Patents

Literature

33 results about "Soluble oxalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soluble oxalates are a toxic component that is found in a number of plant species. This type of oxalate is absorbed into the bloodstream where it can cause metabolic imbalance and kidney failure.

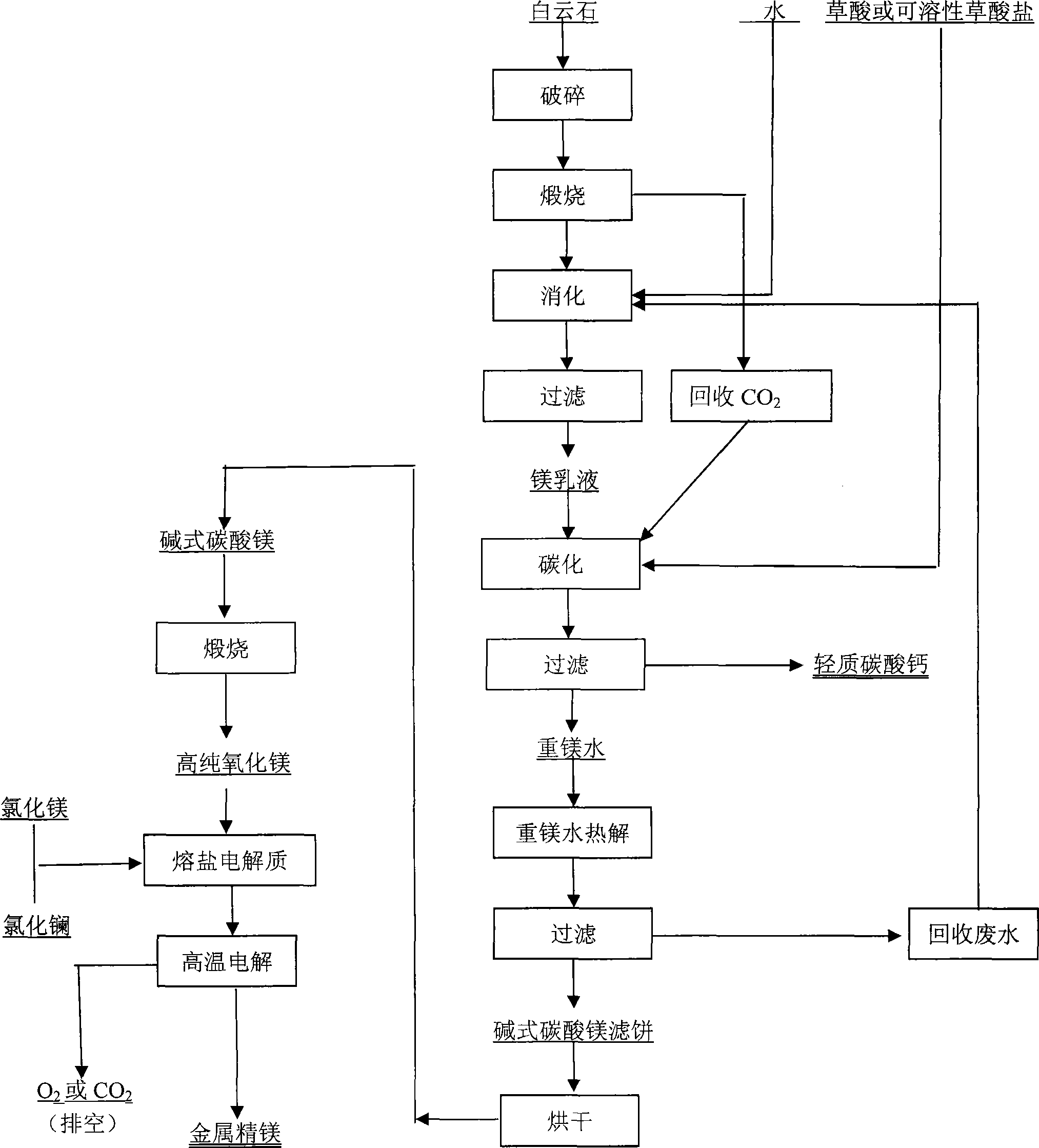

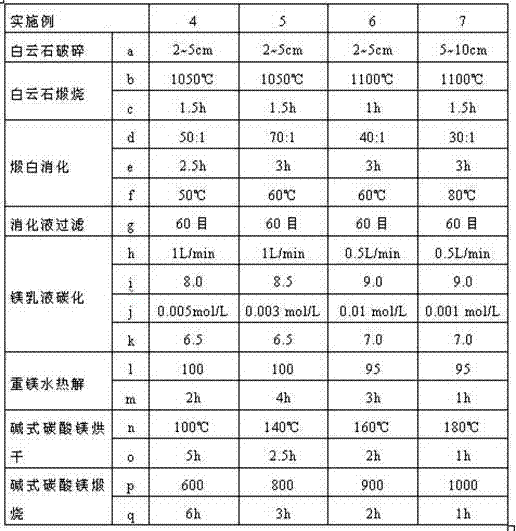

A process for producing high-purity magnesium oxide from dolomite

InactiveCN102275957ASolve problems that are difficult to cleanly separateHigh purityMagnesiaOXALIC ACID DIHYDRATESoluble oxalate

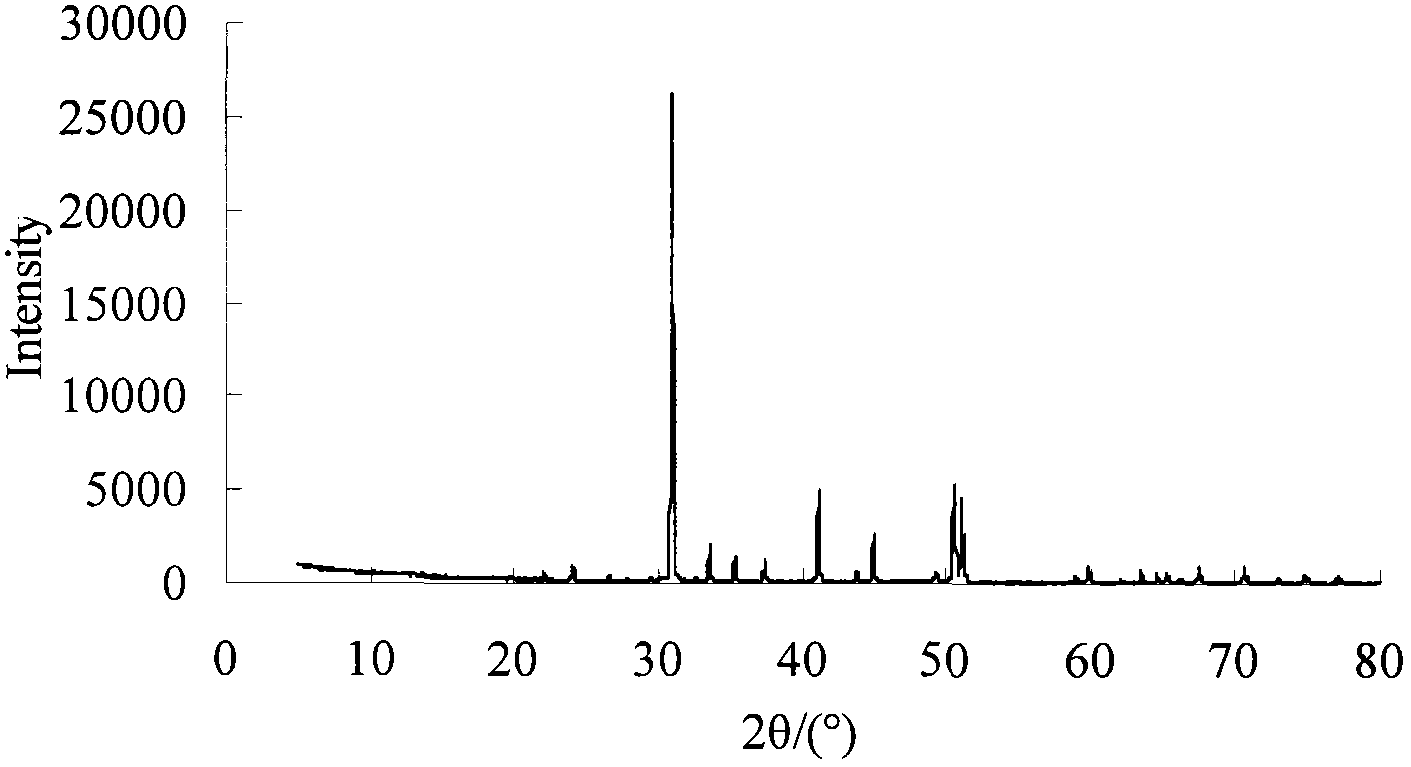

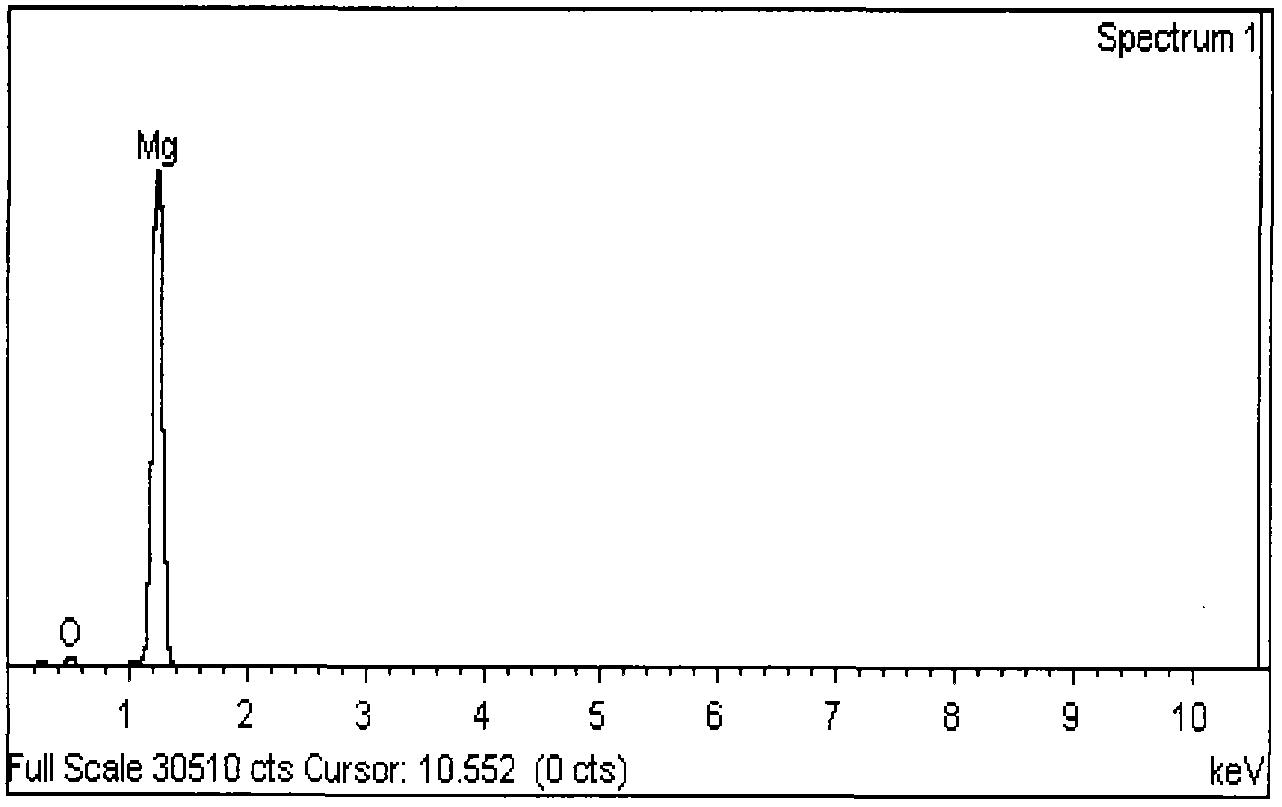

The invention discloses a process for producing high purity magnesium oxide with dolomite, comprising the steps of: subjecting dolomite to fragmentation, calcination, digestion, filtration, carbonization, solid-liquid separation, pyrolysis, basic magnesium carbonate drying and basic magnesium carbonate calcination, thus obtaining high purity magnesium oxide with CaO content less than 0.2%, Fe content less than 0.01% and MgO content higher than 98%. The process is totally in accord with the technical requirements of HG / T2573-2006 "industrial lightweight magnesium oxide" for Class I and Class II high-class products. The invention puts forward an improving method for the digestion and carbonization processes during high purity magnesium oxide production from dolomite, thus raising the extraction rate of MgO from dolomite. By adding a certain amount of oxalic acid and soluble oxalate into the carbonization system, the technical problem that calcium and magnesium are difficult to be separated thoroughly in a dolomite carbonization method can be solved. The process of the invention has the characteristics of simple technology, easy control, high extraction rate of magnesium oxide and high purity product.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +2

Polishing liquid, preparation method and application

ActiveCN105385356AExcellent wear resistance and weather resistanceBright mirror effect is goodPolishing compositions with abrasivesWaxSoluble oxalate

The present invention belongs to the technical field of marble or wood-based panel surface brightening and protection treatments, in particular relating to polishing liquid, a preparation method and an application. The polishing liquid comprises a pH modifier, soluble oxalate, a lubricant, fluosilicate, nano titanium dioxide, nano silicon dioxide, a coupling agent, a palm wax emulsion and / or a paraffin emulsion and water. By applying the polishing liquid provided by the present invention to a marble or wood-based panel surface, under a series of physical and chemical actions, a thick layer of dense bright glassy substances can be generated on the surface; the bright glassy substances are hard, wear-resistant and weather-resistant, so that the 'water'-like bright mirror effect on a floor surface is achieved; and a surface scratch can be easily repaired. When the marble or wood-based panel surface is treated by the polishing liquid, the polishing liquid is only required to be poured onto the marble or wood-based panel, and is spread by a polishing pad. Polishing steel wire cotton is not needed; production efficiency is improved; cost is saved; and polishing brightness is improved.

Owner:GUANGZHOU GAOCHEN STONE TECH CO LTD

Chlorine gas decontaminant

ActiveCN101322904AAchieve harmless decontamination effectStop the spreadDispersed particle separationBetaineSoluble oxalate

The invention discloses a chlorine decontaminant, which is characterized in that the chlorine decontaminant is prepared by mixing organic reducer accounting for 89.8 percent to 96 percent of the total weight, 3 percent to 10 percent of surfactant, 0.1 percent to 0.5 percent of thickener polyvinyl alcohol (PVA) and 0.1 percent to 0.5 percent of foam stabilizer dodecyl dimethyl amine oxide (DDAO). The organic reducer is chosen from soluble oxalate, citrate or ascorbic acid, starch, glucose, fruit sugar, tartrate, malate or lactate; the surfactant is chosen from polyoxyethylene alkyl ether sulfo-sodium succinate, coco-amide propyl betaine (CAPB), alpha-alkenyl sulfonate sodium, fluorine surfactant or sodium ethoxylated alkyl sulfate. When the decontaminant is carried out, the water solution with the concentration being 0.3 percent to 10 percent (weight percentage) is used and sprayed to the leakage area of chlorine by a fine water atomizing nozzle; the decontaminant of the invention combines physical dilution and chemical reaction, thus inhibiting the diffusion of chlorine and enhancing the reaction ratio, and the remained substances of the reaction are free of contamination and can be easily decomposed.

