A kind of preparation method of cu/lif composite cathode material of lithium ion battery

A technology for composite cathode materials and lithium-ion batteries, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as complex processes, difficulty in adapting to large-scale production, and high equipment requirements, and achieve simple preparation processes and avoid corrosive electrodes. The use of strong and highly toxic hydrofluoric acid, the effect of low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of Cu / LiF composite cathode material of the present invention, comprises the steps:

[0028] ⑴ 9.9884 grams of CuSO 4 ·5H 2 O, 5.6302 g Li 2 SO 4 ·H 2 O was dissolved in distilled water to prepare solution I, in which CuSO 4 The mass percent concentration is 30%.

[0029] ⑵Will 4.9640 grams (NH 4 ) 2 C 2 o 4 , 3.2595 g NH 4 F was dissolved in distilled water to prepare solution II, in which (NH 4 ) 2 C 2 o 4 The mass percentage concentration is 8%.

[0030] (3) Add solution I to solution II and carry out precipitation reaction at 50°C for 3 hours, then centrifuge and wash the suspension, and dry at 80°C to obtain a solid isolate;

[0031] (4) Sinter the solid isolate obtained in step (3) in an inert atmosphere furnace at 400° C. for 0.5 hour, and then cool to room temperature to obtain a Cu / LiF composite positive electrode material.

