Different grade composite first kind absorption heat pump

An absorption heat pump, three-stage absorption technology, applied in heat pumps, energy-saving heating/cooling, lighting and heating equipment, etc., can solve the problems of ineffective utilization of waste heat, high cost, and inability to fully utilize the driving heat and cooling capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

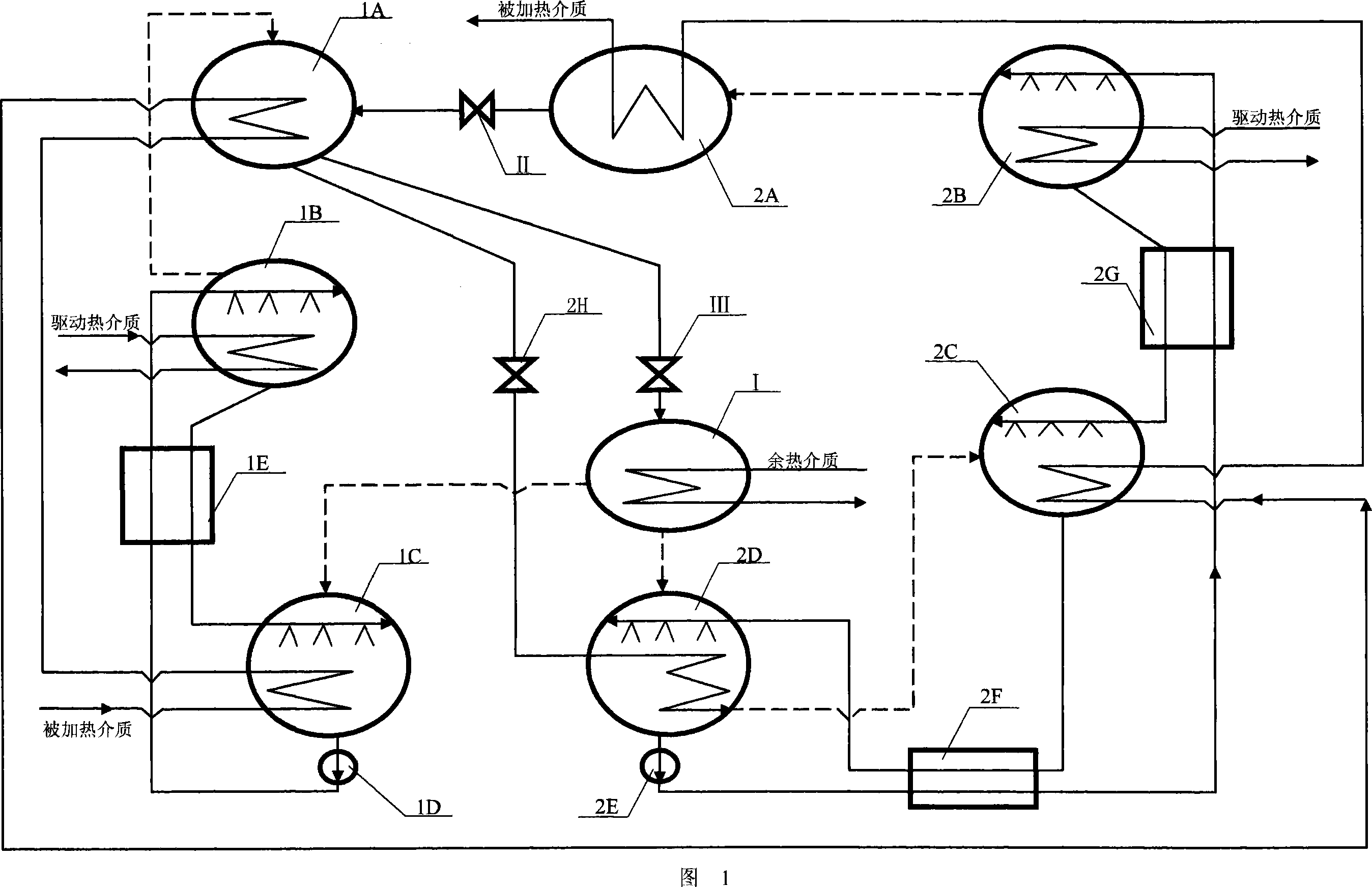

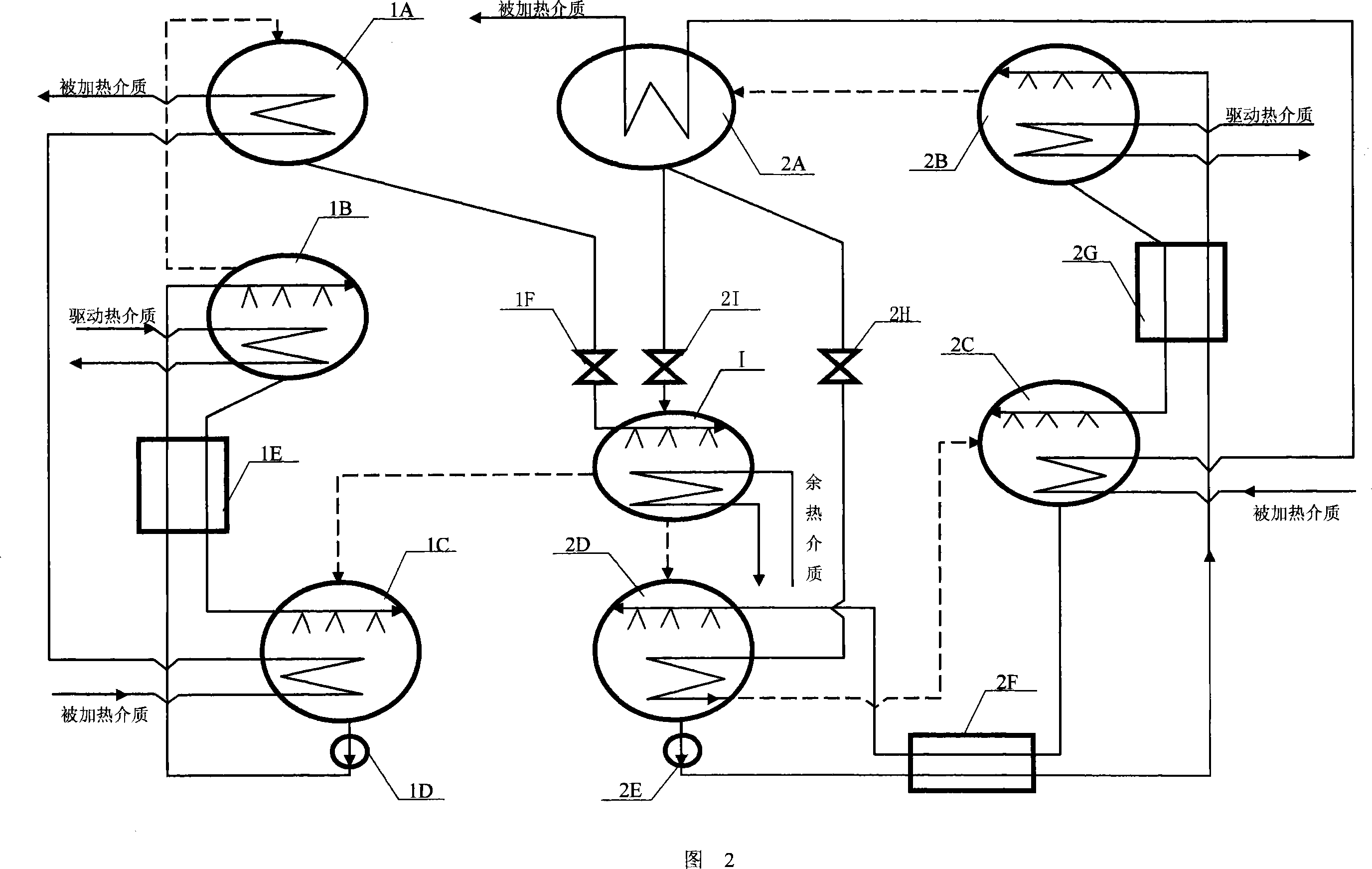