Owner:UNIV OF SCI & TECH OF CHINA

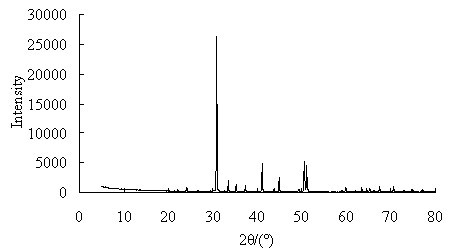

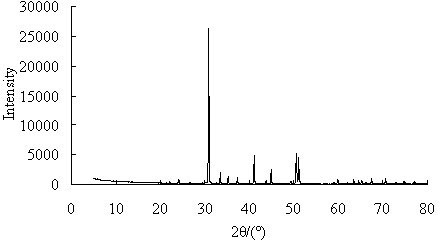

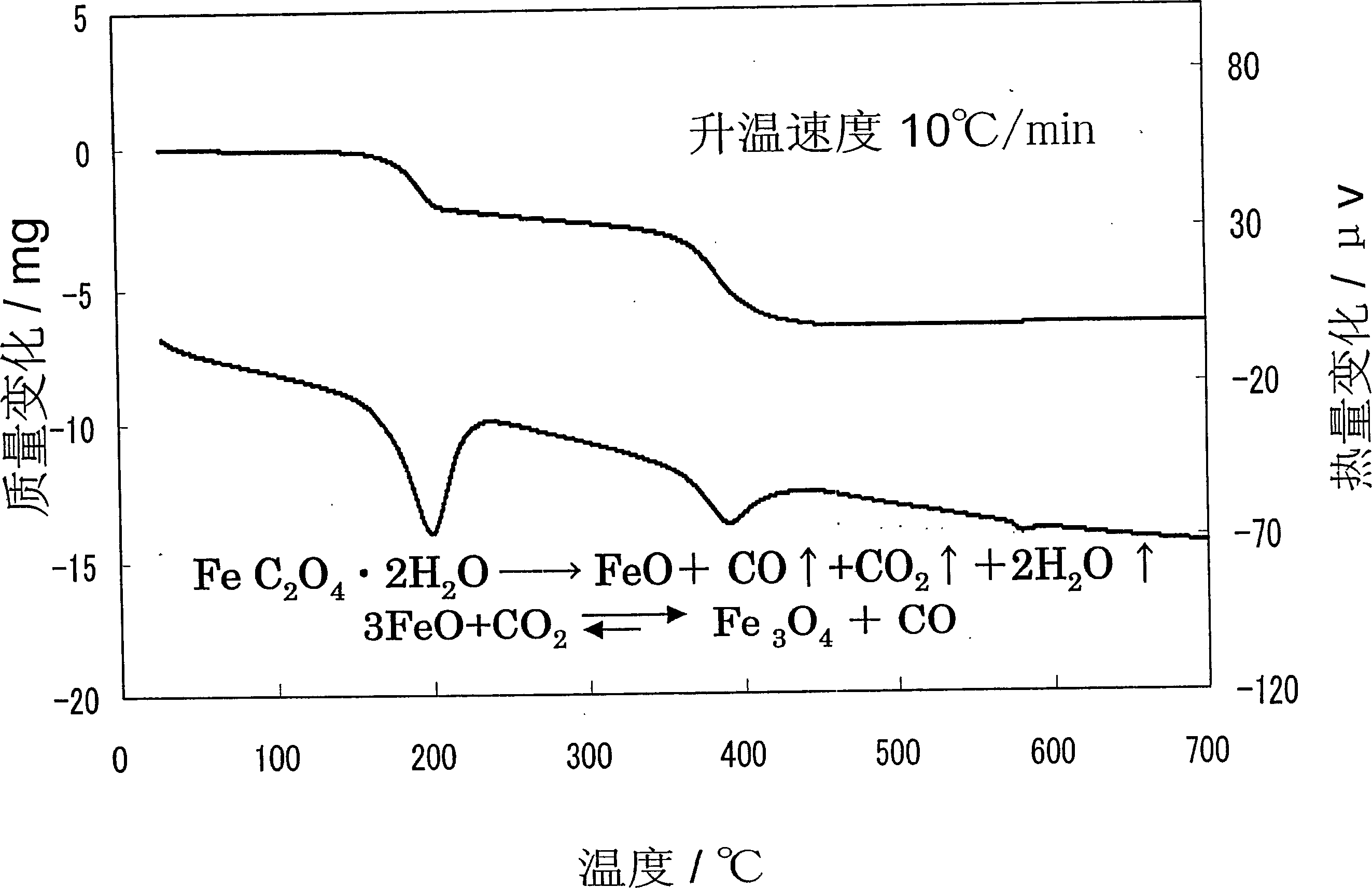

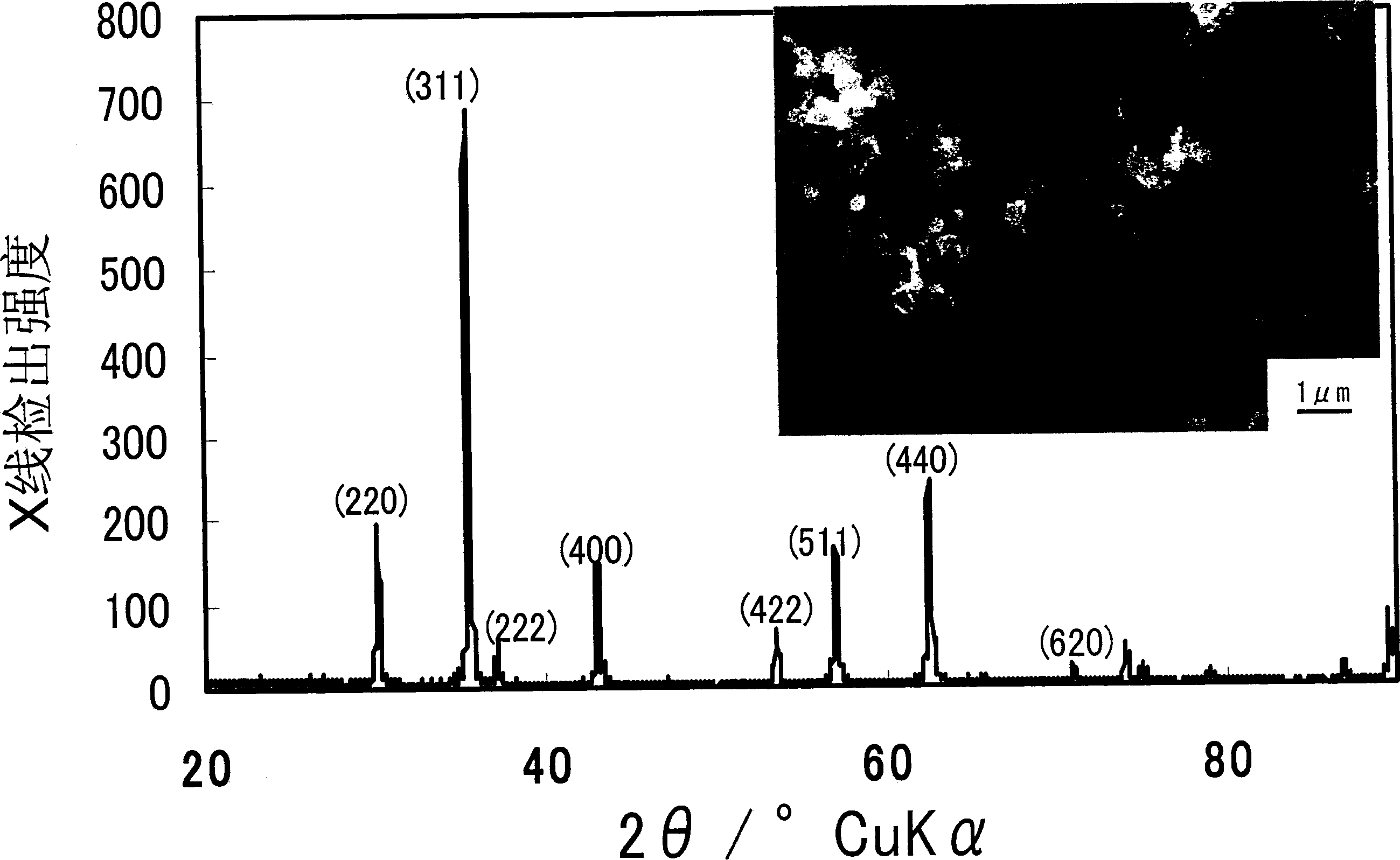

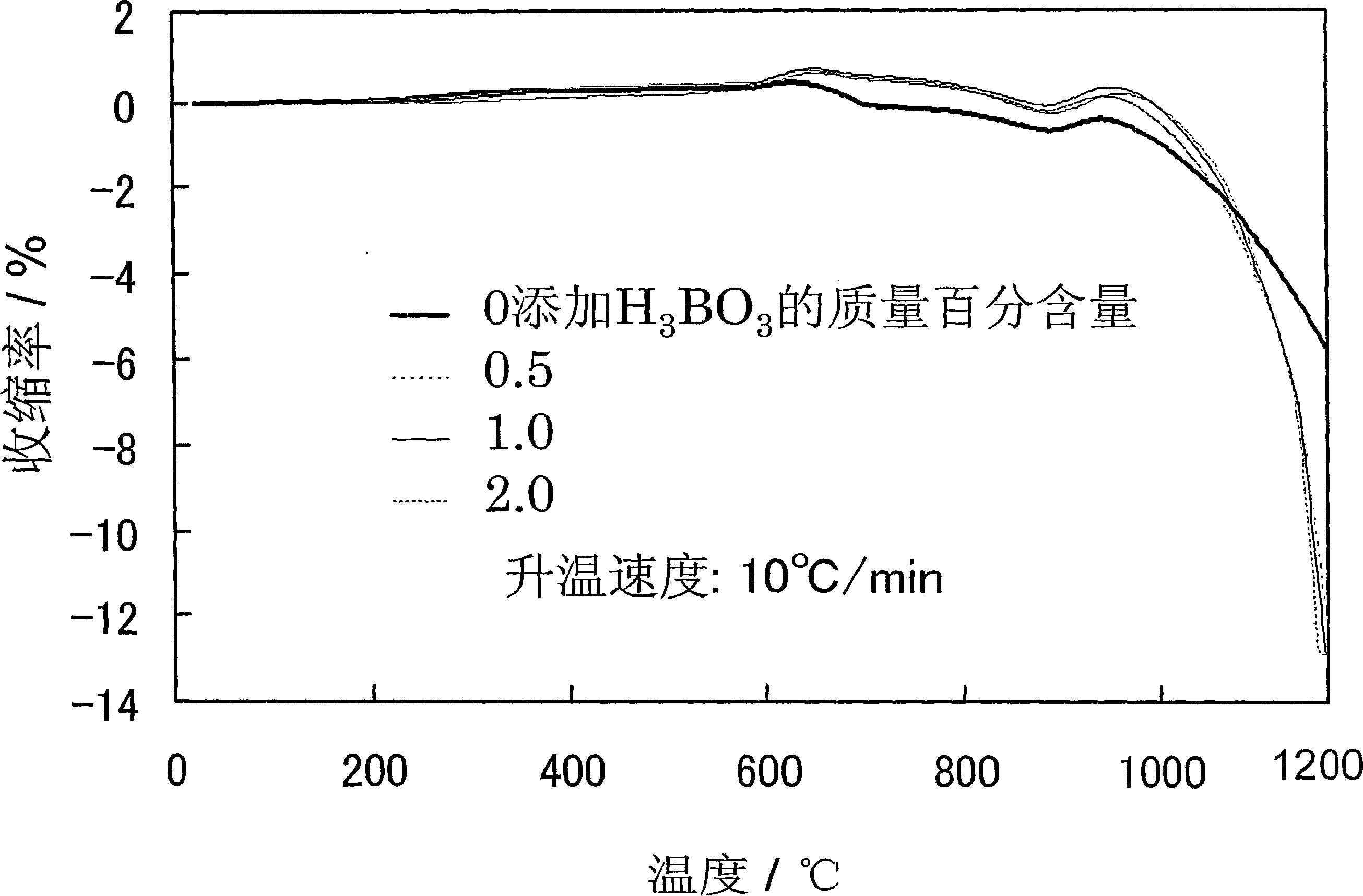

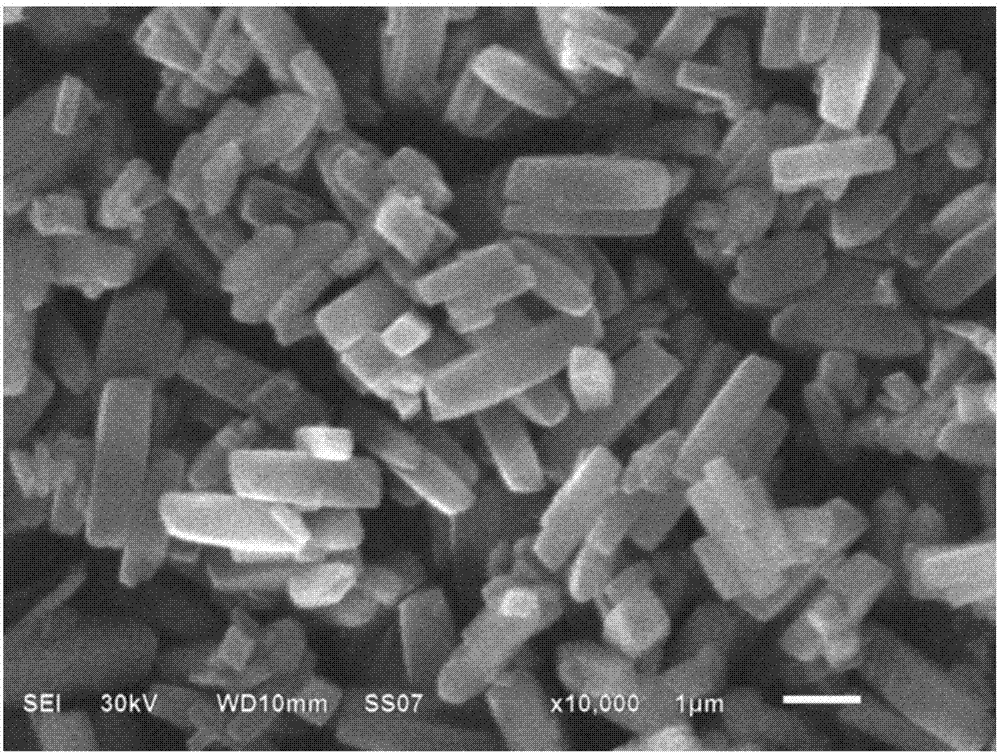

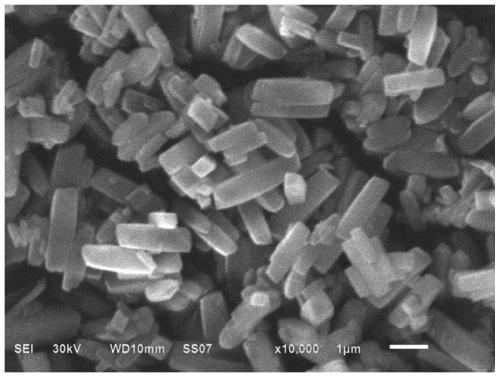

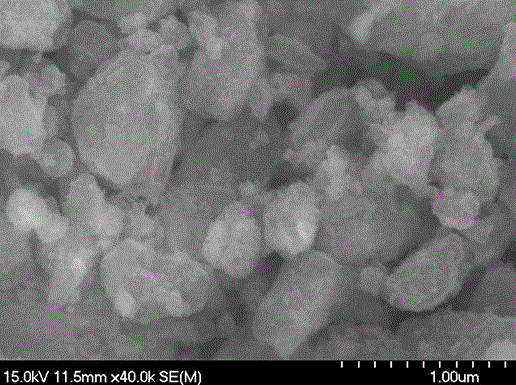

Low-temperature sintering production technology for magnetic ferrite and inductive material

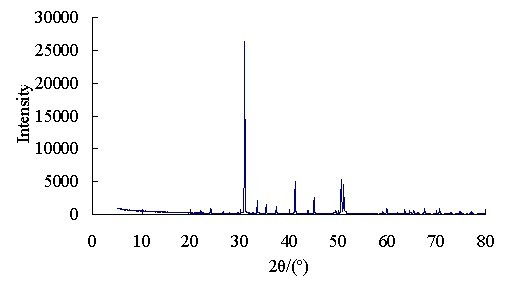

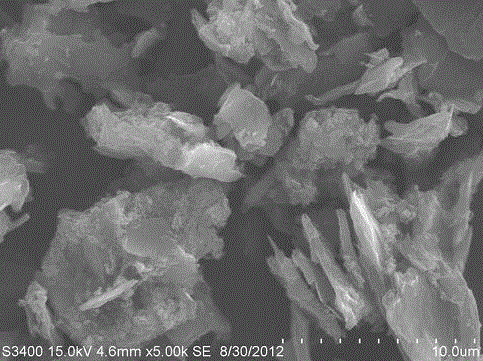

InactiveCN1812019ASmall particlesUniform particle sizeInorganic material magnetismCoils manufactureSoluble oxalateFiltration

This method provides a kind of manufacture method of low-temperature sintering magnetic ferrite material using on electric induction coil. To use a kind of or various kinds of mixture solution metal salt (the salt is soluble salt of metal such as iron, nickel, manganese, copper, zinc, barium, cobalt, strontium and magnesium) to react with soluble oxalate solution and generate metal oxalate deposition. After filtration, washing and separating, heating and decompose to generate even particle diameter ferrite powder under protection gas. Add an amount of addition agents (such as compounds of calcium, silicon, bismuth or boron) to the powder. Adjust sintering temperature and electromagnetic property of sintering body through adjusting the components and contents of addition agents. Put the powder in the mould and press to form shape. Keep under protection gas and temperature of 800-1000DEG C for 1-20 hours and sintering to make the sintering body.

