Teaching experiment system control module for mechanics of material

An experimental system and material mechanics technology, applied in the field of material mechanics teaching experiment system control module, can solve the problems of single use, poor versatility and high cost

Inactive Publication Date: 2008-01-30

山东省机电学校

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of this invention is to provide a kind of material mechanics teaching experiment system control module, it is used in cooperation with existing computer, and is connected with the sensor of different types on various test equipments, the analog and digital of various different types of sensors Signals can all be processed and converted by the present invention for computer processing, calculation and display of experimental results. It can solve the problem that the existing technology must be developed item by item according to the different functions of the testing machine and the cost is high, and it also solves the problem of Solve the problems of single purpose, poor versatility and cumbersome comprehensive teaching operation existing in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

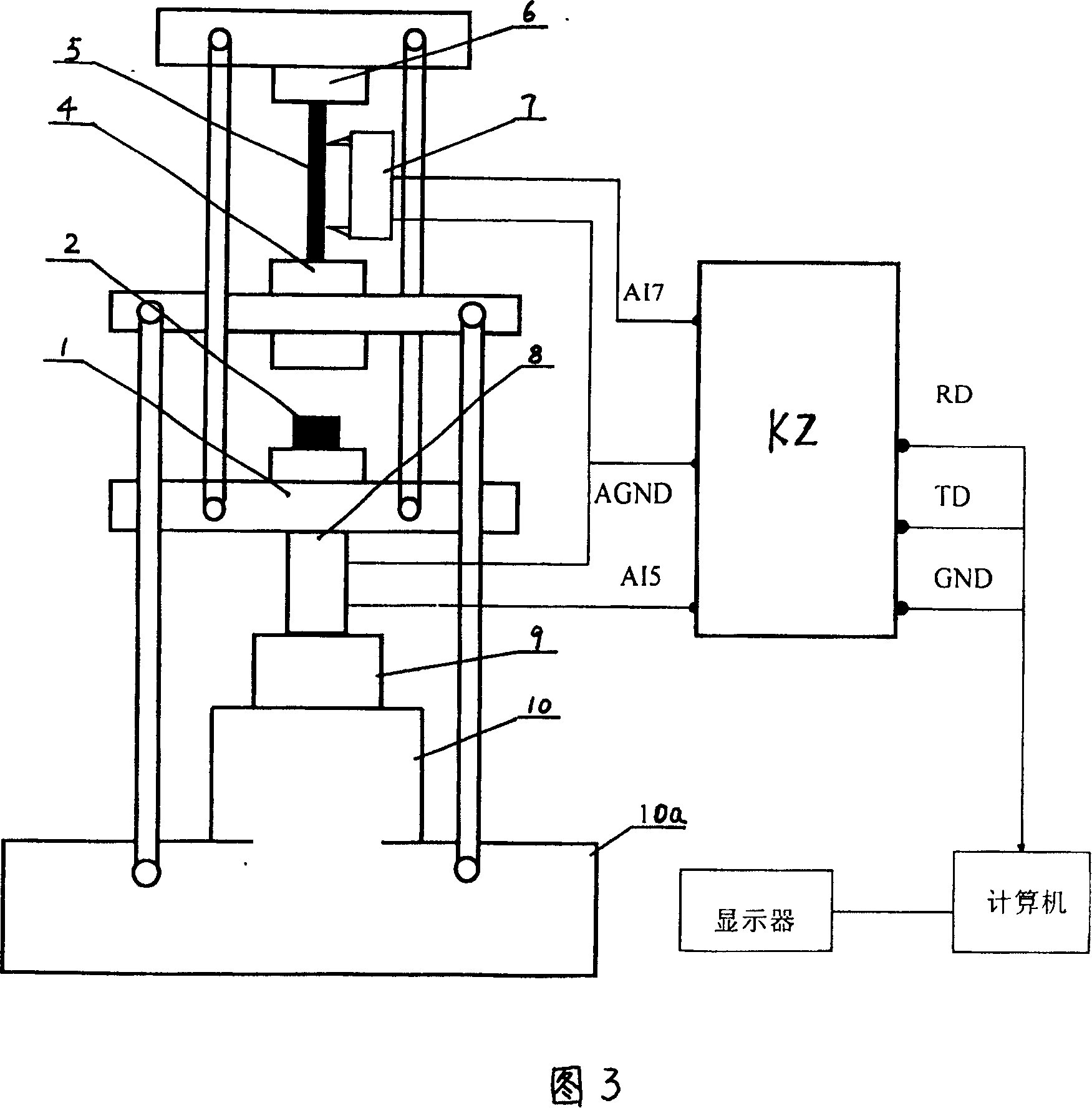

[0042] 1. The present invention is applied to tensile and compression testing machines and used as an extensometer

