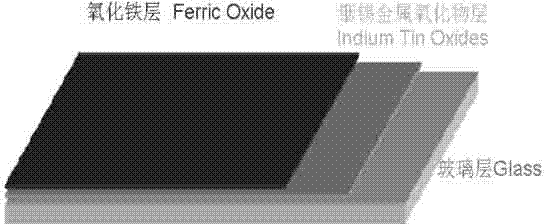

Production method for depositing iron oxide film on ITO conductive glass

A technology of conductive glass and iron oxide, which is applied in the field of metal oxide semiconductor thin film preparation, can solve the problems of unresolved film uniformity and adhesion firmness, complex control factors and conditions, and high equipment requirements, and achieves convenient control and Flexible, good light transmission performance, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Initial solution preparation: Weigh a certain amount of ferric nitrate and sodium oxalate so that the molar ratio of ferric ions and oxalate is 1:3, dissolve them in deionized water to form a solution of ferric trioxalate with a concentration of 0.05M.

[0025] Conductive glass preparation: Cut the conductive glass according to the size of 2cm×2cm, and then wash it. The washing sequence is detergent solution-deionized water-acetone-absolute ethanol, and each solution is washed under ultrasonic for 20min.

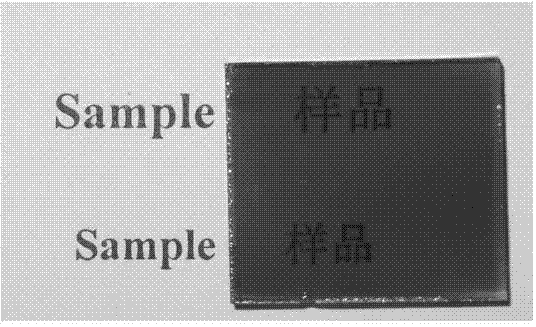

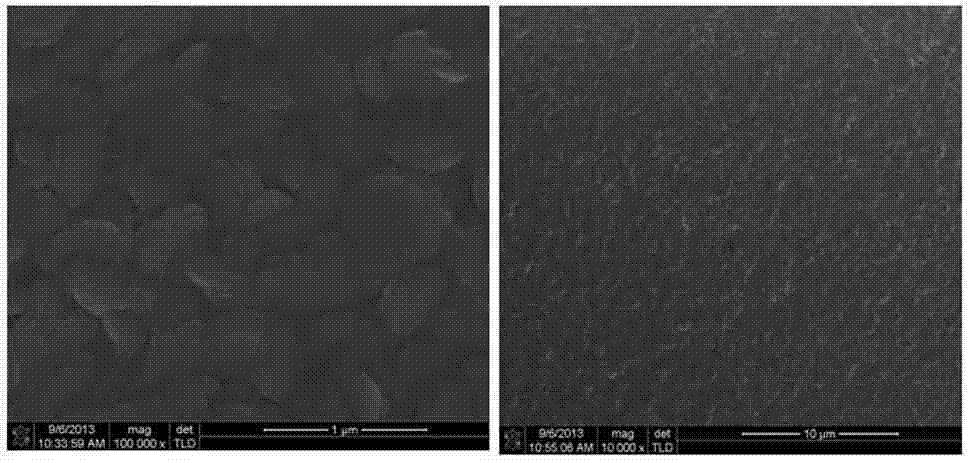

[0026] Thin film deposition: Put the ITO conductive glass vertically into the polytetrafluoroethylene-lined cup of the reaction kettle, pour the initial reaction solution, put it in the stainless steel reaction kettle, put it into the constant temperature furnace after sealing, and set the temperature 160°C, constant temperature for 12 hours, after natural cooling to room temperature, unseal, take out the conductive glass, wash with deionized water and ethanol several ...

Embodiment 2

[0028] The preparation of the initial solution and the preparation of the conductive glass are the same as in Example 1.

[0029] Thin film deposition: the process is the same as Example 1, but the reaction conditions are changed to 170° C. for 8 hours at a constant temperature, and an iron oxide film with good transparency is also obtained.

Embodiment 3

[0031] The preparation of the initial solution and the preparation of the conductive glass are the same as in Example 1.

[0032] Thin film deposition: the process is the same as Example 1, but the reaction conditions are changed to 180° C. for 4 hours at a constant temperature, and an iron oxide film with good transparency is also obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com