Low-smoke, halogen-free, high-flame-retardance, oil-resistant and cold-resistant cable material, preparation method thereof and cable

A cable material, high flame-retardant technology, applied in the field of halogen-free flame-retardant cable material and its preparation, can solve the problems of unsatisfactory weather resistance, not well resolved, and poor low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of the cable can adopt conventional techniques in the art.

[0054] Preparation

[0055] The third aspect of the present invention provides a method for preparing the low-smoke, halogen-free, highly flame-retardant, oil-resistant and cold-resistant cable material of the present invention, the preparation method comprising the following steps:

[0056] 1) Put the prescribed amount of methyl vinyl silicone rubber and EVA into the mixer, and mix for 3-4 minutes;

[0057] 2) Put all the remaining ingredients into the internal mixer, and continue to banbury together with the previously input methyl vinyl silicone rubber and EVA for 5-6 minutes; the whole banbury process takes 8-10 minutes to get the finished banbury semi-finished products;

[0058]3) The semi-finished product after banburying is extruded and granulated by double-cone feeding device and twin-screw extruder to obtain the low-smoke, halogen-free, high-flame-retardant, oil-resistant and ...

Embodiment 1

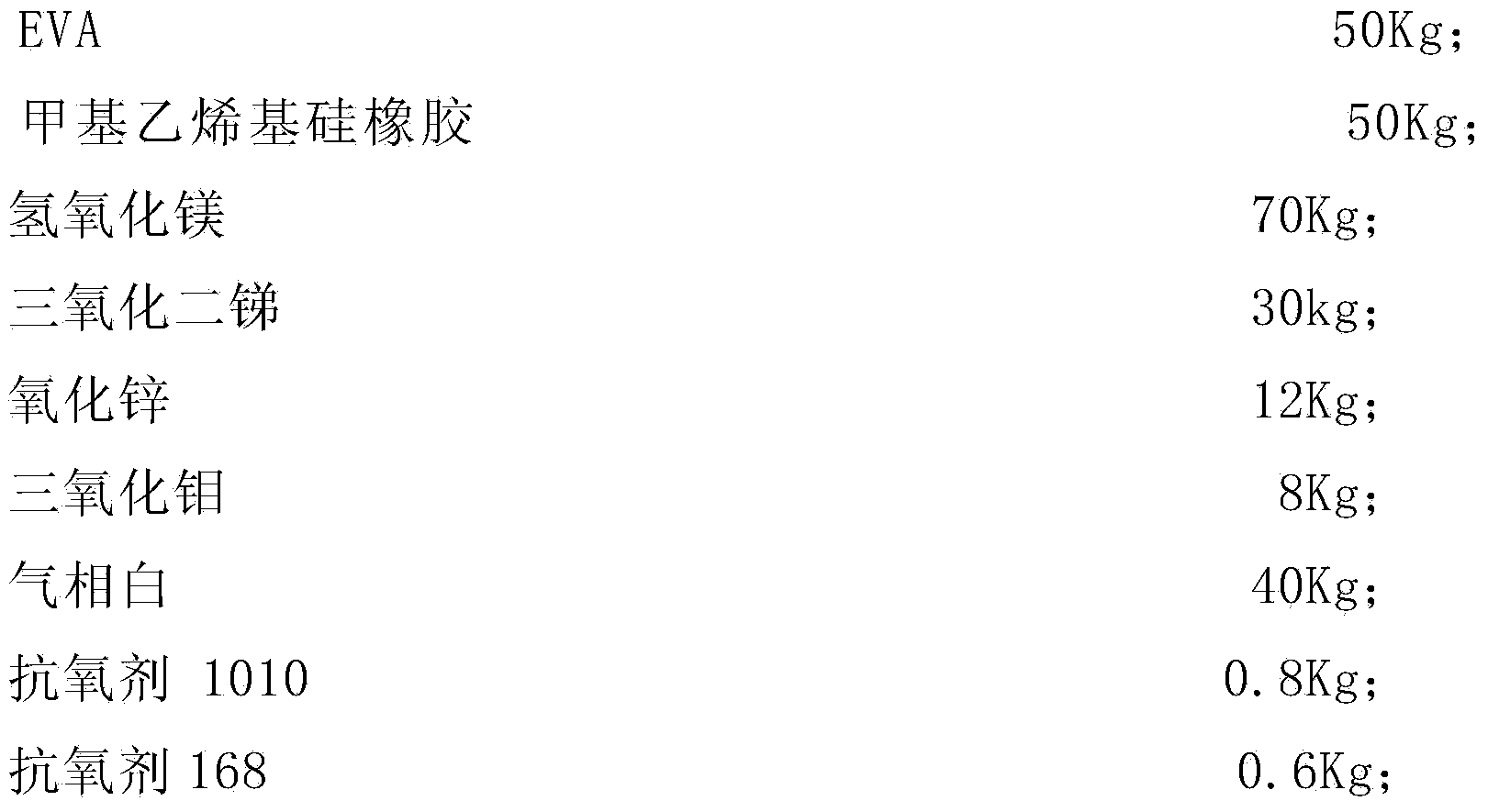

[0067] Each component name and each component parts by weight are as follows:

[0068]

[0069]

[0070] The preparation method of the above-mentioned invention, it comprises the following processing steps:

[0071] 1) Put the prescribed amount of methyl vinyl silicone rubber and EVA into the mixer, and mix for 3-4 minutes;

[0072] 2) Put all the remaining ingredients into the internal mixer, and continue to banbury together with the previously input methyl vinyl silicone rubber and EVA for 5-6 minutes; the whole banbury process takes 8-10 minutes to get the finished banbury Semi-finished products; 3) The semi-finished products that have been banburyed are extruded and granulated through a double-cone feeding device and a twin-screw extruder to obtain the low-smoke, halogen-free, high-flame-retardant, oil-resistant and cold-resistant cable material; each of the twin-screws The stage temperature control starts from the feeding port, which is 90-100°C, 90-100°C, 90-95°C,...

Embodiment 2

[0075] Each component name and each component parts by weight are as follows:

[0076]

[0077] The preparation method of above-mentioned cable material is identical with embodiment 1

[0078] The product in embodiment 2 is carried out performance detection test, and each performance numerical value is as shown in performance embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com