Owner:巨东英 +1

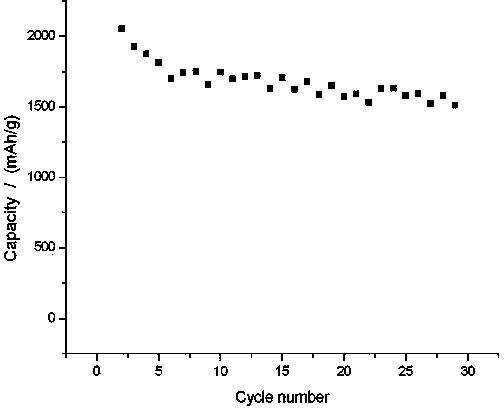

High-capacity lithium ion battery composite negative electrode material and preparation method thereof

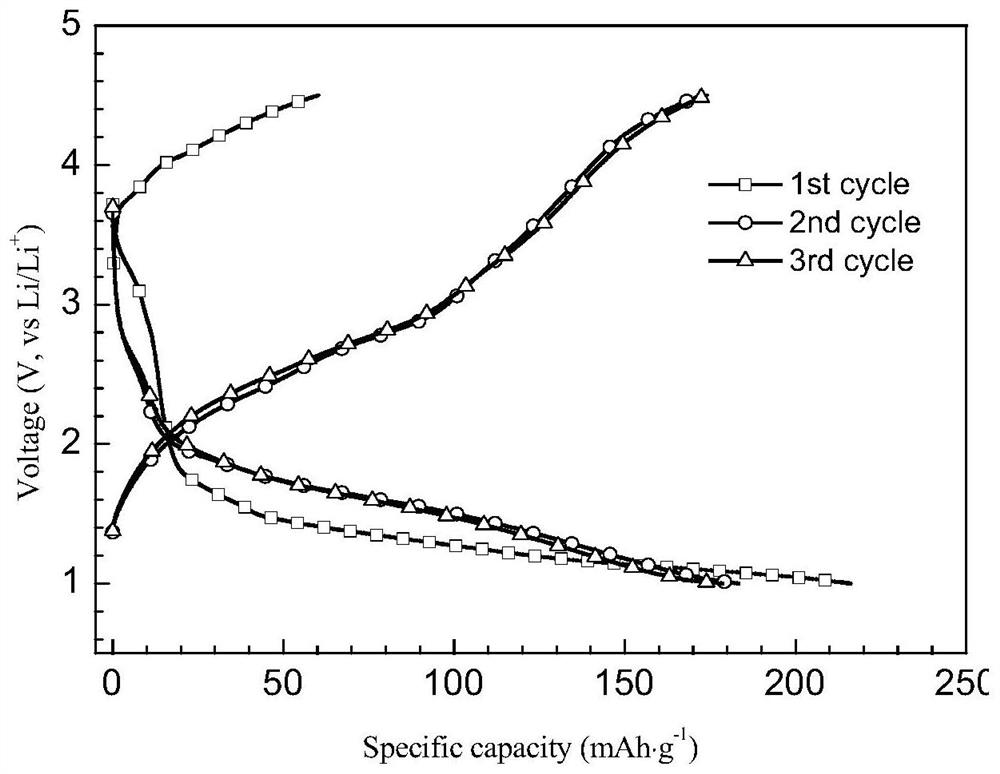

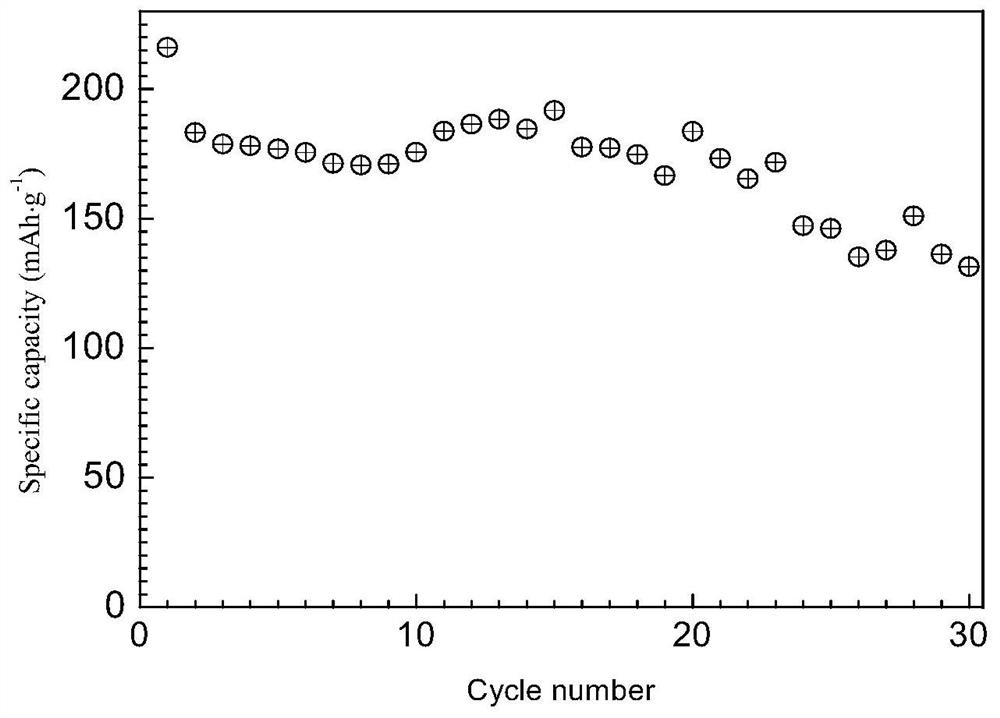

ActiveCN103811730ALarge capacityImprove cycle performanceCell electrodesSecondary cellsSoluble oxalateMass ratio

The invention discloses a high-capacity lithium ion battery composite negative electrode material and a preparation method thereof, wherein problems of low charging-discharging specific capacity and poor cycle performance of application of the existing carbon material as the lithium ion battery negative electrode material are solved. According to the present invention, the high-capacity lithium ion battery composite negative electrode material is a composite powder material comprising a component Si / SnC2O4 or Si / SnC2O4 / C, wherein silicon powder, a soluble stannous salt and a soluble oxalate are subjected to a mixing reaction, the obtained solid is dried to obtain Si / SnC2O4, a carbon material is added according to a ratio, and ball milling is performed to obtain Si / SnC2O4 / C; the particle size of the material is 0.5-30 mum, a mass ratio of Si to SnC2O4 is 1:10-10:1 in Si / SnC2O4 or Si / SnC2O4 / C, and the mass percent content of the elemental carbon in Si / SnC2O4 / C is 5-90%; and the high-capacity lithium ion battery composite negative electrode material has characteristics of high electricity capacity, good cycle performance and good stability, and the preparation method has characteristics of simple process step, easy operation and low production cost.

Owner:WANXIANG 123 CO LTD

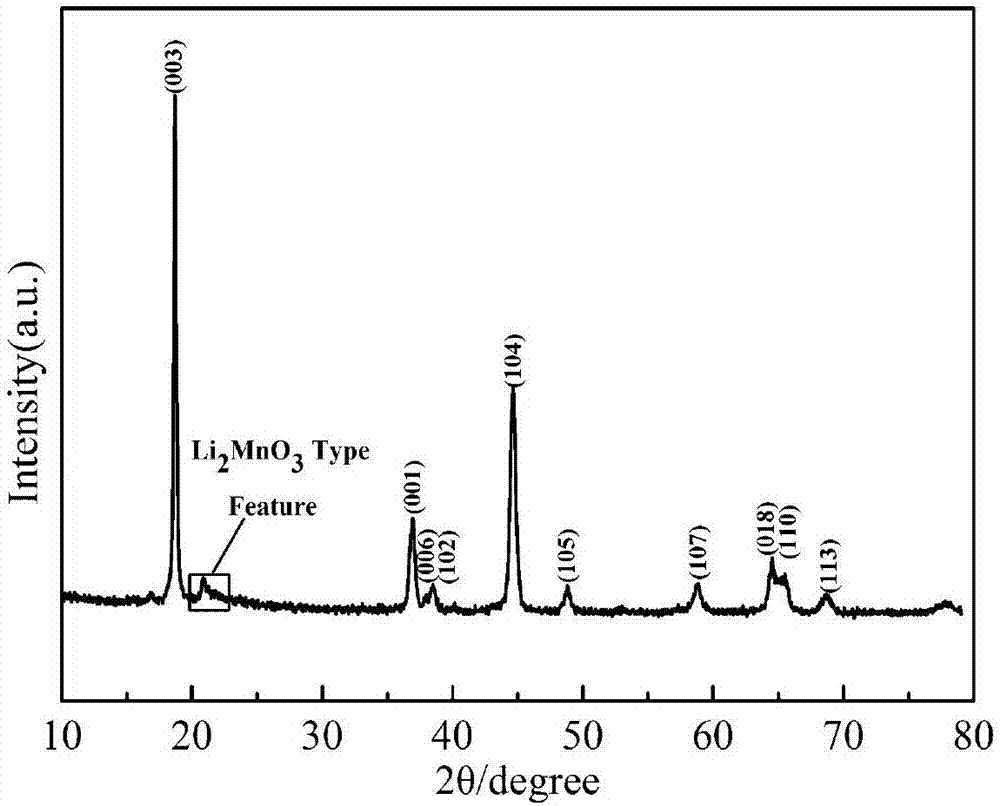

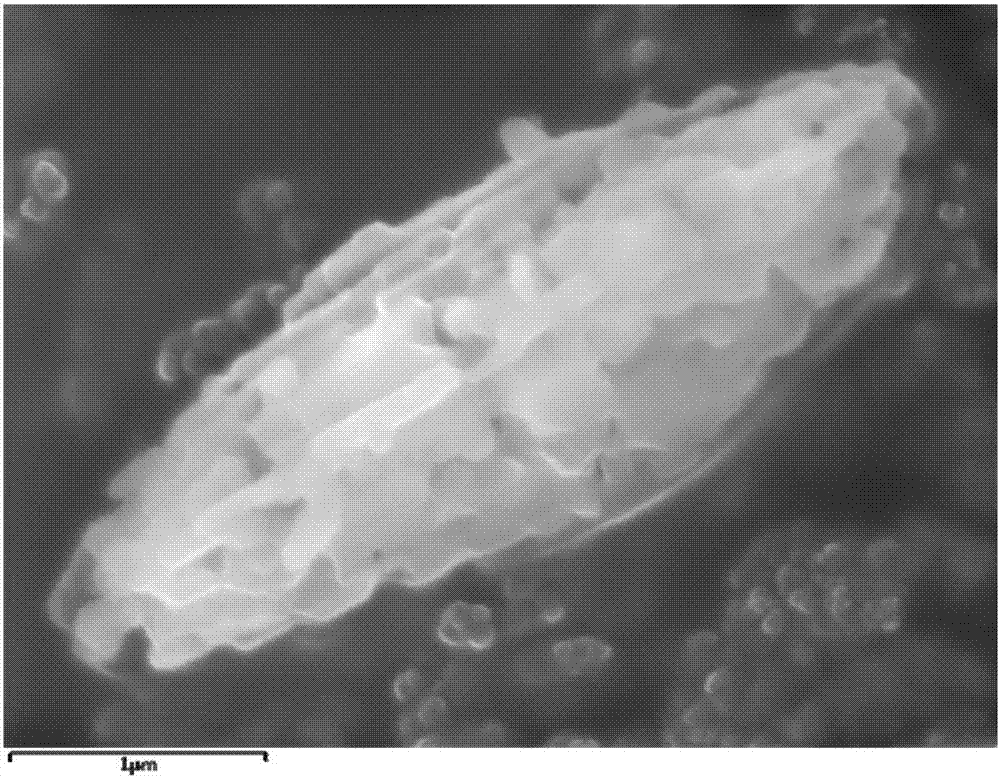

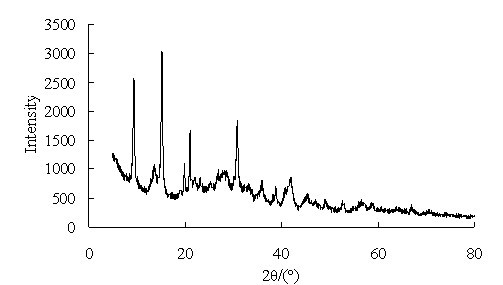

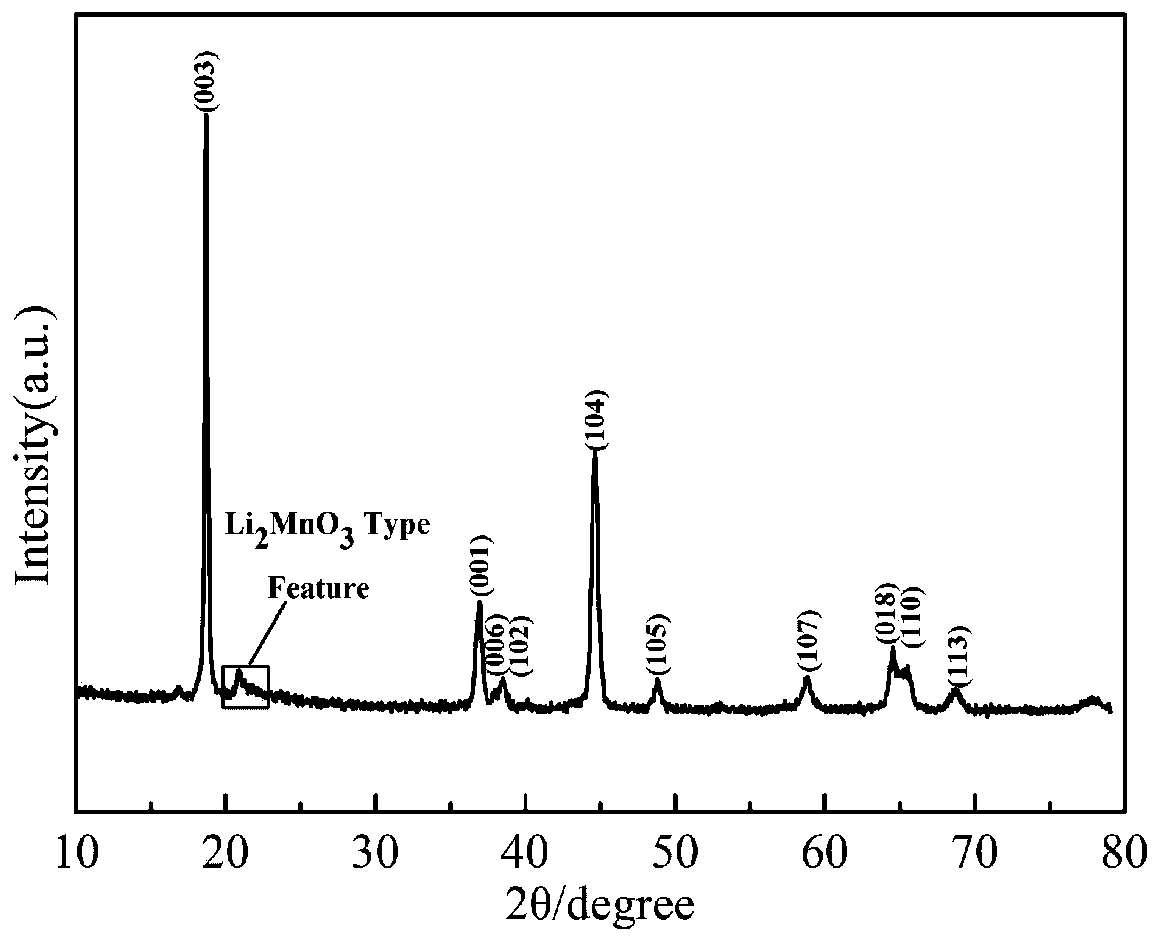

Preparation method for lithium-rich manganese-based positive electrode material with controllable appearance and dimensions

ActiveCN107069030AHigh crystallinityUniform particle size distributionSecondary cellsPositive electrodesSoluble oxalateManganese

The invention discloses a lithium-rich manganese-based positive electrode material with controllable appearance and dimensions and a preparation method therefor. The general formula of the positive electrode material is xLi<2>MnO<3>.(1-x)LiMO<2> (M is one or more of Mn, Ni or Co, and x is greater than 0 and less than 1); the preparation method comprises the following steps of adding a soluble transitional metal into a solvent and stirring into a uniform solution; then adding a surfactant to the solution, stirring uniformly and then adding a soluble oxalate solution; next, performing a co-precipitation reaction at a normal temperature to obtain an oxalate precursor; and performing pre-sintering on the precursor and then mixing with a lithium salt uniformly, and finally, performing a high-temperature solid-phase reaction to obtain the lithium-rich manganese-based positive electrode material. The obtained positive electrode material is uniform in granule grain diameter distribution, high in degree of crystallinity, controllable in appearance and dimensions, excellent in cycling performance and high in rate capability; and in addition, the method is simple in operation, and green and environment friendly.

