Preparation method of high-toughness and high-flexibility copper oxide gas desulfurizing agent

A technology of copper oxide and desulfurizer, which is applied in the removal of gas pollutants, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of low utilization rate of active components, poor vulcanization-regeneration performance of desulfurizer, etc. Achieve excellent mechanical properties and flexibility, high flexibility and toughness, and buffer the effect of pore structure swelling and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

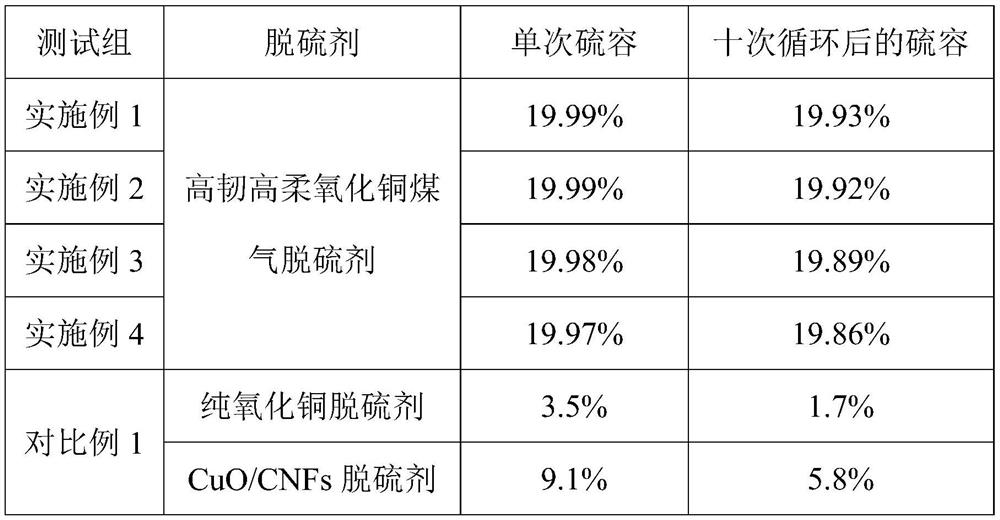

Examples

Embodiment 1

[0026] A preparation method of a high-toughness and high-flexibility copper oxide gas desulfurizer, comprising the following steps:

[0027] A. Preparation of three-dimensional orthogonal structure prefabricated parts: use three-dimensional weaving technology to weave fiber filaments into three-dimensional orthogonal structure prefabricated parts, the number of weaving layers is 15 layers, and the warp and weft yarns of the three-dimensional orthogonal structure prefabricated parts are all carbon fibers Filament, the binding yarn is high silica glass fiber, the warp yarn density is 600 / 10cm, the binding yarn density is 150 / 10cm, and the weft yarn density is 300 / 10cm; the length and The width is 20mm and the thickness is 10mm;

[0028] B. Preparation of impregnation solution: 1.9g copper oxalate powder was dissolved in 20mL water to obtain the impregnation solution;

[0029] C. Equal volume impregnation: immerse the equal volume of the three-dimensional orthogonal structure pr...

Embodiment 2

[0036] A preparation method of a high-toughness and high-flexibility copper oxide gas desulfurizer, comprising the following steps:

[0037] A. Preparation of three-dimensional orthogonal structure prefabricated parts: use three-dimensional weaving technology to weave fiber filaments into three-dimensional orthogonal structure prefabricated parts, the number of weaving layers is 15 layers, and the warp and weft yarns of the three-dimensional orthogonal structure prefabricated parts are all carbon fibers Filament, the binding yarn is high silica glass fiber, the warp yarn density is 600 / 10cm, the binding yarn density is 150 / 10cm, and the weft yarn density is 300 / 10cm; the length and The width is 20mm and the thickness is 10mm;

[0038] B. Preparation of impregnating solution: 3.8g copper oxalate powder was dissolved in 20mL water to obtain impregnating solution;

[0039] C. Equal volume impregnation: immerse the equal volume of the three-dimensional orthogonal structure prefor...

Embodiment 3

[0046] A preparation method of a high-toughness and high-flexibility copper oxide gas desulfurizer, comprising the following steps:

[0047] A. Preparation of three-dimensional orthogonal structure prefabricated parts: use three-dimensional weaving technology to weave fiber filaments into three-dimensional orthogonal structure prefabricated parts, the number of weaving layers is 15 layers, and the warp and weft yarns of the three-dimensional orthogonal structure prefabricated parts are all carbon fibers Filament, the binding yarn is high silica glass fiber; the warp yarn density is 600 / 10cm, the binding yarn density is 150 / 10cm, the weft yarn density is 300 / 10cm, the length and width of the three-dimensional orthogonal structure preform Both are 20mm, and the thickness is 10mm;

[0048] B. Preparation of impregnation solution: 5.7g copper oxalate powder was dissolved in 20mL water to obtain the impregnation solution;

[0049] C. Equal volume impregnation: immerse the equal vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com