A kind of colored road paint

A road and coating technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of wear resistance, weather resistance, corrosion resistance and unsatisfactory adhesion, and achieve strong adhesion performance, Strong corrosion resistance, excellent wear resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 A kind of colored road coating is prepared according to the following steps:

[0020] 21 parts of bisphenol A type epoxy resin, 25 parts of anionic water-based styrene-acrylic emulsion, 16 parts of propylene glycol, 9 parts of organic bentonite, 9 parts of barium sulfate, 9 parts of color paste, 31 parts of deionized water, 2-hydroxy-4-normal 0.168 parts of octyloxybenzophenone, 0.21 parts of phenylenedioctyl phosphite, 8 parts of silica lime, 46 parts of quartz sand, 18 parts of triethylenetetramine, and 9 parts of talcum powder passed through a 800-mesh sieve;

[0021] (1) Mix the above-mentioned amount of epoxy resin, water-based styrene-acrylic emulsion, propylene glycol, wollastonite, talc powder (800 mesh), color paste, and deionized water according to the above-mentioned ratio, and stir until there are no large particles or clusters after melting When the phenomenon occurs, add the above-mentioned amount of organic bentonite and barium sulfate, stir,...

Embodiment 2

[0026] Embodiment 2 A kind of colored road paint, is prepared according to the following steps:

[0027] 18 parts of bisphenol A epoxy resin, 22 parts of anionic water-based styrene-acrylic emulsion, 15 parts of propylene glycol, 7 parts of organic bentonite, 8 parts of barium sulfate, 8 parts of color paste, 25 parts of deionized water, 2-hydroxy-4- 0.054 parts of n-octyloxybenzophenone, 0.054 parts of phenylenedioctyl phosphite, 6 parts of silica lime, 42 parts of quartz sand, 15 parts of triethylenetetramine, and 7 parts of talcum powder passed through a 800-mesh sieve;

[0028] Preparation process: prepared according to the preparation process of Example 1.

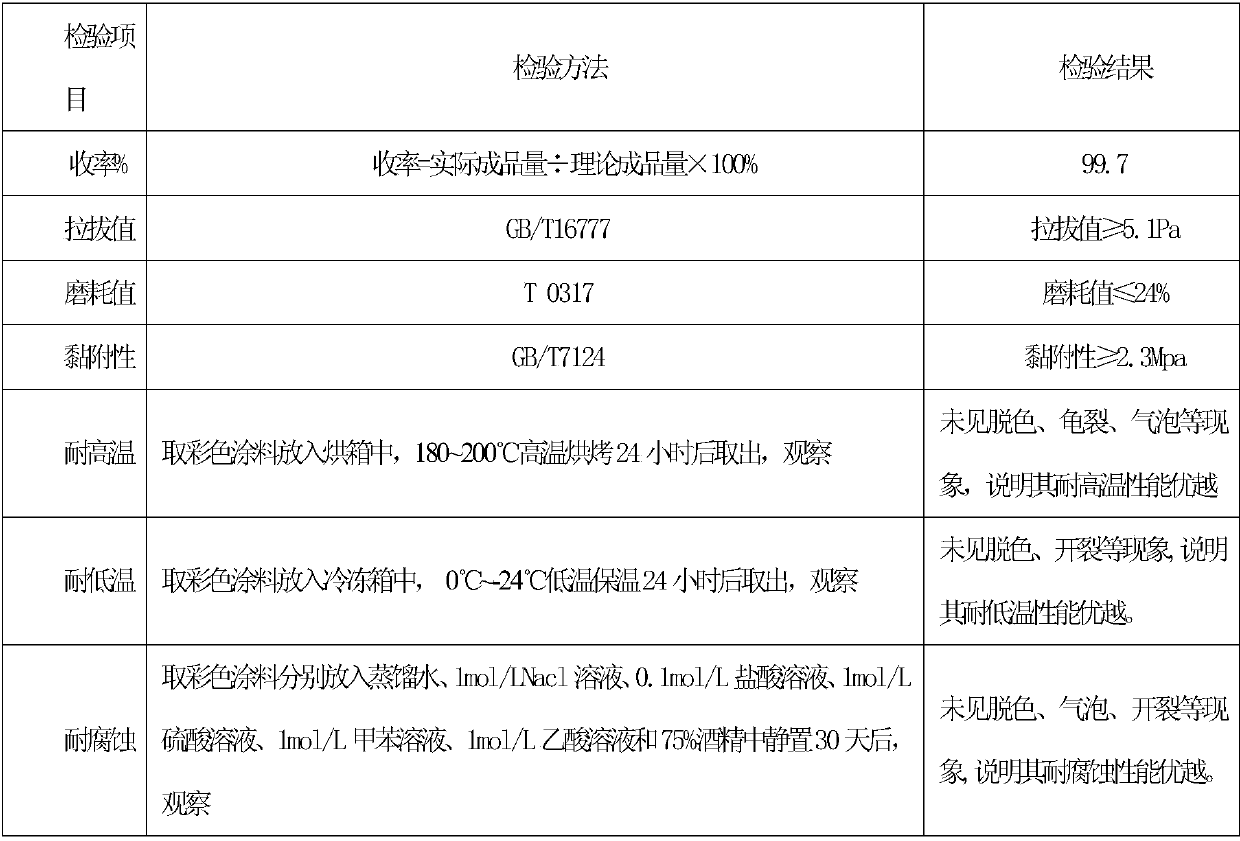

[0029] The color paint prepared by the above method is verified according to the corresponding experiment in "Pavement Marking Paint", and the experimental results are shown in the following table:

[0030]

