Patents

Literature

31results about How to "Excellent wear resistance and weather resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material, preparation method thereof and cable

ActiveCN103627074AGood cold and oil resistanceImprove mechanical propertiesRubber insulatorsInsulated cablesAntioxidantCarvacryl acetate

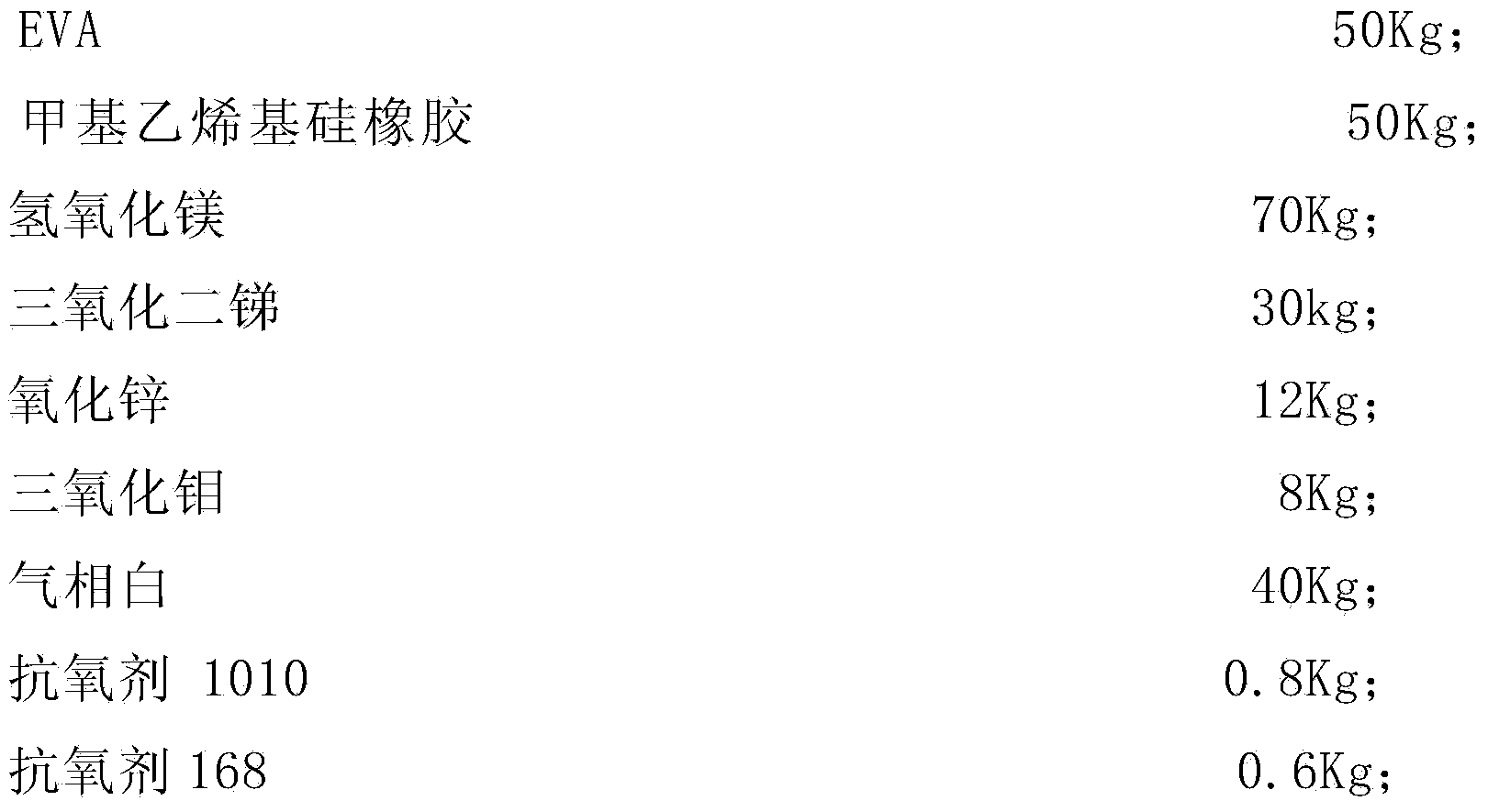

The invention provides a low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material and a preparation method thereof. The low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material comprises the following components in parts by weight: 100 parts of basic material, 80-100 parts of flame retardant A, 10-20 parts of flame retardant B, 0.8-2 parts of antioxidant, 0.4-2 parts of lubricant, 0.8-3 parts of coupling agent, 25-40 parts of reinforcing agent and 0.4-0.6 parts of vulcanizing agent, wherein the basic material is a combination of ethylene-vinyl acetate (EVA) and methyl vinyl silicone rubber; the flame retardant A is a combination of magnesium hydroxide and antimony trioxide; the flame retardant B is a combination of zinc oxide and molybdenum trioxide; the antioxidant is a combination of pentaerythritol tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate), (antioxidant 1010) and tri(2,4-di-tert-butylphenyl) phosphite (antioxidant 168); and the reinforcing agent is fumed silica. The low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material has the following characteristics of high abrasion resistance, high flame retardance, good oil resistance and chemical corrosion resistance, low temperature resistance, aging resistance, and excellent mechanical properties and the like. The invention further provides the preparation method of the low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material.

Owner:上海至正新材料有限公司

Antireflective and antiglare coating composition, antireflective and antiglare film, and method for producing same

InactiveUS20130088779A1Improve wear resistanceLower average reflectancePolarising elementsAnti-reflective coatingsParticulatesManufacturing cost reduction

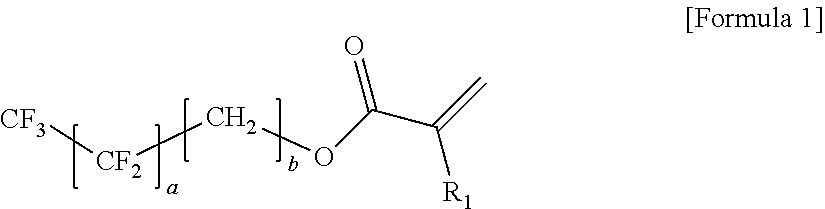

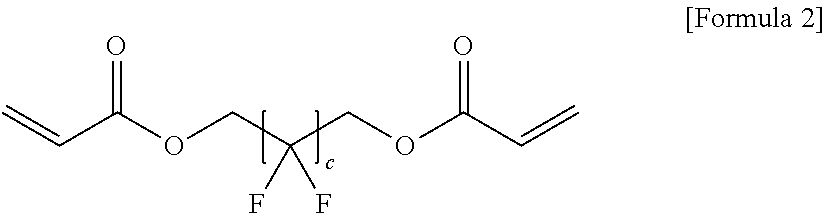

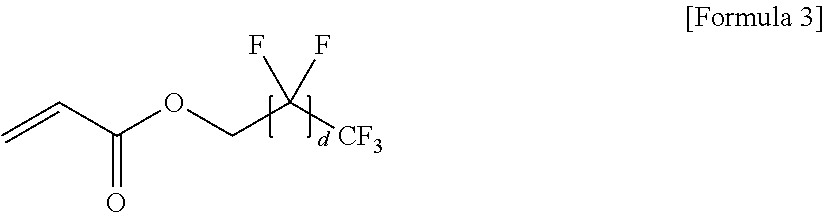

An exemplary embodiment of the present invention provides an antireflective and antiglare coating composition, comprising: a low refractive substance having a refractive index of 1.2 to 1.45, a high refractive substance having a refractive index of 1.46 to 2, a fluorine-based compound and a particulates having an average particle diameter of 1 to 10 μm, wherein a surface energy difference between the low refractive substance and the high refractive substance is 5 mN / m or more, an antireflective and antiglare film manufactured by using the same, and a method for manufacturing the same. According to the exemplary embodiment of the present invention, an antireflective and antiglare film having excellent wear resistance and antireflection function may be manufactured by a single coating process using the single composition, such that a manufacturing cost may be decreased.