Owner:XIANGTAN UNIV

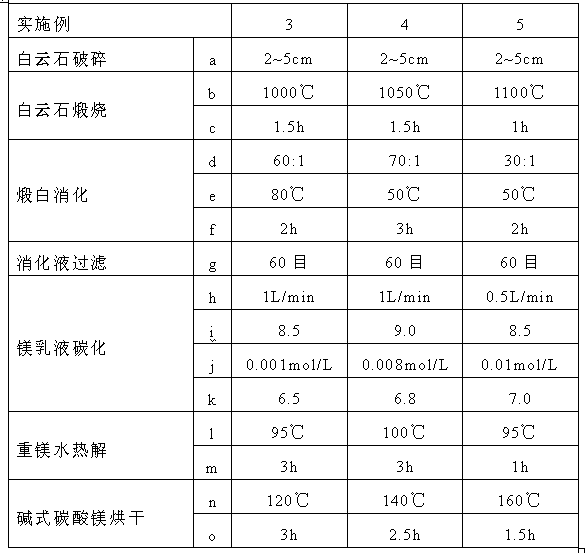

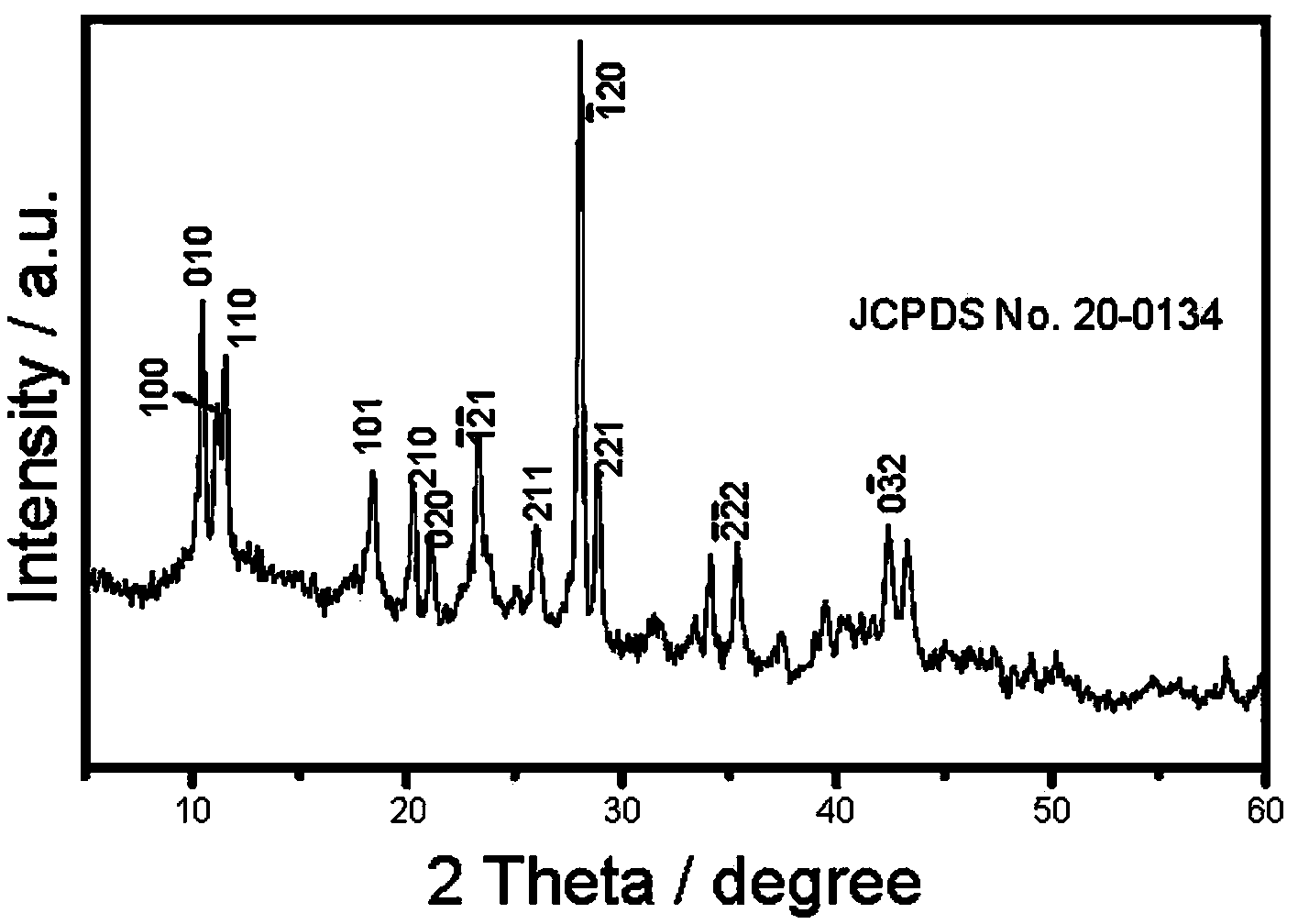

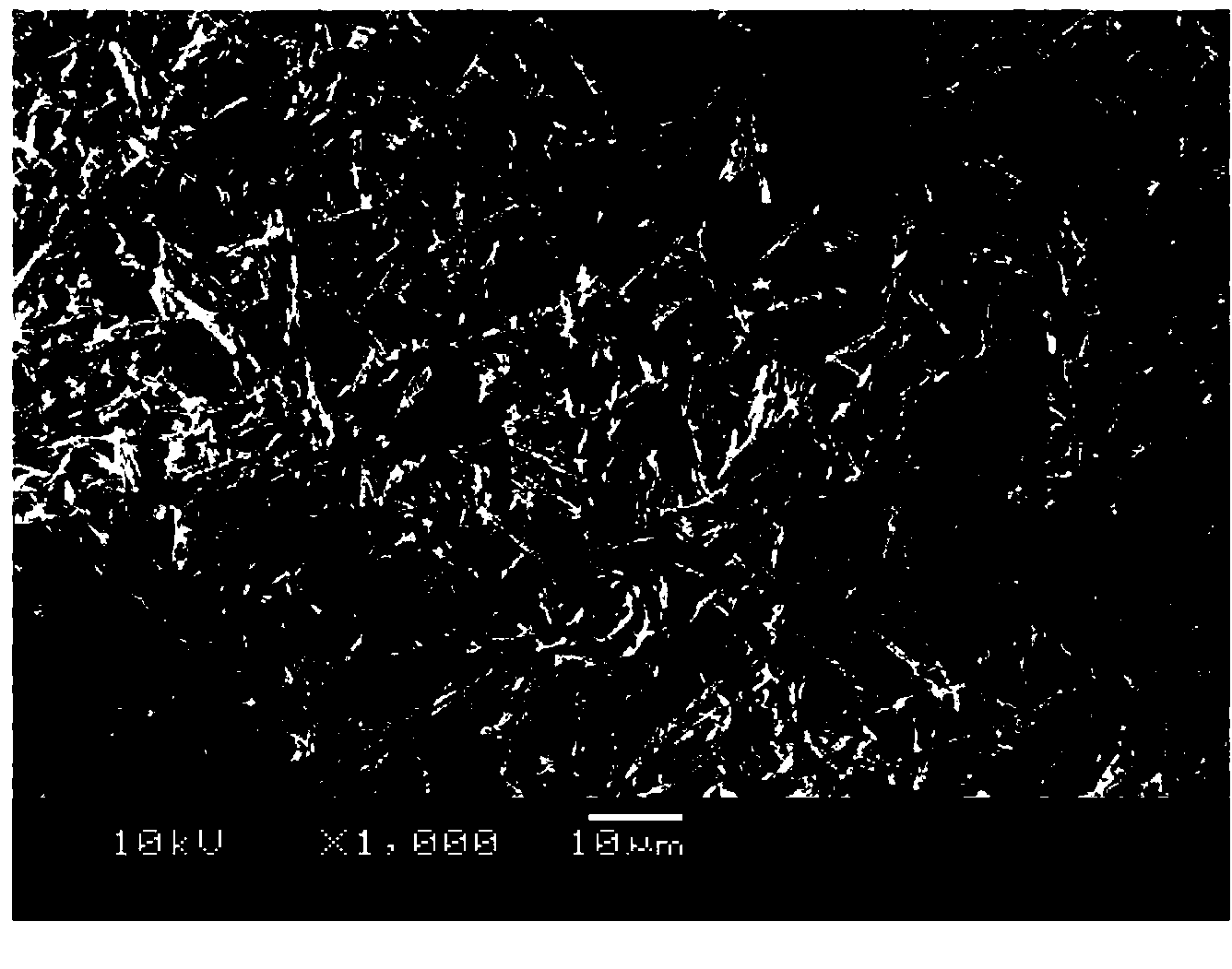

A kind of process method of dolomite producing high-purity basic magnesium carbonate

InactiveCN102275959AHigh puritySolve problems that are difficult to cleanly separateMagnesium carbonatesOXALIC ACID DIHYDRATEHigh magnesium

The invention discloses a process for producing high-purity basic magnesium carbonate from dolomite, which adopts a carbonization method and uses dolomite as a raw material. The method comprises the following steps: grinding, calcining, digesting the calcined dolomite, filtering, carbonizing magnesium emulsion, pyrolyzing a heavy magnesium solution, and drying to obtain basic magnesium carbonate.The carbonization process of the magnesium emulsion is as follows: after the magnesium emulsion is cooled, carbon dioxide is introduced; when the pH value reaches 7.5-9.5, oxalic acid or soluble oxalate is added to ensure that the concentration of oxalate groups in the system is 0.001-0.01mol / L; and after the system is mixed evenly, carbonization is performed continuously until the pH value is 6.5-7.0, filtration is performed, the filtrate is the refined heavy magnesium solution, and the residue is light calcium carbonate. By adding oxalic acid in the digesting process, the technical problem of the dolomite carbonization method that calcium and magnesium are difficult to separate thoroughly can be solved. The process is simple, is easy to control and has high magnesium oxide extraction rate and high product purity.

Owner:内蒙古昶泰资源循环再生利用科技开发有限责任公司 +2

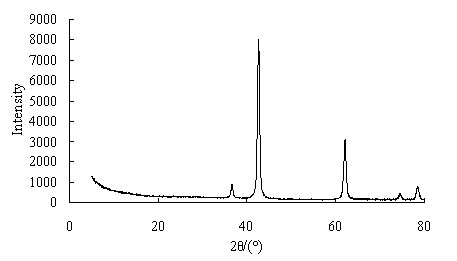

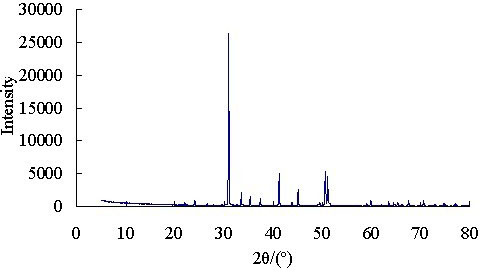

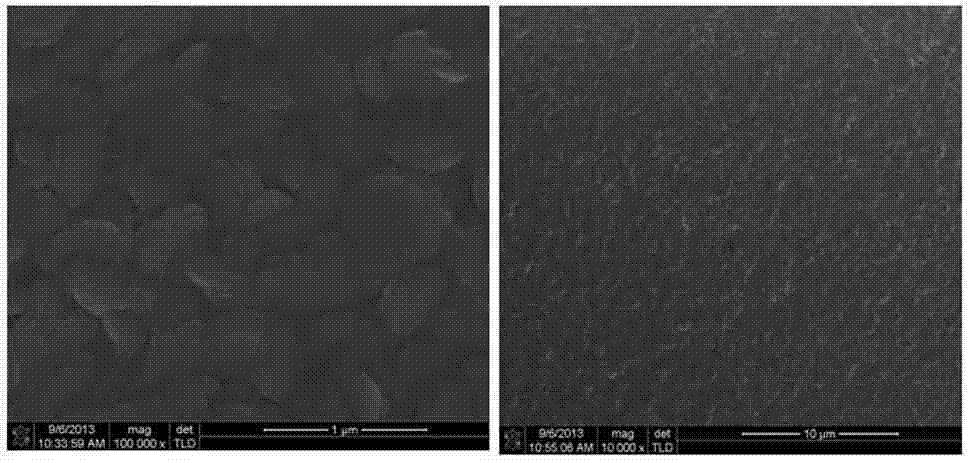

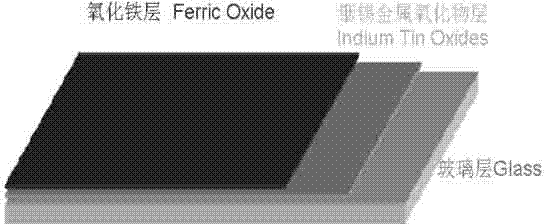

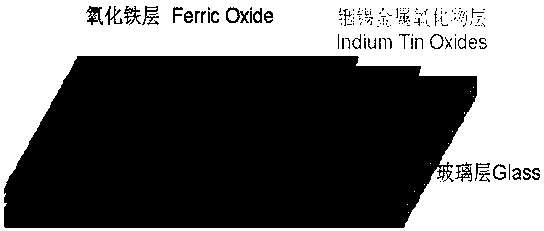

Production method for depositing iron oxide film on ITO conductive glass

The invention belongs to the technical filed of production of metal oxide semiconductor thin film materials, and concretely relates to a production method for depositing an iron oxide film on ITO conductive glass. The method is a simple production method for depositing the highly-transparent, uniform and stable iron oxide film on the ITO conductive glass. The iron oxide film is deposited on the ITO conductive glass through a hydrothermal technology by adopting soluble ferric salt and soluble oxalate as raw materials. The iron oxide film obtained in the invention is very uniform, has good light transmission performance and can be firmly combined with a substrate. The raw materials used in the invention are simple and cheap, and the raw materials and reaction raffinate have no pollution, so large scale industrial application does not generate the pollution problem. The method has the advantages of simple process operation, low requirements on a device, small energy consumption, and convenient and flexible control of the film.

Owner:FUZHOU UNIV

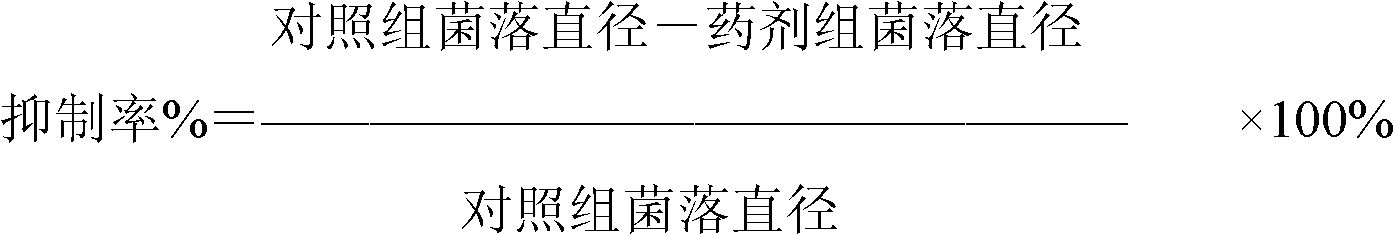

Method for preparing material slowly releasing chlorine dioxide and application thereof

ActiveCN102318644AEasy to makeRaw materials are cheap and easy to getBiocideFungicidesChlorine dioxideSoluble oxalate

The invention discloses a method for preparing a material slowly releasing chlorine dioxide and application thereof. The material releasing chlorine dioxide, provided by the invention, a comprise A and a component B which are respectively packed individually, wherein the component A is a compound material obtained after adsorbed substances are loaded on an absorbing medium; the adsorbed substances are one or two components in a disinfectant; the disinfectant comprises a component a, a component b and a component c; the component a is soluble chlorate; the component b is oxalic acid or solubleoxalate; the component c is citric acid; the component B is an activating agent; and the activating agent comprises other components in the disinfectant except the adsorbed substances. The material slowly releasing chlorine dioxide, with a nano composite structure, provided by the invention, can be used for slowly releasing chlorine dioxide gas in long action, prolonging the effective service life of an antistaling agent and effectively inhibiting and killing bacteria, and has good anticorrosive, mildewproof and freshness-preserving effects on fruits and vegetables.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Process method for preparing metal refined magnesium from dolomite

InactiveCN103408042ASolve problems that are difficult to cleanly separateHigh purityMagnesiaOXALIC ACID DIHYDRATESoluble oxalate

The invention discloses a process method for preparing metal refined magnesium from dolomite. The process method comprises the following steps of: performing crushing, calcination, digestion, filtration, carbonization of a magnesium emulsion, solid-liquid separation, heavy magnesium water pyrolysis, drying and calcination of basic magnesium carbonate and high-purity magnesium oxide electrolysis on dolomite to prepare the metal refined magnesium with the purity being above 99%, which is fully in line with the technical requirements of GB / T 3499-2003 'primary magnesium ingot' on magnesium ingots with grades of Mg9980-Mg9995. The invention provides a process technology for producing the metal refined magnesium from the dolomite by calcination-carbonization-electrolysis, and a certain quantity of oxalic acid or soluble oxalate is added into a carbonization system, so that a high-purity magnesium oxide intermediate product can be obtained and the target of finally obtaining the high-purity electrolysis metal refined magnesium can be reached. The process method disclosed by the invention has the advantages of smooth process, easiness in implementation of industrial production, high extraction rate of metal magnesium and stable product quality.

