Life cultivation and health care composite and preparation method thereof

A composite material and material technology, which is applied in special materials for cooking utensils, water/sewage treatment with added substances, etc., can solve the problems of increasing production cost and production difficulty, poor production convenience, melting of elemental substances, and large differences in gasification temperature, etc. Achieve the effect of avoiding excessive intake, good mechanical strength and high temperature resistance, reducing production cost and production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

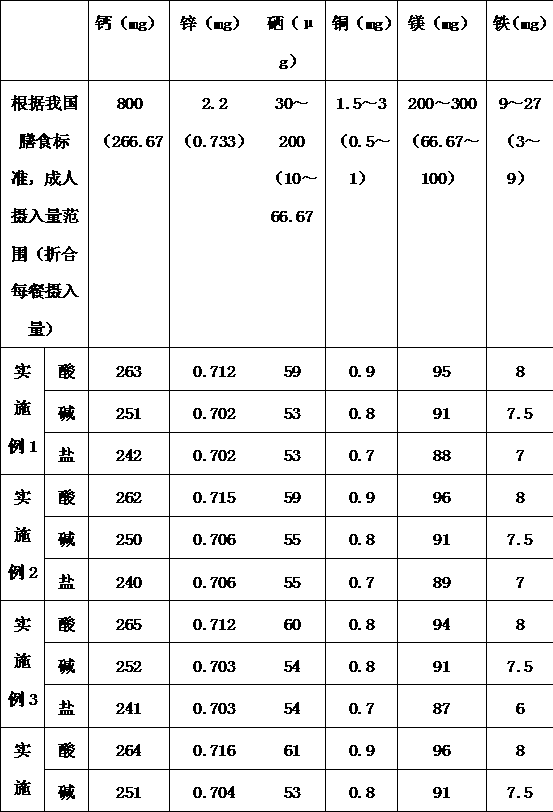

Examples

Embodiment 1

[0029] A preparation method of a health care composite material, the specific steps are as follows:

[0030] (1) Add calcium nitrate and sodium phosphate to water, mix well, add zinc nitrate, selenium dioxide, and copper oxalate, heat up to 80°C for the first time, keep the temperature for 12 hours, filter the solid, dry, pulverize, and inert gas Under protection, the temperature was raised to 340°C for the second time, stirred and kept for 2 hours to obtain a composite material;

[0031] (2) The high-purity iron is melted into molten iron, and magnesium phosphate and the composite material obtained in step (1) are added to the molten iron while stirring to obtain a high-temperature mixture;

[0032] (3) Cool the high-temperature mixture to 800°C and let it stand for 2 hours to obtain the cooling mixture;

[0033] (4) Under the protection of inert gas, the cooling mixture is injected into the mold, and formed to obtain a billet;

[0034] (5) Homogenization treatment, multipl...

Embodiment 2

[0043] A preparation method of a health care composite material, the specific steps are as follows:

[0044] (1) Add calcium nitrate and sodium phosphate into water, mix well, add zinc nitrate, selenium dioxide, and copper oxalate, heat up to 90°C for the first time, keep it for 15 hours, filter the solid, dry, pulverize, and inert gas Under protection, the temperature was raised to 350°C for the second time, stirred and kept for 3 hours to obtain a composite material;

[0045] (2) The high-purity iron is melted into molten iron, and magnesium phosphate and the composite material obtained in step (1) are added to the molten iron while stirring to obtain a high-temperature mixture;

[0046] (3) Cool the high-temperature mixture to 900°C and let it stand for 3 hours to obtain the cooling mixture;

[0047] (4) Under the protection of inert gas, the cooling mixture is injected into the mold, and formed to obtain a billet;

[0048] (5) Homogenization treatment, multiple cold roll...

Embodiment 3

[0057] A preparation method of a health care composite material, the specific steps are as follows:

[0058] (1) Add calcium nitrate and sodium phosphate into water, mix well, add zinc nitrate, selenium dioxide, and copper oxalate, heat up to 80°C for the first time, keep it for 15 hours, filter the solid, dry, pulverize, and inert gas Under protection, the temperature was raised to 340°C for the second time, stirred and kept for 3 hours to obtain a composite material;

[0059] (2) The high-purity iron is melted into molten iron, and magnesium phosphate and the composite material obtained in step (1) are added to the molten iron while stirring to obtain a high-temperature mixture;

[0060] (3) Cool the high-temperature mixture to 800°C and let it stand for 3 hours to obtain the cooling mixture;

[0061] (4) Under the protection of inert gas, the cooling mixture is injected into the mold, and formed to obtain a billet;

[0062] (5) Homogenization treatment, multiple cold roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com