Owner:LG CHEM LTD

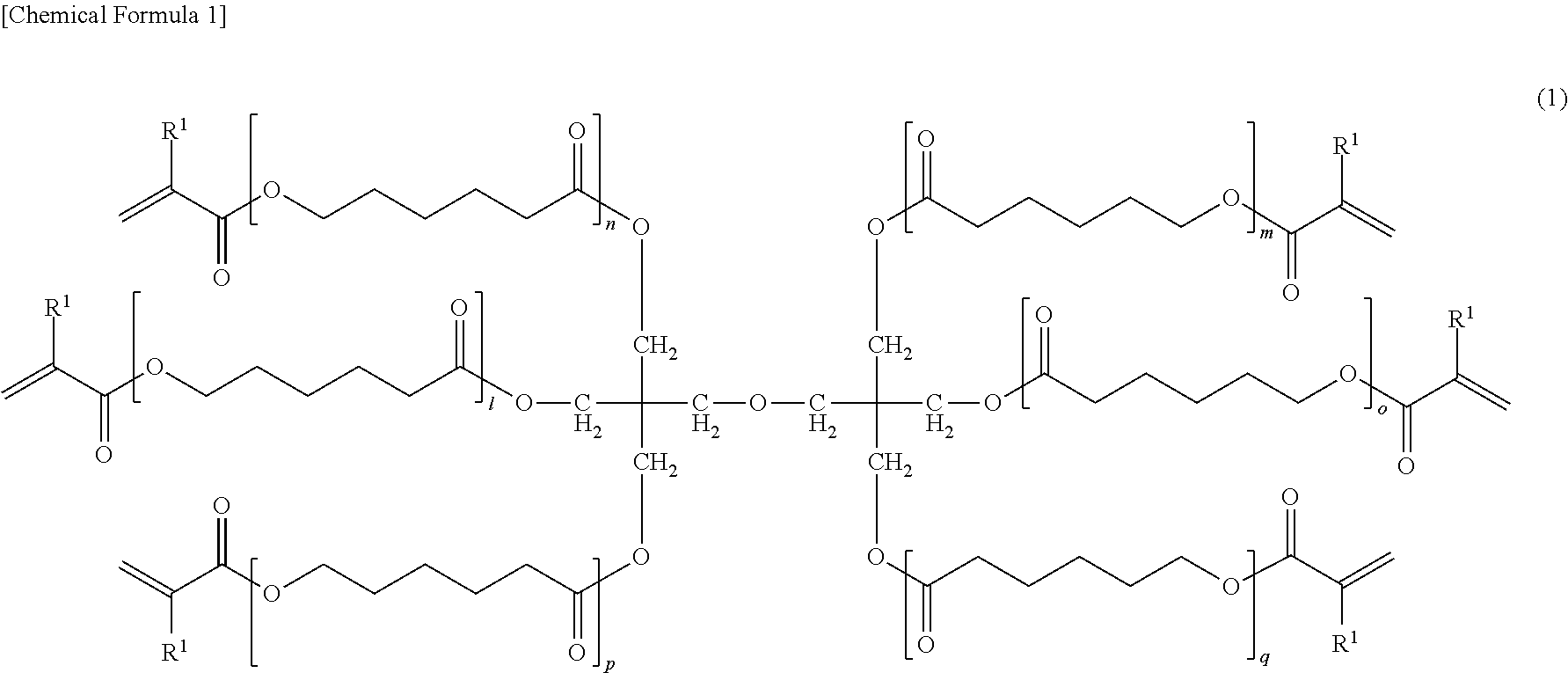

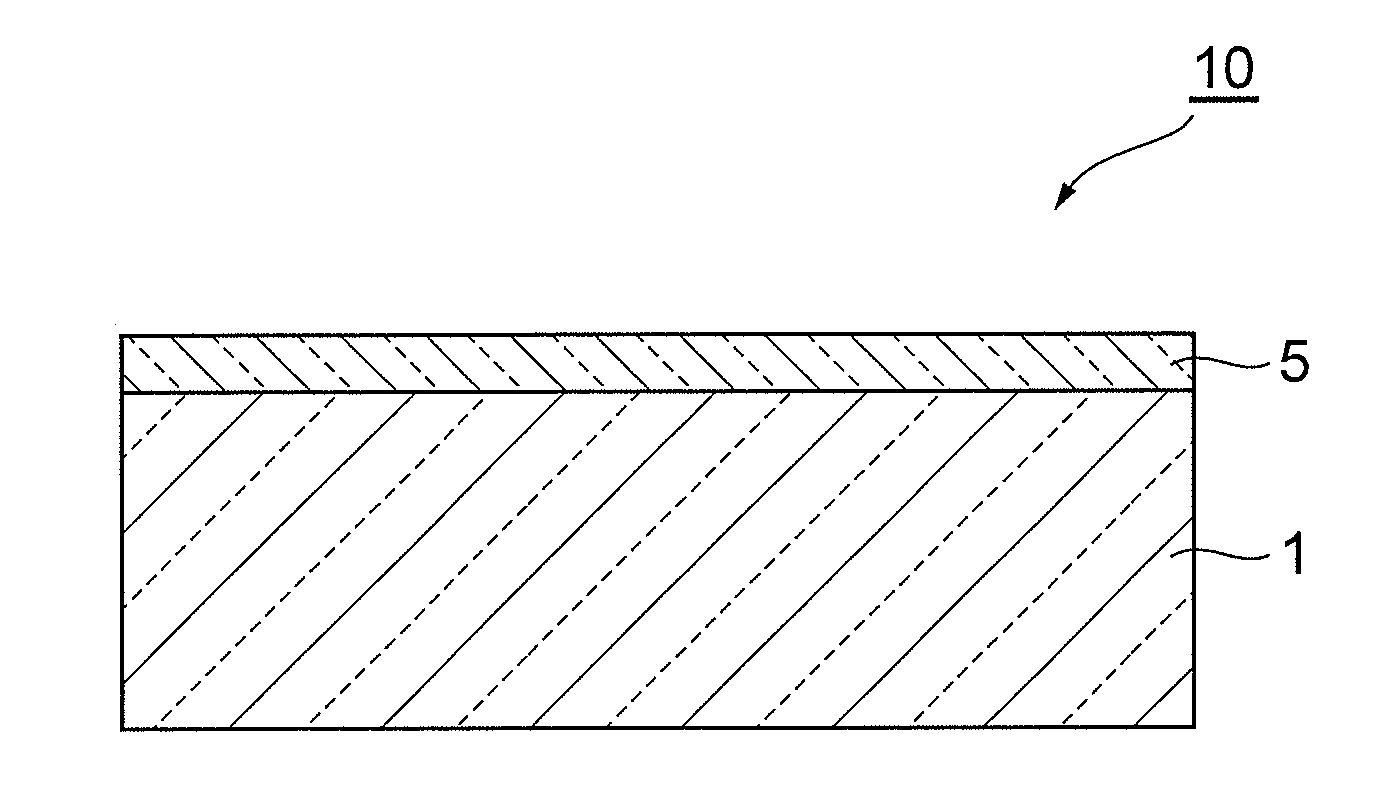

Curable composition, laminate, and automobile headlamp lens

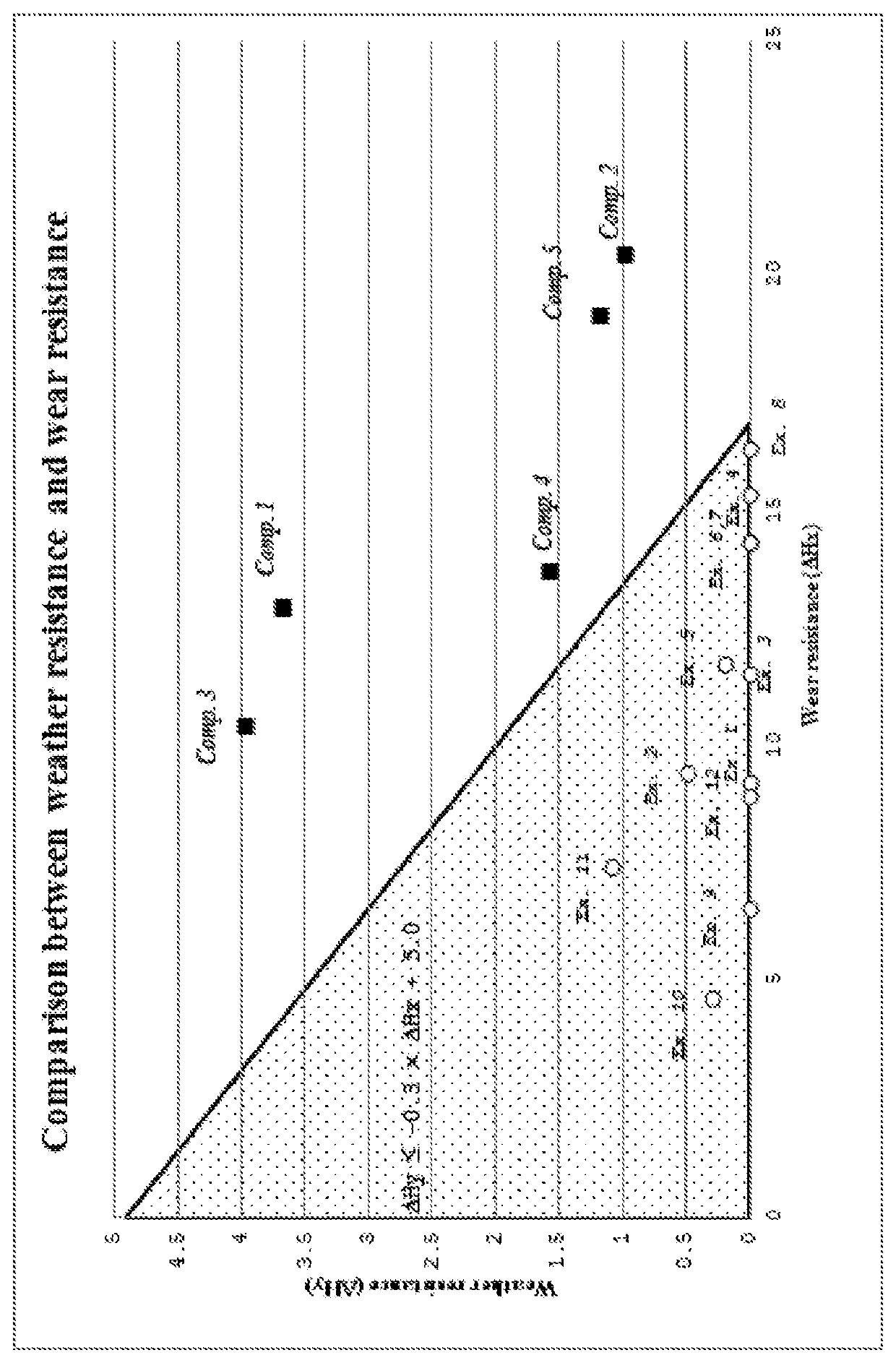

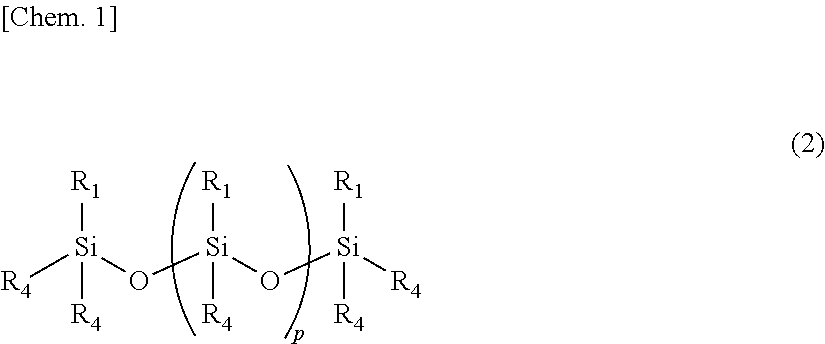

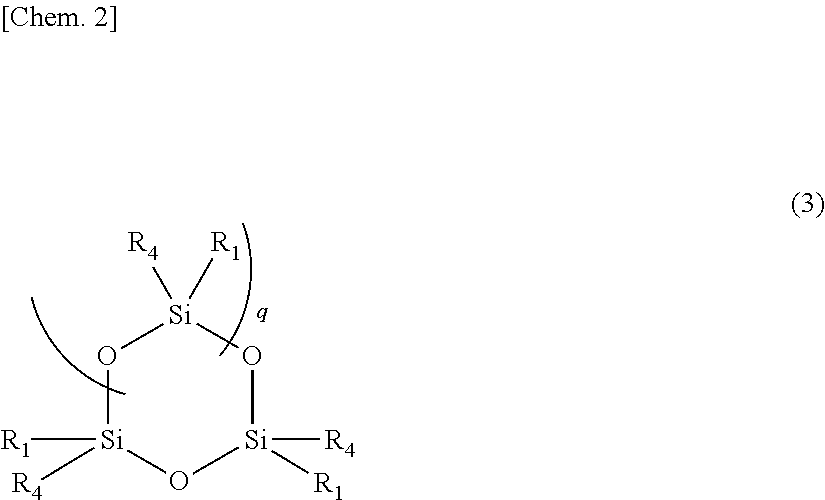

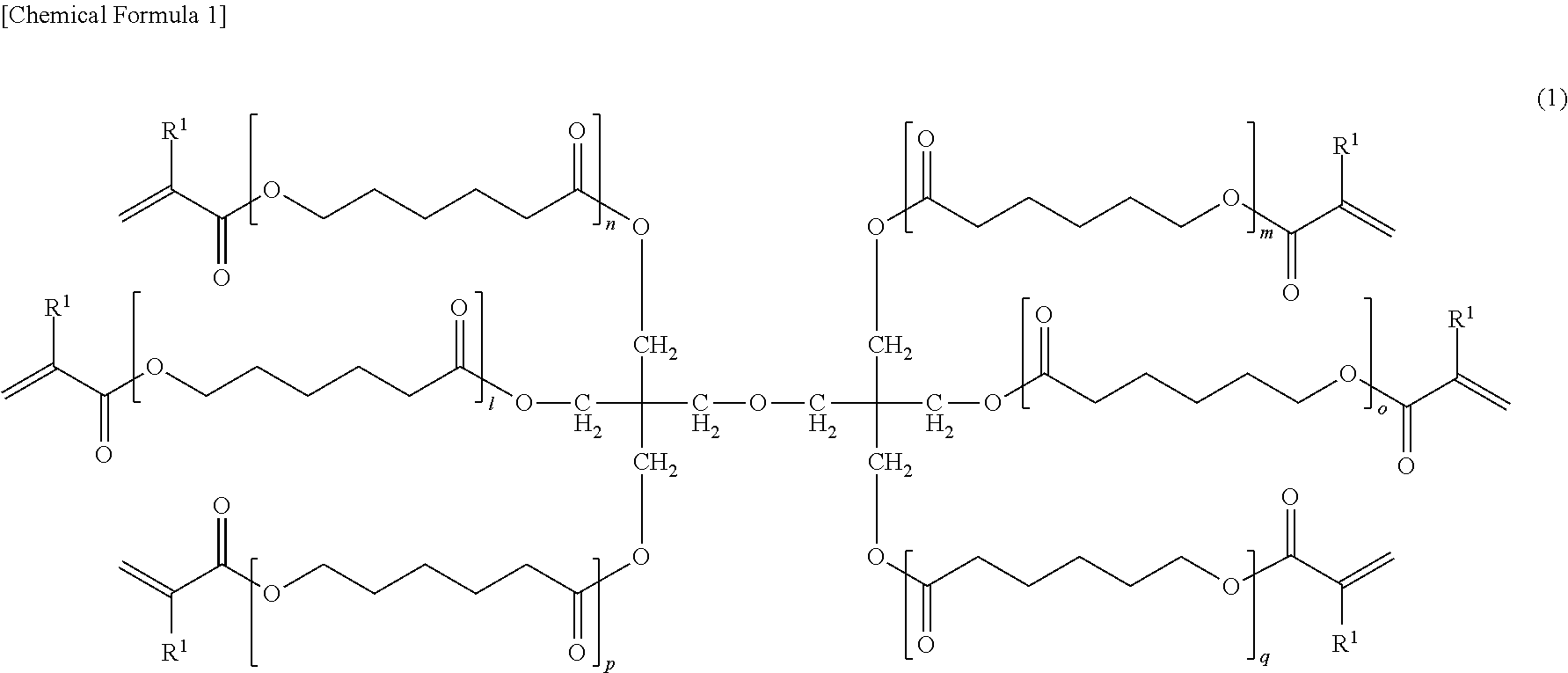

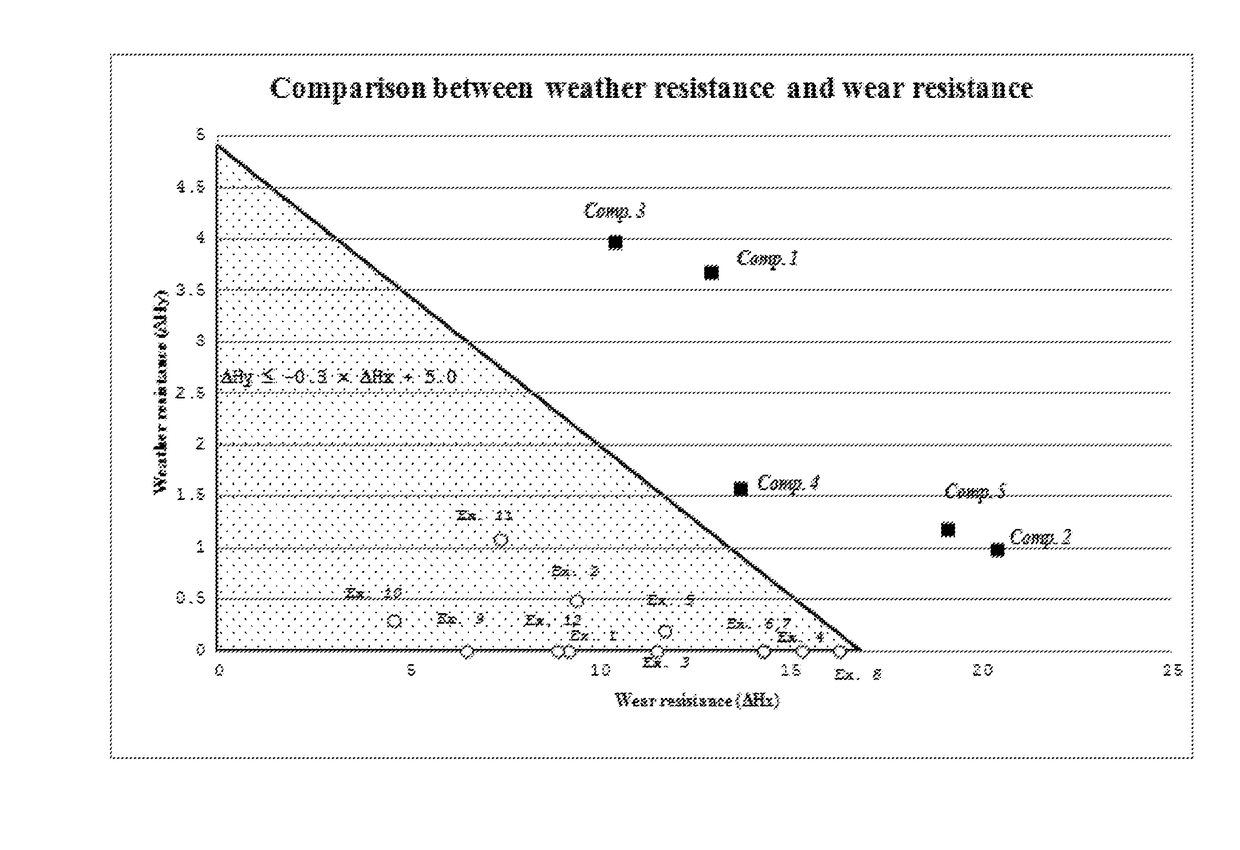

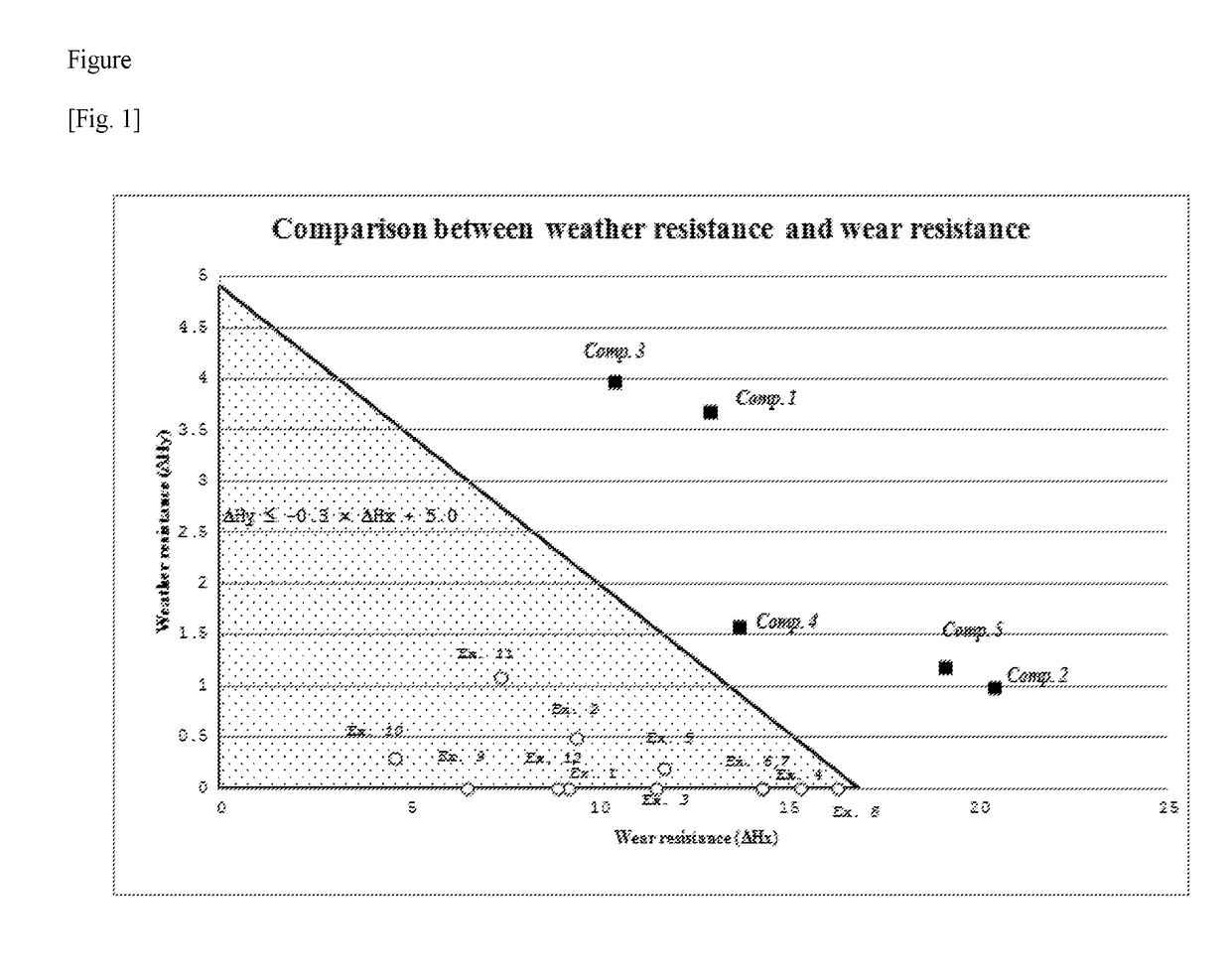

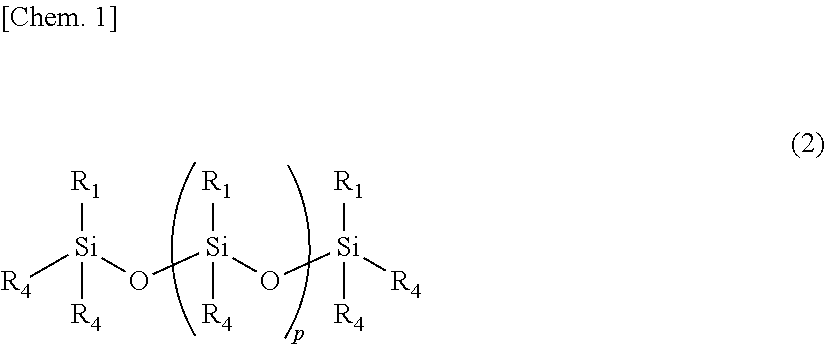

ActiveUS11021618B2Excellent wear resistance and weather resistanceImprove wear and weather resistanceVehicle headlampsLighting and heating apparatusWeather resistanceEngineering

Provided are: a curable composition that makes it possible to form a cured film having excellent wear resistance and weather resistance; a laminate that is provided with the cured film; and an automobile headlamp lens. The curable composition makes it possible to obtain a cured film in which the relationship between a haze value (ΔHx) that is obtained by a wear resistance test and a haze value (ΔHy) that is obtained by a weather resistance test satisfies ΔHy≤−0.3 ΔHx+5.0 when a cured film having a thickness of 10 μm is produced.

Owner:MITSUBISHI CHEM CORP

Electroconductive carbon fiber production technology

InactiveCN106592013AImprove performanceHigh strengthElectroconductive/antistatic filament manufactureFilament/thread formingHigh resistanceCarbon fibers

The invention discloses an electroconductive carbon fiber production technology. An electroconductive carbon fiber consists of an inner layer and an outer layer, wherein the section of the inner layer is in a three-leaf shape, the cylindrical outer layer wraps the inner layer, the inner layer comprises, by mass, 80-150 parts of polyamide-6, and the outer layer comprises, by mass, 40-80 parts of polyamide-6, 6-12 parts of carbon black, 1-3 parts of graphene powder and 0.1-1 part of titanium dioxide. The electroconductive carbon fiber production technology has the advantages that the inner layer and the outer layer of the electroconductive carbon fiber are replaceable; with the carbon black and the graphene powder added for improving fiber performance, the electroconductive carbon fiber not only is of high strength, high elasticity and high resistance to wear and weather as same as common polyamide fibers, but also overcomes the defect that the polyamide fibers are prone to generation and accumulation of static electricity, thereby being excellent in antistatic performance, endowing people with better wearing experience and being applicable to flammable and combustible occasions.

Owner:嘉兴博锐新材料有限公司

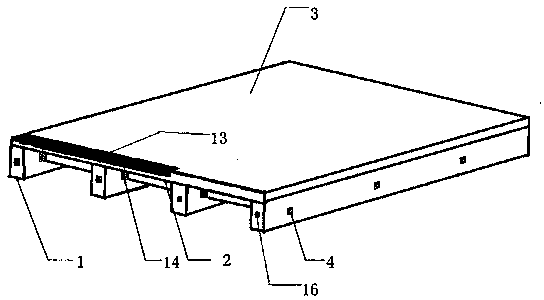

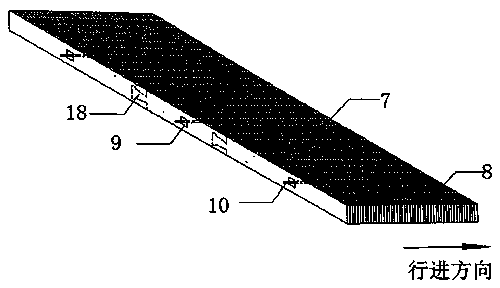

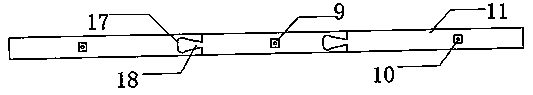

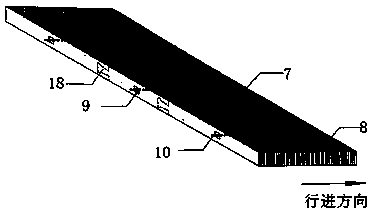

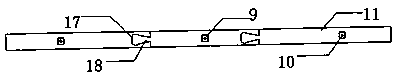

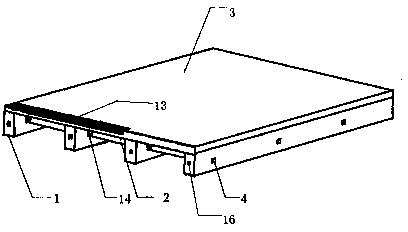

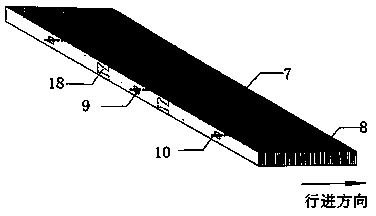

Assembly type bamboo bridge with variable expansion coefficients

ActiveCN103452035AHigh tensile strengthNo possibility of crackingSynthetic resin layered productsBridge structural detailsPolymer sciencePolymer chemistry