Owner:内蒙古昶泰资源循环再生利用科技开发有限责任公司 +1

Preparing method for pure glycerine

InactiveCN1583988AReduce oxidative decompositionImprove qualityFatty acids production/refiningSoluble oxalateGlycerol

This invention is a producing method of pure glycerol. It improve the existing method of continuous distillation. First remove the gas from coarse glycerol and dry it circularly and then insert soluble oxalate. Secondly, mix them statically and then filter it. Thirdly, distill them under certain temperature and pressure. Finally, deodorize it circular and decolor it continuous. The invention solves the problem that the existing method to produce pure glycerol involves by-reaction, and it avoids contaminant such as hydronitrogen, volatile grease, and acrolein. Additionally, the pureness of the glycerol can be up to 99.5%, and moreover, it has no peculliar smell and meets the demand of food and medicine.

Owner:杨宏

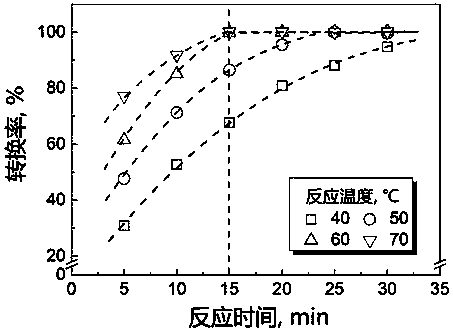

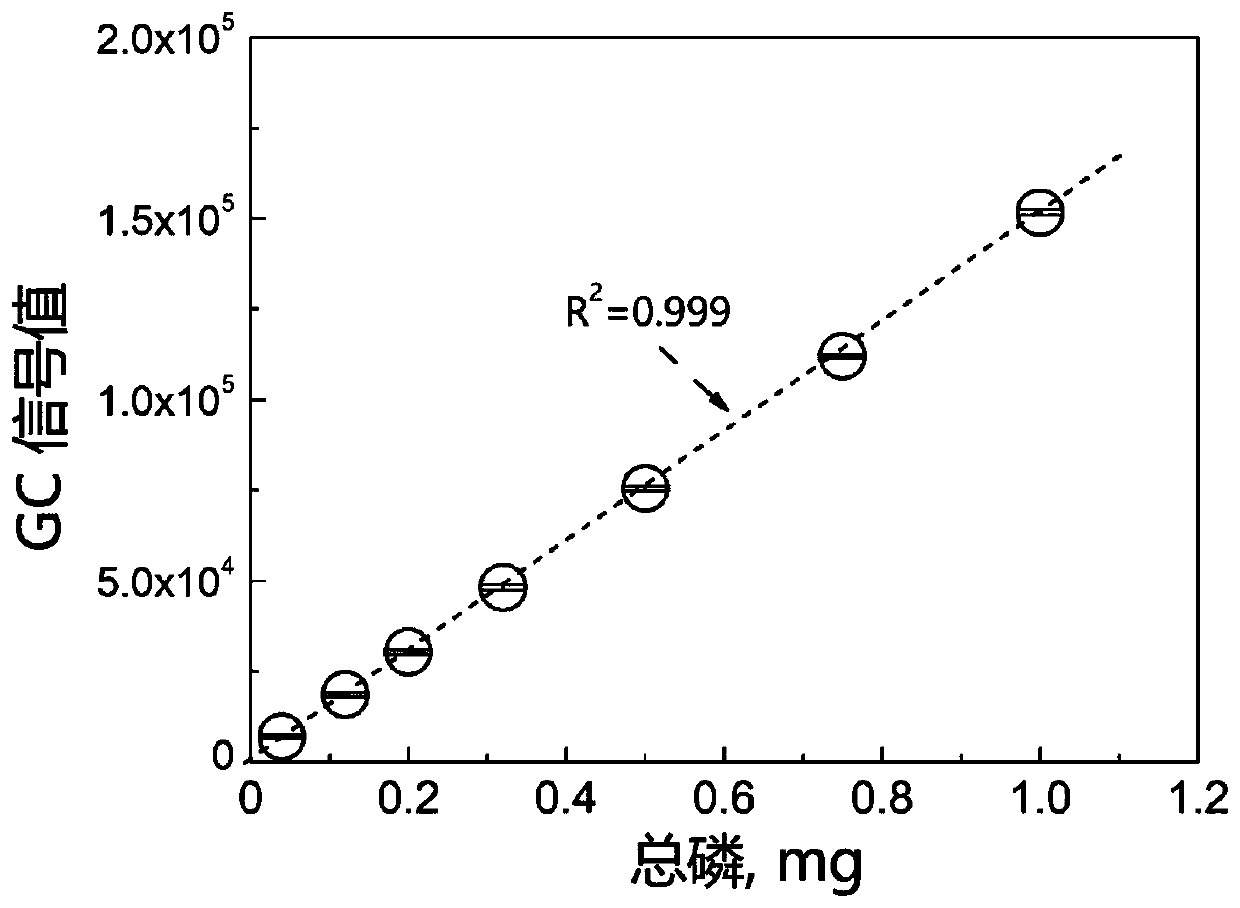

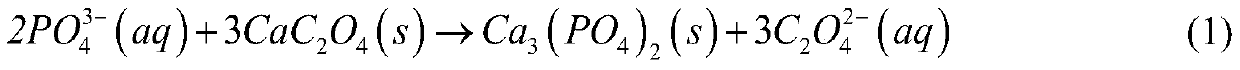

Method for determining total phosphorus content of soil or sludge

PendingCN111239275AFast measurementImprove accuracyComponent separationSoluble oxalatePermanganic acid

The invention relates to the technical field of environmental monitoring and analysis, and discloses a method for determining total phosphorus in soil or sludge, which comprises the following steps: (1) pretreating a sample; (2) converting phosphate; (3) establishing a standard curve; (4) detecting the sample by headspace gas chromatography; (5) calculating a result. The method comprises the following steps: by utilizing a phase inversion headspace gas chromatographic analysis technology, firstly, enabling phosphate to react with a calcium oxalate solid under an alkaline condition to generatecalcium phosphate and release soluble oxalate, and then enabling oxalate to react with permanganate under an acidic condition to generate carbon dioxide gas; the content of total phosphorus in soil and sludge samples can be calculated by measuring chromatographic signal values of carbon dioxide generated after phosphate is converted twice. The method not only can simplify the operation process andgreatly reduce the influence of interfering substances, but also does not use an organic extraction agent, thereby avoiding secondary pollution and meeting the purpose of green chemistry. The methodprovided by the invention is especially suitable for large-batch sample analysis of soil and sludge related research units.

Owner:GUANGXI UNIV

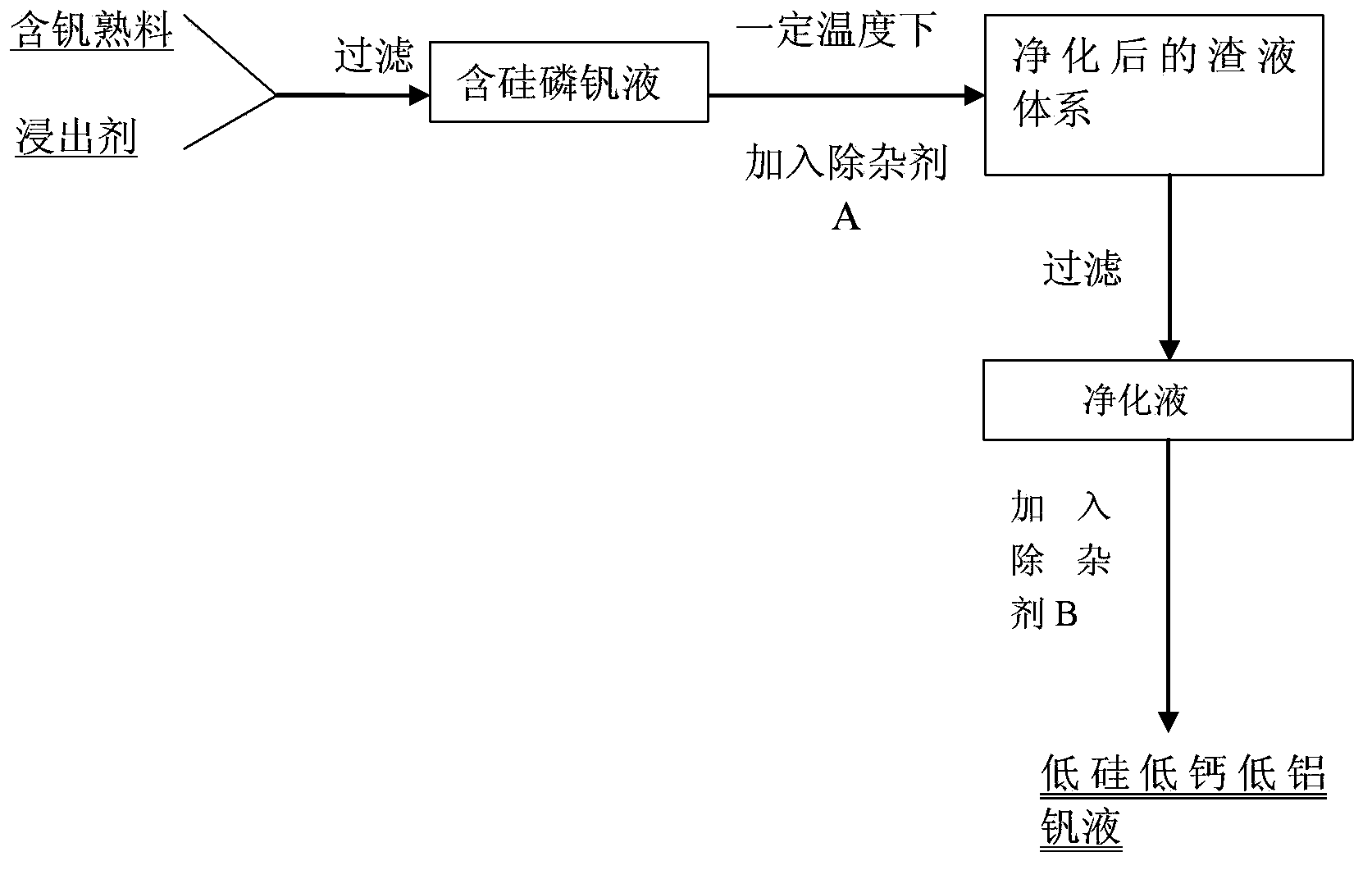

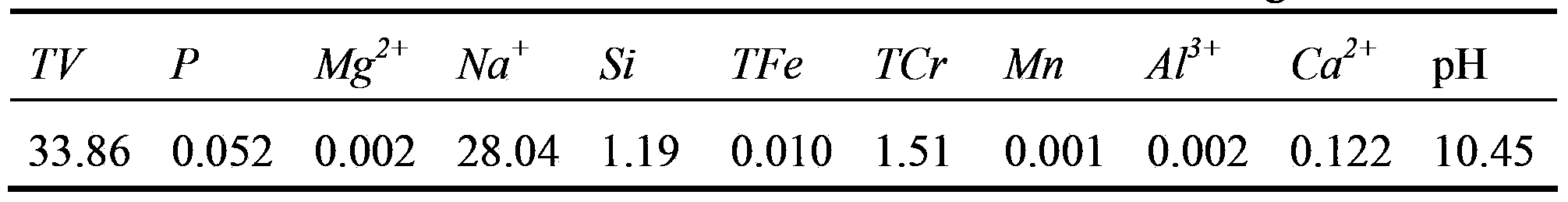

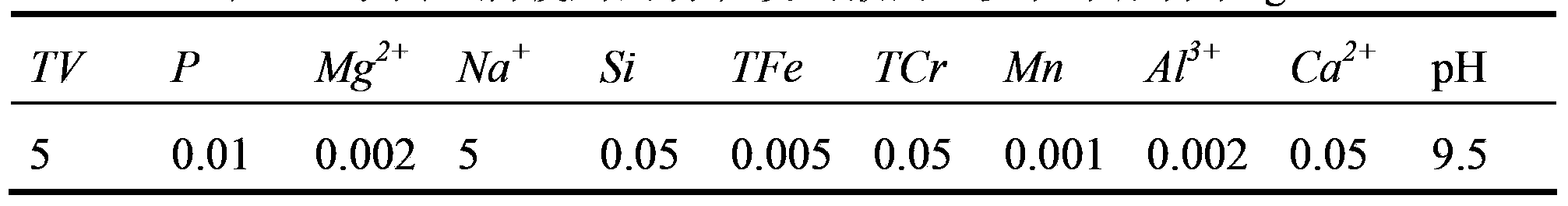

Method for preparing low-silicon low-calcium low-aluminium vanadium liquid

InactiveCN103409627AEfficient removalSimple processProcess efficiency improvementAluminium nitrateSoluble oxalate

The invention provides a method for preparing low-silicon low-calcium low-aluminium vanadium liquid, which comprises the following steps of dissolving a vanadium-containing material, and filtering to obtain a vanadium-containing solution; heating the vanadium-containing solution to 60 DEG C for boiling; adjusting the pH value of the vanadium-containing solution to 8-11; adding a first impurity removal agent into the vanadium-containing solution, and filtering to obtain a first purified solution; adjusting the pH value of the first purified solution to 8-11, and adding a second impurity removal agent into the first purified solution, wherein the first impurity removal agent is one or more of aluminium sulphate, aluminium sulphate, aluminium nitrate, iron sulphate, iron chloride, iron nitrate, magnesium sulphate, magnesium sulphate and magnesium nitrate, and the second impurity removal agent is soluble oxalate; and after the reaction is over, cooling and filtering to obtain vanadium liquid in which the Si content is lower than 0.005g / L, the Ca content is lower than 0.005g / L and the Al content is lower than 0.01g / L. The method provided by the invention can be used for effectively removing impurities such as silicon, calcium, aluminium and the like in the vanadium liquid; and the technology is simple and easy to use, the application range of the raw materials is wide, and the cost is low.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

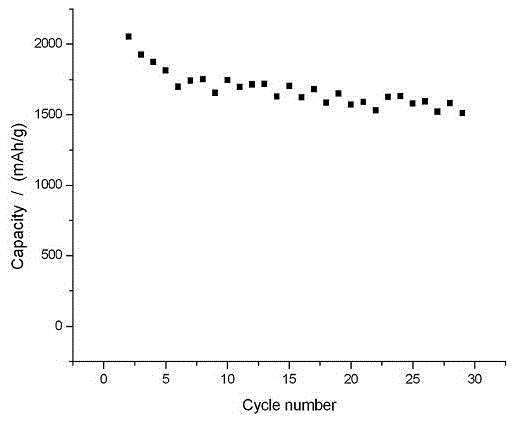

Preparation method of high-specific capacity lithium ion battery anode material

InactiveCN105895859AHigh specific capacityImprove cycle stabilitySecondary cellsNegative electrodesSoluble oxalateFiltration

The invention discloses a preparation method of a high-specific capacity lithium ion battery anode material. The preparation method comprises the following specific steps: preparing micro-expansive graphite; adding silica powder and soluble stannous salt into water to obtain a turbid liquid, and adding soluble oxalate into the turbid liquid to obtain Si / SnC2O4 after solid-liquid separation of an obtained reaction liquid A; adding a manganese source and a zinc source into a solvent for reaction to obtain a reaction liquid B; adding the micro-expansive graphite and Si / SnC2O4 into the reaction liquid B, and carrying out ultrasonic dispersion, suction filtration and drying to obtain powder; and carrying out mixing cladding on the powder and a carbon source precursor to obtain the high-specific capacity lithium ion battery anode material. The preparation method is simple in processing steps, low in reaction condition requirement, easy to operate and low in cost; and the raw materials are economical and environment-friendly, and the materials are higher in specific capacity and cycling stability and easy for industrial production, so that the electric capacity of the prepared lithium ion battery anode material is high, the production efficiency can be greatly improved, and the material is suitable for volume production.

