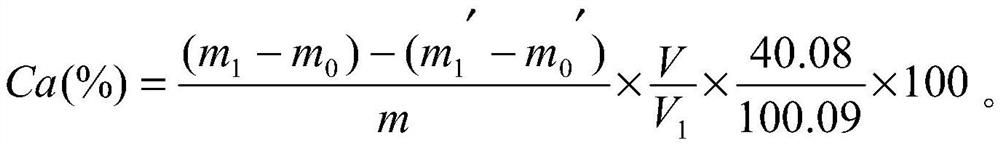

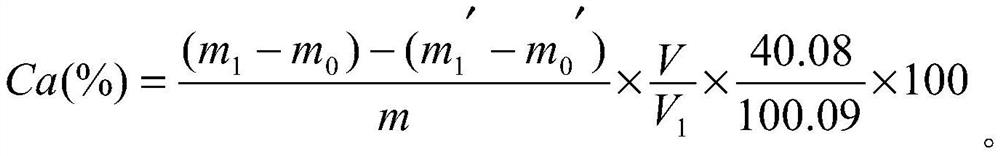

Method for measuring calcium content in feed

A method for measuring calcium content, which is applied in measuring devices, weighing materials, and analyzing materials, can solve the problems of easy sealing of indicators, high detection costs, and expensive instruments, and achieve easy operation, popularization, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

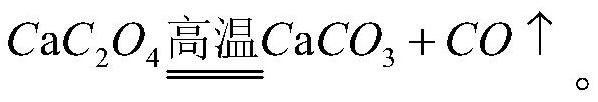

[0095] This embodiment provides a method for determining calcium content in feed, which can be carried out according to the following steps.

[0096] 1 Preparation of reagents required for the experiment

[0097] 1.1 concentrated nitric acid;

[0098] 1.2 Hydrochloric acid solution: mix hydrochloric acid and distilled water at a volume ratio of 1:3;

[0099] 1.3 Ammonia solution: mix ammonia water and distilled water at a volume ratio of 1:1;

[0100] 1.4 urea;

[0101] 1.5 Ammonium oxalate solution (42g / L): Weigh 42g ammonium oxalate and dissolve in 1000mL water;

[0102] 1.6 Ammonium oxalate solution (1g / L): Weigh 1g of ammonium oxalate and dissolve it in 1000mL of water;

[0103] 1.7 Calcium chloride solution (10g / L): Weigh 1g of calcium chloride solution and dissolve it in 100mL of water;

[0104] 1.8 Methyl red indicator (1g / L): Weigh 0.1g methyl red and dissolve in 100mL 95% ethanol;

[0105] 1.9 Quantitative slow filter paper: the diameter is 15cm, and the pore si...

Embodiment 2

[0178] This embodiment provides a method for determining calcium content in feed, which can be carried out according to the following steps.

[0179] 1 Preparation of sample decomposition solution

[0180] Weigh 4g of fishmeal from 5 different feed ingredients in a crucible, accurate to 0.0001g, carbonize carefully on an electric furnace, then put it into a muffle furnace and burn at 550°C for 3 hours until there are no carbon particles, take it out and cool it to room temperature, and put it in a crucible Add 10mL of 1+3 hydrochloric acid solution and 3 drops of concentrated nitric acid, boil carefully, transfer this solution into a 100mL volumetric flask, cool to room temperature, dilute with water to the mark, shake well, and become the sample decomposition solution.

[0181] 2 Precipitation of calcium ions

[0182] Accurately pipette 50mL of decomposition solution into a 250mL beaker, add water to dilute to 100ml, add 2 drops of methyl red indicator, add 1+1 ammonia water...

Embodiment 3

[0193] This embodiment provides a method for determining calcium content in feed, which can be carried out according to the following steps.

[0194] 1 Preparation of sample decomposition solution

[0195] Weigh 3g of fishmeal from 5 different feed ingredients into a crucible, accurate to 0.0001g, carbonize carefully on an electric furnace, then put it into a muffle furnace and burn at 550°C for 3 hours until there are no carbon particles, take it out and cool it to room temperature, and put it in a crucible Add 10mL of 1+3 hydrochloric acid solution and 3 drops of concentrated nitric acid, boil carefully, transfer this solution into a 100mL volumetric flask, cool to room temperature, dilute with water to the mark, shake well, and become the sample decomposition solution.

[0196] 2 Precipitation of calcium ions

[0197] Accurately pipette 30mL of decomposition solution into a 250mL beaker, add water to dilute to 100ml, add 2 drops of methyl red indicator, add 1+1 ammonia wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com