The invention provides an assembly type bamboo bridge. The assembly type bamboo bridge comprises bamboo longitudinal beams (1), bamboo transverse beams (2), bamboo panels (3), transverse pre-stressing tendons (4) and longitudinal pre-stressing tendons (16), the outer surface of a bamboo is sequentially and uniformly coated with a layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resorcinol formaldehyde resin, and the expansion coefficients of the four coating layers are sequentially lessened from the outer surface of the bamboo to outside. The assembly type bamboo bridge provided by the invention has the advantages that the structural strength is large, the ductility is good, a selected material is environment-friendly, standardization degree and assembling degree of structural members are high, the structural integrity is good, the advantages of the material can be fully expressed, and the requirements on normal use and durability of a bridge structure can be met.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Wear-resisting and weather-resisting modified paint

InactiveCN107266989AExcellent wear resistance and weather resistanceHigh hardnessCoatingsCyclohexanoneAcrylic resin

The invention discloses a wear-resistant and weather-resistant modified coating. The raw materials include fluorocarbon resin, caprolactone modified acrylic resin, styrene-acrylic emulsion, polyvinyl chloride resin, modified composite filler, modified adhesive, polyurethane, ortho Dioctyl phthalate, modified nano-montmorillonite, nano-titanium dioxide, sericite powder, magnesium hydroxide, ultrafine silica, calcined kaolin, kaolin, alumina, butyl acetate, sodium persulfate, fluorosilicone oil, Xylene, cyclohexanone, defoamer, silane coupling agent KH‑560, dispersant, silane coupling agent KH‑570, wetting agent and water. The modified coating of the invention has excellent wear resistance and weather resistance.

Owner:TIANCHANG JULONG TRAVEL PAINT

Elastic high-conductivity wool top fiber and preparation method thereof

InactiveCN110318118AHigh strengthIncrease elasticityElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsFiberPolyamide

The invention discloses an elastic high-conductivity wool top fiber. The elastic high-conductivity wool top fiber comprises an inner layer and an outer layer; the inner layer has a triangular cross section, the outer circumference of the inner layer is coated with the outer layer, and the outer layer has a circular cross-sectional profile; the inner layer is prepared from, by weight, 65-75 parts of polyamide-6 and 30-36 parts of polyether polyurethane elastomers; the outer layer is prepared from, by weight, 60-70 parts of polyamide-6, 15-20 parts of polyparaphenylene hexamethylene diamine, 20-28 parts of elastomers, 3-5 parts of graphene, 6-8 parts of carbon black and 3.5-5.5 parts of nano fillers. The elastic high-conductivity wool top fiber has the advantages of low volume specific resistance, good and long-lasting conductivity, great antistatic property, soft hand feeling, high elasticity and strength, excellent wearing and weather resistance and the like. Therefore, the elastic high-conductivity wool top fiber is suitable for being prepared into various conductive fabrics with high wearing comfort.

