Copper separation system for strong-oxidation high-acidity copper-containing waste liquid

A separation system, high oxidation technology, applied in the direction of separation method, dispersed particle separation, centrifugal separation water/sewage treatment, etc., can solve the problems that cannot be popularized and used, difficult to filter, etc., achieve shortened filtration time, long life, reduce The effect of operating and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

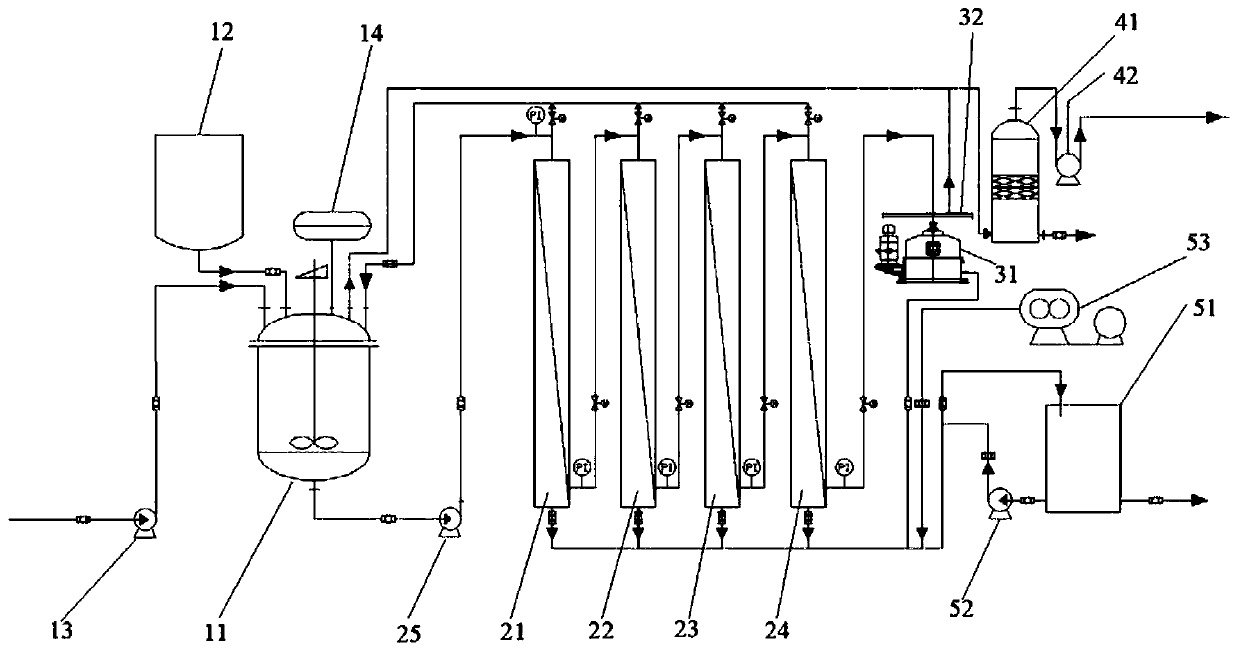

Image

Examples

Embodiment 1

[0044] Take 1m from a PCB company 3 Copper-containing deplating waste nitric acid is transported to the reaction kettle 11 through the waste liquid feed pump 13, the reaction kettle 11 is turned on for stirring, and an oxalic acid solution is added from the oxalic acid dispensing tank 12 to the reaction kettle 11 to precipitate copper ions to obtain a copper oxalate precipitation mixed solution. After the above reaction for 2 hours, open the reaction liquid outlet of the reaction kettle 11, turn on the reaction liquid feed pump 25, and the copper oxalate precipitation mixed liquid enters the membrane concentration system, and is concentrated and separated by cross-flow through the first-stage tubular silicon carbide ceramic membrane 21 , to obtain the concentrated solution and the permeate of the first-level copper oxalate precipitation mixed solution, the concentrated solution of the first-level copper oxalate precipitation mixed solution is then passed through the second-leve...

Embodiment 2

[0048] Take 1m 3 The PCB acid etching waste liquid containing Cu 100g / L and HCl 2mol / L produced by a PCB company was tested with oxalic acid as the copper precipitation agent for comparison, and the operation was the same as above. The copper separation system takes 0.7 hours, and there is no waste gas emission during the test process, which is environmentally friendly. The chamber filter press takes 4.5 hours. During the test, the filter press emits exhaust gas and pollutes the environment. The results show that the efficiency of the copper separation system is significantly improved, and the environment is friendly; the test obtained a regenerated acidic etching solution containing 3g / L of copper ions, and used the regenerated acidic etching solution to prepare an acidic etching solution. The test results fully meet the requirements of the existing etching solution. While recovering copper, it can also achieve the purpose of acid solution recycling.

Embodiment 3

[0050] Take 1m 3 A PCB company produced 15% nitric acid, Cu 2+ 11.3g·L -1 , Fe 3+ 23.5g·L -1 , Sn 2+ / Sn 4+ 110g·L -1 The nitric acid type tin stripping waste liquid is tested with oxalic acid as the copper precipitation agent, and the relevant reactions are as follows:

[0051] Cu 2+ +H 2 C 2 o 4 →CuC 2 o 4 ↓+2H +

[0052] 2Fe 3+ +3H 2 C 2 o 4 → Fe 2 (C 2 o 4 ) 3 ↓+6H +

[0053] Sn(OH) 6 2- +2H + →Sn(OH) 4 ↓+2H 2 o

[0054] Add oxalic acid solution according to the 90% amount measured by the reaction formula, and stir the reaction time for 2 hours for a comparative test. The copper separation system takes 0.5 hours, and there is no waste gas emission during the test process, which is environmentally friendly. The box filter press takes 5 hours, and the filter press emits exhaust gas during the test process, which pollutes the environment. The results show that the efficiency of the copper separation system is significantly improved, and the env...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com