Process for deeply removing oxalic acid

A technology for removing oxalic acid, which is applied in photography technology, photography auxiliary technology, process efficiency improvement, etc., can solve the problem of excessive residue of oxalic acid in medium, achieve high removal rate, low cost, avoid toxicity and secondary pollution problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

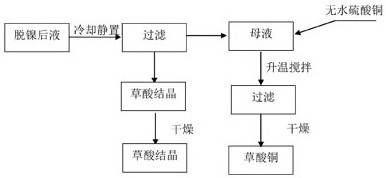

Image

Examples

Embodiment 1

[0014] Embodiment 1, a kind of technology of depth removing oxalic acid is as follows:

[0015] a. Weigh 1L of the nickel-removed solution into a container, place it in a temperature environment of -5°C, let it stand for 8 hours, take it out and filter it quickly, and keep the mother liquor. The oxalic acid content in the mother liquor is 2.1 g / L, and the precipitate on the filter paper The product was dried at 40°C to obtain the finished product of oxalic acid;

[0016] b. Add 5.83g of industrial copper sulfate pentahydrate containing 23% copper to the above mother liquor, raise the temperature to 40°C and stir for 1 hour, then filter, and dry the light blue-green precipitate on the filter paper at 40°C to obtain the copper oxalate product.

[0017] After analysis, the content of oxalate in the solution was 0.2 g / L. The removal rate of oxalic acid in the treated liquid after nickel removal is 90.47%.

Embodiment 2

[0018] Embodiment 2, a kind of technology of depth removing oxalic acid is as follows:

[0019] a. Weigh 1L of the nickel-removed solution into a container, place it in an environment with a temperature of 15°C, let it stand for 24 hours, take it out and filter it quickly, and keep the mother liquor. The oxalic acid content in the mother liquor is 29.3 g / L, and the precipitate on the filter paper The product was dried at 80°C to obtain the finished product of oxalic acid;

[0020] b. Add 97.7g of industrial copper sulfate pentahydrate containing 23% copper to the above mother liquor, raise the temperature to 80°C and stir for 5 hours, then filter, and dry the light blue-green precipitate on the filter paper at 80°C to obtain copper oxalate product.

[0021] After analysis, the content of oxalate in the solution was 1.8g / L, and the removal rate of oxalic acid in the solution after nickel removal was 93.86%.

Embodiment 3

[0022] Embodiment 3, a kind of technology of depth removing oxalic acid is as follows:

[0023] a. Weigh 1L of the nickel-removed solution into a container, place it in a temperature environment of -3°C, let it stand for 12 hours, take it out and filter it quickly, and leave the mother liquor. The oxalic acid content in the mother liquor is 3.7 g / L. The precipitate was dried at 70°C to obtain the finished product of oxalic acid;

[0024] b. Add 14.4g of industrial copper sulfate pentahydrate containing 23% copper to the above mother liquor, raise the temperature to 70°C and stir for 2 hours, then filter, and dry the light blue-green precipitate on the filter paper at 70°C to obtain copper oxalate product.

[0025] After analysis, the content of oxalate in the solution was 0.17g / L, and the removal rate of oxalic acid in the solution after nickel removal was 95.38%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com