Owner:陈友根

Environment-friendly nontoxic raticide

The invention relates to an environment-friendly nontoxic raticide, which is prepared by adopting soluble oxalate as a raticide bait, and specifically comprises 1-20% of oxalate, 2% of a synergist, 0.05% of a sweetener, 0.1% of a phagostimulant, 0.1% of a pigment, 3% of water, and the balance of grain. According to the invention, oxalate is a non-toxic and harmless natural product and cannot damage the environment, so that harm cannot be caused to human beings and other animals due to no toxicity; rescue is easy to achieve, wherein even if people or other animals eat the deratization bait containing oxalate by mistake to cause hypocalcemia and pain, the hypocalcemia symptom can be quickly eliminated by orally taking calcium tablets or injecting a calcium supplement injection, death cannotbe caused to people, and any sequelae cannot be left; the raticide provided by the invention is good in palatability, low in price and easily available in raw materials, is a real third-generation raticide, adopts oxalate to achieve deratization, is environment-friendly, safe, economic and efficient, is a cause of benefiting the nation and the people, and has good economic value and development prospect.

Owner:河南韩氏卫生用品科技有限公司

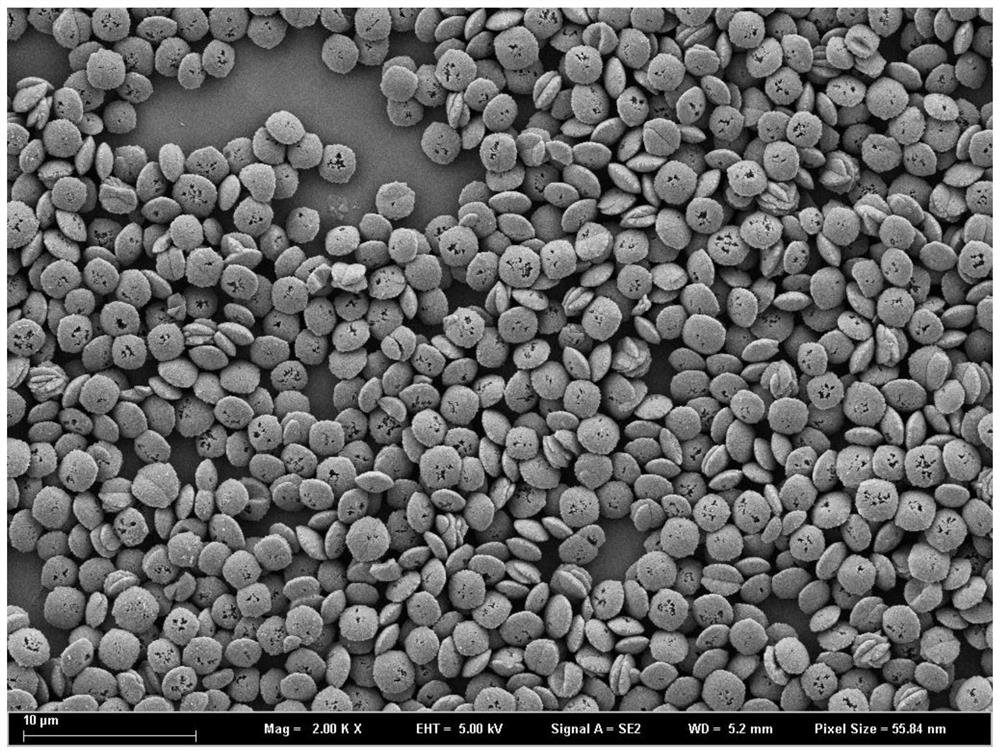

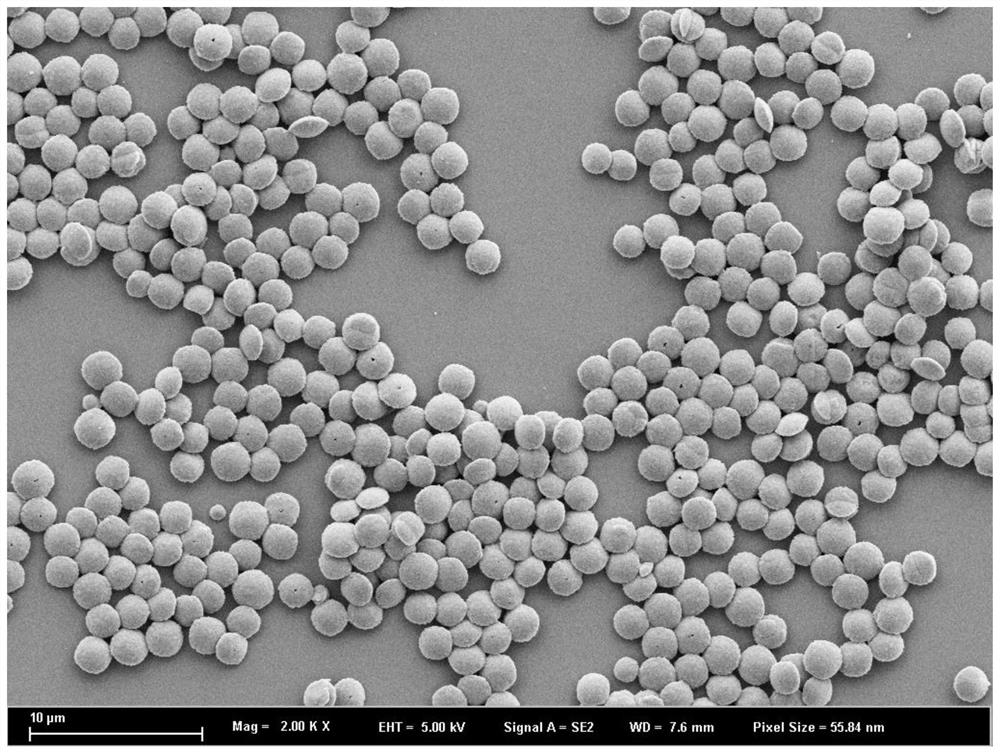

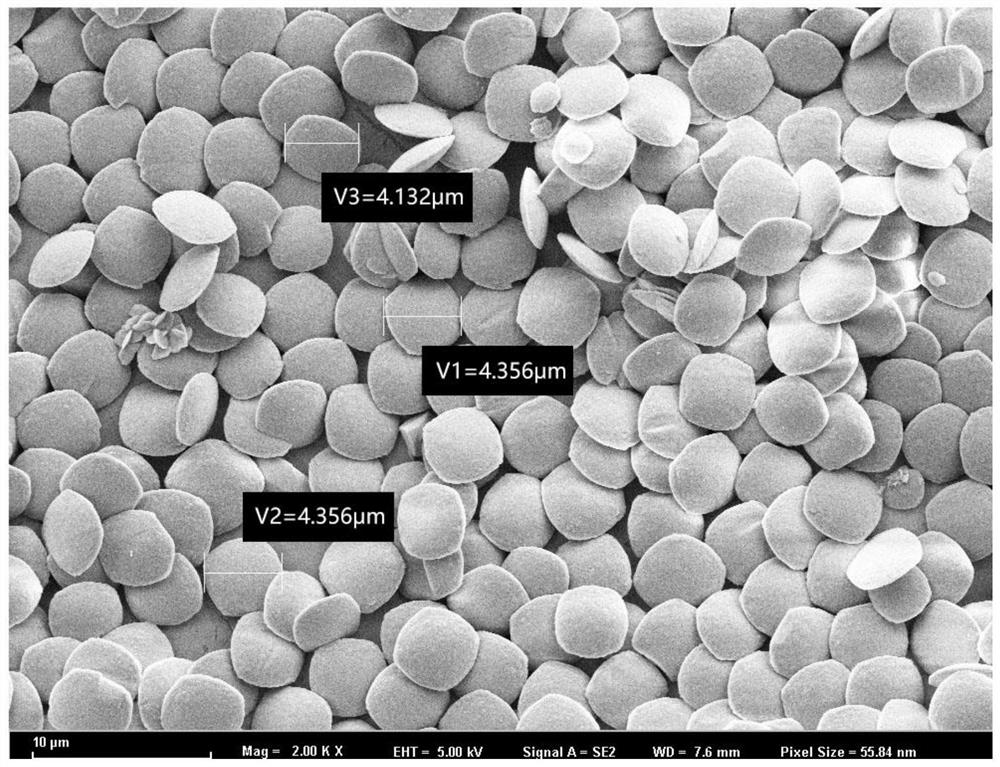

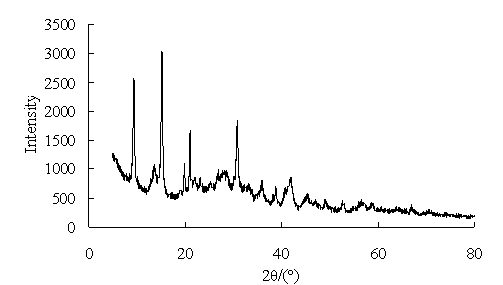

A kind of controllable preparation method of monodisperse copper oxalate powder

ActiveCN107759464BGood monodispersityEasy to operateOrganic compound preparationCarboxylic acid salt preparationSoluble oxalatePhysical chemistry

Owner:UNIV OF SCI & TECH BEIJING

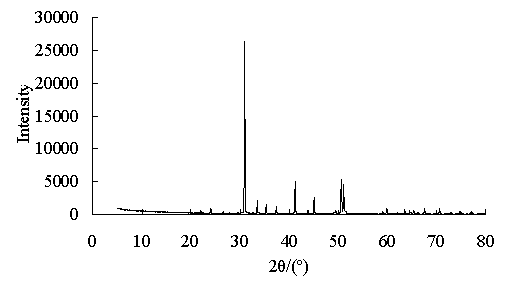

Production process of high pure superfine tin oxide

The invention discloses a manufacturing method of a high-pure super-fined tin oxide. The manufacturing method comprises the steps as follows: a tin oxalate is firstly prepared by the soluble tin salt and soluble oxalate; the tin oxalate is washed and dried, then is discomposed with a moderate temperate and then is baked with high temperature, and the baked tin oxide powder is pickled with a reagent grade inorganic acid and then is washed with a deionized water till the CL <-> is washed away, and then the high-pure super-fined tin oxide with average granule-diameter which is less than 1 micrometer and a purity which is equal to or greater than 99.5 percent and loose density which is 0.2 to 0.80g per cm <3> can be obtained sequentially by filtering, drying and crushing. The manufacturing process is verified through a pilot scale production.

Owner:GANZHOU RUIDE CHEM

Method for preparing material slowly releasing chlorine dioxide and application thereof

ActiveCN102318644BEasy to makeRaw materials are cheap and easy to getBiocideFungicidesSoluble oxalateChlorine dioxide

The invention discloses a method for preparing a material slowly releasing chlorine dioxide and application thereof. The material releasing chlorine dioxide, provided by the invention, a comprise A and a component B which are respectively packed individually, wherein the component A is a compound material obtained after adsorbed substances are loaded on an absorbing medium; the adsorbed substances are one or two components in a disinfectant; the disinfectant comprises a component a, a component b and a component c; the component a is soluble chlorate; the component b is oxalic acid or soluble oxalate; the component c is citric acid; the component B is an activating agent; and the activating agent comprises other components in the disinfectant except the adsorbed substances. The material slowly releasing chlorine dioxide, with a nano composite structure, provided by the invention, can be used for slowly releasing chlorine dioxide gas in long action, prolonging the effective service life of an antistaling agent and effectively inhibiting and killing bacteria, and has good anticorrosive, mildewproof and freshness-preserving effects on fruits and vegetables.

Owner:INST OF CHEM CHINESE ACAD OF SCI

A kind of polishing liquid, preparation method and application

ActiveCN105385356BExcellent wear resistance and weather resistanceBright mirror effect is goodPolishing compositions with abrasivesSoluble oxalateWear resistant

The invention belongs to the technical field of surface enhancement and protective treatment of marble or wood-based panels, and in particular relates to a polishing liquid, a preparation method and an application. The polishing solution comprises pH regulator, soluble oxalate, lubricant, fluorosilicate, nano titanium dioxide, nano silicon dioxide, coupling agent, palm wax emulsion and / or paraffin wax emulsion and water. The polishing liquid of the present invention is applied to the surface of marble or wood-based panels. Under a series of physical and chemical actions, a thick layer of dense glass-like bright substance can be formed on the surface. This glass-like bright substance is hard and has good wear resistance and weather resistance. The surface of the floor forms a bright mirror effect of "a puddle of water", which is easy to repair after the surface is scratched. When polishing the surface of marble or wood-based panels, just pour the polishing solution on the marble or wood-based panels and throw it away with a polishing pad. There is no need to use polishing steel wool, which improves production efficiency, saves costs, and improves polishing brightness.

