Nano copper oxalate composite three-dimensional graphene anode material as well as preparation method and application thereof

A graphene negative electrode and nanograss technology, applied in chemical instruments and methods, carbon compounds, battery electrodes, etc., can solve the problems of low coulombic efficiency, irreversible specific capacity loss, coulombic efficiency of only 50% to 70%, etc., to achieve preparation The process is simple, the Coulomb efficiency is improved, and the effect of breaking through the technical bottleneck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

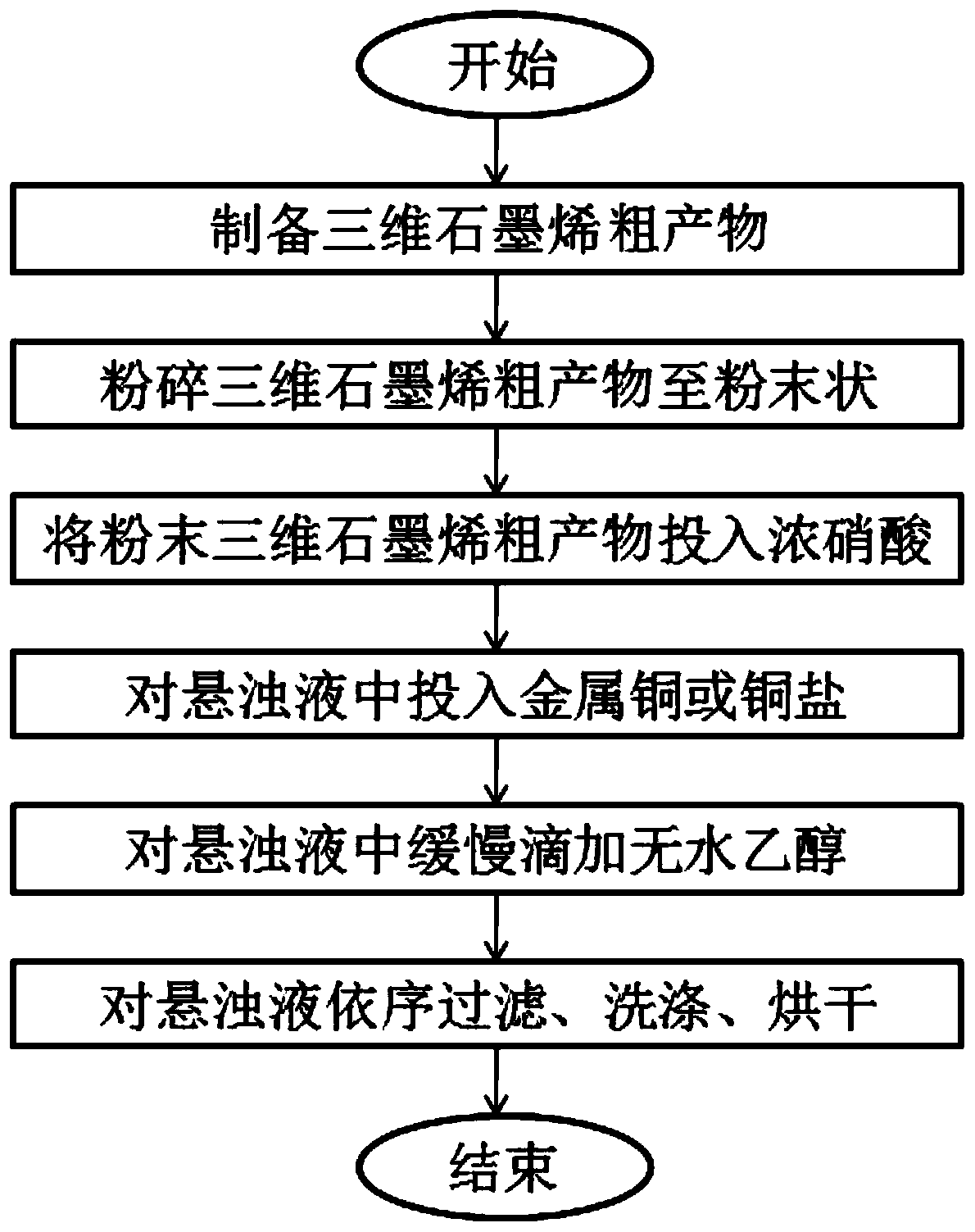

[0020] The preparation process of a set of nano-copper oxalate composite three-dimensional graphene anode materials:

[0021] S1: Weigh 1g of metal lithium in an inert gas glove box and put it into a ceramic boat, quickly put the ceramic boat into the tube furnace, and evacuate the tube furnace to 10Pa;

[0022] S2: Fill the tube furnace with carbon dioxide gas to 0.4Mpa, then heat the tube furnace to 550°C at a rate of 5°C per minute and keep it for 24 hours to obtain a crude three-dimensional graphene product;

[0023] S3: crushing the crude three-dimensional graphene product obtained in S2 to a size above 100 mesh;

[0024] S4: Put the powdered three-dimensional graphene crude product obtained in S3 into concentrated nitric acid with a concentration of 68%, soak for 12 hours, and make the mass ratio of the three-dimensional graphene crude product to concentrated nitric acid reach 1:5;

[0025] S5: After adding copper powder to the suspension obtained in S4 and fully stirri...

Embodiment 2

[0029] The preparation process of a set of nano-copper oxalate composite three-dimensional graphene anode materials:

[0030] S1: Weigh 1g of metal lithium in an inert gas glove box and put it into a ceramic boat, quickly put the ceramic boat into the tube furnace, and evacuate the tube furnace to 10Pa;

[0031] S2: Fill the tube furnace with carbon dioxide gas to 0.4Mpa, then heat the tube furnace to 600°C at a rate of 8°C per minute and keep it for 36h to obtain a crude three-dimensional graphene product;

[0032] S3: crushing the crude three-dimensional graphene product obtained in S2 to a size above 100 mesh;

[0033] S4: Put the powdery three-dimensional graphene crude product obtained in S3 into concentrated nitric acid with a concentration of 68%, soak for 12 hours, and make the mass ratio of the three-dimensional graphene crude product to concentrated nitric acid reach 1:4;

[0034]S5: After adding copper sulfate to the suspension obtained in S4 and fully stirring, th...

Embodiment 3

[0038] The preparation process of a set of nano-copper oxalate composite three-dimensional graphene anode materials:

[0039] S1: Weigh 1g of metal lithium in an inert gas glove box and put it into a ceramic boat, quickly put the ceramic boat into the tube furnace, and evacuate the tube furnace to 10Pa;

[0040] S2: Fill the tube furnace with carbon dioxide gas to 0.5Mpa, then heat the tube furnace to 575°C at a rate of 10°C per minute and keep it for 48 hours to obtain a crude three-dimensional graphene product;

[0041] S3: crushing the crude three-dimensional graphene product obtained in S2 to a size above 100 mesh;

[0042] S4: Put the powdered three-dimensional graphene crude product obtained in S3 into concentrated nitric acid with a concentration of 68%, soak for 12 hours, and make the mass ratio of the three-dimensional graphene crude product to concentrated nitric acid reach 1:4.5;

[0043] S5: After adding copper carbonate to the suspension obtained in S4 and fully ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com