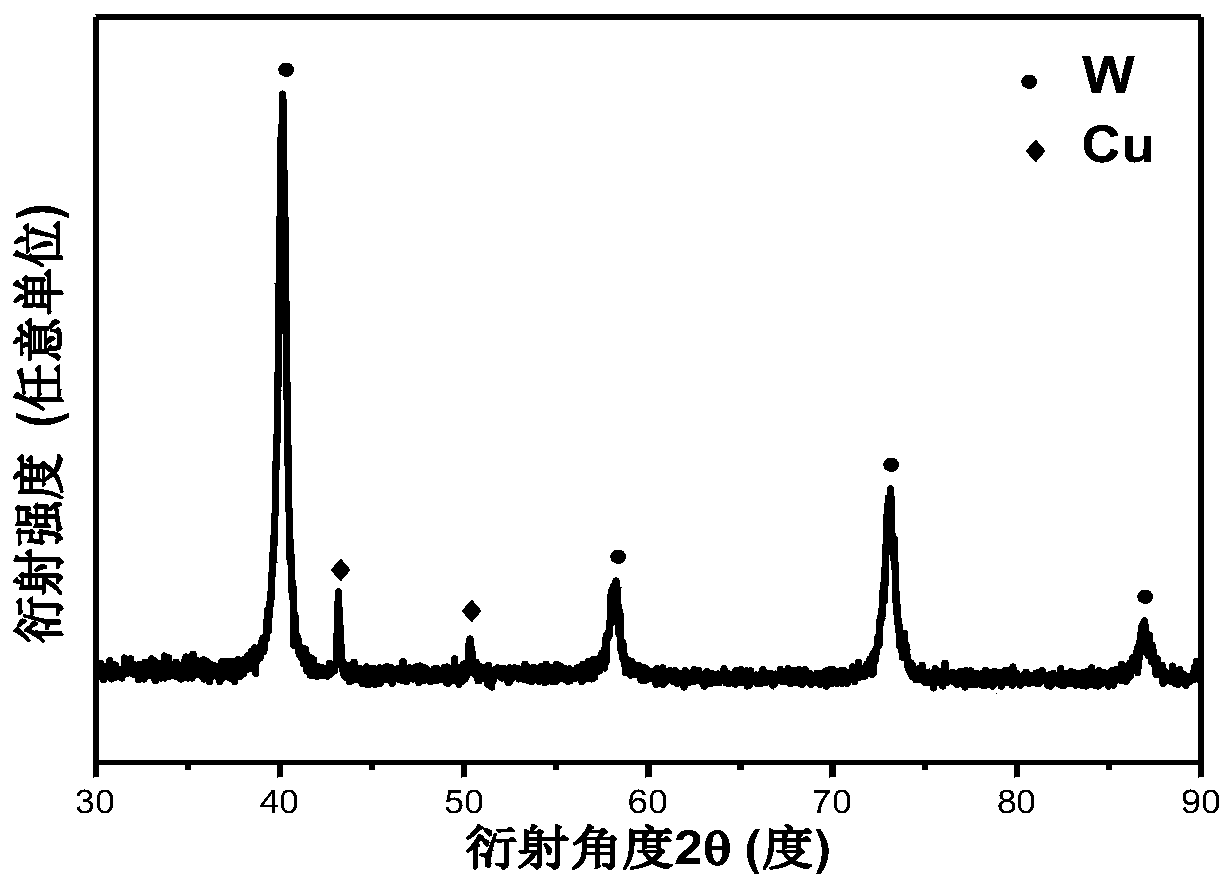

A low-temperature preparation method of pure nano w-cu composite powder

ActiveCN107983963BInhibit growthHigh purityTransportation and packagingMetal-working apparatusAl powderOXALIC ACID DIHYDRATE

Owner:BEIJING UNIV OF TECH

A Process for Improving the Uniformity of Microstructure and Properties of Manganese Copper Sintered Damping Alloy

Owner:CENT SOUTH UNIV

Method for using metallic copper to carry out in-situ modification on mesoporous organic polymer or carbon material

InactiveCN101531771BThe synthesis steps are simpleEasy to operateCoatingsPolymer scienceNitrogen gas

The invention discloses a method for using metallic copper to carry out in-situ modification on mesoporous organic polymer or carbon material. The method comprises the following steps of: fully stirring and mixing mesoporous organic polymer, mineralizer, copper source, acid and water according to mass ratio of 1.0 to 5.0 : 0.5 to 3.5 : 1.0 to 6.0 : 1.0 to 2.0 : 6, putting the mixture in a sealed container, heating at the temperature 80 to 120 DEG C for two days in water, washing the obtained precipitates with deionized water after filtering the precipitates, drying and then obtaining the mesoporous organic polymer material modified by copper oxalate; baking the material in nitrogen atmosphere at the temperature 400 DEG C to 500 DEG C or 500 DEG C to 900 DEG C; and obtaining the mesoporousorganic polymer or carbon material modified by metallic copper. The method has simple steps and easy operation and is beneficial to industrialized production; and the obtained organic polymer or carbon material has good hydrogen storage property in charging and discharging experiments and can be used as excellent electrode material.

Owner:EAST CHINA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com