Owner:海宁泰尔欣新材料有限公司

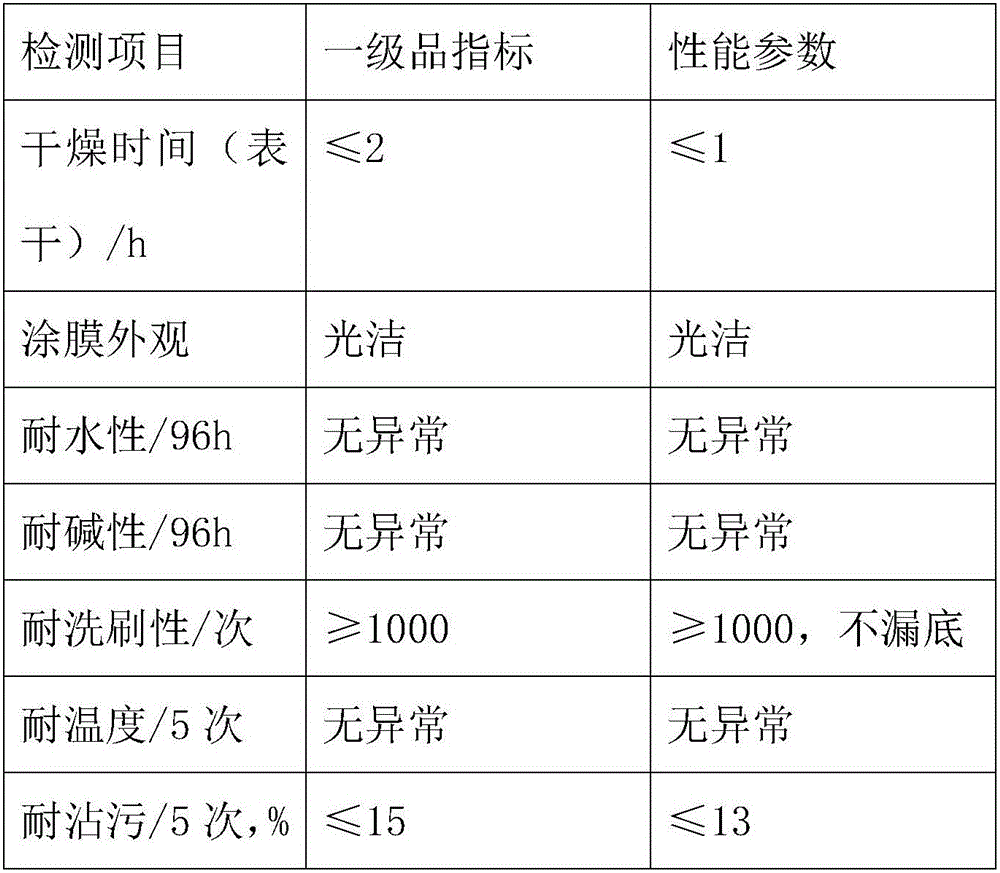

Waterproof stain-resistant silica sol polyurethane emulsion composite coating for building interior wall

InactiveCN105838220AImproves wear and weather resistanceImprove wear resistanceAntifouling/underwater paintsPaints with biocidesEmulsionOxide

The invention discloses a waterproof stain-resistant silica sol polyurethane emulsion composite coating for a building interior wall .The coating is prepared from, by weight, 30-50 parts of a composite base material, 5-15 parts of vinyl acetate, 2-8 parts of styrene-acrylic emulsion, 3-9 parts of dioctyl terephthalate, 2-5 parts of nano-titanium dioxide, 1-6 parts of zinc oxide, 1-5 parts of magnesium hydrate, 2-5 parts of ultrafine silicon dioxide, 3-6 parts of calcined kaolin, 1-4 parts of white corundum micropowder, 2-5 parts of carbon fluoride, 2-6 parts of sodium persulfate, 1-3 parts of talcum powder, 2-4 parts of nano-silicon dioxide, 2-6 parts of xylene, 3-9 parts of a stain-resistant agent, 3-5 parts of a water repellent agent, 2-5 parts of a levelling agent, 1-5 parts of a titanate coupling agent NDZ-311, 2-6 parts of a diluting agent and 8-16 parts of water .The coating is used for the building interior wall and has the excellent water resistance and strain resistance.

Owner:梁冬

High-conductivity wool top fiber and preparation method thereof

InactiveCN110318119ALow volume specific resistanceImprove conductivityElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsElastomerFiber

The invention discloses a high-conductivity wool top fiber. The high-conductivity wool top fiber comprises an inner layer and an outer layer, wherein the cross section of the inner layer is triangular, the outer layer wraps the outer circumference of the inner layer, and the cross section of the outer layer is circular; the inner layer is prepared from, by weight, 65-75 parts of polyamide-6, 15-22parts of poly-p-benzoyl hexamethylenediamine, 10-14 parts of an elastomer, 4.5-6.5 parts of graphene, 6-10 part of carbon black and 6.5-10.5 parts of a nanofiller; the outer layer is prepared from 6-100 parts of polyamide by weight. The high-conductivity wool top fiber is formed by finely selecting raw materials, and the contents of various raw materials are optimized, so that the prepared high-conductivity wool top fiber has low volume resistivity, good electrical conductivity, long-lasting electrical conductivity and good antistatic performance, the high-conductivity wool top fiber also hasthe advantages of soft hand feeling, elasticity, higher strength, good wear resistance and weather resistance and the like, and therefore, the high-conductivity wool top fiber is suitable for being prepared into various conductive fabrics, is comfortable to wear, and is especially suitable for places sensitive to static electricity.

Owner:海宁泰尔欣新材料有限公司

Scratch-resistant and weather-resistant polyurethane (PU) bright black finishing coat

ActiveCN103709918AHigh hardnessImprove flexibilityPolyurea/polyurethane coatingsToluene diisocyanateHardness

The invention relates to a scratch-resistant and weather-resistant polyurethane (PU) bright black finishing coat, which is mainly prepared from three components A, B and C according to the weight ratio 1:(0.8-1):(0.6-0.8) in a mixing manner. Aiming at the technical defects that the product in the prior art is poor in hardness, poor in scratch resistance and poor in weather fastness in the application process, the materials with excellent weatherability, such as acrylic resin and 6# carbon material are adopted to react with a toluene diisocyanate (TDI) trimer curing agent with high hardness, high flexibility and high scratch resistance, so that the product has the characteristics of being high in weatherability, high in hardness, high in flexibility, high in scratch resistance and the like. Thus, the defects of poor hardness and poor scratch resistance easily generated in the product, and fading, discoloring, shading and the like of a film along with time lapse are overcome.

Owner:上海巴德士化工新材料有限公司

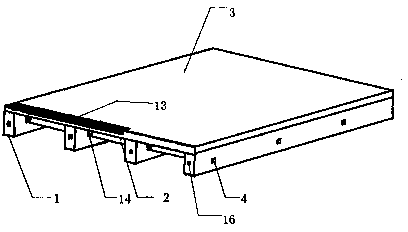

Assembly type bamboo bridge

ActiveCN103437271AHigh tensile strengthNo possibility of crackingSynthetic resin layered productsBridge structural detailsPolymer sciencePolymer chemistry

The invention provides an assembly type bamboo bridge. The assembly type bamboo bridge consists of bamboo longitudinal beams (1), bamboo transverse beams (2), bamboo panels (3), a transverse pre-stressing tendon (4) and a longitudinal pre-stressing tendon (16). All bamboos used by the assembly type bamboo bridge are soaked in a gum dipping tank which contains polyurethane resin and phenolic resin before being assembled, and boiled for 10-15 minutes at 100 DEG C-110 DEG C, wherein the volume ratio of the polyurethane resin to the phenolic resin is (2-2.5):1; and then, the bamboos are got out and dried, and a layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resurcinolformaldehyde resin are uniformly coated on the outer surfaces of all bamboos in sequence. The assembly type bamboo bridge is large in structural strength, good in drawability, green and environment-friendly in used materials, standard in structural components, high in assembly degree, good in structural integrity, and capable of sufficiently bringing the advantages of the materials into play, and satisfying the normal use and durability needs of the bridge beam structure.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

