Method for manufacturing high-stability solid wood composite floor by odd-even-symmetry assembling

A solid wood composite floor, high-stability technology, applied in the joining of wooden veneers, chemical instruments and methods, non-polymer adhesive additives, etc. problem, to achieve durable waterproof effect, excellent waterproof performance, and reduce the effect of end pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing high-stability solid wood composite flooring from odd-even symmetric blanks, the preparation method comprising the following steps:

[0036] (1) Substrate preparation: select wooden veneers with a moisture content of 6%, and sequentially go through glue distribution, billet formation, cold pressing, and hot pressing to obtain the substrate. The species of the wooden veneers is poplar;

[0037] The blank assembly adopts the "odd-even symmetrical structure" method; specifically, the odd-numbered layers use wooden veneers with the same elements, and the even-numbered layers use wooden veneers with the same elements; the elements include moisture content, texture, tree species and thickness;

[0038] (2) Surface coating: the upper surface of the substrate is covered with natural precious veneer, and the lower surface of the substrate is covered with a balance layer veneer. The balance layer veneer is birch veneer

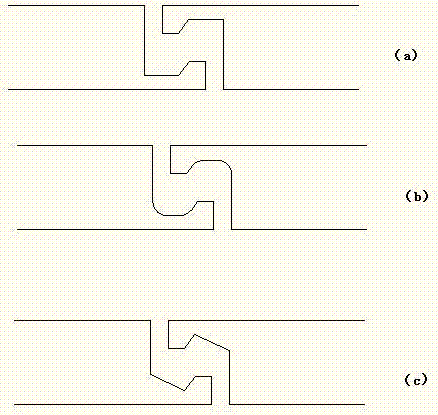

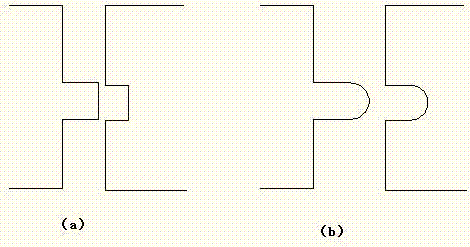

[0039] (3) Tenon and groove: such as...

Embodiment 2

[0043] A method for preparing high-stability solid wood composite flooring from odd-even symmetric blanks, the preparation method comprising the following steps:

[0044] (1) Substrate preparation: choose a wooden veneer with a moisture content of 12%, and sequentially go through glue laying, billet formation, cold pressing, and hot pressing to obtain the substrate. The species of the wooden veneer is eucalyptus;

[0045] The blank assembly adopts the "odd-even symmetrical structure" method; specifically, the odd-numbered layers use wooden veneers with the same elements, and the even-numbered layers use wooden veneers with the same elements; the elements include moisture content, texture, tree species and thickness;

[0046] (2) Surface coating: the upper surface of the base material is covered with a restructured decorative veneer, and the lower surface of the base material is coated with a balance layer. The balance layer veneer is birch veneer;

[0047] (3) Open the mortise a...

Embodiment 3

[0051] A method for preparing high-stability solid wood composite flooring from odd-even symmetric blanks, the preparation method comprising the following steps:

[0052] (1) Base material preparation: select wooden veneers with a moisture content of 8%, and then obtain the base material through glue laying, billet formation, cold pressing, and hot pressing in sequence. The tree species of the wooden veneers is birch.

[0053] The blank assembly adopts the "odd-even symmetrical structure" method; specifically, the odd-numbered layers use wooden veneers with the same elements, and the even-numbered layers use wooden veneers with the same elements; the elements include moisture content, texture, tree species and thickness;

[0054] (2) Surface coating, covering the upper surface of the substrate with natural precious veneer, and covering the lower surface of the substrate with a balance layer veneer, the balance layer veneer is birch veneer;

[0055] (3) Open the mortise and gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com