Embodiment 3-6

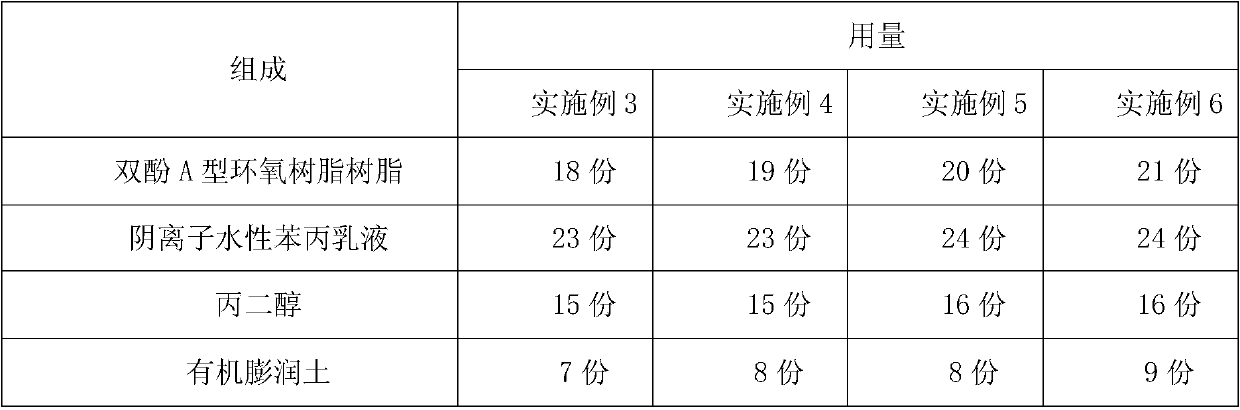

[0031] Embodiment 3-6: a kind of colored road coating, is prepared according to the following steps:

[0032]

[0033]

[0034] Preparation process: prepared according to the preparation process of Example 1.

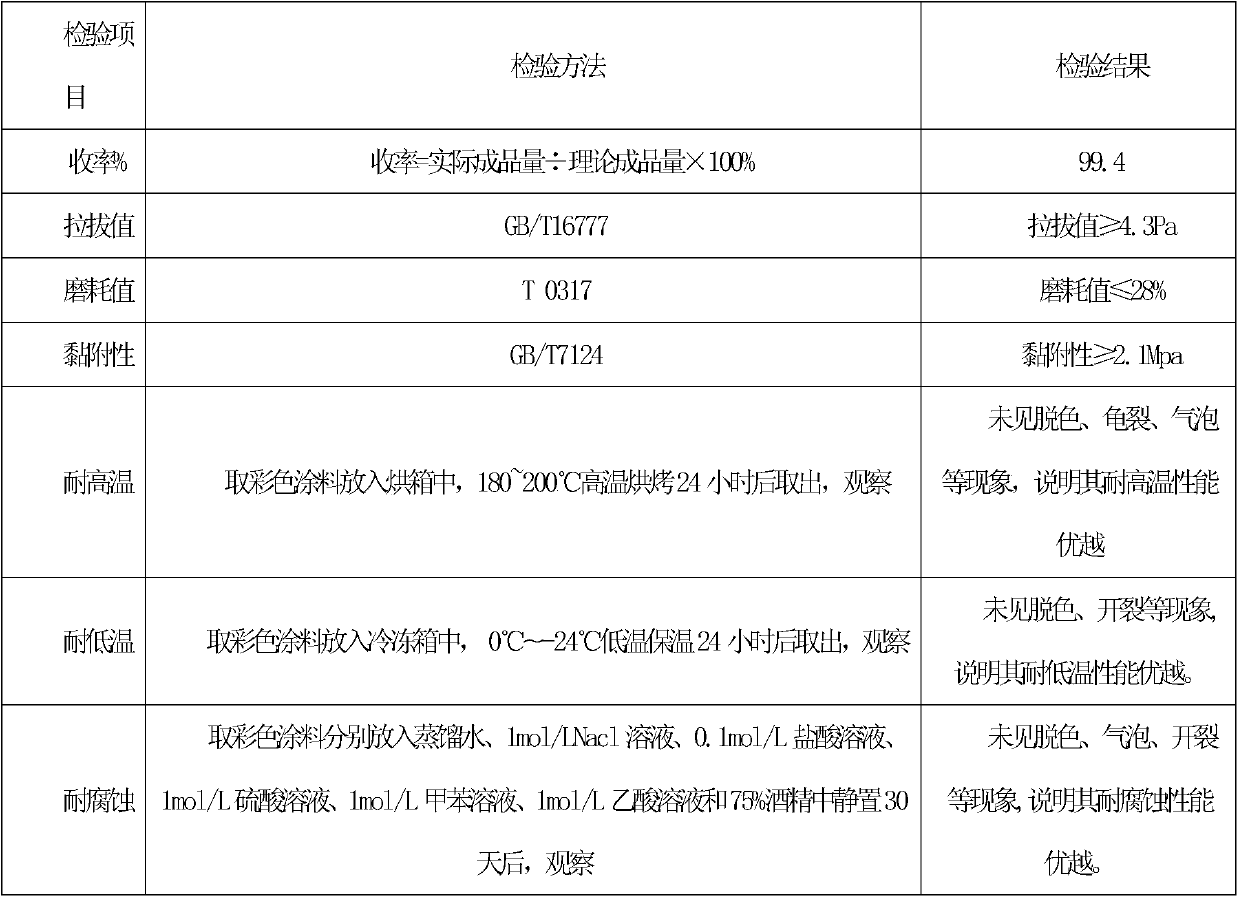

[0035] The color paint that will be made by the above method is verified according to the corresponding experiment in "Pavement Marking Paint". The test method is shown in Example 1, and its experimental results are shown in the following table:

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com