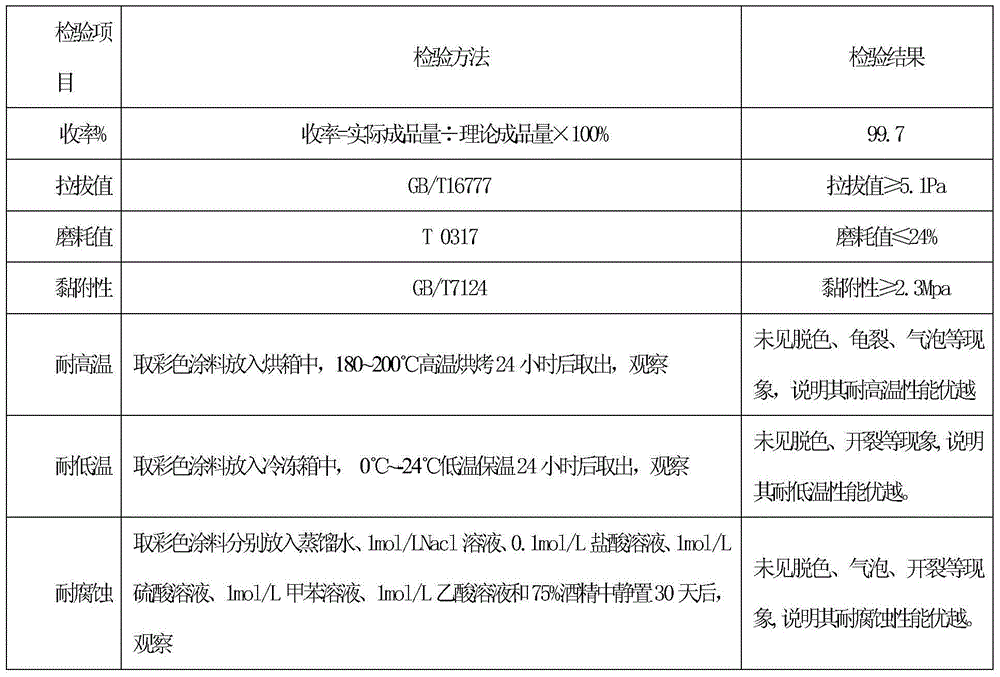

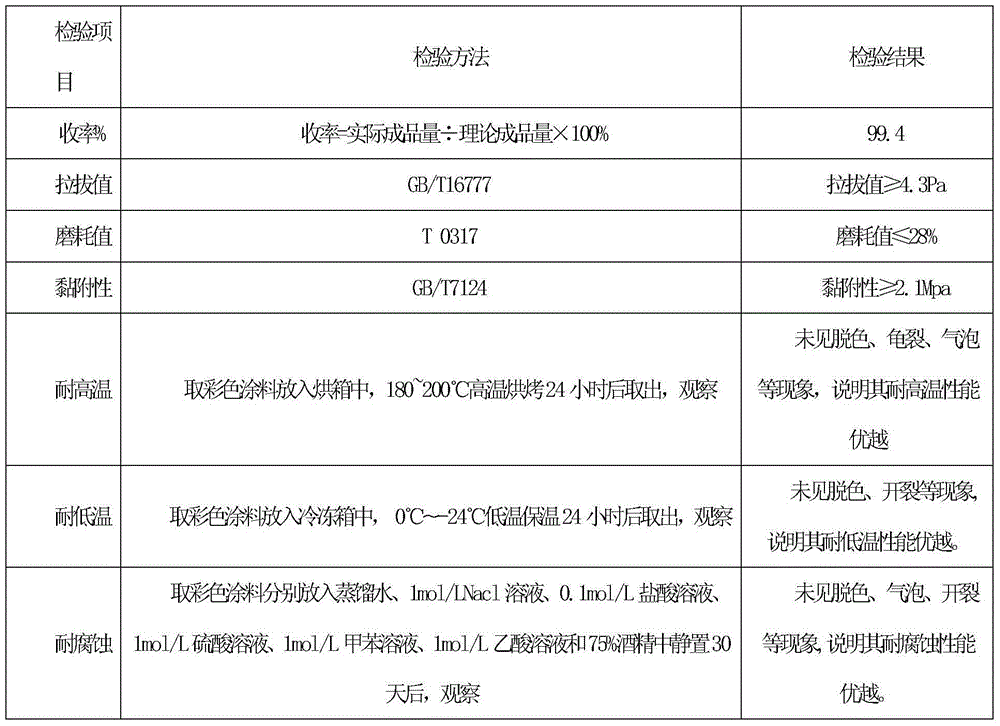

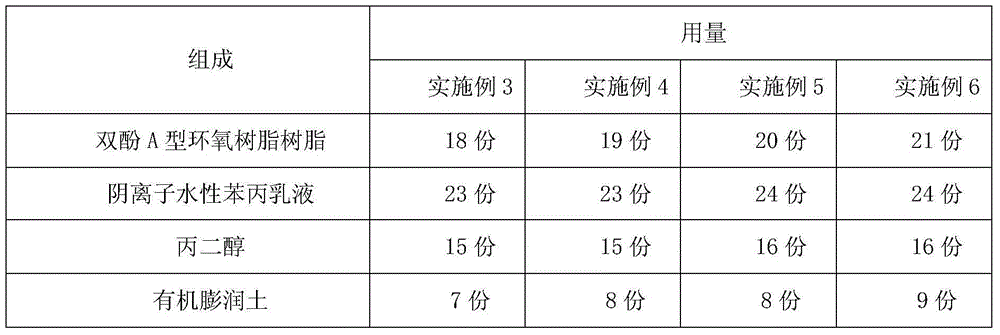

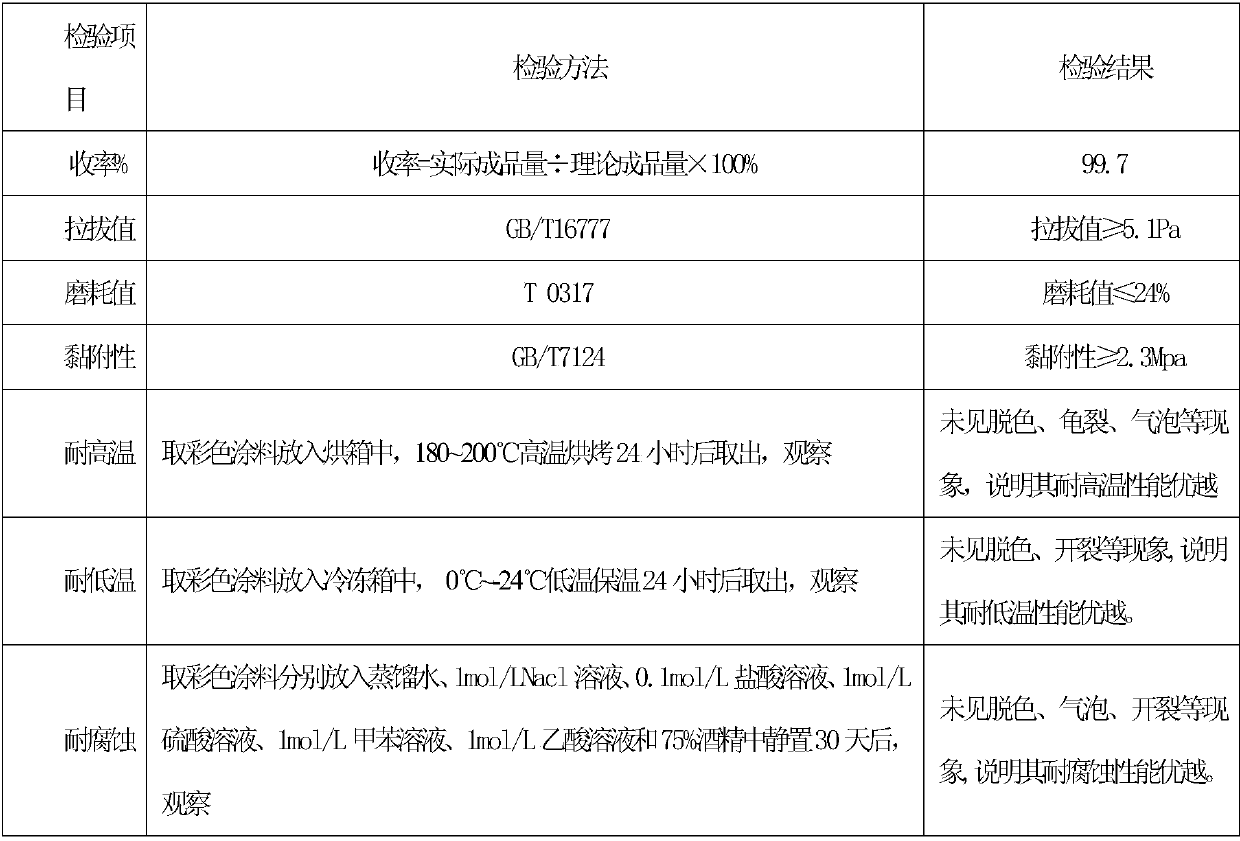

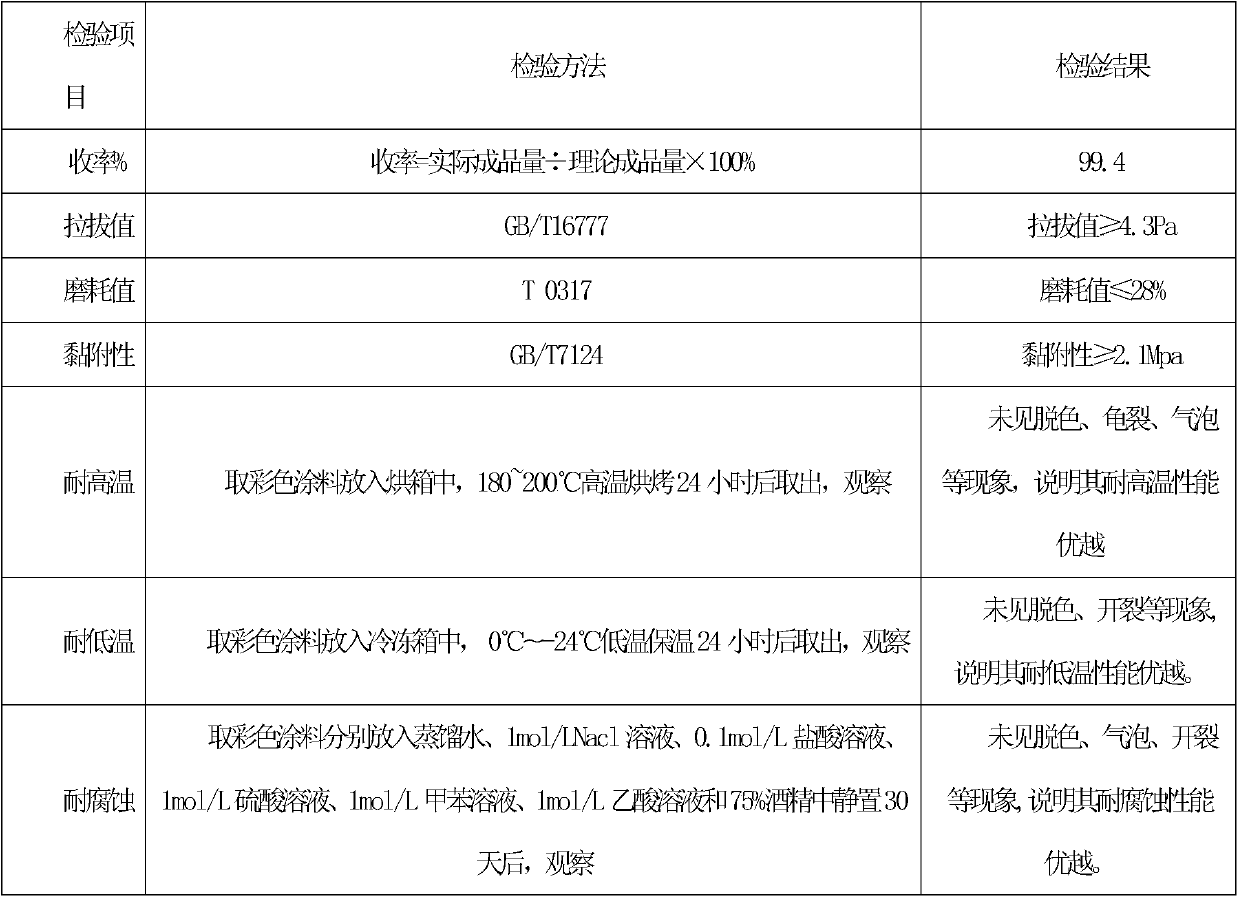

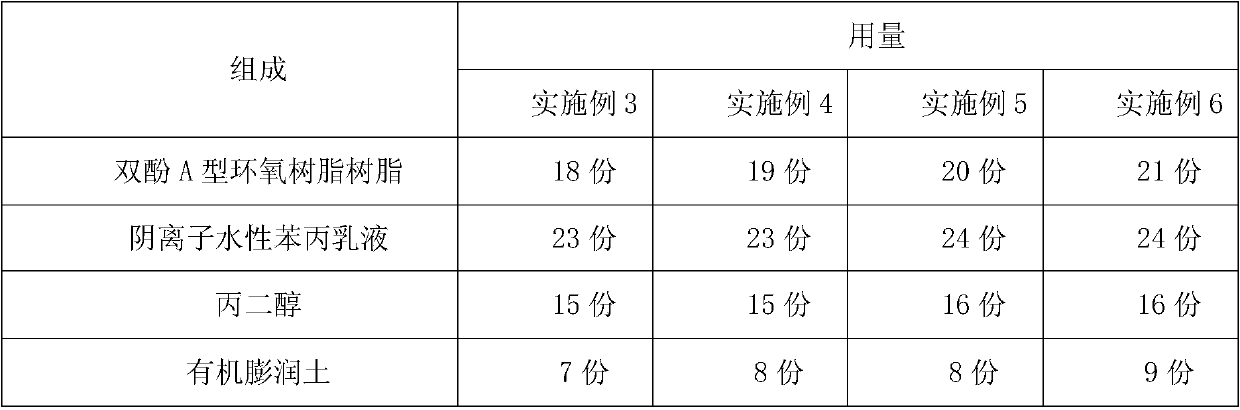

Paint for colored roads

ActiveCN104789059AExcellent wear resistance and weather resistanceStrong corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEmulsionWeather resistance

The invention relates to a paint for colored roads, which is prepared from the following raw materials in parts by weight: 10-30 parts of bisphenol A epoxy resin, 15-40 parts of anionic water-based styrene-acrylic emulsion, 12-18 parts of propanediol, 3-12 parts of organobentonite, 5-10 parts of barium sulfate, 5-10 parts of color paste and 20-45 parts of deionized water. The paint for colored roads is a bright-color wear-resistant weather-resistant high polymer material applicable to a cement concrete pavement and an asphalt pavement. The paint for colored roads has the characteristics of excellent wear resistance, excellent weather resistance, high corrosion resistance, high adhesion performance and low cost. The drawing value is greater than or equal to 5.9 Pa, the wear value is less than or equal to 18%, the adhesion performance is greater than or equal to 2.9 MPa, and the high yield is up to 99% above. The paint for colored roads has the advantages of simple preparation technique, high yield and low cost, and is suitable for industrial production.

Owner:重庆市智翔铺道技术工程有限公司

High-heat-dissipation insulating composite coating used for supercapacitor shells

InactiveCN106867365AGood dispersionImprove insulation performanceFireproof paintsEpoxy resin coatingsEpoxySolvent

The invention discloses a high-heat-dissipation insulating composite coating used for supercapacitor shells. The high-heat-dissipation insulating composite coating used for supercapacitor shells is prepared from, by mass, 60 to 80 parts of epoxy resin, 20 to 35 parts of alkyd resin, 5 to 20 parts of liquid phenyl siloxane rubber, 3 to 6 parts of thiosemicarbazide, 40 to 60 parts of a nitride, 4 to 5 parts of tetrabutyl titanate, 2 to 5 parts of TTS, 5 to 7 parts of polydimethylsiloxane, 2 to 5 parts of a curing agent, and an appropriate amount of a solvent. The formula composition of the high-heat-dissipation insulating composite coating is reasonable; the raw materials are safe and easily available; the high-heat-dissipation insulating composite coating is prepared via steps such as heating, mixing, ultrasonic treatment, and grinding; the dispersibility of the raw materials is excellent; the obtained high-heat-dissipation insulating composite coating is uniform and flat; the heat dissipation performance and insulating properties of the high-heat-dissipation insulating composite coating are improved greatly via modification treatment of inorganic filling materials; the adhesive force of the high-heat-dissipation insulating composite coating is high; the high-heat-dissipation insulating composite coating possesses excellent flame resistance, wear resistance, and weather resistance, and is capable of improving application safety and prolonging the service life of capacitors obviously.