Owner:GUANGZHOU GAOCHEN STONE TECH CO LTD

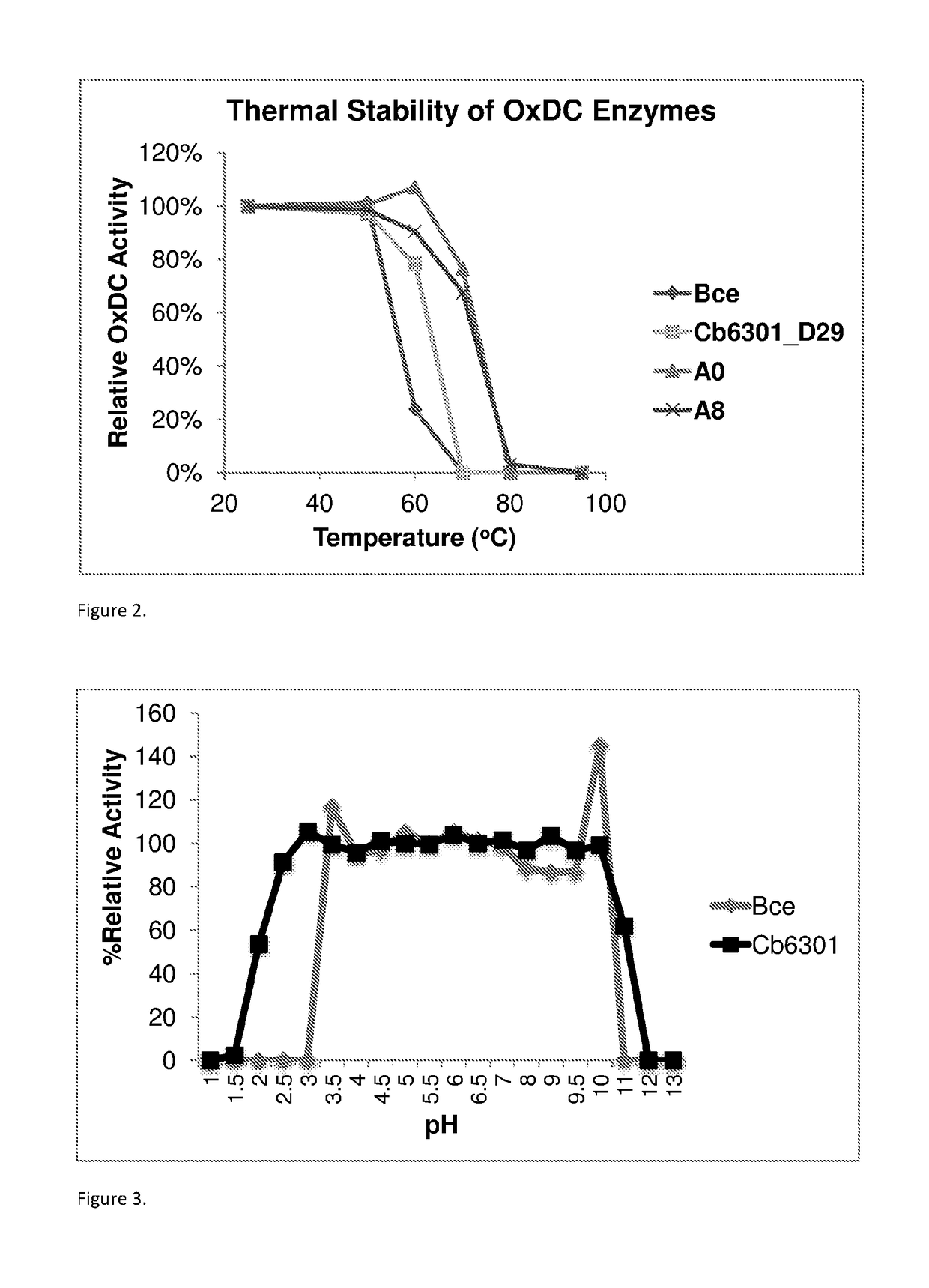

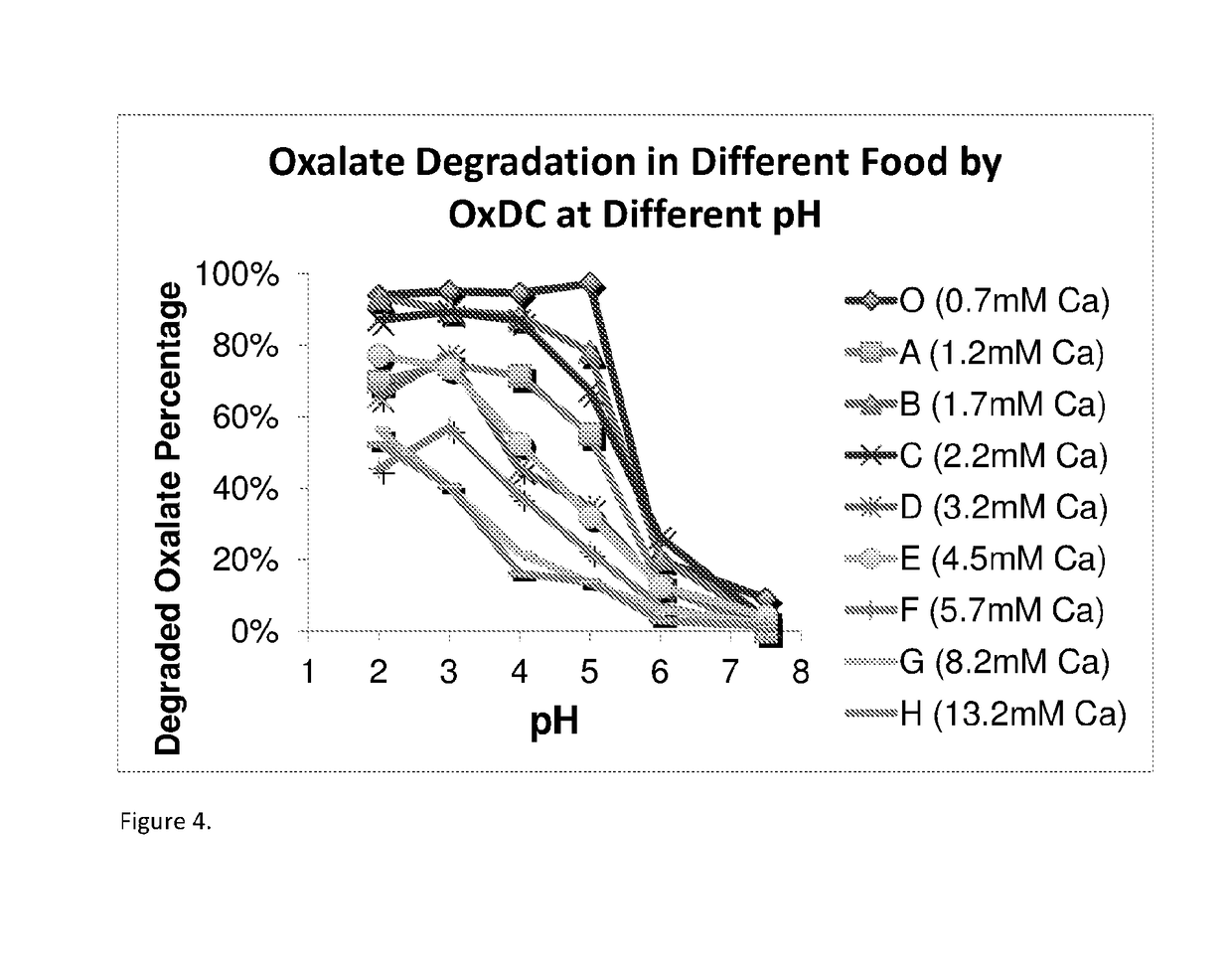

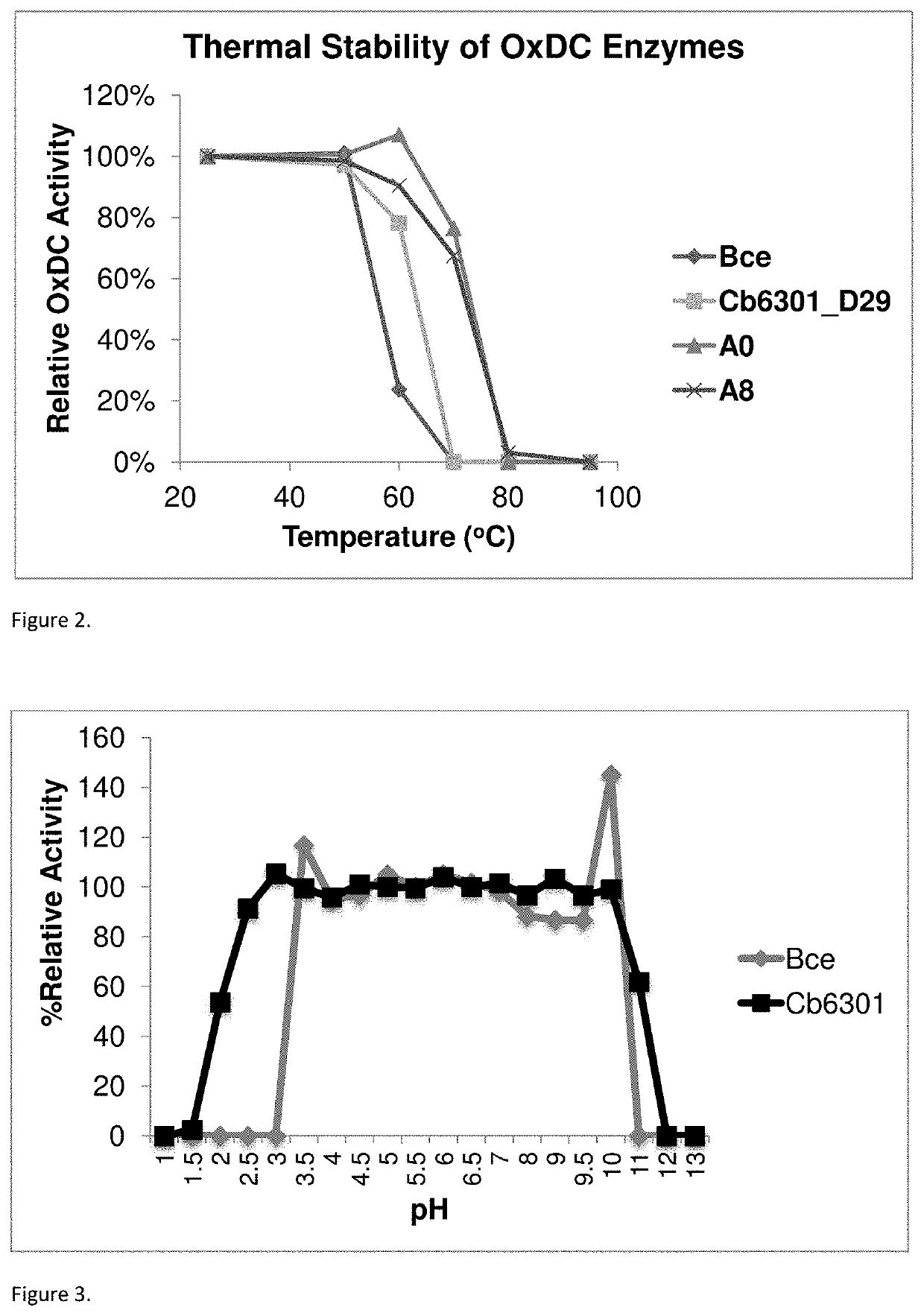

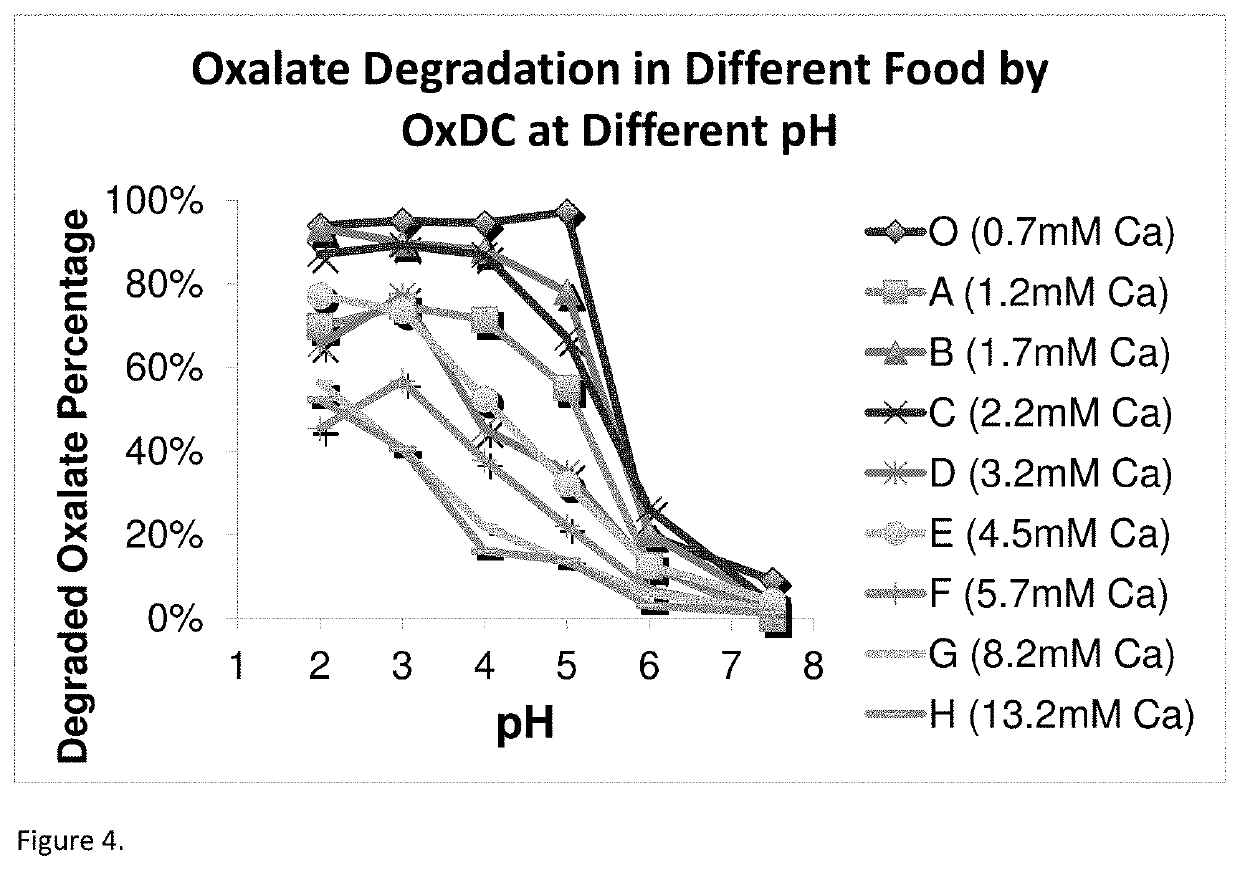

High efficiency oxalate-degrading enzymes for degradation of insoluble and soluble oxalate

ActiveUS20180362955A1Improve catalysisImprove stabilityPeptide/protein ingredientsAntibody mimetics/scaffoldsSoluble oxalateThermal stability

Disclosed herein are oxalate inducing enzymes with pH and thermal stability and methods of using for oxalate related conditions for in food processing.

Owner:OXIDIEN PHARMACEUTICALS LLC

A preparation method of lithium-rich manganese-based cathode material with double controllable morphology and size

ActiveCN107069030BHigh crystallinityUniform particle size distributionSecondary cellsPositive electrodesLithiumSoluble oxalate

Owner:XIANGTAN UNIV

Process for producing high-purity basic magnesium carbonate from dolomite

InactiveCN102275959BHigh puritySolve problems that are difficult to cleanly separateMagnesium carbonatesOXALIC ACID DIHYDRATEHigh magnesium

Owner:内蒙古昶泰资源循环再生利用科技开发有限责任公司 +2

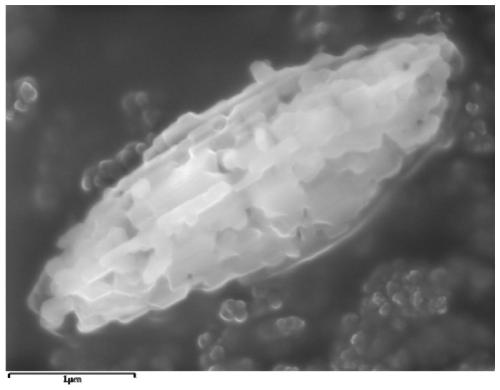

Preparation method of barium oxalate hydrate microcrystal with firewood morphology

InactiveCN102320952BSimple process routeReduce manufacturing costCarboxylic acid salt preparationChemical industrySoluble oxalate

The invention belongs to the field of preparation of inorganic non-metallic materials, and in particular relates to a preparation method of hydrated barium oxalate (BaC2O4·0·5H2O) microcrystals with the appearance of firewood. At 50°C, aging for 2-24 hours, then filtered, washed, and dried to obtain hydrated barium oxalate microcrystals. The soluble divalent barium salt of the present invention is one or a mixture of barium chloride, barium nitrate or barium acetate, and the soluble oxalate is one or a mixture of sodium oxalate, potassium oxalate or ammonium oxalate. The process of the invention is simple and easy, high in purity, low in impurity content, good in dispersibility and low in cost, and the obtained product has a diameter of 1-3 mm and a length of 5-15 mm. The hydrated barium oxalate crystallite with the appearance of firewood prepared by the invention can be widely used in the fields of automobiles, electronics, machinery, chemical industry, construction and the like, and is also an excellent precursor for preparing other barium salt functional materials.

