A kind of controllable preparation method of monodisperse copper oxalate powder

A copper oxalate, monodisperse technology, applied in the preparation of carboxylates, carboxylates, chemical instruments and methods, etc., can solve the problems of easy agglomeration of amorphous precipitated particles, difficult to control the shape well, and difficult to disperse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

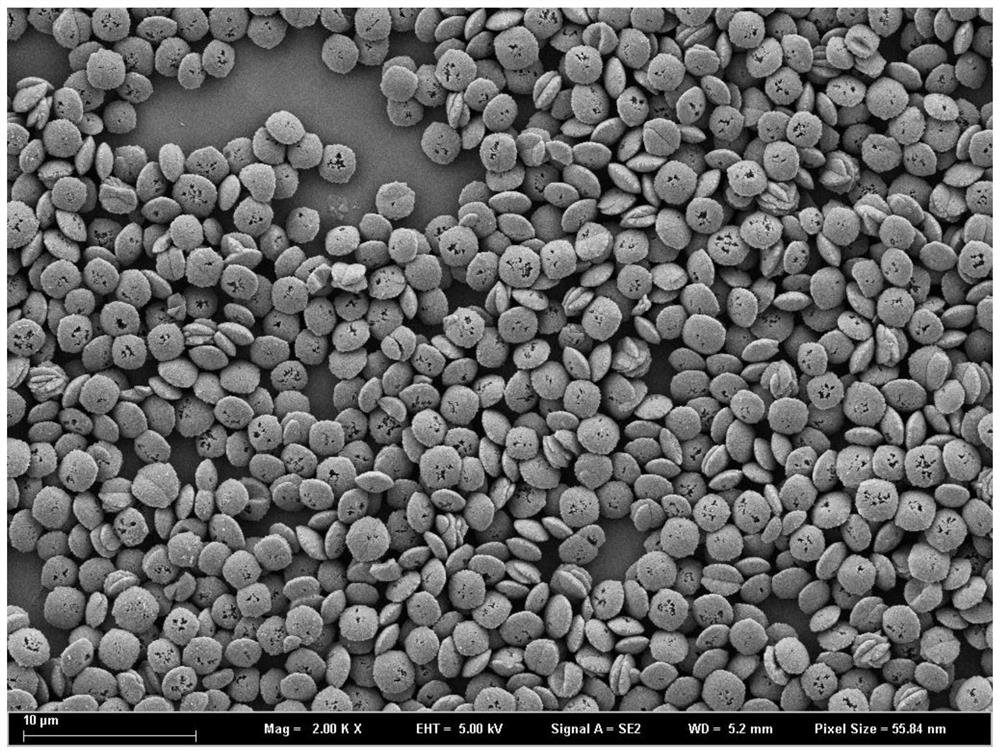

[0030] Take 1.6 liters of deionized water without adding EDTA, stir to dissolve it completely, and control its pH to 5; then add 200ml of copper salt solution with a concentration of 0.1mol / l, stir for 5-30 minutes, and then add 200ml with a concentration of 0.1 mol / l oxalate solution, stirred for 5 minutes, then allowed to stand at room temperature for 1 hour; sampled and filtered, washed repeatedly to remove impurity ions, and collected solid copper oxalate powder with an average particle size of 2.3 microns. Its typical morphology features are as figure 1 shown.

