High-flame-retardant oil-resistant low-temperature resistant neoprene cable material and preparation process thereof

A technology of neoprene and chlorinated butyl rubber, applied to rubber insulators, organic insulators, etc., can solve the problems of expensive imported neoprene, achieve superior processing performance and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

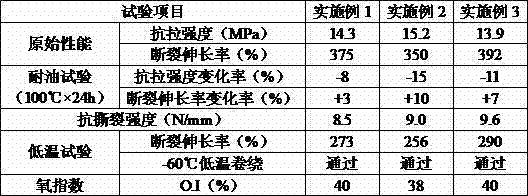

Embodiment 1

[0029] A high flame-retardant, oil-resistant and low-temperature-resistant neoprene cable material disclosed by the present invention uses 60 parts of neoprene, 40 parts of chlorinated butyl rubber, 4 parts of antimony trioxide, and 15 parts of decabromodiphenyl ether. 1 part of stearic acid, 8 parts of vaseline, 2 parts of white wax, 5 parts of dioctyl sebacate, 0.4 parts of silane coupling agent KH-550, 10 parts of N-330 carbon black, 15 parts of white carbon black, 60 parts of calcined clay , 5 parts of zinc oxide, 4 parts of magnesium oxide, 1 part of NA-22, 3 parts of ODA as raw materials.

[0030] A method for preparing a highly flame-retardant, oil-resistant, and low-temperature-resistant neoprene cable material disclosed by the present invention specifically includes the following steps:

[0031] a. Put neoprene and chlorinated butyl rubber into the internal mixer, masticate for 2 minutes, control the rubber discharge temperature at 60°C; discharge the rubber to the X...

Embodiment 2

[0035] A high flame-retardant, oil-resistant and low-temperature-resistant neoprene cable material disclosed by the present invention uses 50 parts of neoprene rubber, 50 parts of chlorinated butyl rubber, 8 parts of antimony trioxide, and 8 parts of decabromodiphenyl ether. 3 parts of stearic acid, 8 parts of vaseline, 2 parts of white wax, 30 parts of N-330 carbon black, 6 parts of zinc oxide, 5 parts of magnesium oxide, 1 part of NA-22, and 6 parts of ODA are used as raw materials.

[0036] A method for preparing a highly flame-retardant, oil-resistant, and low-temperature-resistant neoprene cable material disclosed by the present invention specifically includes the following steps:

[0037] a. Put neoprene and chlorinated butyl rubber into the internal mixer, masticate for 6 minutes, control the rubber discharge temperature at 90°C; discharge the rubber to the XK-450 open mixer, thin pass 3 times, and roll up for use;

[0038] b. Put the glue prepared in step a, antimony...

Embodiment 3

[0041] A high flame-retardant, oil-resistant and low-temperature-resistant neoprene cable material disclosed by the present invention uses 55 parts of neoprene, 45 parts of chlorinated butyl rubber, 15 parts of antimony trioxide, and 4 parts of decabromodiphenyl ether. 3 parts of Vaseline, 2 parts of white wax, 15 parts of dioctyl sebacate, 4 parts of silane coupling agent KH-550, 80 parts of white carbon black, 20 parts of clay, 8 parts of zinc oxide, and 5 parts of ODA are used as raw materials.

[0042] A method for preparing a highly flame-retardant, oil-resistant, and low-temperature-resistant neoprene cable material disclosed by the present invention specifically includes the following steps:

[0043] a. Put neoprene and chlorinated butyl rubber into the internal mixer, masticate for 5 minutes, and control the rubber discharge temperature at 80°C; discharge the rubber to the XK-450 open mill, and roll it up after 5 times of thinning;

[0044] b. The glue prepared in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com