Owner:BOHAI UNIV

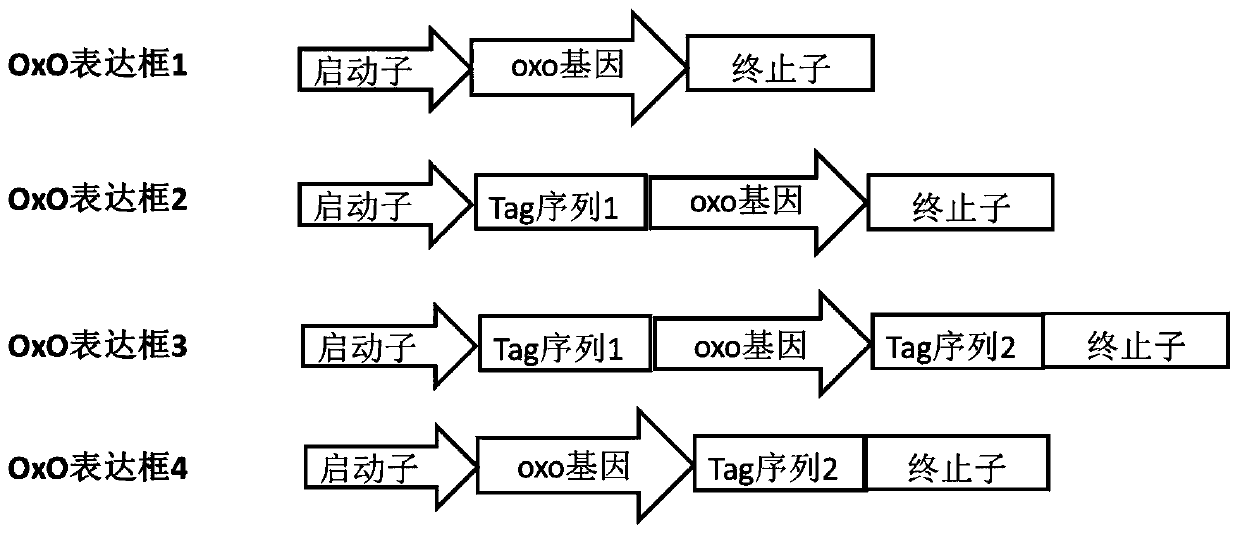

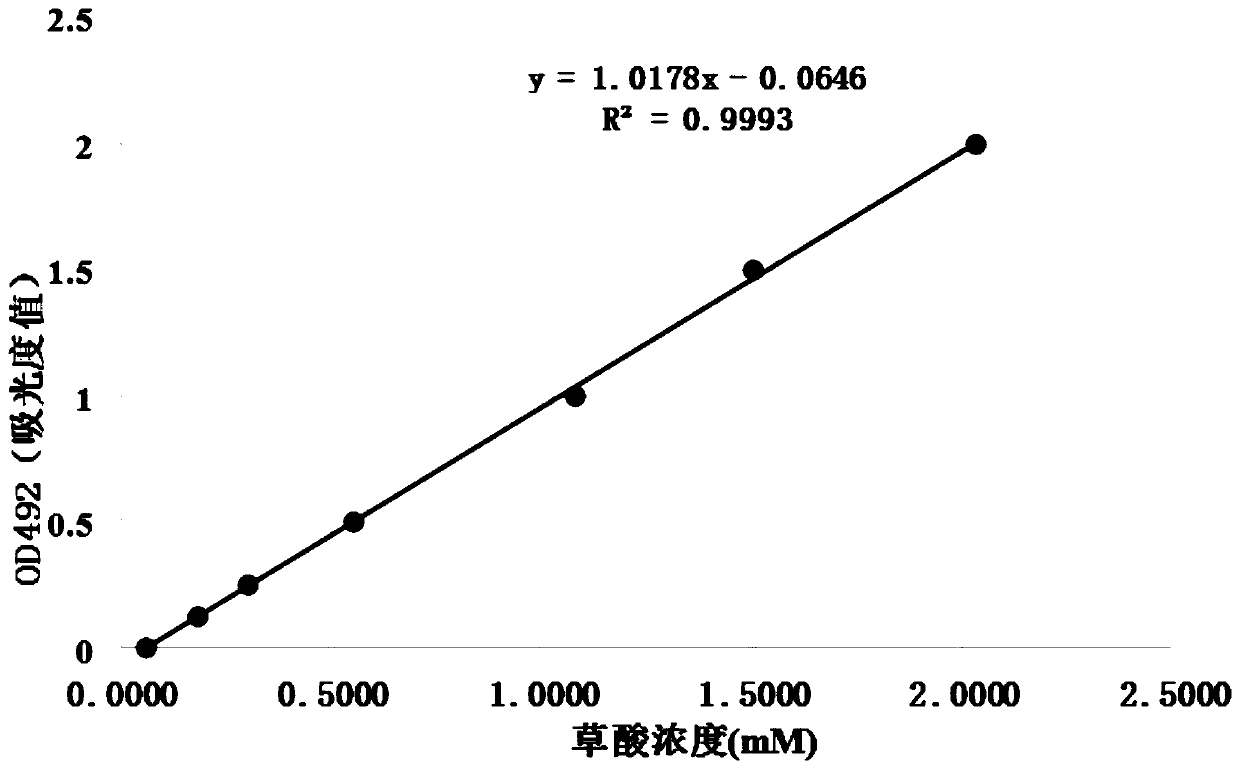

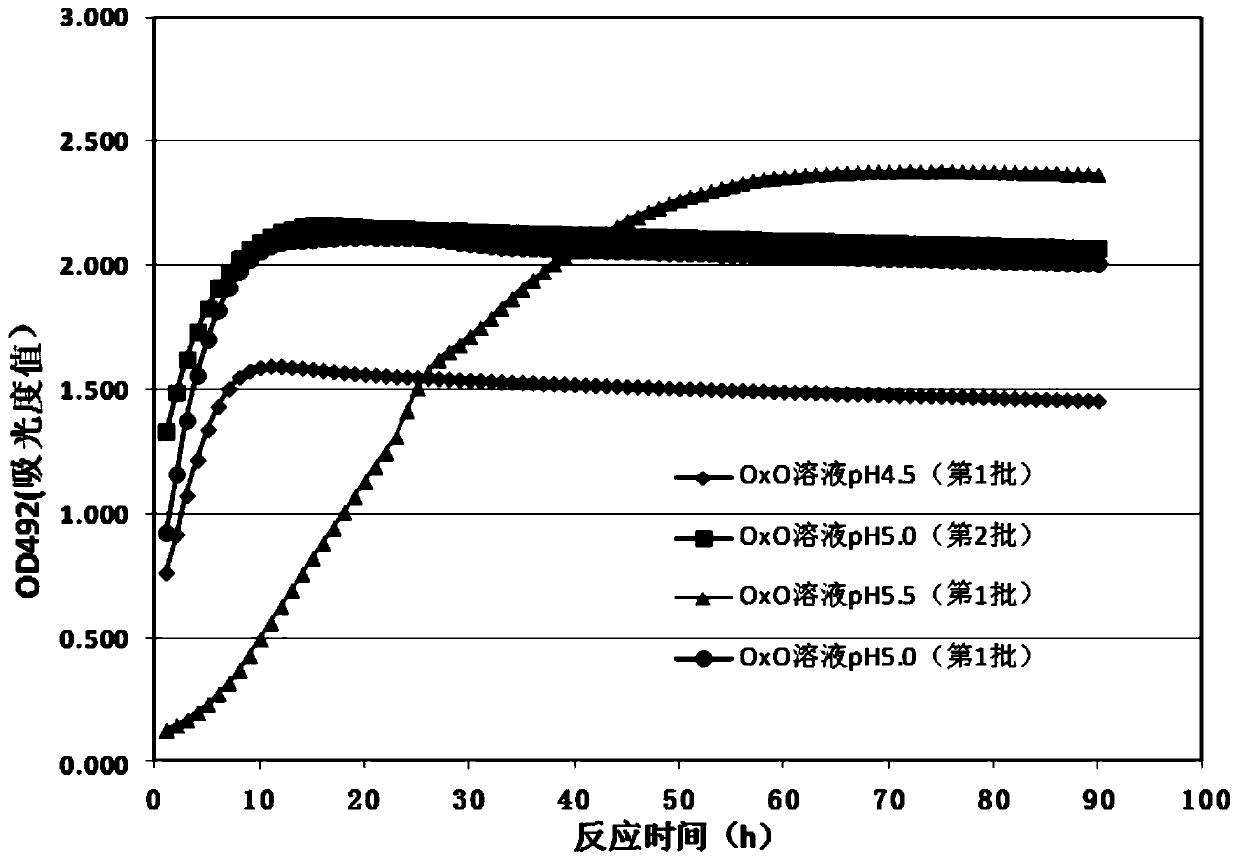

A kind of preparation method and application of soluble oxalate oxidase

ActiveCN106906227BEase of high-throughput assaysHigh precisionBacteriaMicrobiological testing/measurementEscherichia coliOXALIC ACID DIHYDRATE

The invention discloses a recombinant expression cassette for efficiently expressing soluble oxalic acid oxidase and a preparation method of an oxalic acid oxidase capable of efficiently expressing solubility and activity in Escherichia coli. Cellular supernatant is precipitated through ammonium sulfate, and a solution, which is re-dissolved through citric acid-sodium-citrate and contains oxalic acid oxidase, is directly applied to activity determination of oxalate decarboxylase. Compared with traditional methods such as commercially available oxalate determination kits and HPLC (high performance liquid chromatography), the determination method is higher in accuracy and sensitivity, low in time consumption and cost, applicable to high-throughput determination on a large number of samples through a micro-plate reader and high in practicality. The prepared oxalic acid oxidase can be applied to activity determination of enzymes with oxalic acid as substrate or product as well as to determination of the content of the oxalic acid in blood or urine of human or animals as well as various samples containing oxalic acid.

Owner:WUHAN KANGFUDE BIOTECH CO LTD

High efficiency oxalate-degrading enzymes for degradation of insoluble and soluble oxalate

PendingUS20220298497A1Enhanced stability and activityIncrease the number ofPeptide/protein ingredientsAntibody mimetics/scaffoldsBiotechnologySoluble oxalate

Owner:OXIDIEN PHARMACEUTICALS LLC

Process for producing high purity magnesium oxide with dolomite

InactiveCN102275957BSolve problems that are difficult to cleanly separateHigh purityMagnesiaOXALIC ACID DIHYDRATESoluble oxalate

The invention discloses a process for producing high purity magnesium oxide with dolomite, comprising the steps of: subjecting dolomite to fragmentation, calcination, digestion, filtration, carbonization, solid-liquid separation, pyrolysis, basic magnesium carbonate drying and basic magnesium carbonate calcination, thus obtaining high purity magnesium oxide with CaO content less than 0.2%, Fe content less than 0.01% and MgO content higher than 98%. The process is totally in accord with the technical requirements of HG / T2573-2006 "industrial lightweight magnesium oxide" for Class I and Class II high-class products. The invention puts forward an improving method for the digestion and carbonization processes during high purity magnesium oxide production from dolomite, thus raising the extraction rate of MgO from dolomite. By adding a certain amount of oxalic acid and soluble oxalate into the carbonization system, the technical problem that calcium and magnesium are difficult to be separated thoroughly in a dolomite carbonization method can be solved. The process of the invention has the characteristics of simple technology, easy control, high extraction rate of magnesium oxide and high purity product.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +2

A kind of preparation method of depositing iron oxide film on ito conductive glass

The invention belongs to the technical filed of production of metal oxide semiconductor thin film materials, and concretely relates to a production method for depositing an iron oxide film on ITO conductive glass. The method is a simple production method for depositing the highly-transparent, uniform and stable iron oxide film on the ITO conductive glass. The iron oxide film is deposited on the ITO conductive glass through a hydrothermal technology by adopting soluble ferric salt and soluble oxalate as raw materials. The iron oxide film obtained in the invention is very uniform, has good light transmission performance and can be firmly combined with a substrate. The raw materials used in the invention are simple and cheap, and the raw materials and reaction raffinate have no pollution, so large scale industrial application does not generate the pollution problem. The method has the advantages of simple process operation, low requirements on a device, small energy consumption, and convenient and flexible control of the film.

Owner:FUZHOU UNIV

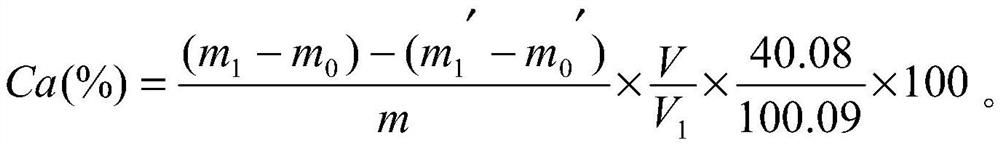

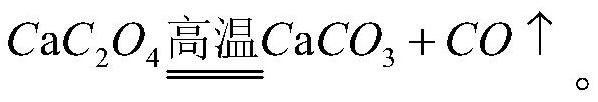

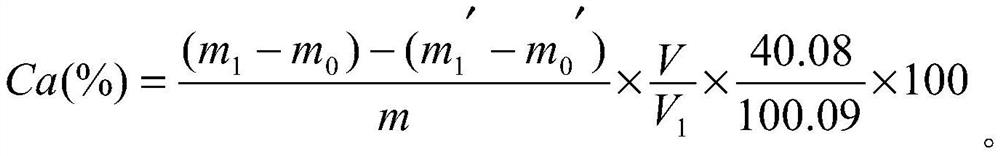

Method for measuring calcium content in feed

InactiveCN111965063AAchieving precise measurementsSolve complex and cumbersome operationsMaterial weighingSoluble oxalateCalcium content

The invention discloses a method for determining the content of calcium in a feed, and belongs to the technical field of feed component detection. The determination method comprises the following steps: completely precipitating calcium ions in a to-be-determined feed into calcium oxalate by using a soluble oxalate solution, firing the calcium oxalate at 420-660 DEG C until the weight of generatedcalcium carbonate is constant, metering the mass of the generated calcium carbonate, and calculating the mass percentage content of calcium in the to-be-determined feed according to the mass of calcium in the calcium carbonate. According to the method, a titration analysis method in the prior art is converted into a gravimetric analysis method, so that the method solves the problems of complex andtedious operation steps, high requirements of an experiment method on detection personnel, long reaction process time, large measurement result error, narrow application range, high equipment cost and the like of an existing measurement method, can realize accurate measurement of calcium in the feed in a relatively short time, and has the advantages of being more accurate, quicker, low in cost, easy to operate and popularize and the like.

Owner:GANSU AONONG FEED TECH CO LTD +3

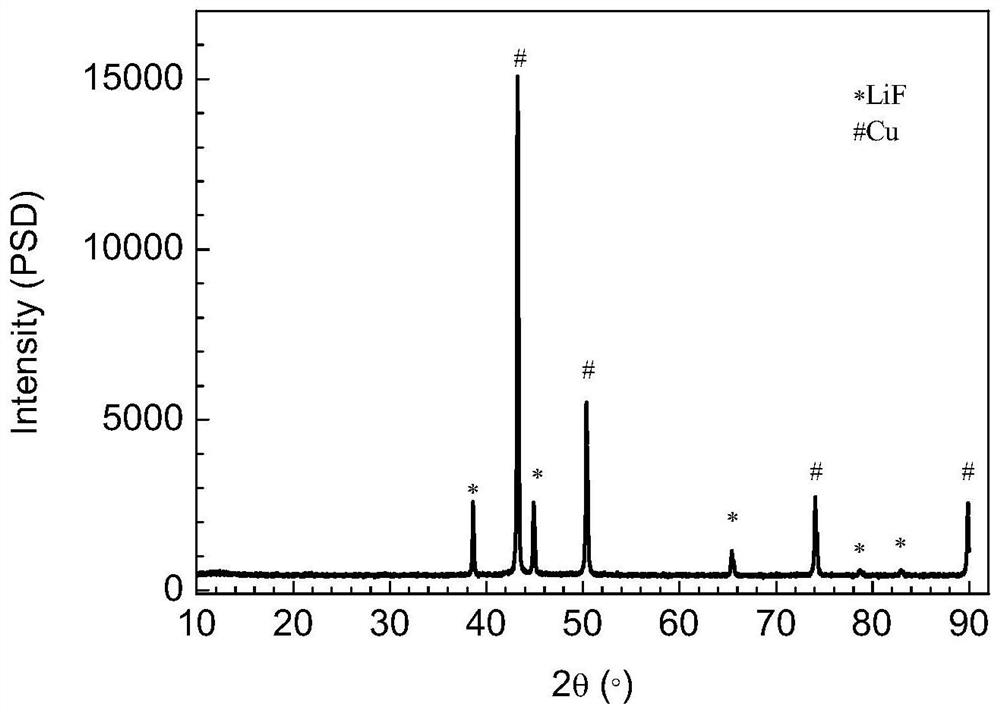

A kind of preparation method of cu/lif composite cathode material of lithium ion battery

ActiveCN108767236BHigh puritySolve the defect of poor lithiumCell electrodesSecondary cellsSoluble oxalateHigh energy

The invention discloses a preparation method of a lithium ion battery Cu / LiF composite cathode material. The method comprises the following steps: firstly, dissolving soluble copper salt and lithium salt in distilled water to be prepared into a solution I and dissolving soluble oxalate and NH4F in distilled water to be prepared into a solution II; then, adding the solution I into the solution II to perform precipitation reaction and separating a suspension to obtain solid separated matter; finally, sintering the obtained solid separated matter in an inert atmosphere furnace to obtain a Cu / LiFcomposite cathode material. Compared with the prior art, the preparation method disclosed by the invention has the advantages of simple preparation technology, low sintering temperature and the like;furthermore, a process is easy to control, and the purity of an obtained product is high; the defect of poor lithium of a CuF2 cathode material is solved, use of hydrofluoric acid with strong corrosion and poison is avoided, and the defects of complex equipment, high energy consumption and the like of a high energy ball milling method and a pulsed laser deposition method are overcome.

Owner:HUNAN UNIV OF SCI & TECH

A kind of composite negative electrode material of high-capacity lithium-ion battery and preparation method thereof

ActiveCN103811730BLarge capacityImprove cycle performanceCell electrodesSecondary cellsElectricitySoluble oxalate

The invention discloses a high-capacity lithium ion battery composite negative electrode material and a preparation method thereof, wherein problems of low charging-discharging specific capacity and poor cycle performance of application of the existing carbon material as the lithium ion battery negative electrode material are solved. According to the present invention, the high-capacity lithium ion battery composite negative electrode material is a composite powder material comprising a component Si / SnC2O4 or Si / SnC2O4 / C, wherein silicon powder, a soluble stannous salt and a soluble oxalate are subjected to a mixing reaction, the obtained solid is dried to obtain Si / SnC2O4, a carbon material is added according to a ratio, and ball milling is performed to obtain Si / SnC2O4 / C; the particle size of the material is 0.5-30 mum, a mass ratio of Si to SnC2O4 is 1:10-10:1 in Si / SnC2O4 or Si / SnC2O4 / C, and the mass percent content of the elemental carbon in Si / SnC2O4 / C is 5-90%; and the high-capacity lithium ion battery composite negative electrode material has characteristics of high electricity capacity, good cycle performance and good stability, and the preparation method has characteristics of simple process step, easy operation and low production cost.

Owner:WANXIANG 123 CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com