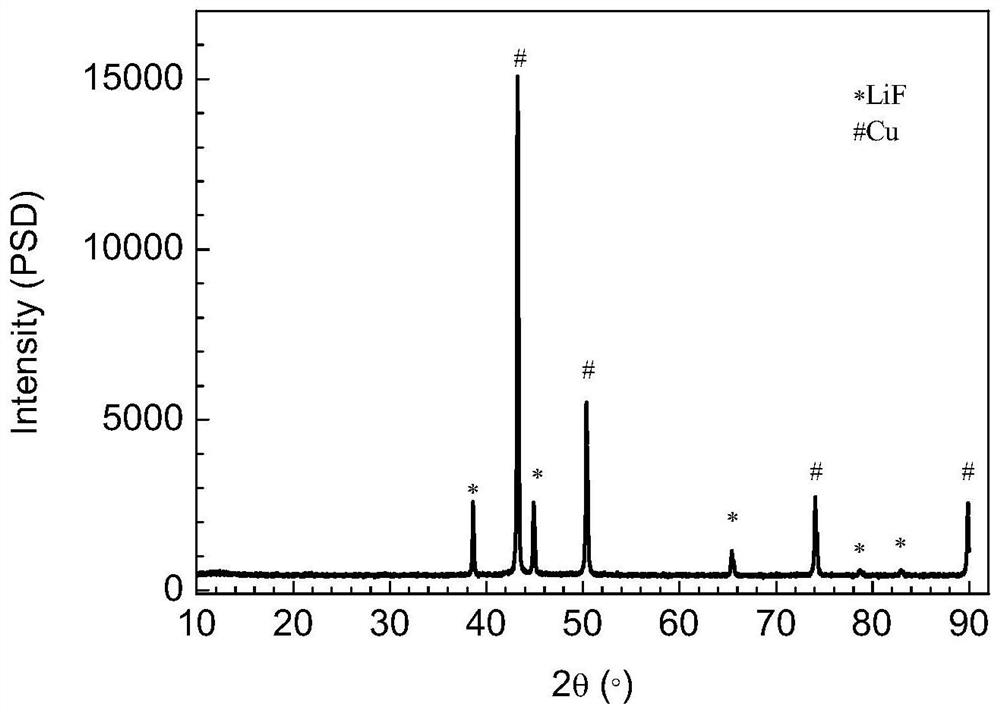

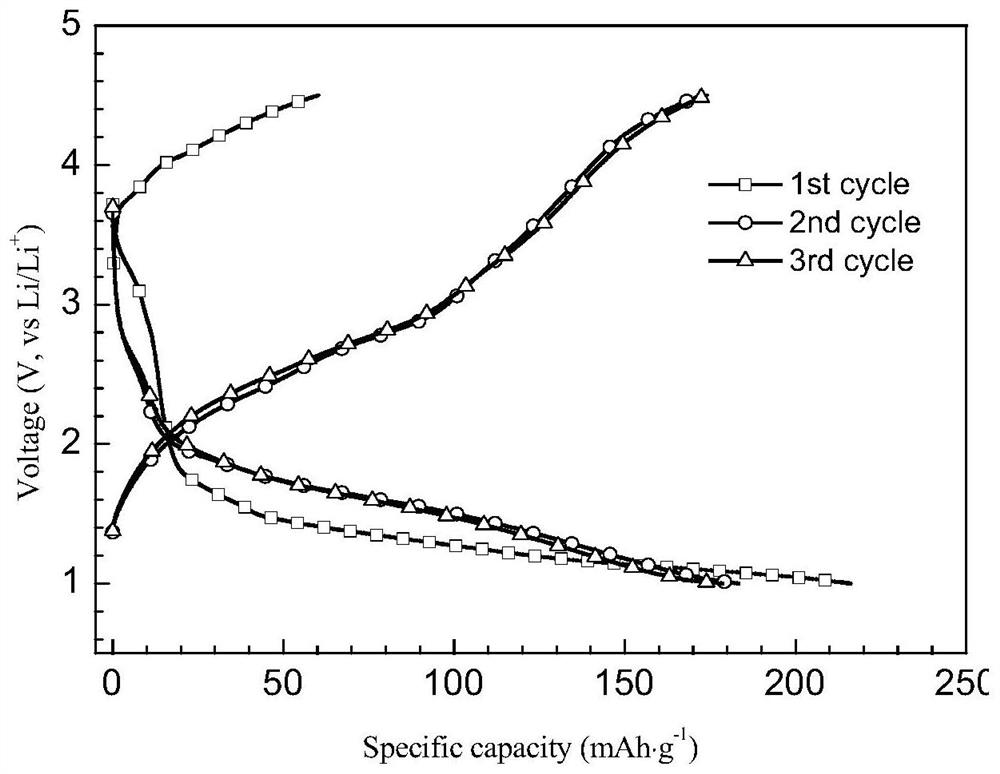

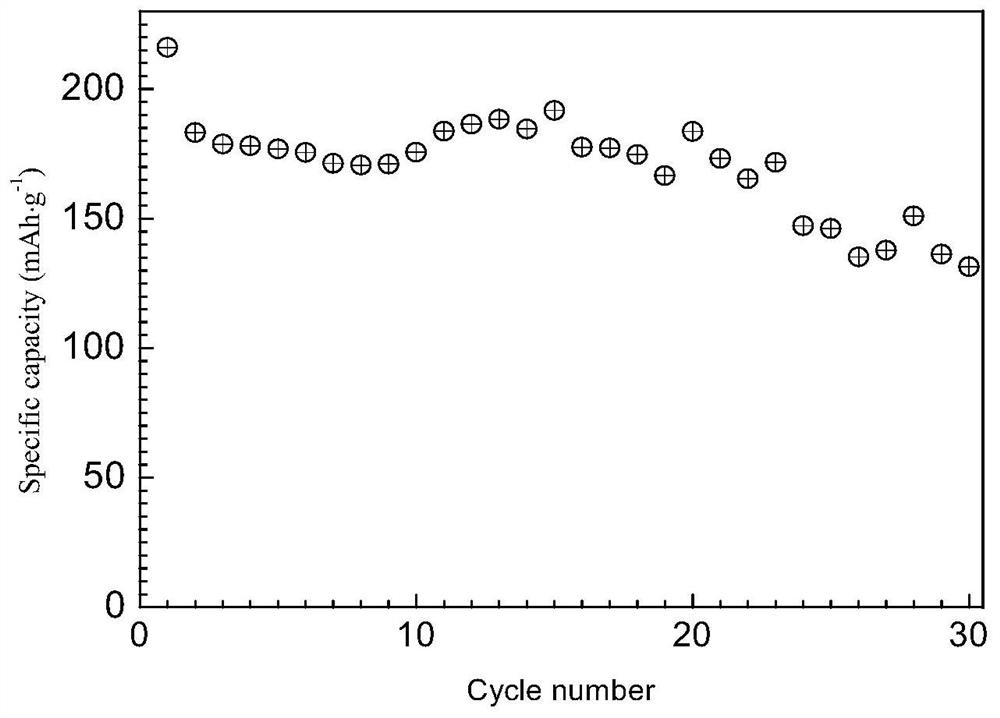

[0032] The samples of Example 1 were measured by a Brucker D8 Advance X-ray diffractometer. Its X...

Embodiment 2

[0035] ⑴ 6.8192 grams of CuCl 2 ·5H 2 O, 5.3161 g LiCl·H 2 O was dissolved in distilled water to prepare solution I, in which CuCl 2 The mass percentage concentration is 50%.

[0036] ⑵The 5.3600 grams of Na 2 C 2 o 4 , 3.2595 g NH 4 F was dissolved in distilled water to prepare solution II, in which Na 2 C 2 o 4 The mass percent concentration is 4%.

[0037] (3) Add solution I to solution II and carry out precipitation reaction at 80°C for 1 hour, then centrifuge and wash the suspension, and dry at 80°C to obtain a solid isolate;

[0038] (4) ball mill the solid isolate obtained in step (3) with an appropriate amount of acetylene black for 1 hour, then sinter in an inert atmosphere furnace at 350° C. for 2 hours, and then cool to room temperature to obtain a Cu / LiF composite positive electrode material with a carbon content of 5 wt%. .

[0039] The sample of Example 2 was measured by a Brucker D8 Advance X-ray diffractometer. The XRD pattern of the obtained produ...

Embodiment 3

[0041] ⑴ 7.5024 grams of Cu (NO 3 ) 2 , 5.7918 g LiNO 3 Dissolved in distilled water, prepared as solution I, in which Cu(NO 3 ) 2 The mass percentage concentration is 40%.

[0042] ⑵Will 4.9640 grams (NH 4 ) 2 C 2 o 4 , 3.1113 g NH 4 F was dissolved in distilled water to prepare solution II, in which (NH 4 ) 2 C 2 o 4 The mass percent concentration is 12%.

[0043] (3) Add solution I to solution II and carry out precipitation reaction at 60°C for 2 hours, then centrifuge and wash the suspension, and dry at 80°C to obtain a solid isolate;

[0044] (4) The solid isolate obtained in step (3) is ball-milled with an appropriate amount of conductive carbon black for 1 hour, then sintered in an inert atmosphere furnace at 600° C. for 0.5 hour, and then cooled to room temperature to obtain a Cu / LiF composite positive electrode with a carbon content of 10 wt%. Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com