Embodiment 2

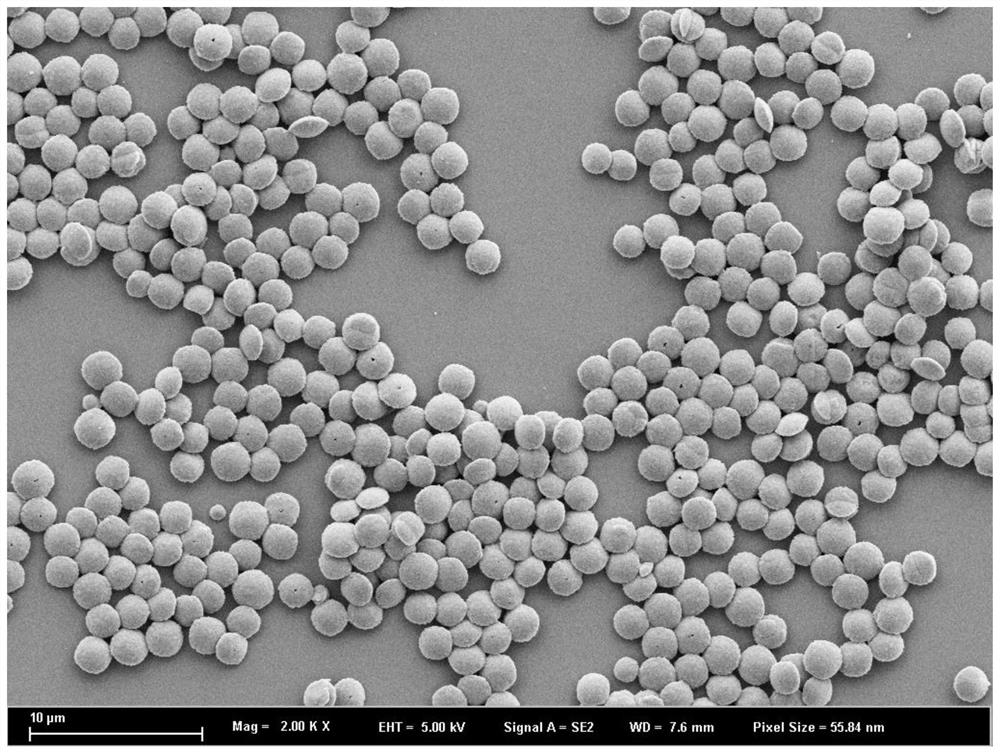

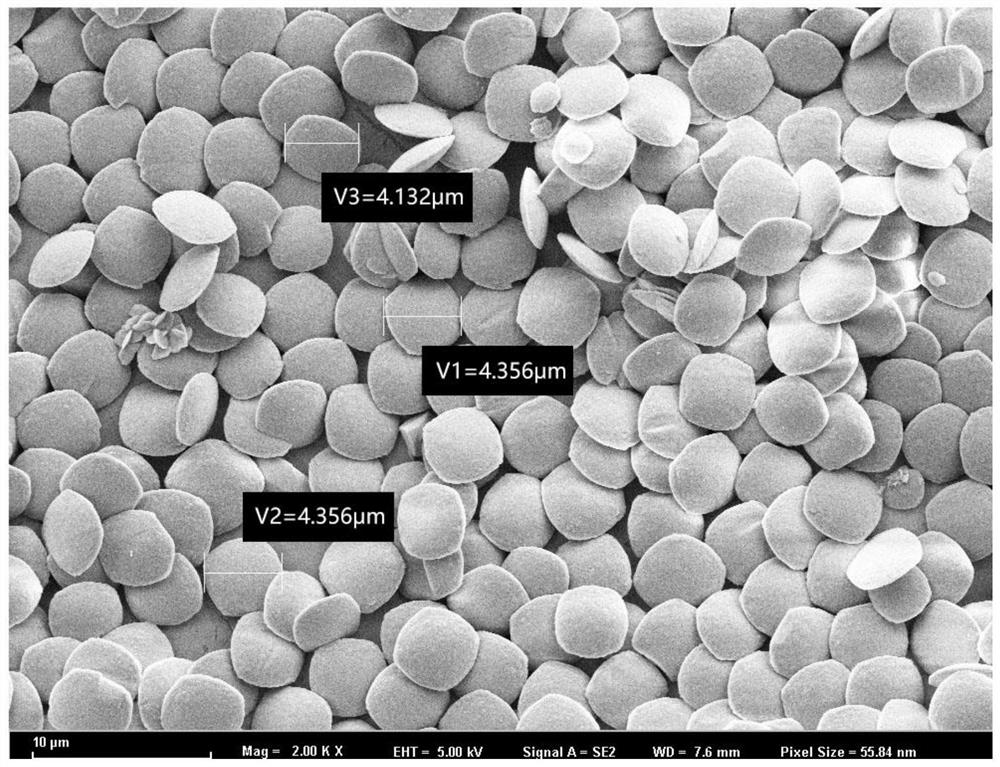

[0032] Take 1.6 liters of deionized water, add 4g of EDTA, stir to dissolve completely, and control its pH to 7; then add 200ml of copper salt solution with a concentration of 0.1mol / l, and stir for 5-10 minutes; then add 200ml with a concentration of 0.1 mol / l oxalate solution, stirred for 5 minutes; stood at room temperature for 1 hour; then sampled and filtered at 10 minutes and 1 hour respectively, after repeated cleaning to remove impurity ions, collected solid copper oxalate powder, sampled and filtered at 10 minutes The average particle diameter of the solid copper oxalate powder is 2.1 microns, and the average particle diameter of the solid copper oxalate powder that is sampled and filtered in 1 hour is 3.1 microns. Its typical morphology features are as follows figure 2 and image 3 shown.

Embodiment 3

[0034] Take 1.6 liters of deionized water, add 4g of EDTA, stir to dissolve it completely, and control its pH to 7; then add 200ml of copper salt solution with a concentration of 0.1mol / l, and stir for 5-30 minutes; then add 200ml with a concentration of 0.1 mol / l oxalate solution, stirred for 2 minutes; stood at room temperature for 1 hour; then sampled and filtered at 10 minutes and 1 hour respectively, after repeated cleaning to remove impurity ions, collected solid copper oxalate powder, sampled and filtered at 10 minutes The average particle diameter of the solid copper oxalate powder is 2.1 microns, and the average particle diameter of the solid copper oxalate powder that is sampled and filtered in 1 hour is 3.1 microns. Its typical morphology features are as follows Figure 4 and Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com