Method for using metallic copper to carry out in-situ modification on mesoporous organic polymer or carbon material

An organic polymer, in-situ modification technology, applied in the direction of coating, etc., to achieve the effect of good repeatable results, uniform load distribution, and simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

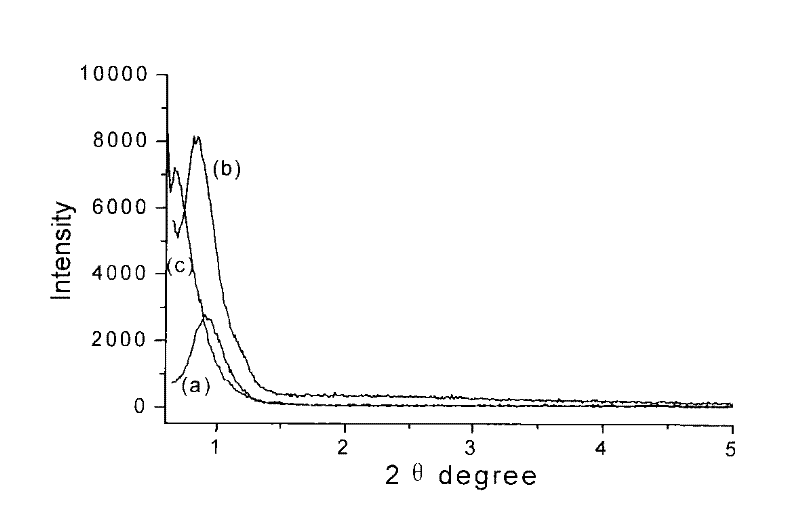

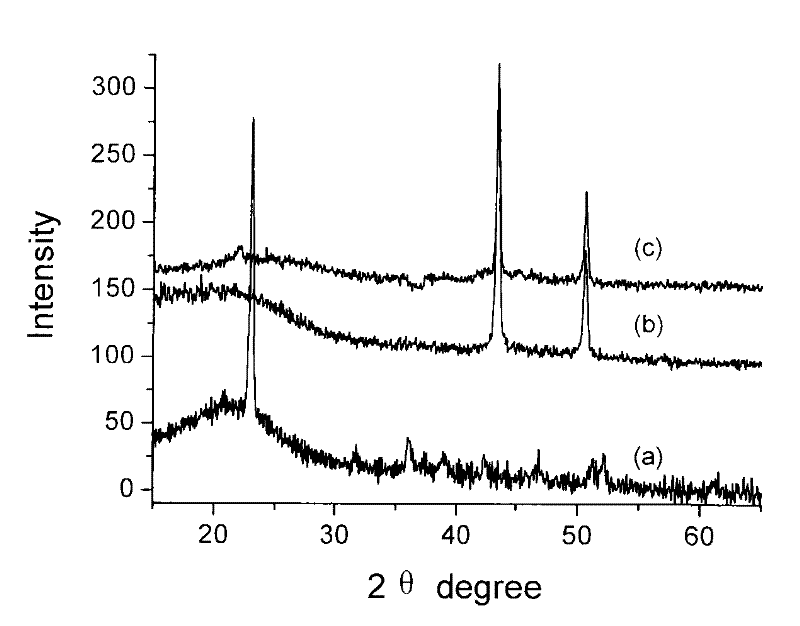

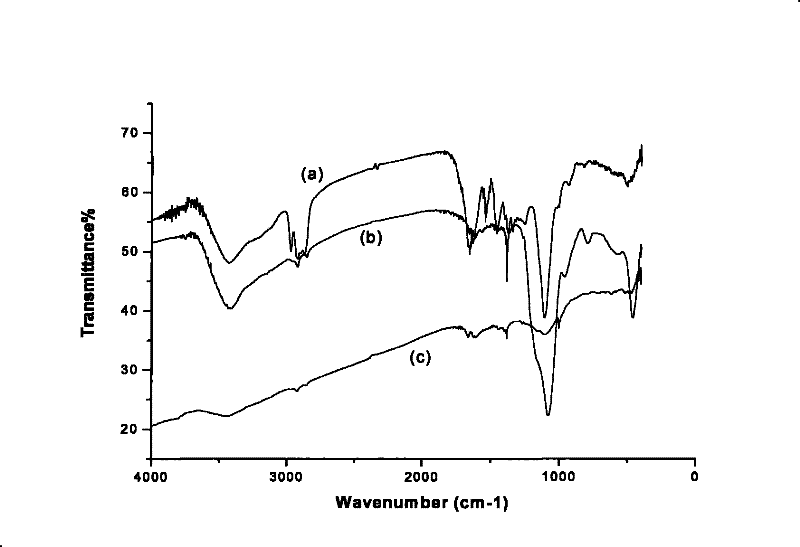

[0024] Add 5.0 g of dry mesoporous organic polymer material containing block polymer to 10.0 g Al(NO 3 ) 3 9H 2 O, 12g CuSO 4 ·5H 2 O, 6.8gH 3 PO 4 In the aqueous solution formed with 30ml of water, seal it and place it in a polytetrafluoroethylene reaction kettle, and heat it with water at 80°C for two days. The resulting product was filtered, washed and dried. The mesoporous organic polymer material modified by copper oxalate is obtained; its small-angle powder diffraction pattern is shown in figure 1 (a); the large-angle powder diffraction pattern is shown in figure 2 (a); see the infrared spectrum image 3 (a).

[0025] Copper oxalate modified mesoporous organic polymer materials in N 2 After calcination at 400℃ for 30min, the metal copper-modified mesoporous organic polymer material was obtained; the small-angle powder diffraction pattern is shown in figure 1 (b); the large-angle powder diffraction pattern is shown in figure 2 (b); Infrared spectrogram see ...

Embodiment 2

[0028] Add 5.0 g of dry mesoporous organic polymer material containing block polymer to 2.5 g Al(NO 3 ) 3 9H 2 O, 12g CuSO 4 ·5H 2 O, 10g H 3 PO 4 and 30ml of water to form an aqueous solution, sealed and placed in a polytetrafluoroethylene reactor, heated at 90°C for two days. The resulting product was filtered, washed and dried. That is, the copper oxalate modified mesoporous organic polymer material was obtained.

[0029] Copper oxalate modified mesoporous organic polymer materials in N 2 After calcination at 400°C for 30 minutes, the metal copper-modified mesoporous organic polymer material was obtained.

[0030] Copper oxalate modified mesoporous organic polymer materials in N 2 Calcined at 550°C for 4 hours to obtain a copper-modified mesoporous carbon material.

Embodiment 3

[0032] Add 5.0 g of dry mesoporous organic polymer material containing block polymer to 10.0 g Al(NO 3 ) 3 9H 2 O, 5g CuSO 4 ·5H 2 O, 5g H 3 PO 4 and 30ml of water, sealed and placed in a polytetrafluoroethylene reactor, heated at 100°C for two days. The resulting product was filtered, washed and dried. That is, the copper oxalate modified mesoporous organic polymer material was obtained.

[0033] Copper oxalate modified mesoporous organic polymer materials in N 2 After calcination at 500°C for 30 minutes, the metal copper-modified mesoporous organic polymer material was obtained.

[0034] Copper oxalate modified mesoporous organic polymer materials in N 2 Calcined at 600°C for 4 hours to obtain a copper-modified mesoporous carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com