Precise Temperature Measurement Method for Sand Casting Based on Positioning of Temperature Measurement Unit

A technology of sand casting and temperature measurement, which is applied in the parts of thermometers, thermometers, and heat measurement, and can solve problems that need to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The precise measurement steps of the temperature field in the aluminum alloy sand casting process are as follows:

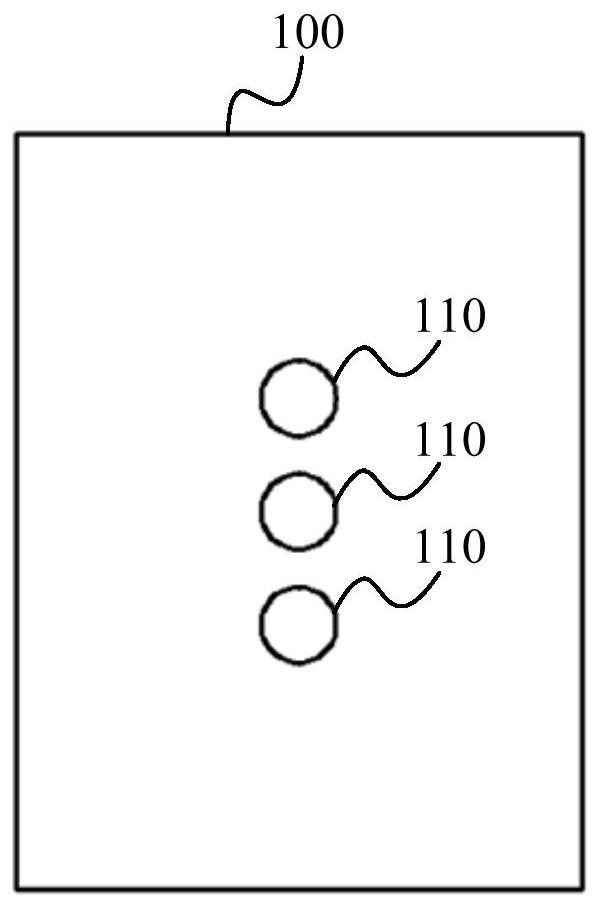

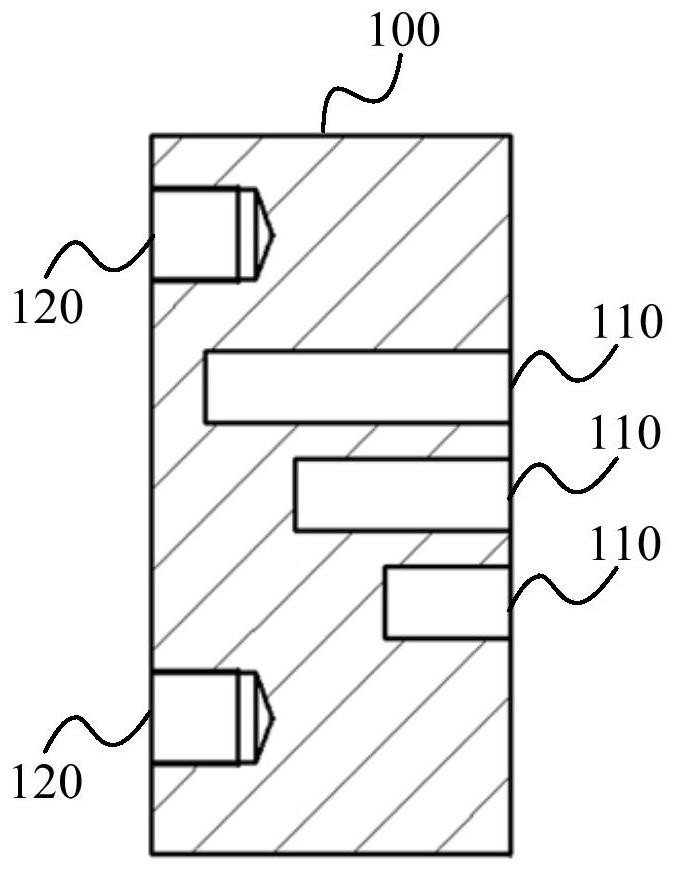

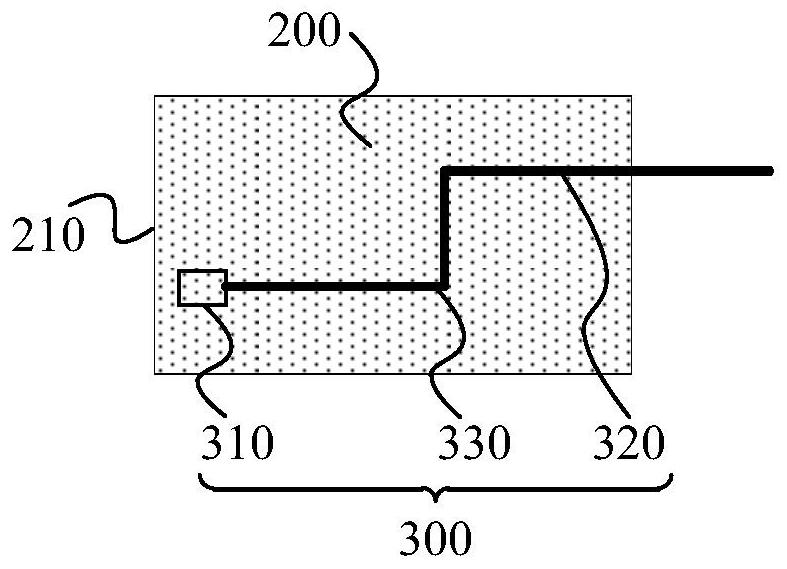

[0061] 1. Design the temperature measurement unit. The temperature measurement unit includes three parts: sand block, limit block and thermocouple. The sand block is the main body of the temperature measuring unit, which is made of the same material as the molding sand to avoid the disturbance of the temperature field caused by different materials. The limit block is used to locate the thermocouple in the sand block, and it plays a positioning role. It can be processed with aluminum, iron and other alloys. After the positioning is completed, it will be taken out of the temperature measurement unit. The casting used for the experimental test is a flat casting of 200mm×200mm×20mm. The shape of the sand block is designed according to the shape of the casting surface to ensure that it can fit the casting surface. Corresponding positioning grooves are process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com