Laser welding device and method for melting ball on filament end face

A technology of laser welding and welding method, applied in laser welding equipment, auxiliary devices, welding equipment and other directions, can solve the problems of eccentricity of the welding ball of medical guide wire, inaccurate control of welding heat input, easy oxidation, etc. Small influence area and improved welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

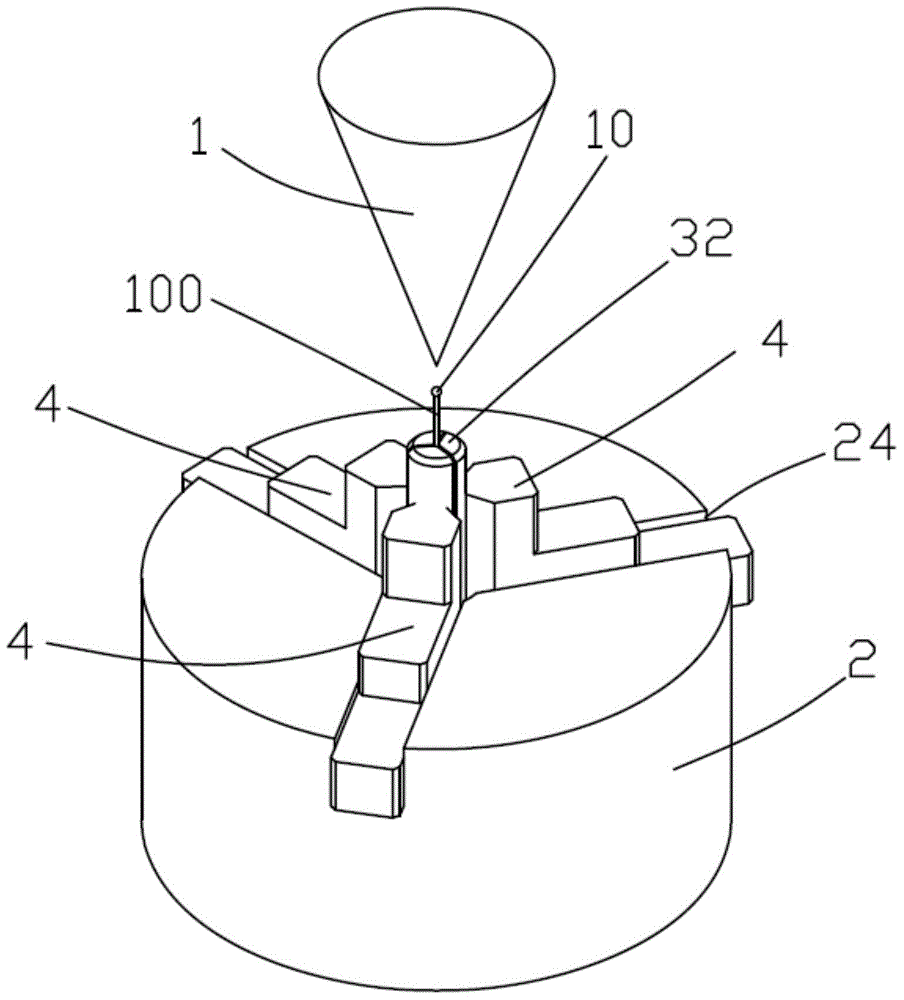

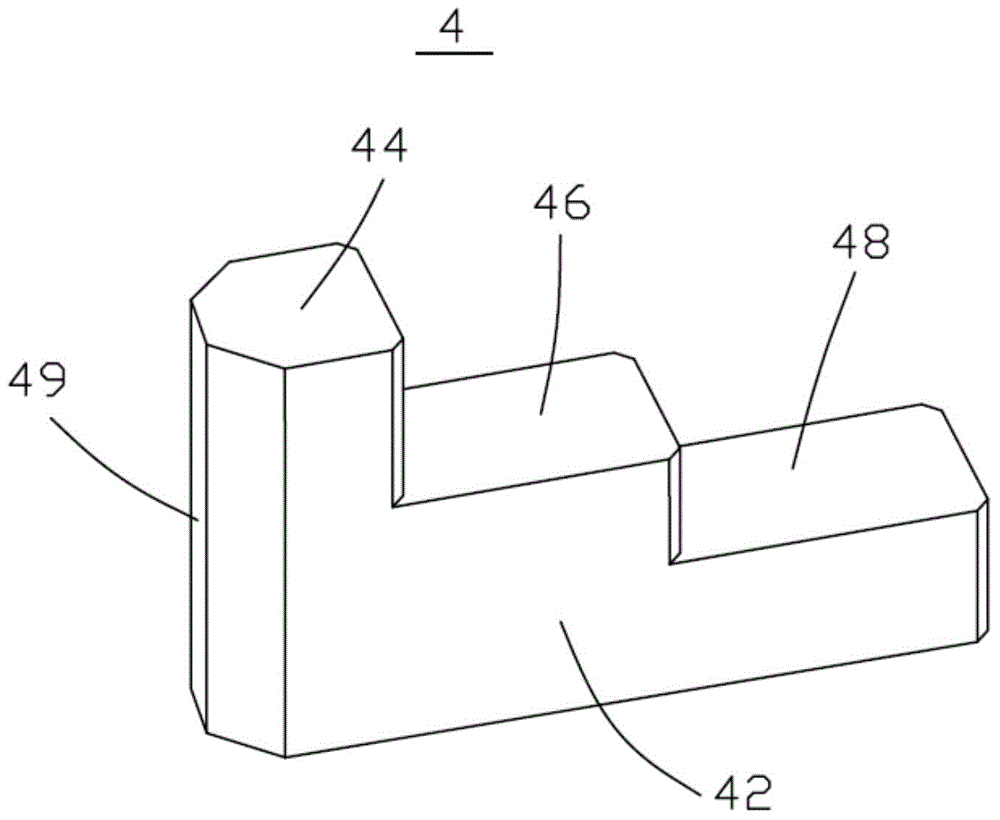

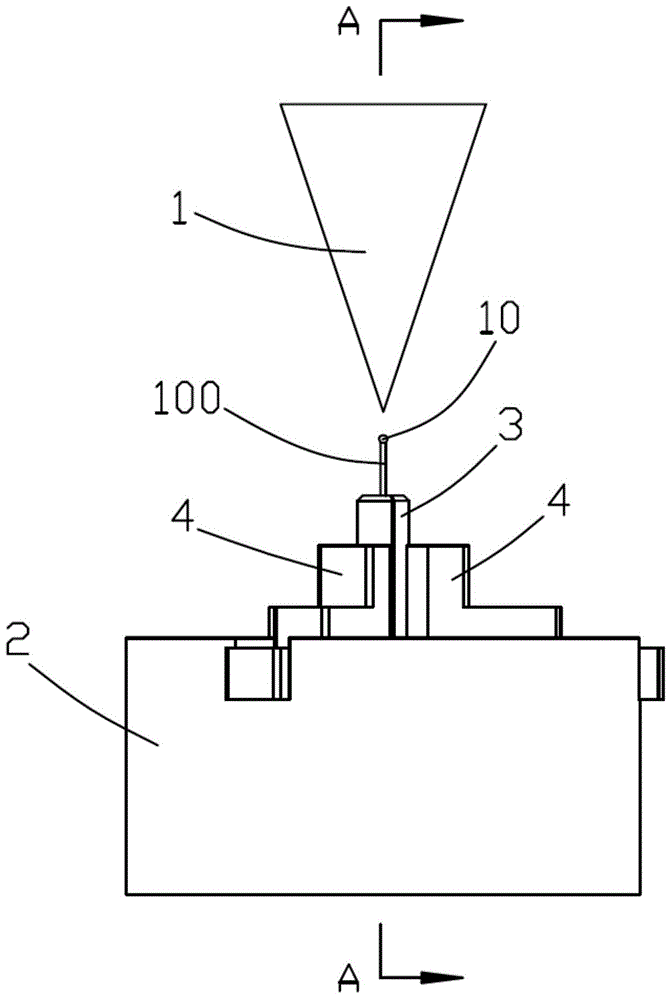

[0027] see Figure 1 to Figure 4 , the laser welding device of the wire end face of the present invention includes a laser (not shown) for generating a laser beam 1, a round table 2, and a clamping member 3 for clamping and fixing the filament 100 (see image 3 ) and a plurality of fixed blocks 4, the clamping member 3 is vertically fixed to the center of the round platform 2, and the plurality of fixed blocks 4 are symmetrically fixed on the round platform 2 with respect to the filament 100 and abut against On the clamping member 3 , the laser beam 1 is arranged coaxially with the filament 100 , and the filament 100 can rotate around the axis of the filament 100 driven by the rotation of the round table 2 . In this way, the laser welding of the filament 100 is carried out during high-speed rotation. Due to the action of centrifugal force, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com