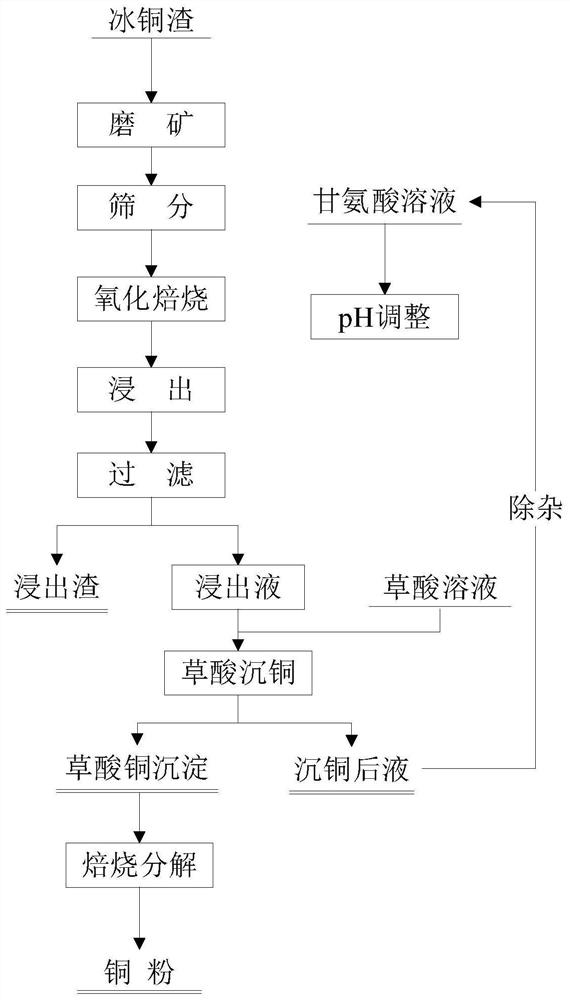

A kind of process method of alkaline wet leaching copper from matte slag

A process method and matte technology, applied in the field of alkaline wet leaching of copper, can solve the problems of purification and enrichment of leaching solution, high volatility of ammonia, slow microbial leaching speed, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

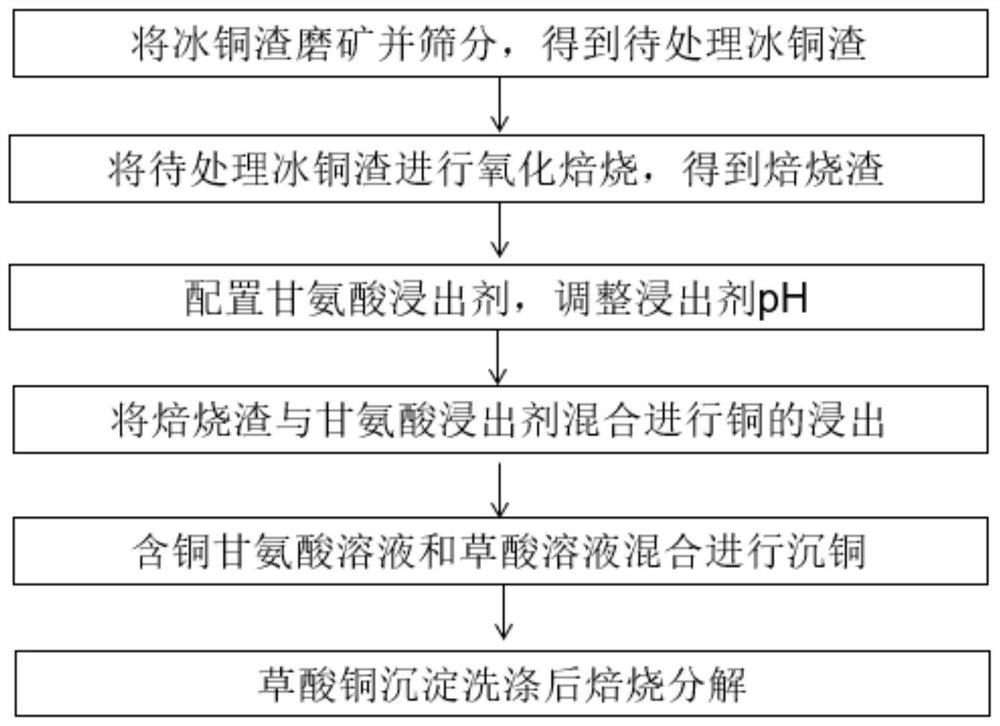

Method used

Image

Examples

Embodiment 1

[0062] The ice copper slag used is slow cooling slag, of which the copper content is 0.2%.

[0063] (1) Grinding ore: the crushing, grinding and sieving of ice copper slag to the particle size of less than 0.074mm accounts for 90%;

[0064] (2) Oxidation roasting: the ice copper slag that meets the requirements of the screening is put into the high-temperature muffle furnace, and the oxidation roasting is carried out for 30 minutes at a temperature of 500 ° C, and then taken out for cooling;

[0065] (3) Alkaline leaching:

[0066] The concentration of glycine extractant is 50g / L, and the pH of the extractant solution is adjusted to 10 by using sodium hydroxide solution; The prepared glycine extractant was mixed with the slag after roasting according to the liquid-solid ratio of 5:1, heated to 40 °C, and leached for 1 hour under mechanical stirring of 50 revolutions per minute, and the copper leaching rate reached 50%; The leaching slurry is filtered by the plate and frame filtrat...

Embodiment 2

[0070] The ice copper slag used is quenched slag, of which the copper content is 0.5%.

[0071] (1) Grinding ore: the crushing, grinding and sieving of ice copper slag to the particle mass of less than 0.074mm accounts for 95%;

[0072] (2) Oxidation roasting: the ice copper slag that meets the requirements of the screening is put into the high-temperature muffle furnace, and the oxidation roasting is carried out for 60 minutes under the condition of temperature 550 °C, and then taken out for cooling;

[0073] (3) Alkaline leaching:

[0074] The concentration of the glycine extract is 100g / L, and the pH of the extractant solution is adjusted to 10.5 by using sodium hydroxide solution; the prepared glycine extractant is mixed with the slag after roasting according to the liquid-solid ratio of 10:1, heated to 60 °C, leached for 5 hours under mechanical stirring of 150 revolutions per minute, and the copper leaching rate reaches 70%; The leaching slurry is filtered by the plate and f...

Embodiment 3

[0078] The ice copper slag used is quenched slag, of which the copper content is 1.5%.

[0079] (1) Grinding ore: the crushing, grinding and sieving of ice copper slag to the particle mass of less than 0.074mm accounts for 95%;

[0080] (2) Oxidation roasting: the ice copper slag that meets the requirements of the screening is put into the high-temperature muffle furnace, and the oxidation roasting is carried out for 90 minutes at a temperature of 600 ° C, and then taken out for cooling;

[0081] (3) Alkaline leaching:

[0082] The concentration of glycine extractant is 150g / L, and the pH of the extractant solution is adjusted to 11 by using sodium hydroxide solution; The prepared glycine extractant was mixed with the slag after roasting according to the liquid-solid ratio of 15:1, heated to 75 °C, leached for 10 hours under mechanical stirring of 200 revolutions per minute, and the copper leaching rate reached 75%; The leaching slurry is filtered by the plate and frame filtration d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com