A recycling method for multi-component mixed plastic waste

A waste, multi-component technology, applied in the recycling and reuse of microplastics in water bodies, and the recycling and reuse of multi-component mixed plastic waste Secondary pollution of the environment and other problems, to achieve the effect of easy operation, good commercial value, and protection of the living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] In this embodiment, a method for recycling multi-component mixed plastic waste mainly includes the following steps:

[0102] (1) Mix the collected plastic waste according to the following ratio:

[0103] Polypropylene waste 60%,

[0104] Polyethylene waste 5%,

[0105] Polyethylene terephthalate waste 15%,

[0106] Nylon 6 waste 20%,

[0107] The mixed plastic waste obtained after mixing, after washing and drying, is processed into plastic film strips with a long diameter of no more than 1 to 5 cm as recycling mixtures;

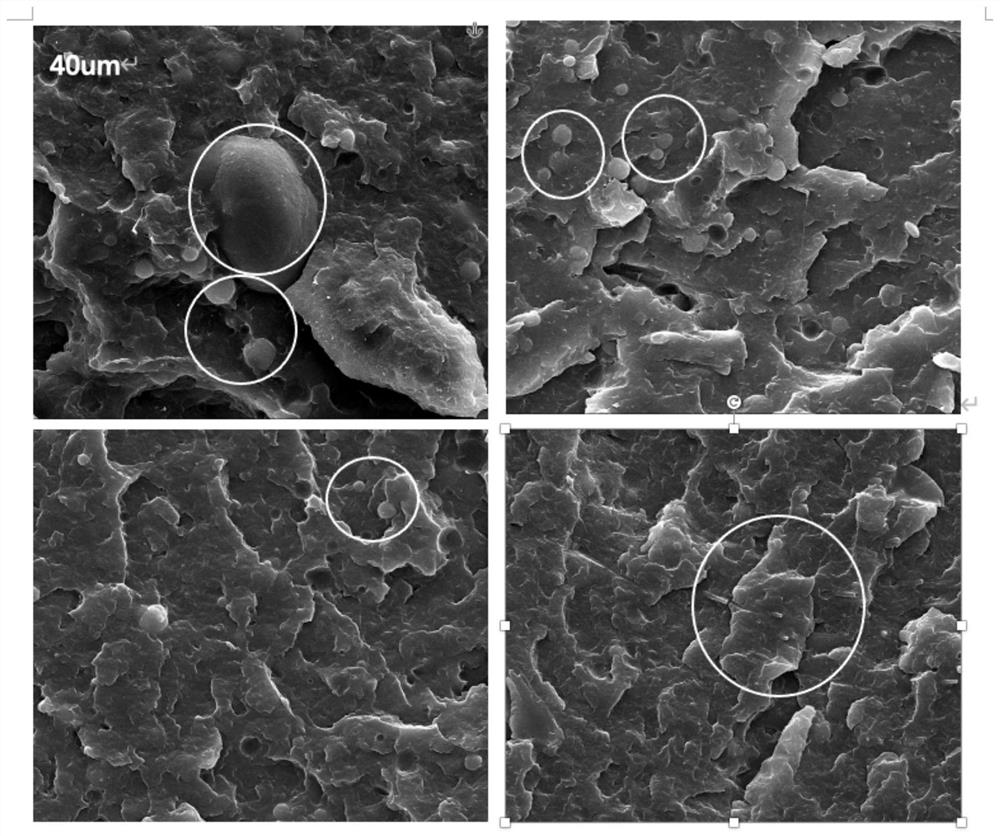

[0108] (2) Add the recovered mixed material obtained in step (1) into a millstone-type solid-phase mechanochemical reactor for grinding and pulverization. After the milling is completed, an ultrafine hybrid powder is collected; The process parameters of the device are: 20 cycles of grinding, the grinding pressure of the 1st to 5th cycle grinding is 5MPa, the grinding pressure of the 6th to 20th cycle of grinding is 8MPa, the speed of the grinding d...

Embodiment 2

[0112] In this embodiment, a method for recycling multi-component mixed plastic waste mainly includes the following steps:

[0113] (1) Mix the collected plastic waste according to the following ratio:

[0114] Polypropylene waste 60%,

[0115] Polyethylene waste 5%,

[0116] Polyethylene terephthalate waste 15%,

[0117] Nylon 6 waste 20%,

[0118] The mixed plastic waste obtained after mixing, after washing and drying, is processed into plastic film strips with a long diameter of no more than 1 to 5 cm as recycling mixtures;

[0119] (2) Add the recovered mixed material obtained in step (1) into a millstone-type solid-phase mechanochemical reactor for grinding and pulverization. After the milling is completed, an ultrafine hybrid powder is collected; The process parameters of the device are: 30 cycles of grinding, the grinding pressure of the 1st to 5th cycle grinding is 5MPa, the grinding pressure of the 6th to 30th cycle of grinding is 8MPa, the speed of the grinding d...

Embodiment 3

[0134] In this embodiment, a method for recycling multi-component mixed plastic waste mainly includes the following steps:

[0135] (1) Mix the collected plastic waste according to the following ratio:

[0136] Polypropylene waste 60%,

[0137] Polyethylene waste 5%,

[0138] Polyethylene terephthalate waste 15%,

[0139] Nylon 6 waste 20%,

[0140] The mixed plastic waste obtained after mixing, after washing and drying, is processed into plastic film strips with a long diameter of no more than 1 to 5 cm as recycling mixtures;

[0141] (2) Add the recovered mixed material obtained in step (1) into a millstone-type solid-phase mechanochemical reactor for grinding and pulverization. After the milling is completed, an ultrafine hybrid powder is collected; The process parameters of the device are: 30 cycles of grinding, the grinding pressure of the 1st to 5th cycle grinding is 5MPa, the grinding pressure of the 6th to 30th cycle of grinding is 9MPa, the speed of the grinding d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com