Multi-layer molded high-load-bearing municipal road well lid and manufacturing method thereof

A municipal road, multi-layer molding technology, used in artificial islands, infrastructure engineering, construction, etc., can solve problems such as unreasonable formulation components and processing technology, manhole cover load-bearing capacity and service life problems, etc., to improve affinity and penetration. Good strength, wear resistance and weather resistance, good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

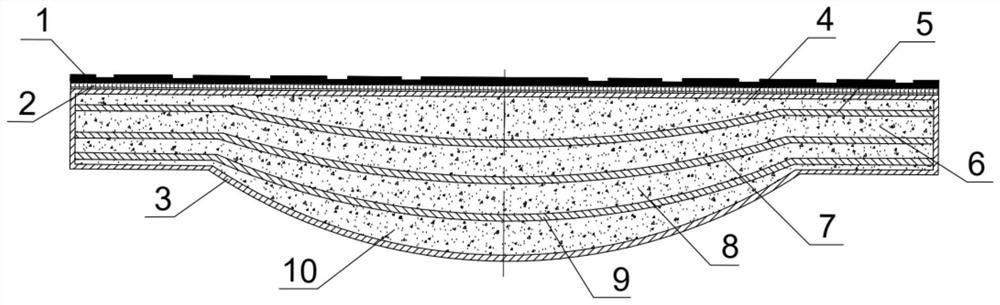

[0042] Embodiment 1: as figure 1 As shown, a multi-layer molded high load-bearing municipal road manhole cover includes a wear-resistant layer 1, a fixed support layer 2, a protective layer 3, a first filling layer 4, a first reinforcement layer 5, a second filling layer 6, and a second reinforcement layer. Layer 7, third filling layer 8, third reinforcement layer 9, fourth filling layer 10.

[0043]The upper surface of the protective layer 3 is covered with a fixed support layer 2, the fixed support layer 2 is equipped with a wear-resistant layer 1, and the first reinforcement layer 5 and the second reinforcement layer are sequentially arranged in the protection layer 3 from top to bottom. 7 and the third reinforcement layer 9, the first filling layer 4 is filled between the inner top surface of the protection layer 3 and the first reinforcement layer 5, and the first filling layer 4 is filled between the first reinforcement layer 5 and the second reinforcement layer 7 Two f...

Embodiment 2

[0069] Embodiment 2: as figure 1 As shown, a multi-layer molded high load-bearing municipal road manhole cover includes a wear-resistant layer 1, a fixed support layer 2, a protective layer 3, a first filling layer 4, a first reinforcement layer 5, a second filling layer 6, and a second reinforcement layer. Layer 7, third filling layer 8, third reinforcement layer 9, fourth filling layer 10.

[0070] The upper surface of the protective layer 3 is covered with a fixed support layer 2, the fixed support layer 2 is equipped with a wear-resistant layer 1, and the first reinforcement layer 5 and the second reinforcement layer are sequentially arranged in the protection layer 3 from top to bottom. 7 and the third reinforcement layer 9, the first filling layer 4 is filled between the inner top surface of the protection layer 3 and the first reinforcement layer 5, and the first filling layer 4 is filled between the first reinforcement layer 5 and the second reinforcement layer 7 Two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com