Device and process for preparing ultrahigh-purity hydrogen chloride gas for semiconductors

A hydrogen chloride gas and preparation process technology, applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, inorganic chemistry, etc., can solve the problems of heavy metal solid hazardous waste, limited raw material selection, complicated process flow, etc., and achieve industrial application with small limitations, The effect of a wide range of materials and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

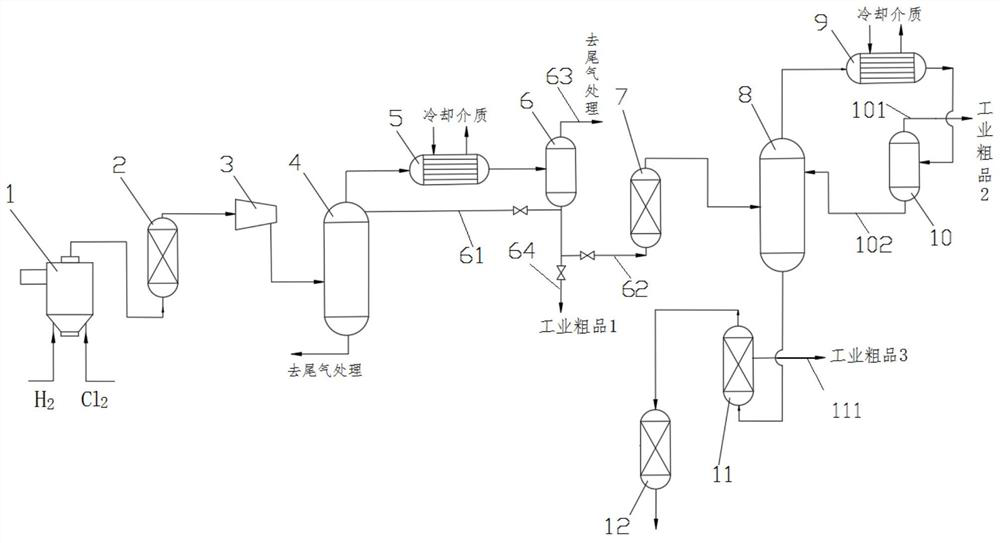

Method used

Image

Examples

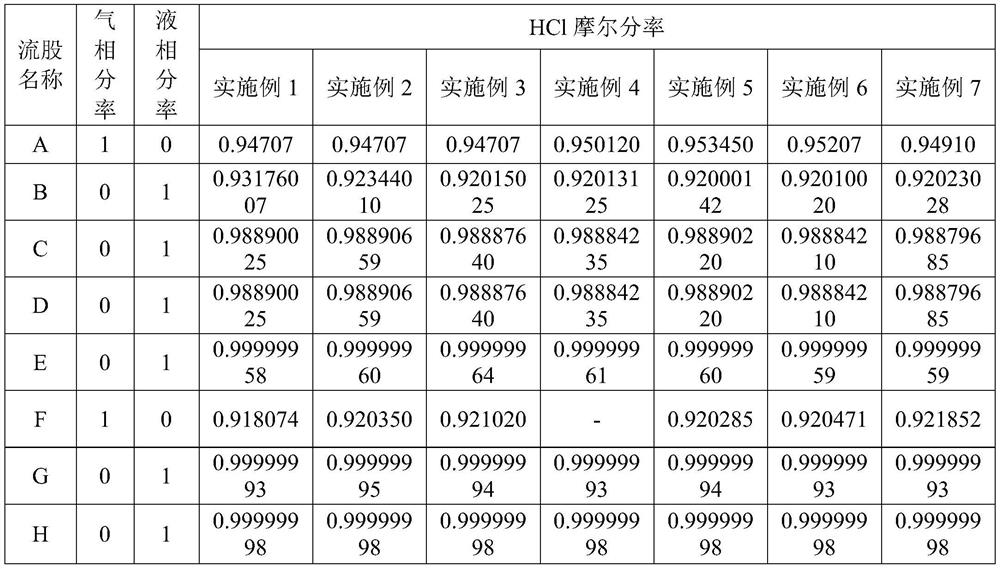

Embodiment 1

[0052] S1. Industrial hydrogen chloride gas is dewatered by the first purifier 3 to below 1ppm, compressed to liquefaction, and light fractions are obtained through the first rectification tower 4; the pressure of the first rectification tower 4 is 4.0MPa, and the temperature at the top of the tower is controlled at 12°C, the temperature of the tower kettle is controlled at 15°C;

[0053] S2. The light fraction at the top of the first rectification tower 4 enters the first gas-liquid separator 6 after passing through the first condenser 5, and the obtained liquid phase enters the second purifier 7 for second water removal;

[0054] S3. The gas after the second water removal enters the second rectification tower 8 for further rectification, and the heavy components in the tower reactor are purified by the third purifier 11 and the fourth purifier 12 to obtain ultra-high-purity hydrogen chloride gas; The second rectification tower 8 overhead components are completely refluxed af...

Embodiment 2

[0056] Using the same industrial hydrogen chloride gas as in Example 1, the purification method and steps are the same as in Example 1, except that the condition of the first rectifying tower 4 is 4.6MPa, the temperature at the top of the tower is 16°C, and the temperature at the bottom of the tower is 21°C; The pressure of the secondary rectification tower 8 is 4.4 MPa, the temperature at the top of the tower is 15° C., and the temperature at the bottom of the tower is 19° C.

Embodiment 3

[0058] Using the same industrial hydrogen chloride gas as in Example 1, the purification method and steps are the same as in Example 1, except that the pressure of the first rectifying tower 4 is 6.0MPa, the temperature at the top of the tower is 25°C, and the temperature at the bottom of the tower is 30°C; The pressure of the second rectification column 8 is 5.5 MPa, the temperature at the top of the column is 22°C, and the temperature at the bottom of the column is 27°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com