Fire-proof material for power cable

A technology of refractory materials and power cables, applied in the direction of insulating cables, cables, circuits, etc., can solve problems such as the lack of mechanical strength of burnt residues, failure to maintain product integrity, dangerous secondary disasters, etc., achieve excellent processing performance, prevent water The effect of stable infiltration and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

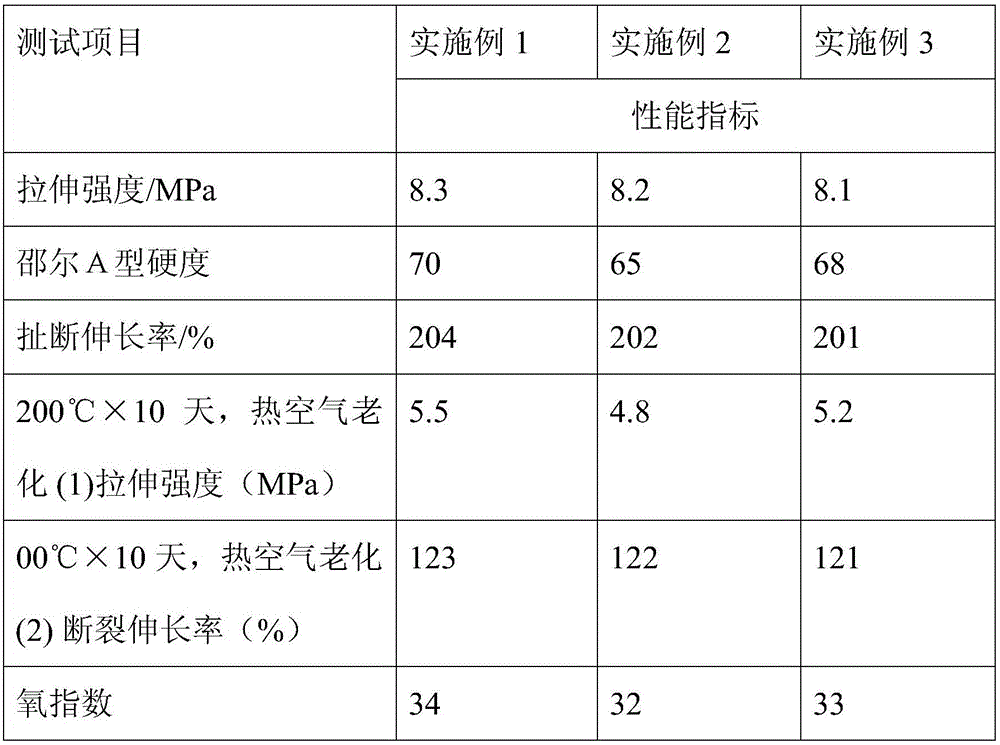

Embodiment 1

[0015] Embodiment 1. A refractory material for power cables. The material is composed of the following raw materials in parts by weight. The material is composed of the following raw materials in parts by weight. The composition of parts by weight is 100 parts of silicone rubber, 45 parts of glass fiber, 20 parts of D4-treated fumed silica, 15 parts of fumed silica, 40 parts of mica, 20 parts of quartz powder, and 4 parts of rutile titanium dioxide. 2 parts, 7 parts of coupling agent, 252 parts of vulcanizing agent, 4 parts of hydroxy silicone oil, 6 parts of flame retardant, 4 parts of heat stabilizer, 3 parts of anti-termite agent; described flame retardant is aluminum hydroxide and hydroxide The ratio of magnesium, aluminum hydroxide and magnesium hydroxide is 1 / 9-6 / 4; the heat stabilizer is selenium oxide, selenium hydroxide or selenium octoate; the mass fraction of hydroxyl in the hydroxy silicone oil is 0.09.

Embodiment 2

[0016] Embodiment 2, a kind of refractory material for power cables, the material is composed of the following raw materials in parts by weight, the material is composed of the following raw materials in parts by weight, and the material is composed of the following raw materials Parts by weight ratio, the material is composed of the following raw materials by weight ratio, 80 parts of silicone rubber, 40 parts of glass fiber, 15 parts of fumed silica treated with D4, and 10 parts of fumed silica , 30 parts of mica, 15 parts of quartz powder, 3 parts of rutile titanium dioxide, 6 parts of coupling agent, 1 part of vulcanizing agent Shuang25, 3 parts of hydroxyl silicone oil, 4 parts of flame retardant, 3 parts of heat stabilizer, anti-termite agent 1 part; the flame retardant is aluminum hydroxide and magnesium hydroxide, and the ratio of aluminum hydroxide and magnesium hydroxide is 1 / 9 to 6 / 4; the heat stabilizer is selenium oxide, selenium hydroxide or selenium octoate; the...

Embodiment 3

[0017] Embodiment 3, a kind of refractory material for power cables, the described material is composed of the following raw materials in proportions by weight, the material is composed of the following raw materials in proportions by weight, 120 parts of silicone rubber, 50 parts of glass fiber 30 parts of fumed silica, 20 parts of fumed silica, 50 parts of mica, 25 parts of quartz powder, 5 parts of rutile titanium dioxide, 8 parts of coupling agent, 3 parts of vulcanizing agent 25 parts, 5 parts of hydroxy silicone oil, 8 parts of flame retardant, 5 parts of heat stabilizer, 2 parts of anti-termite agent; the flame retardant is aluminum hydroxide and magnesium hydroxide, and the ratio of aluminum hydroxide and magnesium hydroxide is 1 / 9~6 / 4; the heat stabilizer is selenium oxide, selenium hydroxide or selenium octanoate; the mass fraction of hydroxyl in the hydroxyl silicone oil is 0.09.

[0018] During preparation, the raw materials were mixed in a Z-type paddle mixer for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com