Copper recovery method

A recovery method and technology of copper nitrate, applied in the direction of instrument, optics, process efficiency improvement, etc., can solve the problems of low copper purity, high total nitrogen in waste liquid and difficult recycling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

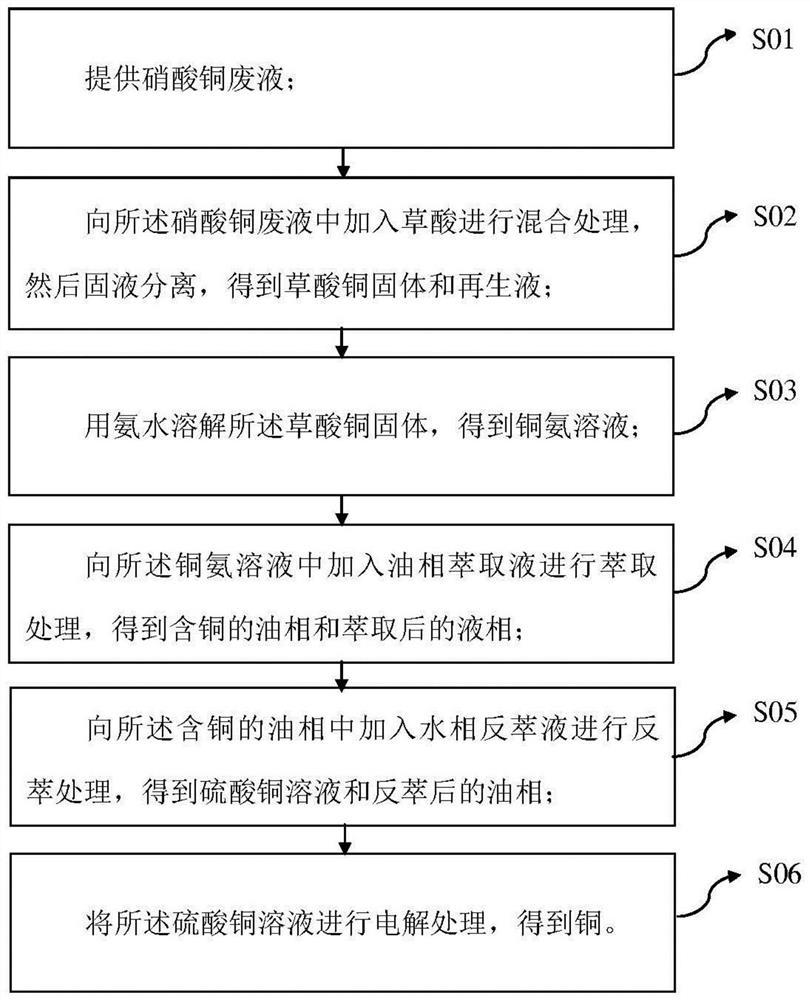

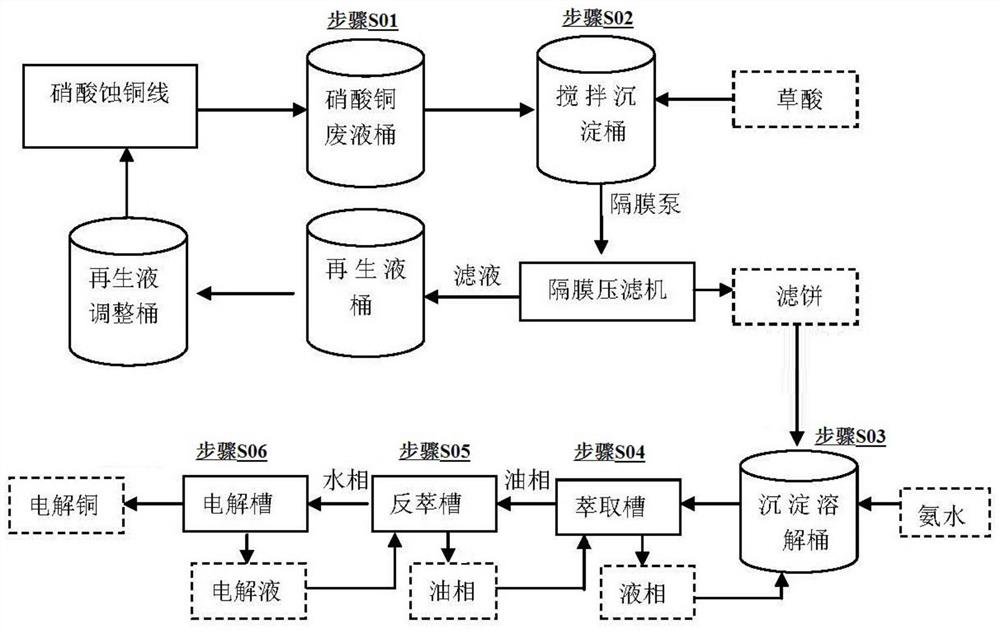

[0058] A method for copper recovery from copper nitrate waste liquid, comprising the steps of:

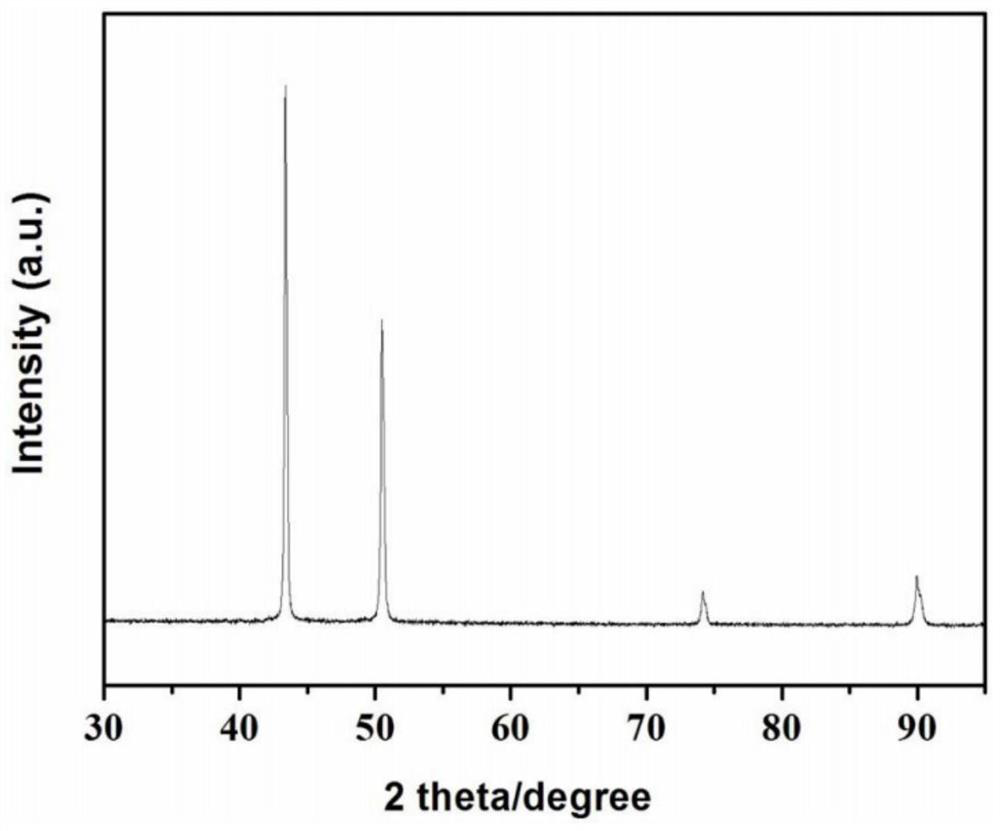

[0059] Provide copper nitrate waste liquid sample, sample acidity (H + Equilibrium concentration) 2.0mol / L, copper ion concentration 48g / L. Add 54g of oxalic acid to 1L of the above copper nitrate waste liquid, stir for 30min, aerate for 2h, let it settle naturally for 6-8h, filter and dry the solid to obtain 92g of dry copper oxalate solid; the main component of the filtrate is nitric acid, of which The acidity is 3.2mol / L, and after adding 65% nitric acid, it can be returned to the production line for continued use. The above-mentioned dry copper oxalate solid is dissolved with ammonia water with a mass fraction of 10%, and the cuproammonia solution is obtained after the solid is completely dissolved. Add Mextral 984H extractant to the above cuproammonia solution, where the volume ratio O / W=3:1, at this time, the copper ions are transferred from the water phase to the oil phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com