Harmless high-carbon conversion method for non-food-residue household garbage as well as product and application of harmless high-carbon conversion method

A technology for domestic waste and meal waste, which is applied in the field of harmless high-carbon conversion of non-meal waste domestic waste, can solve the problems of not meeting the raw material requirements, not being able to directly use domestic waste for recycling, etc., to achieve high-value recycling and realize economic value , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

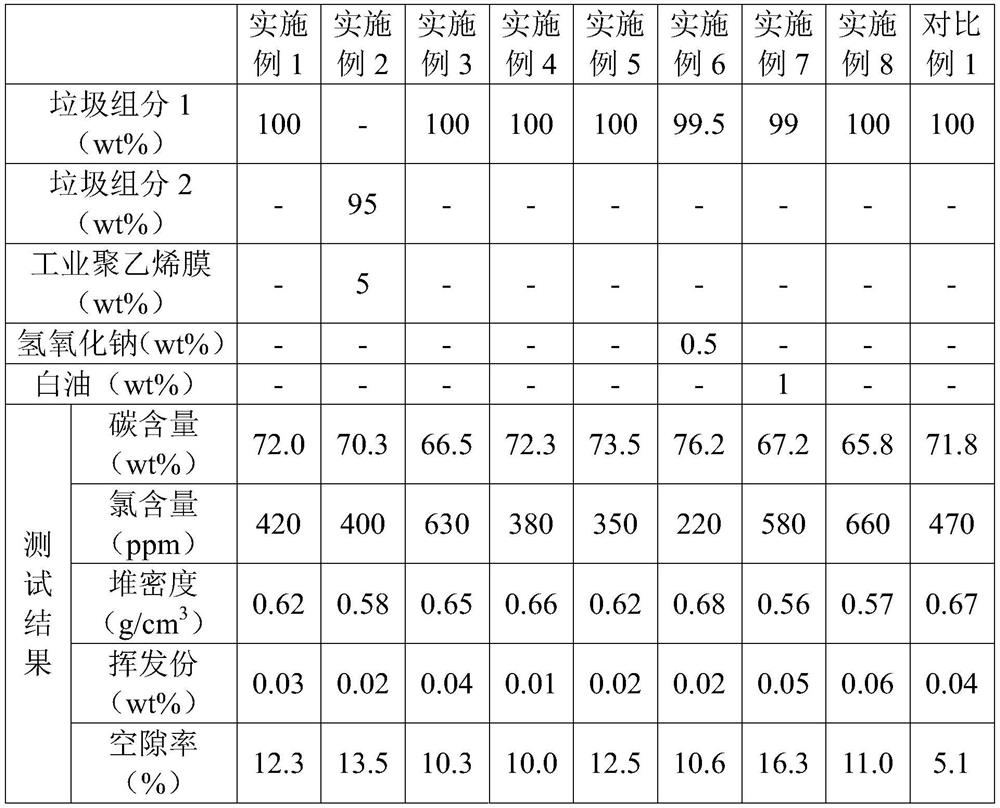

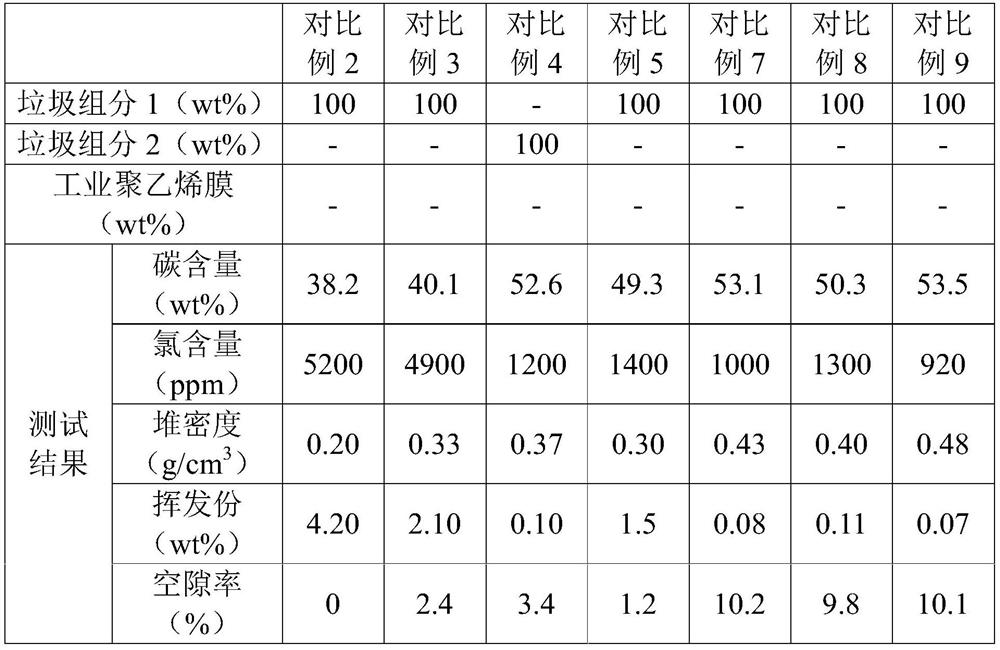

Embodiment 1

[0041] After sorting and dehydrating the non-dinner domestic waste (garbage component 1) from the garbage collection station, the moisture content is 8.2wt%, and it is crushed by a pulverizer into blocks or flakes with a size of 2 to 4 cm. According to the analysis, the content of polyethylene and polypropylene mixture (thermoplastic component, chlorine-free polyolefin) is 12.2wt%, which can be used directly. Using a specially configured co-rotating twin-screw extruder, the basic configuration of the extruder is: screw diameter D = 65mm, length-to-diameter ratio L / D = 52, motor power P = 120KW, screw combination front screw interval 0.2mm, Accounting for 70% of the length of the screw, the screw gap at the back section of the screw is 0.4mm, accounting for 30% of the length of the screw. The processing conditions of the extruder are as follows: the highest temperature is 350°C, the screw speed is 600rpm, the vacuum is -0.06MPa, no filter is added, and the die head pressure is ...

Embodiment 2

[0053] Same as Example 1, the difference is that the thermoplastic component is 6.2wt% in the non-dinner domestic garbage (garbage component 2) from the garbage collection station, and 5wt% of recycled industrial polymer is added before the twin-screw extruder is processed. vinyl film. The properties of the treated materials are shown in Table 1.

Embodiment 3

[0055] Same as Example 1, except that the maximum temperature of the twin-screw extruder was set to 320°C. The properties of the treated materials are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com