Owner:廖一强

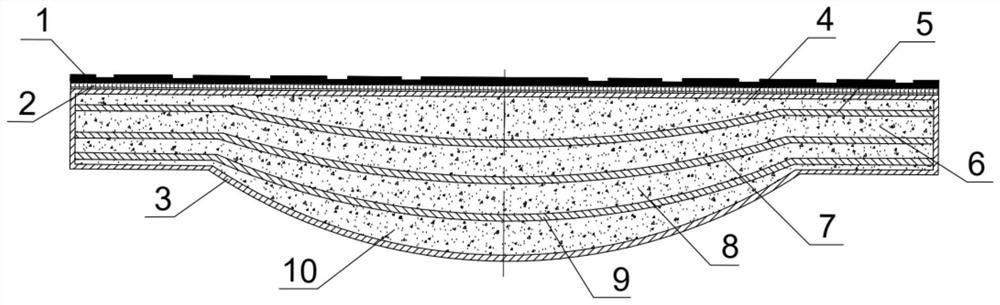

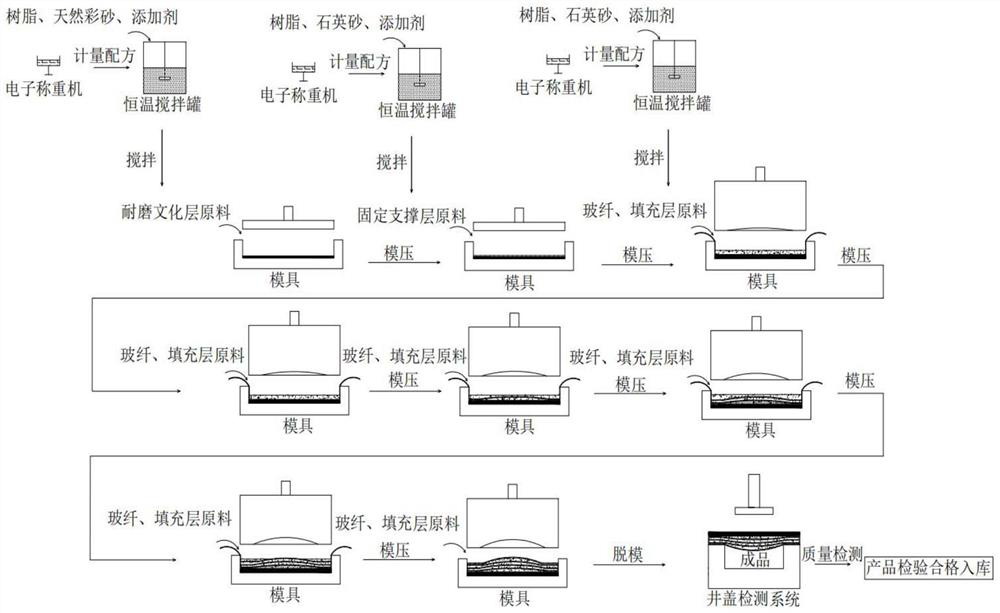

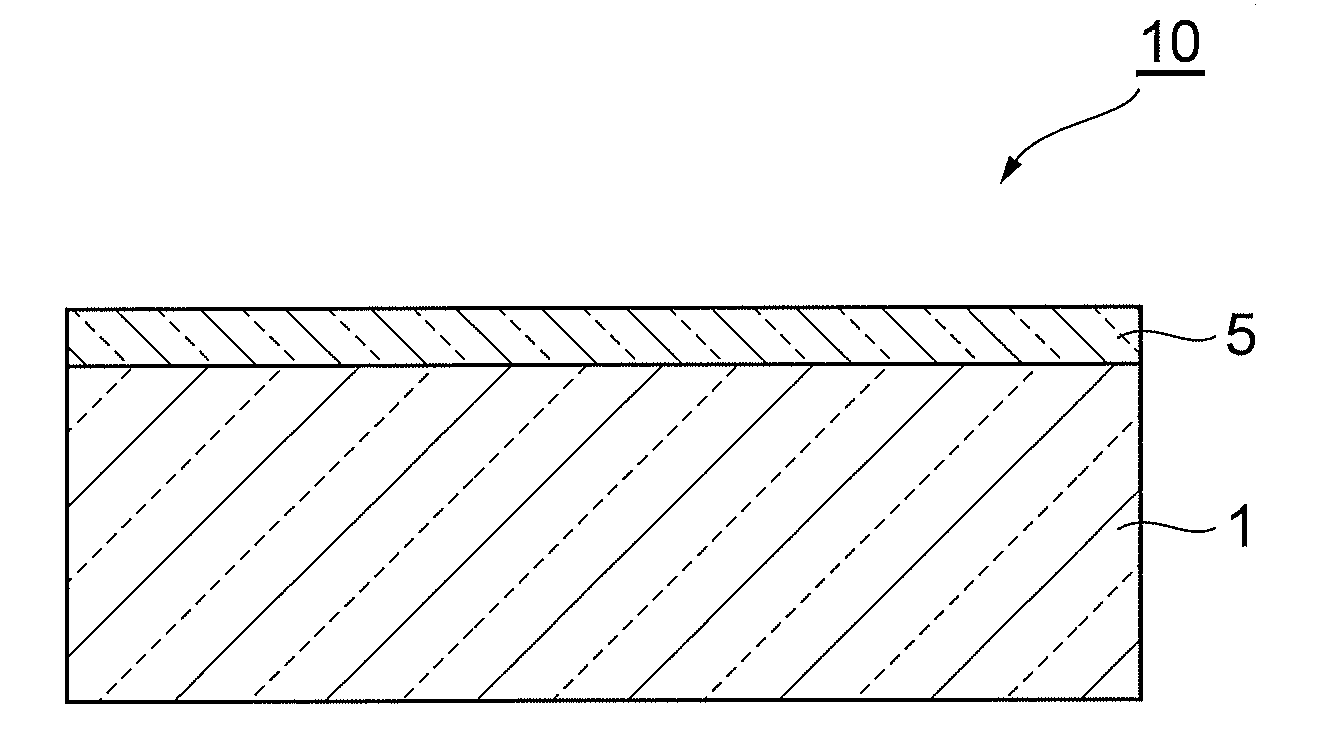

Multi-layer molded high-load-bearing municipal road well lid and manufacturing method thereof

ActiveCN113737859AImprove toughnessImprove fatigue resistanceArtificial islandsClimate change adaptationConstruction engineeringStructural engineering

The invention relates to a multi-layer molded high-load-bearing municipal road well lid and a manufacturing method thereof, and belongs to the technical field of municipal engineering roads. The well lid comprises a wear-resistant layer, a fixed supporting layer, a protective layer, a first filling layer, a first reinforcing layer, a second filling layer, a second reinforcing layer, a third filling layer, a third reinforcing layer and a fourth filling layer, wherein the upper surface of the protective layer is covered with the fixed supporting layer, the wear-resistant layer is installed on the fixed supporting layer, the first reinforcing layer, the second reinforcing layer and the third reinforcing layer are sequentially arranged in the protective layer from top to bottom, the space between the top face in the protective layer and the first reinforcing layer is filled with the first filling layer, the second filling layer is filled between the first reinforcing layer and the second reinforcing layer, the third filling layer is filled between the second reinforcing layer and the third reinforcing layer, and the fourth filling layer is filled between the third reinforcing layer and the inner bottom surface of the protective layer. By the adoption of the multi-layer reverse tensioning force enhanced curved surface type structure, stress in the well lid is more uniform, and the strength is better.

Owner:KUNMING UNIV OF SCI & TECH +1

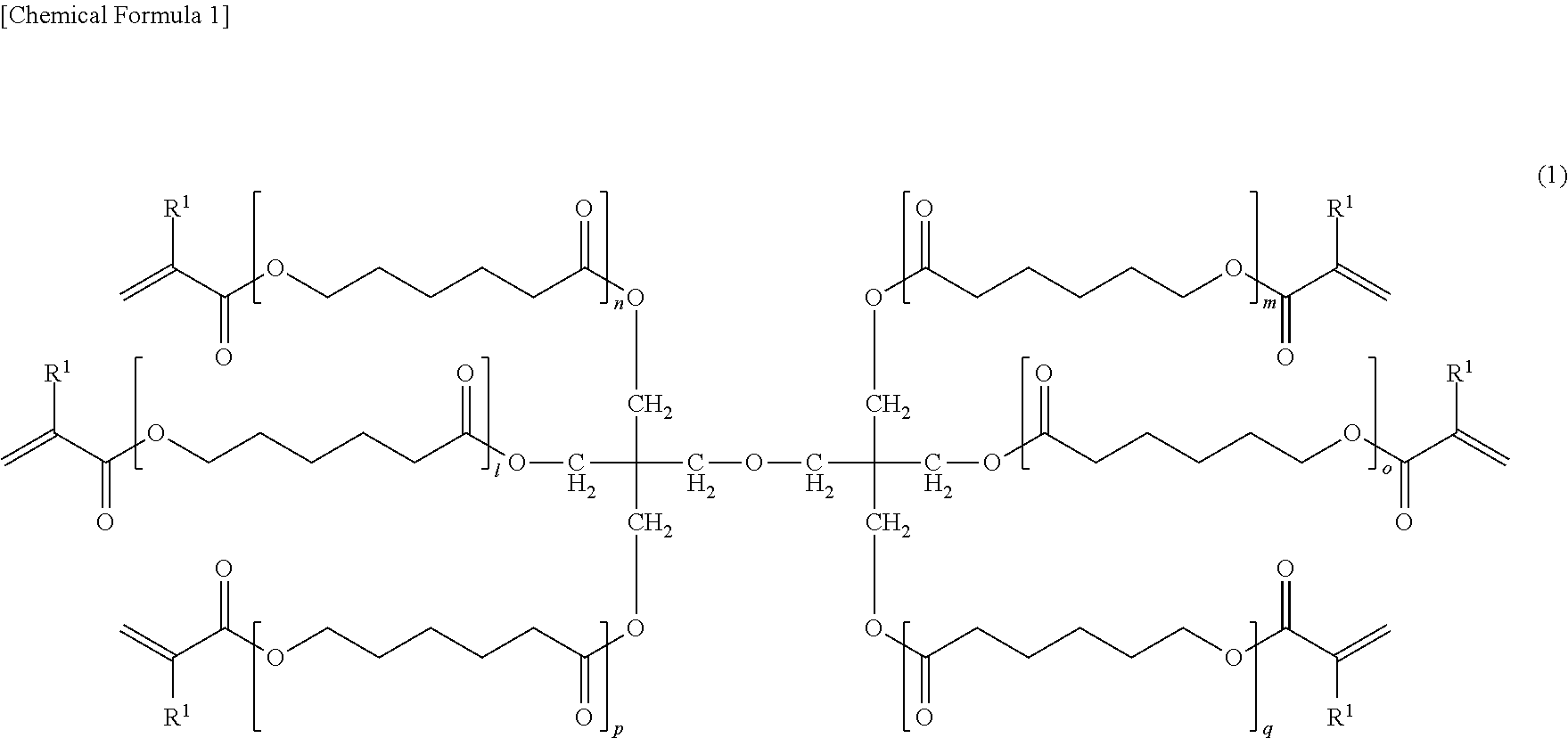

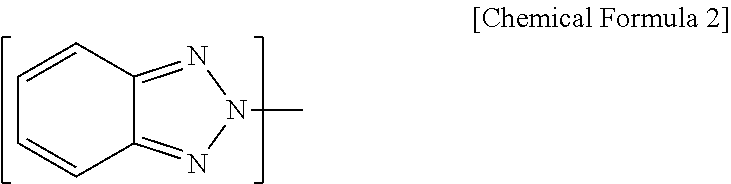

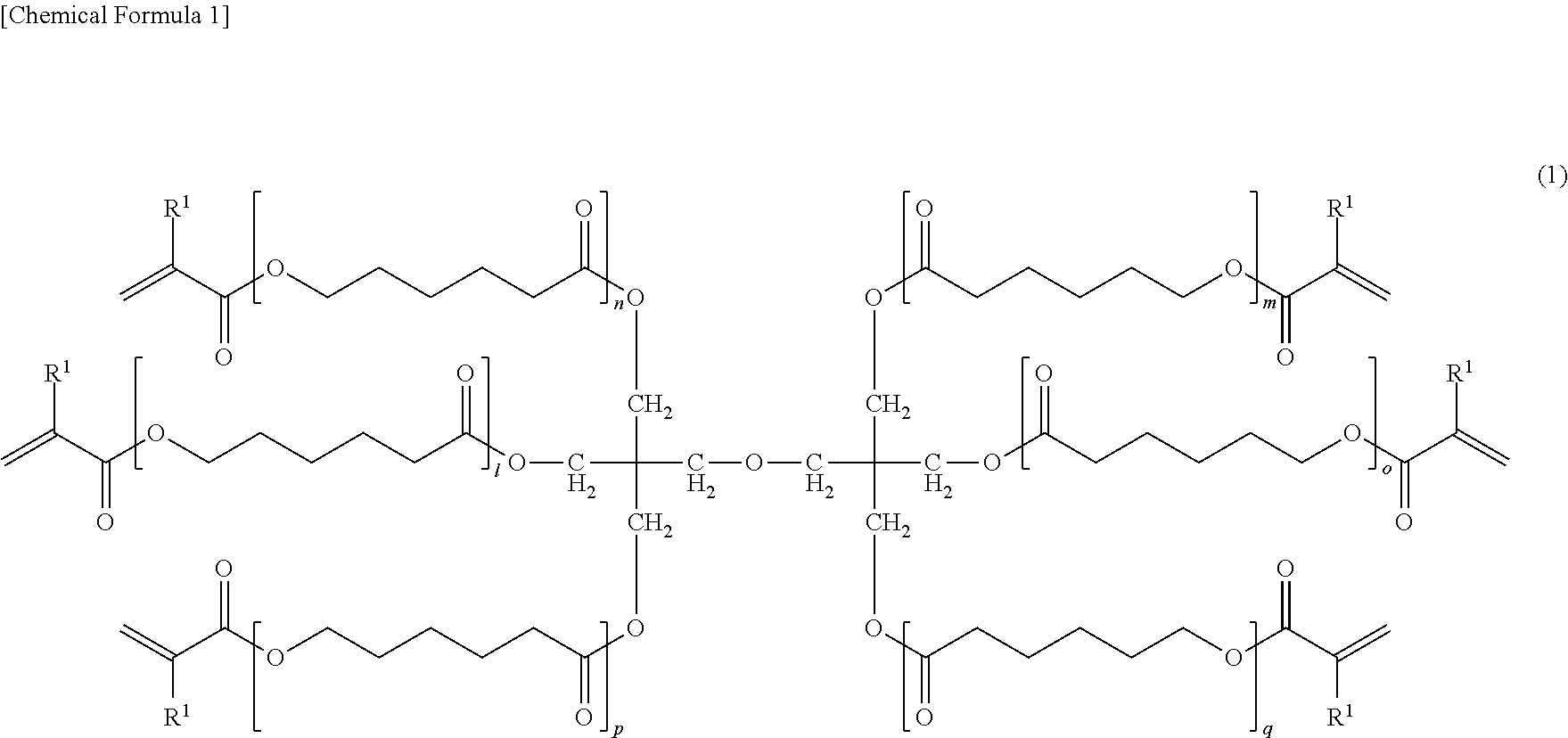

Actinic-light-curable composition, molded polycarbonate resin object with a cured film, and manufacturing method therefor

InactiveUS20130034735A1Improve wear resistanceGood weather resistanceNon-fibrous pulp additionSynthetic resin layered productsBenzotriazolePrepolymer

Disclosed is an active energy ray-curing composition containing an active energy ray-curing prepolymer (A) obtainable by a reaction of an acrylic-based prepolymer having a hydroxyl group and an acrylic monomer (a4) having an isocyanate group, an active energy ray-curing compound (B) having a benzotriazole group, another active energy ray-curing compound (C) differing from the (A) component and the (B) component, and inorganic oxide particles (D). The acrylic-based prepolymer having the hydroxyl group is a copolymer that includes an acrylic monomer (a1) having a piperidinyl group, an acrylic monomer (a2) having a hydroxyl group, etc., as monomer units.

