A preparation process of heating wire for pets

A preparation process and heating wire technology, applied in the field of pet heating wire preparation technology, can solve the problems of poor stretch resistance and flexibility, poor processing performance, easy aging, etc., to achieve a large market advantage and beautiful appearance , good wear resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: This embodiment provides a preparation process of a heating wire for pets, including the following steps:

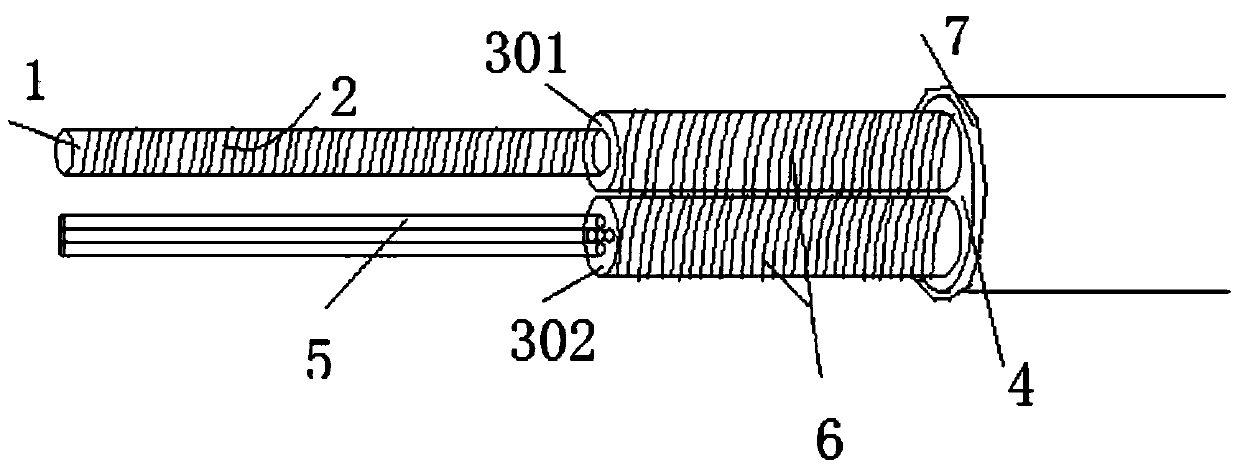

[0030] S1: Send the heating wire 2 and the glass fiber rope 1 to the winding mechanism, and automatically wind the heating wire 2 around the outer periphery of the glass fiber rope 1 through the rotation of the winding mechanism;

[0031] S2: Put the silicone material into the hopper of the extruder, extrude and coat the outer surfaces of the conductive core wire 5 and the heating wire 2 placed side by side to form the first inner insulating layer 301 and the second inner insulating layer 302; The outlet temperature was 150°C.

[0032] S3: winding the temperature-sensing wire 6 around the outer periphery of the inner insulating layers 301 and 302 through a winding mechanism;

[0033] S4: Weigh raw materials according to the following components by weight: 45 parts of PVC, 2 parts of carbon fiber and glass fiber, 5 parts of carboxylated nitrile rubbe...

Embodiment 2

[0038] Example 2: The preparation process of the heating wire for pets provided in this example is basically the same as in Example 1, except that the extrusion temperature in step S2 is 180°C; the components in step S4 are weighed according to the following parts by weight Raw materials: 30 parts of PVC, 4 parts of carbon fiber and short glass fiber with a weight ratio of 1:1, 12 parts of carboxylated nitrile rubber, 11 parts of modified calcium carbonate composite particles, and 15 parts of additives. The extrusion temperature is 250°C; additives include 3 parts of nano-silica, 10 parts of dioctyl azelate and trimellitate with a ratio of 1:2 by weight, and 2 parts of antioxidant 1010. Step S5 weighs raw materials according to the following components by weight: 35 parts of water-based polyurethane acrylate oligomer, 2 parts of photoinitiator hydroxyphenyl ketone, 2 parts of magnesium hydroxide flame retardant grafted by polyimide intercalation , 5 parts of nano silver antiba...

Embodiment 3

[0042] Example 3: The preparation process of the heating wire for pets provided in this example is basically the same as that of Example 1 or 2, except that the extrusion temperature in step S2 is 160°C; the composition of step S4 is as follows: Raw materials were weighed: 35 parts of PVC, 3 parts of carbon fiber and short glass fiber with a weight ratio of 0.9:1, 10 parts of carboxylated nitrile rubber, 10 parts of modified calcium carbonate composite particles, and 13 parts of additives; the extrusion temperature The temperature is 230°C, and the additives include 4 parts of stearic acid, 6 parts of dioctyl azelate and trimellitate at a ratio of 1:1.5 by weight, and 3 parts of antioxidant 1010. Step S5 weighs raw materials according to the following components by weight: 30 parts of water-based polyurethane acrylate oligomer, 1 part of photoinitiator hydroxyphenyl ketone, 2.5 parts of magnesium hydroxide flame retardant grafted by polyimide intercalation , 3 parts of nano si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com