A kind of composite negative electrode material of high-capacity lithium-ion battery and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, batteries, secondary batteries, etc., can solve the problems of poor cycle performance, low charge-discharge specific capacity, etc., and achieve low cost, easy operation, and low requirements for reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Mill silicon balls with a particle size of 20-30 μm in an ethanol medium at a high speed of 300 rpm for 3 hours, then dry at 100°C to obtain silicon powder with a particle size of 0.1-10 μm, and weigh 20 g of ball-milled silicon powder. Silicon fume, by Si / SnC 2 o 4 Medium Si and SnC 2 o 4 The mass ratio is 1:1 to calculate the SnC 2 o 4 The required mass, that is, 20gSnC 2 o 4 , according to the calculated SnC 2 o 4 The required mass, according to the reaction of soluble stannous salt and soluble oxalate to generate SnC 2 o 4 The chemical reaction proportioning metering soluble stannous salt, wherein, soluble stannous salt is stannous chloride, and soluble oxalate is sodium oxalate, obtains 18.4g stannous chloride, silicon powder and the stannous chloride of metering gained Add 60g of water to obtain 98.4g of suspension.

[0033] (2) According to the reaction of soluble stannous salt and soluble oxalate to generate SnC 2 o 4 The chemical reaction ratio...

Embodiment 2

[0040] The rest of the steps of Example 2 are exactly the same as Example 1, the difference is that Si / SnC 2 o 4 After that, press Si / SnC 2 o 4 The mass percentage composition of carbon elemental substance in / C is 10% to measure carbon material, and carbon material is conductive carbon black, and the Si / SnC that carbon material and obtain 2 o 4 After mixing, high-speed ball milling at 100 rpm for 3 hours to obtain Si / SnC particles with a particle size of 0.5-30 μm 2 o 4 / C.

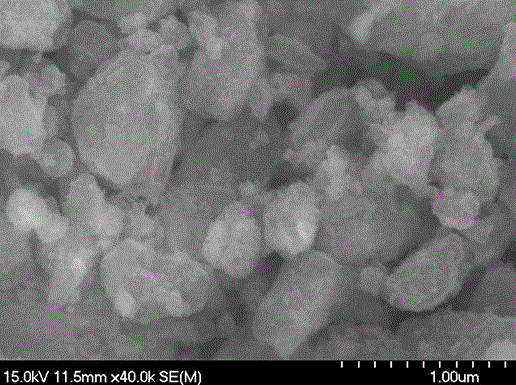

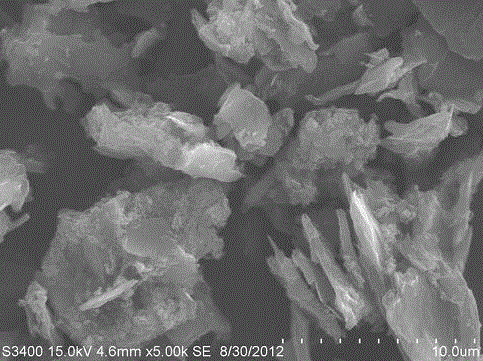

[0041] The resulting Si / SnC 2 o 4 The SEM image of / C is as follows image 3 shown, from image 3 It can be seen that Si is replaced by SnC 2 o 4 After coating, a large particle structure with smooth surface is formed, while C (flaky substance) is uniformly dispersed in Si / SnC 2 o 4 (particles).

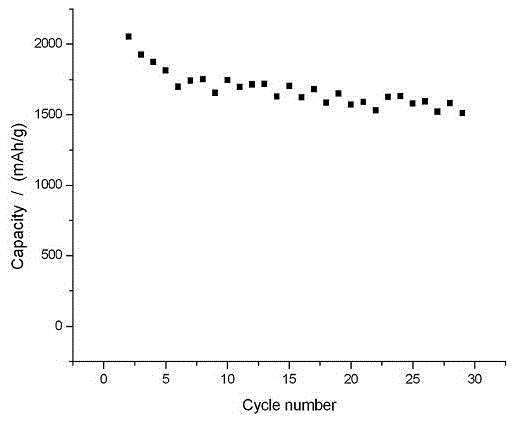

[0042] The resulting Si / SnC 2 o 4 / C is used for the negative electrode of lithium-ion batteries. The cycle performance test is carried out under the conditions of 25°C, 0.1C charge and discharg...

Embodiment 3

[0045] (1) Mill silicon balls with a particle size of 20-30 μm in an ethanol medium at a high speed of 360 rpm for 2.5 hours, then dry at 105°C to obtain silicon powder with a particle size of 0.1-10 μm, weigh 100 g after ball milling silicon powder, according to Si / SnC 2 o 4 Medium Si and SnC 2 o 4 The mass ratio of 1:10 calculated SnC 2 o 4 The required quality, that is, 1000gSnC 2 o 4 , according to the calculated SnC 2 o 4 The required mass, according to the reaction of soluble stannous salt and soluble oxalate to generate SnC 2 o 4 The chemical reaction ratio metering soluble stannous salt, wherein, soluble stannous salt is stannous sulfate, and soluble oxalate is potassium oxalate, obtains 1038.7g stannous sulfate, adds silicon powder and the stannous sulfate that metering gains in 4200g water , to obtain 5338.7g suspension.

[0046] (2) According to the reaction of soluble stannous salt and soluble oxalate to generate SnC 2 o 4 The chemical reaction ratio, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com