Resource recovery method for waste gel-ink pen refills

A technology of resource recovery and gel pen, applied in chemical instruments and methods, removal of solid waste, special forms of dry distillation, etc. Low cost, simple installation, high value recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

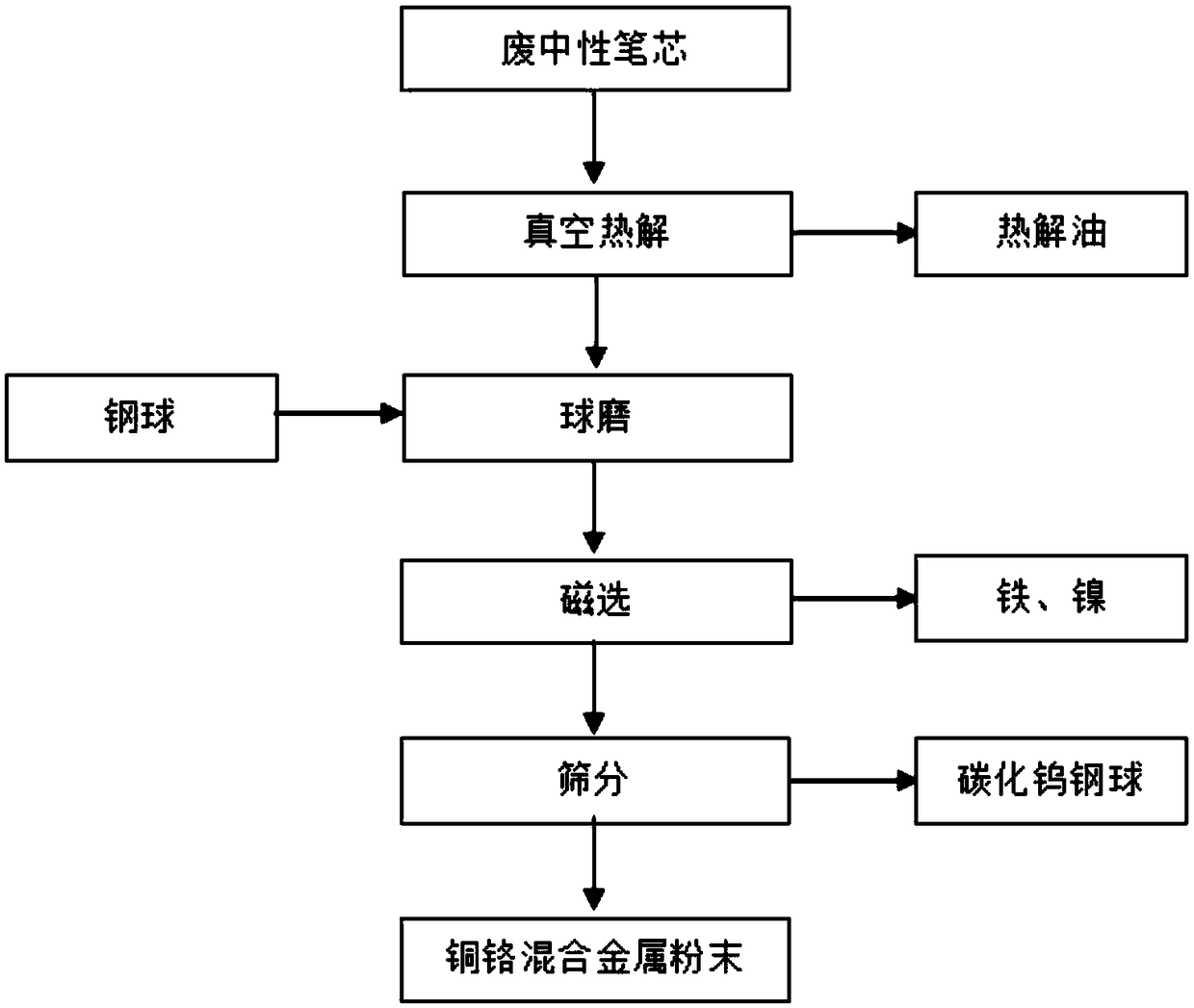

Method used

Image

Examples

Embodiment 1

[0024] Collect the waste gel refills, send the waste gel refills into the vacuum pyrolysis device, the system pressure is less than 1Kpa, heat to 500°C, pyrolyze for 30min, the organic matter in the waste gel refills is pyrolyzed into small molecular substances The volatilization is extracted from the vacuum pyrolysis device, condensed into pyrolysis oil, and the mixture of nib and carbon residue remains in the vacuum pyrolysis device; 1.4kg of the obtained mixture of nib and carbon residue and 2kg of steel balls with a diameter of 30mm are added to the vertical Stir the ball mill, the speed of the ball mill is 300r / min, ball mill for 60 minutes, separate the balls in the nib, and peel off the chromium coating on the surface of the nib; take out the material from the vertical ball mill, use a magnet to suck away the iron and nickel in the material, and sieve points to get balls and copper, chromium metal mixed powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com