Process method for preparing metal refined magnesium from dolomite

A process method, dolomite technology, applied in the direction of magnesium oxide, etc., can solve problems such as chlorine gas environmental pollution, and achieve the effects of high product purity, low production cost, and smooth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

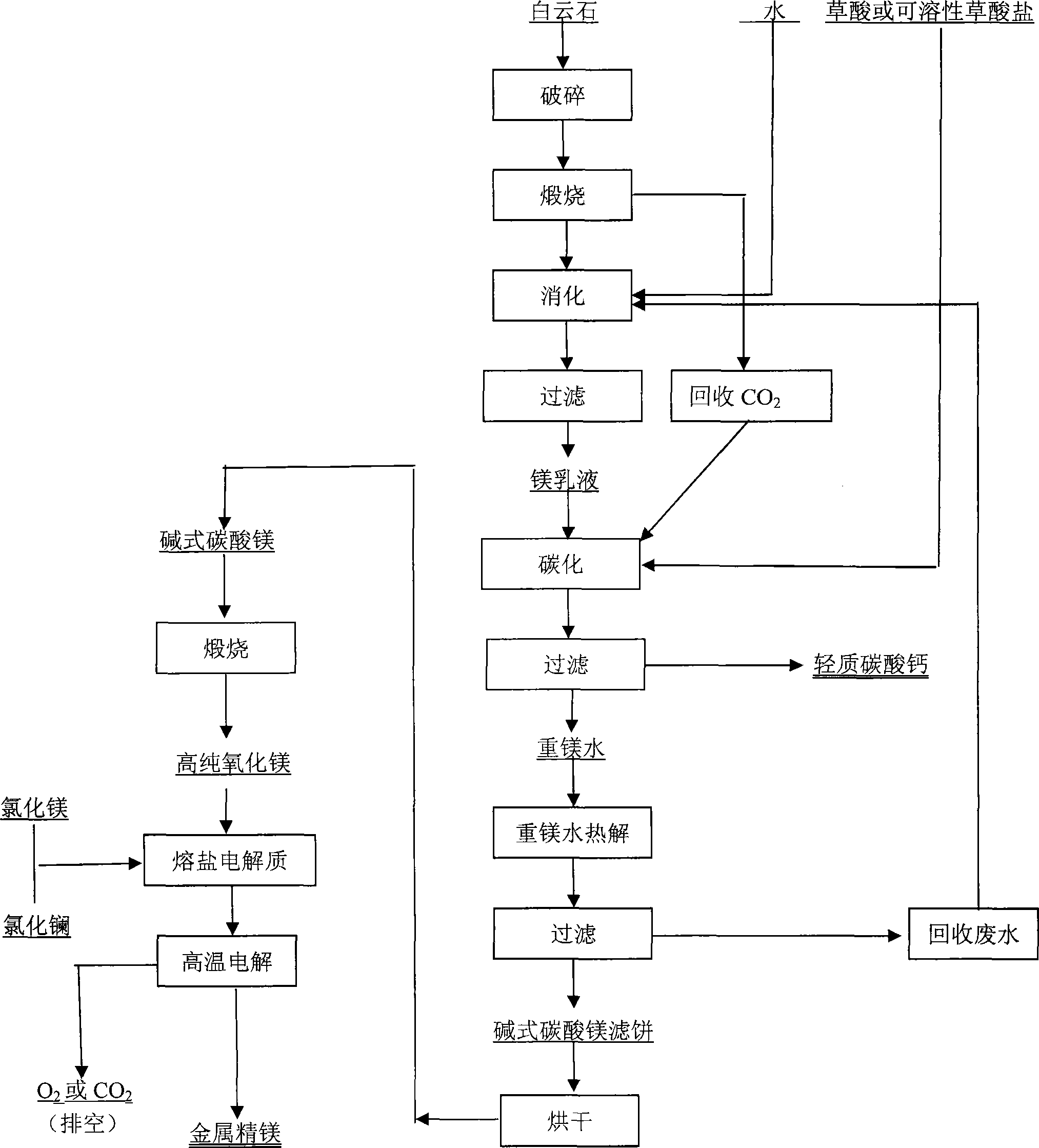

Method used

Image

Examples

Embodiment 1

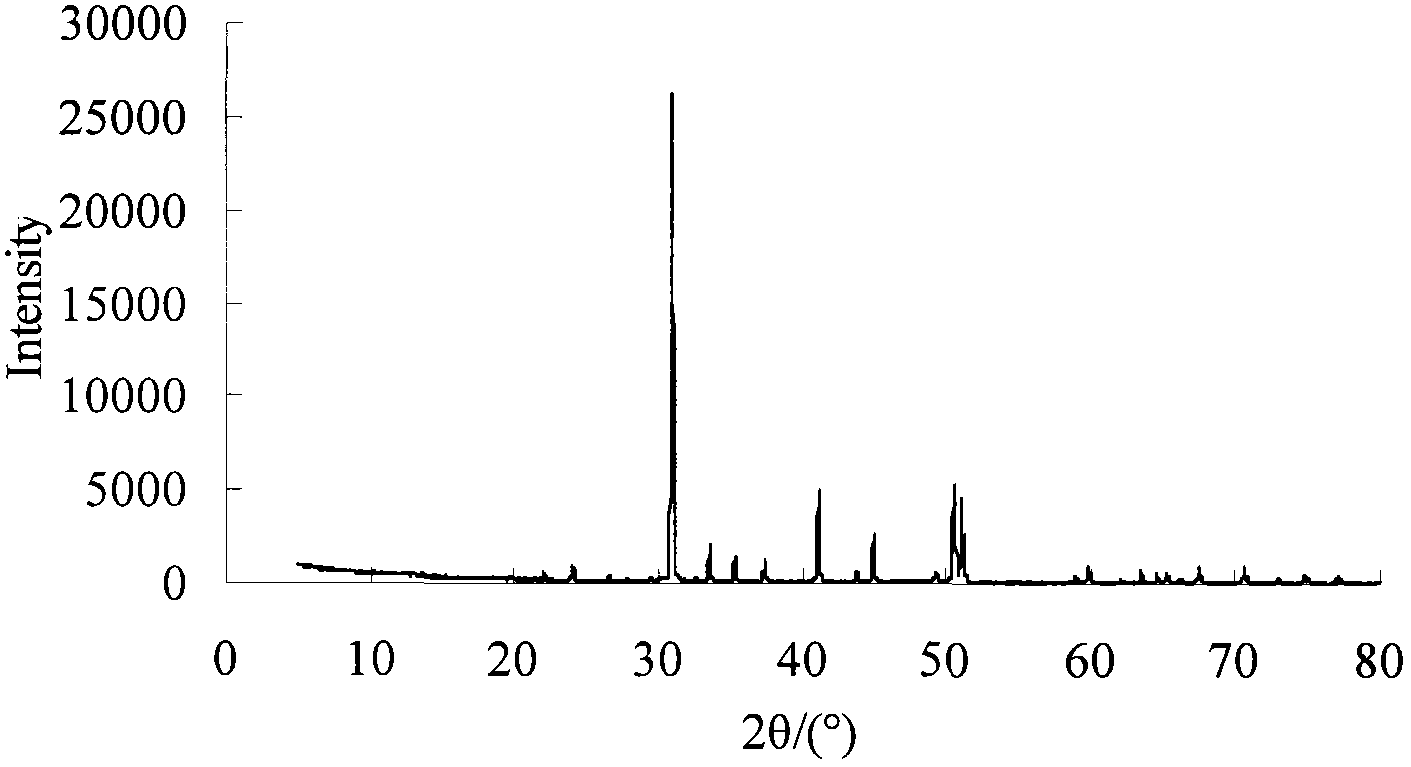

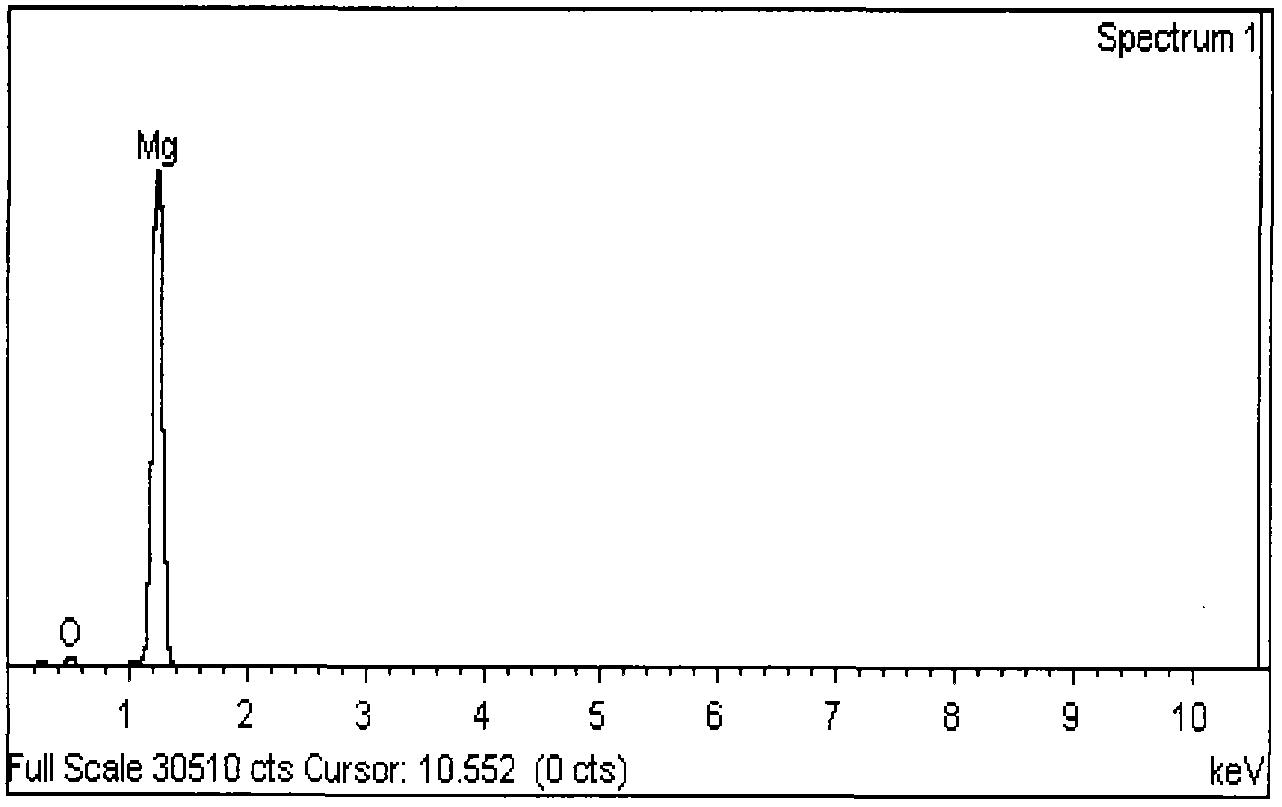

[0038] Embodiment 1: The chemical composition of dolomite is MgO content 20.96%, CaO content 30.06%, broken to 2cm~5cm. Calcined at 900°C for 3h to obtain calcined white. The calcined white is mixed according to the mass ratio of water: calcined white of 50:1, heated and stirred to 60° C., and incubated for 1 hour to obtain an emulsion. The emulsion is passed through a 60-mesh sieve to obtain refined magnesium emulsion. After cooling to room temperature, CO 2 , CO 2 The flow rate is 0.5L / min, and the pH value of the carbonization system is tracked and tested. When the carbonization system is at pH=8.5, ammonium oxalate is added to make the concentration of