Owner:TOYOTA IND CORP

Actinic-light-curable composition, molded polycarbonate resin object with a cured film, and manufacturing method therefor

InactiveUS8754167B2Excellent wear resistance and weather resistanceImprove adhesionFibre treatmentPretreated surfacesPolymer sciencePolycarbonate

Disclosed is an active energy ray-curing composition containing an active energy ray-curing prepolymer (A) obtainable by a reaction of an acrylic-based prepolymer having a hydroxyl group and an acrylic monomer (a4) having an isocyanate group, an active energy ray-curing compound (B) having a benzotriazole group, another active energy ray-curing compound (C) differing from the (A) component and the (B) component, and inorganic oxide particles (D). The acrylic-based prepolymer having the hydroxyl group is a copolymer that includes an acrylic monomer (a1) having a piperidinyl group, an acrylic monomer (a2) having a hydroxyl group, etc., as monomer units.

Owner:TOYOTA IND CORP

Curable composition, laminate, and automobile headlamp lens

ActiveUS20170183515A1Improve wear resistanceGood weather resistanceVehicle headlampsOptical signallingWeather resistanceWear resistance

Provided are: a curable composition that makes it possible to form a cured film having excellent wear resistance and weather resistance; a laminate that is provided with the cured film; and an automobile headlamp lens. The curable composition makes it possible to obtain a cured film in which the relationship between a haze value (ΔHx) that is obtained by a wear resistance test and a haze value (ΔHy) that is obtained by a weather resistance test satisfies ΔHy≦−0.3 ΔHx+5.0 when a cured film having a thickness of 10 μm is produced.

Owner:MITSUBISHI CHEM CORP

Vehicle member and manufacturing method therefor

InactiveUS20130046053A1Improve wear resistanceGood weather resistanceSynthetic resin layered productsPretreated surfacesBenzotriazolePrepolymer

Disclosed is a vehicle member that includes a molded body and a protective film disposed on a surface of the molded body and formed by curing of an active energy ray-curing composition. The active energy ray-curing composition contains an active energy ray-curing prepolymer (A) obtainable by a reaction of an acrylic-based prepolymer having a hydroxyl group and an acrylic monomer (a4) having an isocyanate group, an active energy ray-curing compound (B) having a benzotriazole group, another active energy ray-curing compound (C) differing from the (A) component and the (B) component, and inorganic oxide particles (D). The acrylic-based prepolymer having the hydroxyl group is a copolymer that includes an acrylic monomer (a1) having a piperidinyl group, an acrylic monomer (a2) having a hydroxyl group, etc., as monomer units.

Owner:TOYOTA IND CORP

A kind of colored road paint

ActiveCN104789059BExcellent wear resistance and weather resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsWater basedWear resistant

Owner:重庆市智翔铺道技术工程有限公司

A high-strength and low-cost composite manhole cover

InactiveCN103498485BMeet the requirements of wear resistance and weather resistanceHigh hardnessArtificial islandsUnderwater structuresPolystyreneSteel bar

A high-strength and low-cost composite well lid comprises a fiber-reinforced bottom layer, a reinforcing steel bar padding layer and a high-hardness wearproof top layer. Pulverescent self-fabricated curing agents are formed by mixing the following materials, by weight ratio, 0.025 part of tertiary butyl ester, 0.015 part of methyl ethyl ketone peroxide, 0.6 part of zinc stearate, 0.02 part of calcium hydroxide, 0.8 part of styrene and 0.4 part of polystyrene, and different reinforcing materials are used in different parts of the well lid. The lower portion of the well lib is reinforced by using fibers to guarantee the bearing capacity of the well lid, net-shaped reinforcing steel bars and a large amount of padding are used in the middle portion of the well lid to improve the non-deformability of products, materials with high hardness and good wearproof and weather resistance performance are used on the upper portion of the well lid, and different patterns and different colors are designed and adopted. Thus, the manufactured well lid can meet the wearproof and weather resistance requirements, and has the advantages of being attractive and beautiful.

Owner:ZUNYI XINXING EQUIP

Assembly type bamboo bridge

ActiveCN103437271BHigh tensile strengthNo possibility of crackingSynthetic resin layered productsBridge structural detailsPre stressPre stressing

The invention provides an assembly type bamboo bridge. The assembly type bamboo bridge consists of bamboo longitudinal beams (1), bamboo transverse beams (2), bamboo panels (3), a transverse pre-stressing tendon (4) and a longitudinal pre-stressing tendon (16). All bamboos used by the assembly type bamboo bridge are soaked in a gum dipping tank which contains polyurethane resin and phenolic resin before being assembled, and boiled for 10-15 minutes at 100 DEG C-110 DEG C, wherein the volume ratio of the polyurethane resin to the phenolic resin is (2-2.5):1; and then, the bamboos are got out and dried, and a layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resurcinolformaldehyde resin are uniformly coated on the outer surfaces of all bamboos in sequence. The assembly type bamboo bridge is large in structural strength, good in drawability, green and environment-friendly in used materials, standard in structural components, high in assembly degree, good in structural integrity, and capable of sufficiently bringing the advantages of the materials into play, and satisfying the normal use and durability needs of the bridge beam structure.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Anti-scratch and weather-resistant polyurethane pu glossy black finish

ActiveCN103709918BGood weather resistanceHigh hardnessPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention relates to a scratch-resistant and weather-resistant polyurethane (PU) bright black finishing coat, which is mainly prepared from three components A, B and C according to the weight ratio 1:(0.8-1):(0.6-0.8) in a mixing manner. Aiming at the technical defects that the product in the prior art is poor in hardness, poor in scratch resistance and poor in weather fastness in the application process, the materials with excellent weatherability, such as acrylic resin and 6# carbon material are adopted to react with a toluene diisocyanate (TDI) trimer curing agent with high hardness, high flexibility and high scratch resistance, so that the product has the characteristics of being high in weatherability, high in hardness, high in flexibility, high in scratch resistance and the like. Thus, the defects of poor hardness and poor scratch resistance easily generated in the product, and fading, discoloring, shading and the like of a film along with time lapse are overcome.

Owner:SHANGHAI BADES CHEM NEW MATERIAL CO LTD

A low-smoke, halogen-free, high flame-retardant, oil-resistant and cold-resistant cable material, its preparation method and cable

ActiveCN103627074BGood cold and oil resistanceImprove mechanical propertiesRubber insulatorsInsulated cablesAntioxidantEngineering

The invention provides a low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material and a preparation method thereof. The low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material comprises the following components in parts by weight: 100 parts of basic material, 80-100 parts of flame retardant A, 10-20 parts of flame retardant B, 0.8-2 parts of antioxidant, 0.4-2 parts of lubricant, 0.8-3 parts of coupling agent, 25-40 parts of reinforcing agent and 0.4-0.6 parts of vulcanizing agent, wherein the basic material is a combination of ethylene-vinyl acetate (EVA) and methyl vinyl silicone rubber; the flame retardant A is a combination of magnesium hydroxide and antimony trioxide; the flame retardant B is a combination of zinc oxide and molybdenum trioxide; the antioxidant is a combination of pentaerythritol tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate), (antioxidant 1010) and tri(2,4-di-tert-butylphenyl) phosphite (antioxidant 168); and the reinforcing agent is fumed silica. The low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material has the following characteristics of high abrasion resistance, high flame retardance, good oil resistance and chemical corrosion resistance, low temperature resistance, aging resistance, and excellent mechanical properties and the like. The invention further provides the preparation method of the low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material.

Owner:上海至正新材料有限公司

High-heat-dissipation insulating composite coating for electric appliance

InactiveCN111876055AImprove cooling effectImprove insulation performanceFireproof paintsEpoxy resin coatingsFiberFirming agent

The invention provides a high-heat-dissipation insulating composite coating for an electric appliance. The coating is prepared from the following components in parts by mass: 40-50 parts of bisphenolA epoxy resin, 12-16 parts of alkyd resin, 1-4 parts of fiber slurry, 13-16 parts of nitride, 1-3 parts of hydroxyl silicone oil, 15-18 parts of filler, 2-5 parts of gamma-(2,3-epoxypropoxy)-propyltrimethoxysilane, 5-7 parts of polydimethylsiloxane, 3-10 parts of a curing agent and a proper amount of a solvent. Through the reasonable raw material formula and compounding and cooperations among thecomponents, the coating is uniform and level, the heat conduction and dissipation performance of the coating is greatly improved, the insulating property is good, and the adhesive force of the coatingis high; the coating also has excellent temperature resistance, fire resistance, wear resistance, weather resistance and the like, the use safety of electric appliances is remarkably improved, and the service life of the electric appliances is remarkably prolonged.