[0043] a. Tensile test on the specimen

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

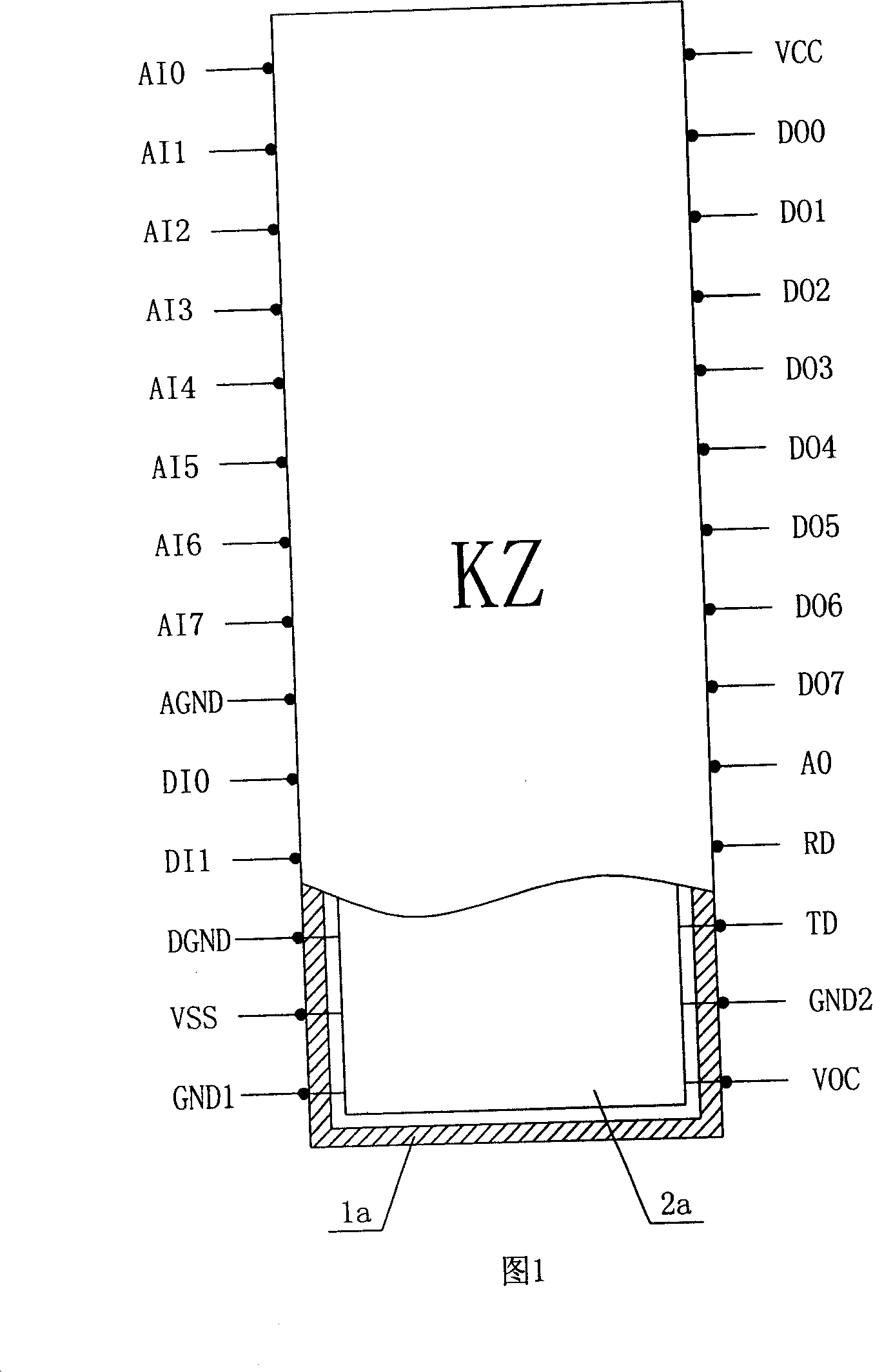

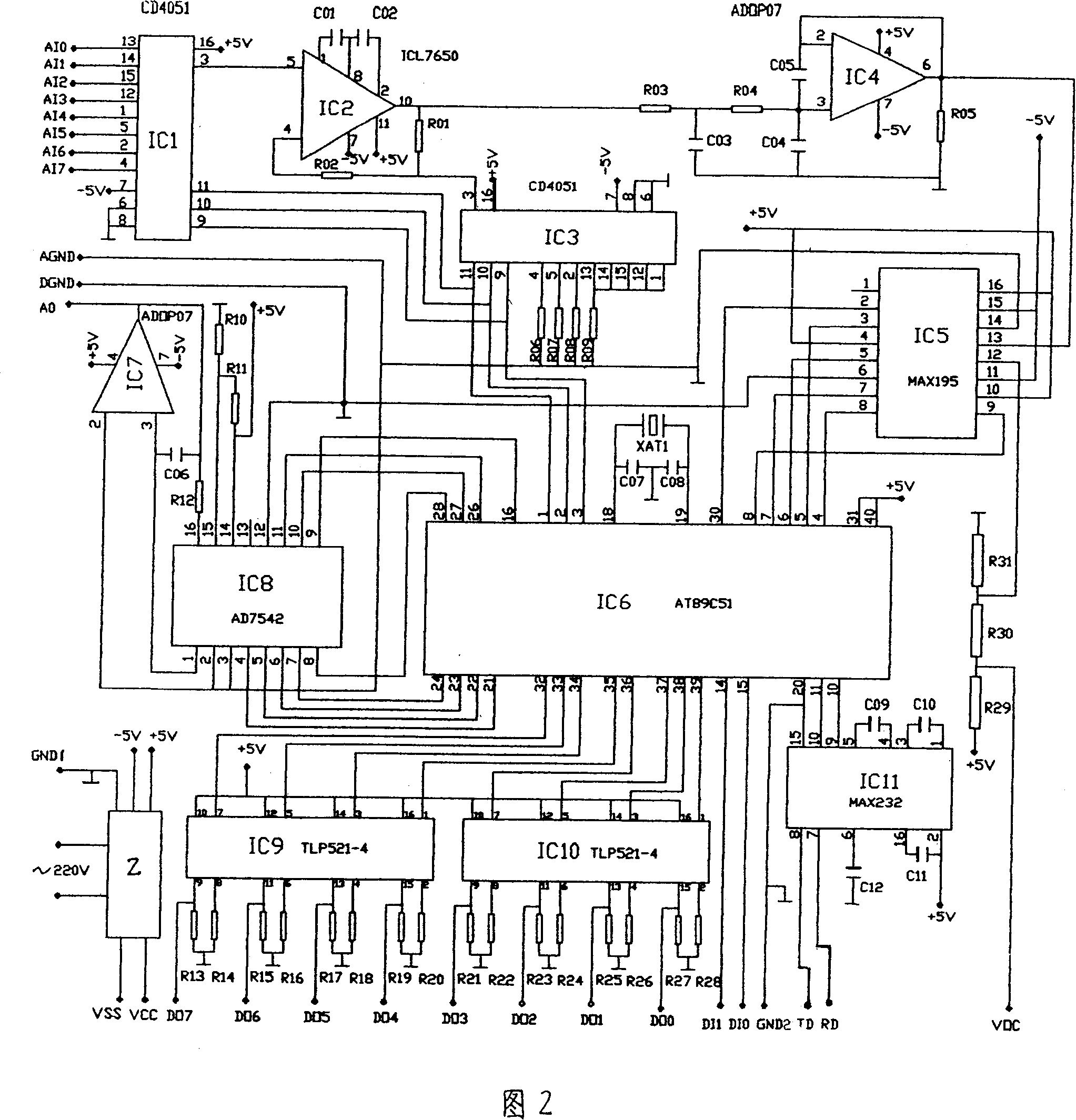

Login to View More Abstract

The invention provides a teaching laboratory system control module for material mechanics, which comprises a shell body in which is placed circuit board, a system control circuit placed on the circuit board includes an integrated module IC1-IC11 and a current regulator Z which are electronically connected with each other, on the shell body are respectively provided with interfaces AI0-7, AGND, DI0-1, DGND, VSS, GND and interfaces VCC, DO0-7, AO, RD, TD, GND, VOC that are connected with integrated module IC1-IC11 and current regulator Z. Matched with computer and different sensors on different laboratory devices, the system control module resolves the problem of high costs on developing individual laboratory function.

Description

technical field [0001] The invention relates to the technical field of control modules, in particular to a control module of a material mechanics teaching experiment system. Background technique [0002] Most of the equipment and instruments used in the teaching experiments of material mechanics are tensile and compression testing machines, torsion testing machines, bending test benches and universal material testing machines, as well as strain gauges, extensometers and torsion meters. At present, with the continuous advancement of science and technology, the control part of the above-mentioned various experimental equipment is developing towards digital control. Because different test equipment has different test functions, the numerical control module that controls its work is also developed and designed for different test functions. It has the characteristics of single purpose when controlling the work of test equipment, that is, strong independence, Versatility is poor....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G05B15/02G05B19/05G01L1/00G08C19/00G06F3/00

Inventor 付新春于忠芳李允志江潮宋连龙刘茂华

Owner 山东省机电学校

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com