oxalate in the system 0.002mol / L, and carbonization is continued until pH=6.5 to stop carbonization. The carbonized system is separated from solid to liquid, the solid phase is light calcium carbonate, and the liquid phase is heavy magnesium water. The obtained heavy magnesium water is pyrolyzed at 95°C for 2 hours, sol...

Embodiment 2

[0039] Example 2: The composition of dolomite is MgO content 20.96%, CaO content 30.06%, broken to 2cm-5cm. Calcined at 950°C for 2.5h to obtain calcined white. The calcined white is mixed according to the mass ratio of water: calcined white of 40:1, stirred and heated to 70° C., and digested with heat for 1.5 hours to obtain an emulsion. The emulsion is passed through a 60-mesh sieve to obtain refined magnesium emulsion. After cooling to room temperature, CO 2 , CO 2 The flow rate is 0.8L / min, and the pH value of the carbonization system is tracked and tested. When the carbonization system is at pH=9.0, add oxalic acid to make the concentration of oxalate in the system 0.005mol / L, continue carbonization to pH=6.8, and stop carbonization. The carbonized system is separated from solid to liquid, the solid phase is light calcium carbonate, and the liquid phase is heavy magnesium water. The obtained heavy magnesium water is pyrolyzed at 100°C for 2 hours, solid-liquid separa...

Embodiment 3

[0040] Example 3: The composition of dolomite is MgO content 20.96%, CaO content 30.06%, broken to 2cm-5cm. Calcined at 1000°C for 2 hours to obtain calcined white. The calcined white was mixed according to water: calcined white = 60:1, stirred and heated to 70°C, and kept for 2 hours to obtain an emulsion. The emulsion is passed through a 60-mesh sieve to obtain refined magnesium emulsion. After cooling to room temperature, CO 2 , CO 2 The flow rate is 1L / min, and the pH value of the carbonization system is tracked and tested. When the carbonization system is at pH=9.0, add oxalic acid so that the concentration of oxalate in the system is 0.008mol / L, continue carbonization to pH=6.5, and stop carbonization. The carbonized system is separated from solid to liquid, the solid phase is light calcium carbonate, and the liquid phase is heavy magnesium water. The obtained heavy magnesium water is pyrolyzed at 100°C for 2 hours, solid-liquid separation after cooling, and the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com