Owner:南京思甲宁新材料科技有限公司

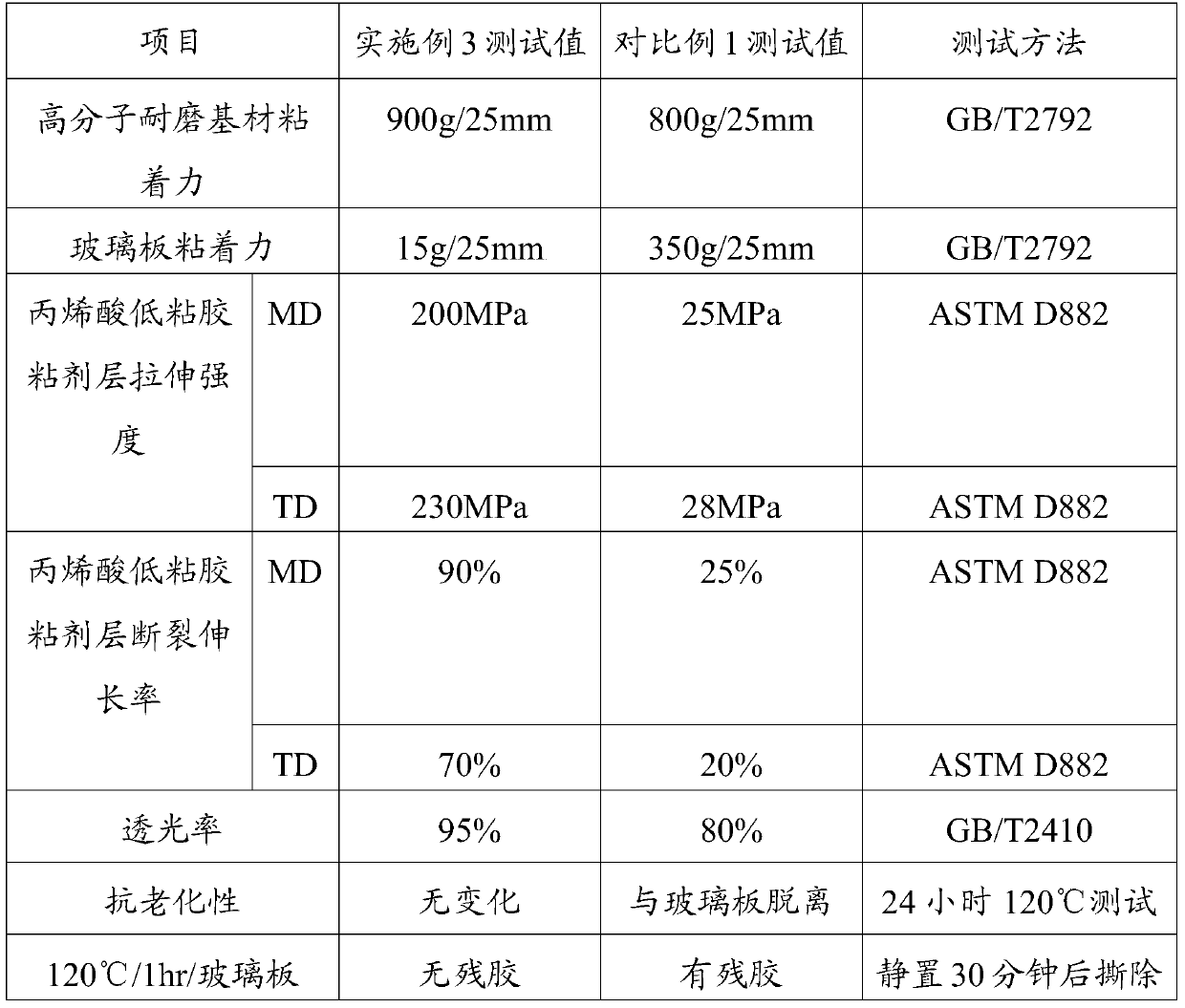

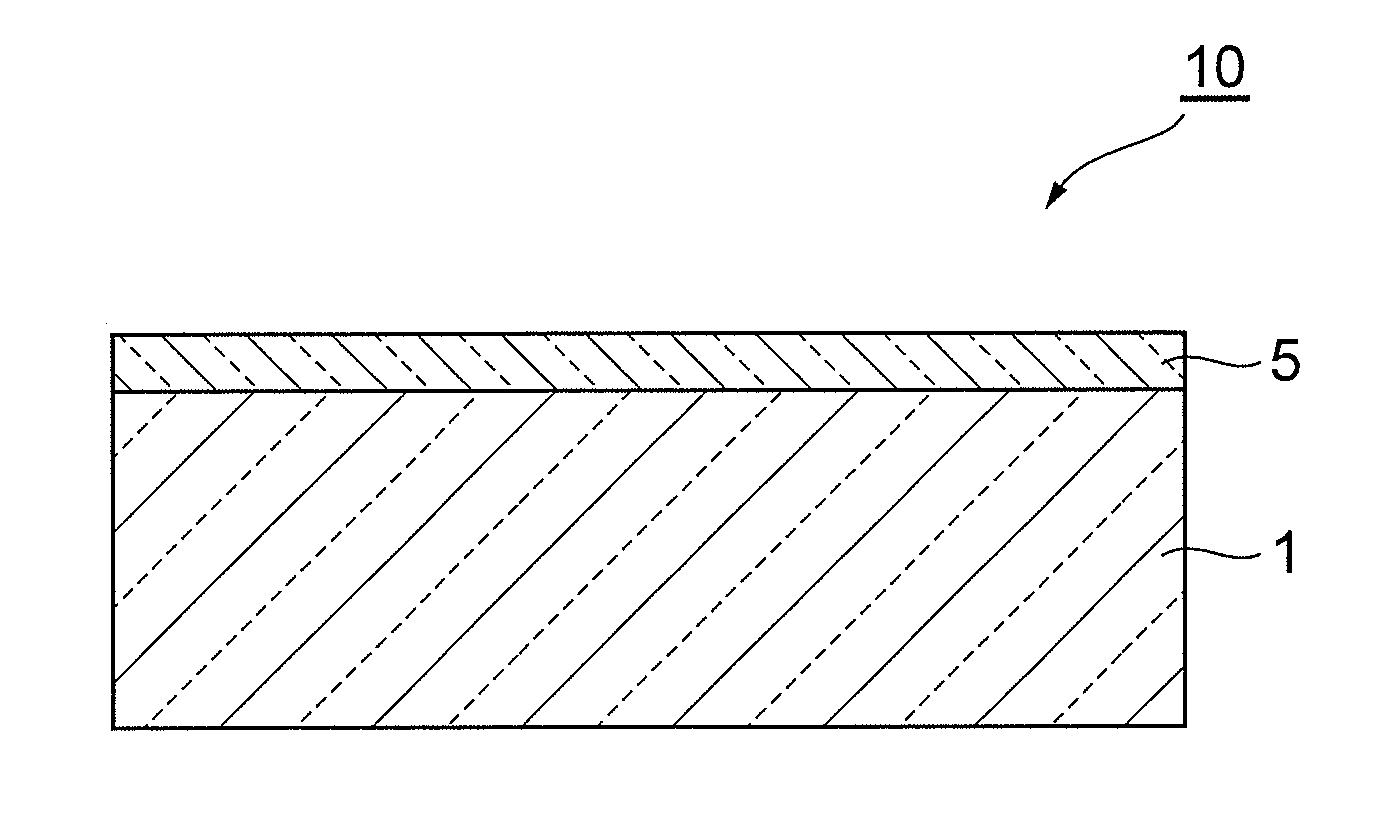

Protective film for delivery of glass cover plates with low film tearing force

InactiveCN110105888AImprove anti-aging propertiesImprove toughnessEster polymer adhesivesFilm/foil adhesive release linersTectorial membraneGlass cover

The invention relates to the field of protective films, and provides a protective film for delivery of glass cover plates with low film tearing force. The protective film comprises a high-molecular wear-resistant base material, an acrylic low-viscosity adhesive layer and an anti-fouling isolation film, wherein one side face of the high-molecular wear-resistant base material is coated with the acrylic low-viscosity adhesive layer, and the anti-fouling isolation film adheres to the side face, away from the high-molecular wear-resistant base material, of the acrylic low-viscosity adhesive layer;the acrylic low-viscosity adhesive layer comprises, by mass, 36.0-50.0 parts of an acrylic acid copolymer, 0.3-0.6 part of an initiator, 50.0-80.0 parts of a diluent and 0.5-3 parts of a curing agent.The protective film has excellent wear resistance, weather resistance, ageing resistance and light transmittance and low film tearing force; the acrylic acid low-viscosity adhesive layer can still firmly adhere to the high-molecular wear-resistant base material in the long-distance delivery and transporting process; the protective film for delivery of the glass cover plates can be torn off easilyfrom the glass plates, and residual glue cannot be left.

Owner:惠州市科域新材料科技有限公司

A kind of polishing liquid, preparation method and application

ActiveCN105385356BExcellent wear resistance and weather resistanceBright mirror effect is goodPolishing compositions with abrasivesSoluble oxalateWear resistant

The invention belongs to the technical field of surface enhancement and protective treatment of marble or wood-based panels, and in particular relates to a polishing liquid, a preparation method and an application. The polishing solution comprises pH regulator, soluble oxalate, lubricant, fluorosilicate, nano titanium dioxide, nano silicon dioxide, coupling agent, palm wax emulsion and / or paraffin wax emulsion and water. The polishing liquid of the present invention is applied to the surface of marble or wood-based panels. Under a series of physical and chemical actions, a thick layer of dense glass-like bright substance can be formed on the surface. This glass-like bright substance is hard and has good wear resistance and weather resistance. The surface of the floor forms a bright mirror effect of "a puddle of water", which is easy to repair after the surface is scratched. When polishing the surface of marble or wood-based panels, just pour the polishing solution on the marble or wood-based panels and throw it away with a polishing pad. There is no need to use polishing steel wool, which improves production efficiency, saves costs, and improves polishing brightness.

Owner:GUANGZHOU GAOCHEN STONE TECH CO LTD

Vehicle member and manufacturing method therefor

InactiveUS8742011B2Excellent wear resistance and weather resistanceFibre treatmentSynthetic resin layered productsBenzotriazolePrepolymer

Disclosed is a vehicle member that includes a molded body and a protective film disposed on a surface of the molded body and formed by curing of an active energy ray-curing composition. The active energy ray-curing composition contains an active energy ray-curing prepolymer (A) obtainable by a reaction of an acrylic-based prepolymer having a hydroxyl group and an acrylic monomer (a4) having an isocyanate group, an active energy ray-curing compound (B) having a benzotriazole group, another active energy ray-curing compound (C) differing from the (A) component and the (B) component, and inorganic oxide particles (D). The acrylic-based prepolymer having the hydroxyl group is a copolymer that includes an acrylic monomer (a1) having a piperidinyl group, an acrylic monomer (a2) having a hydroxyl group, etc., as monomer units.

Owner:TOYOTA IND CORP

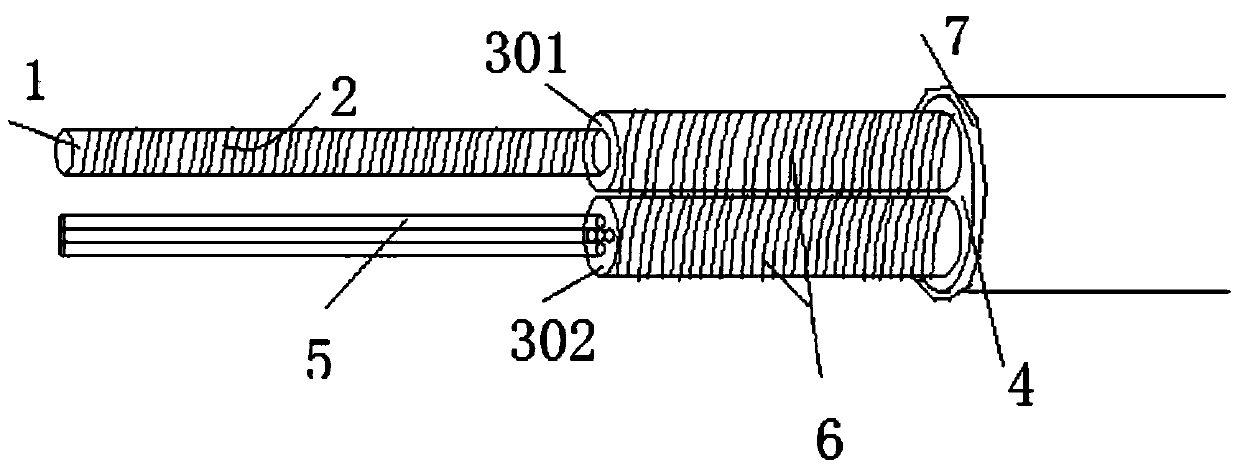

A preparation process of heating wire for pets

ActiveCN105657882BNo eccentricityRealize intelligent heatingAntifouling/underwater paintsPaints with biocidesGlass fiberEngineering

The invention discloses a preparation process for a heat-generating wire of a pet. The preparation process comprises the steps of winding the heat-generating wire on the outer periphery of a glass fiber rope; respectively extruding an inner insulating layer on the outer periphery of a conductive core wire and the outer periphery of a heating wire, wherein the conductive core wire and the heating wire are arranged side by side; respectively winding a temperature-sensing wire on the outer periphery of each inner insulating layer; respectively extruding an outer insulating layer on the outer periphery of each temperature-sensing wire; spraying the UV antimicrobial coating on the surface of the outer insulating layer; and curing the UV antimicrobial coating to form a UV antimicrobial layer. The preparation process is reasonable in technology, and excellent heat-generating wires can be prepared. The prepared heat-generating wire is flame retardant, antimicrobial, good in elasticity and toughness, non-eccentric in wire core placement, and excellent in waterproof performance. Based on the preparation process, a suitable-temperature environment is provided for pets, wherein the environment is high in safety and uniform in temperature. The preparation process can be used for preparing heating and temperature-keeping pads, fish tank heat-generating wires and the like for pets. The heat conversion rate of the preparation process is up to higher than 98%. Meanwhile, the preparation process is convenient to use and high in reliability.

Owner:DONGGUAN CITY GUANSHUN IND CO LTD

High-strength and low-cost composite well lid

InactiveCN103498485AMeet the requirements of wear resistance and weather resistanceHigh hardnessArtificial islandsUnderwater structuresCalcium hydroxideWeather resistance

A high-strength and low-cost composite well lid comprises a fiber-reinforced bottom layer, a reinforcing steel bar padding layer and a high-hardness wearproof top layer. Pulverescent self-fabricated curing agents are formed by mixing the following materials, by weight ratio, 0.025 part of tertiary butyl ester, 0.015 part of methyl ethyl ketone peroxide, 0.6 part of zinc stearate, 0.02 part of calcium hydroxide, 0.8 part of styrene and 0.4 part of polystyrene, and different reinforcing materials are used in different parts of the well lid. The lower portion of the well lib is reinforced by using fibers to guarantee the bearing capacity of the well lid, net-shaped reinforcing steel bars and a large amount of padding are used in the middle portion of the well lid to improve the non-deformability of products, materials with high hardness and good wearproof and weather resistance performance are used on the upper portion of the well lid, and different patterns and different colors are designed and adopted. Thus, the manufactured well lid can meet the wearproof and weather resistance requirements, and has the advantages of being attractive and beautiful.

Owner:ZUNYI XINXING EQUIP

Wear-resisting baked varnish for photo frame

InactiveCN105949953AImprove performanceImprove wear resistanceEpoxy resin coatingsPolyester coatingsCyclohexanoneEpoxy

The invention discloses wear-resisting baked varnish for a photo frame. The wear-resisting baked varnish is composed of a material A, a material B and a material C, the mass ratio of the material A to material B to material C is y:x:z, and y, x and z meets the following function relation: y=k(x+z), wherein (x+z) is larger than 0, y is larger than 0, and k is 0.2-1.8. The material A is prepared from epoxy resin, soya oil acid, acrylic acid, styrene, benzoyl peroxide, phthalic anhydride, colopholic acid, methylbenzene, butyl cellosolve, neopentyl glycol, tri-carboxymethyl propane, polyolefin wax and a catalyst. The material B is prepared from water-borne acrylic acid modified alkyd resin, water-borne amino resin, butylcellosolve, water-borne resin white pulp, polytetrafluoroethylene, epoxy resin adhesive, self-lubricating paint, N,N-methyl formyl, propanel, an anti-settling agent BYK-410, a flatting agent and an antifoaming agent. The material C is prepared from FEVE resin, hydroxy-containing acrylic resin, cyclohexanone, pigment, a drier, aliphatic series isocyanate and wear-resisting powder. The baked paint has excellent wear-resisting performance.

Owner:蚌埠市禹会区贵宾装饰材料商行

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com