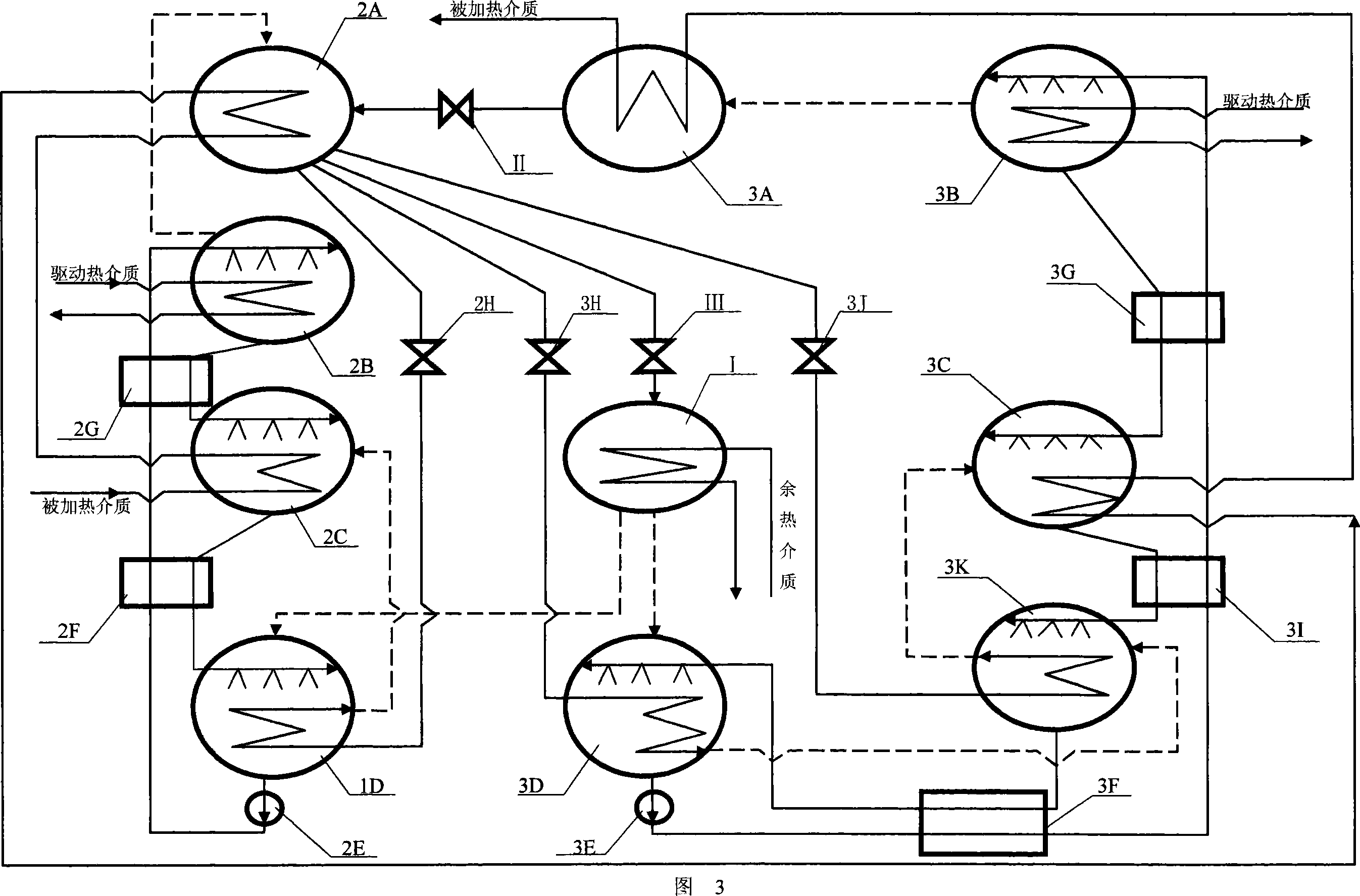

[0037] Taking the shared evaporator-type closed-type hetero-stage composite first-type absorption heat pump composed of a first-stage and a single-generator-type second-stage heat pump as an example, as shown in Figure 1, the purpose of the present invention is achieved in this way:

[0038] ①. In terms of structure, the two heat pump processes have a common evaporator I and a throttle valve III, and the common parts are combined with a primary condenser 1A, a primary generator 1B, a primary absorber 1C, a primary solution pump 1D and a primary solution The heat exchanger 1E constitutes the structure and process of the first-stage heat pump, and the common parts are combined with the second-stage condenser 2A, the second-stage generator 2B, the second-stage absorber 2C, the second-stage absorption-evaporator 2D, the second-stage solution pump 2E, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com