Method for two-stage preparation of methane gas from solid waste

A technology for solid waste and methane gas, applied in chemical instruments and methods, gas fuels, chemical/physical processes, etc., can solve the problem of complex reactor raw material components, difficult optimal temperature requirements, and affecting methane yield and quality To meet the requirements of gas production and economic cost, realize the reduction and utilization of resources, and improve the efficiency of methane conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

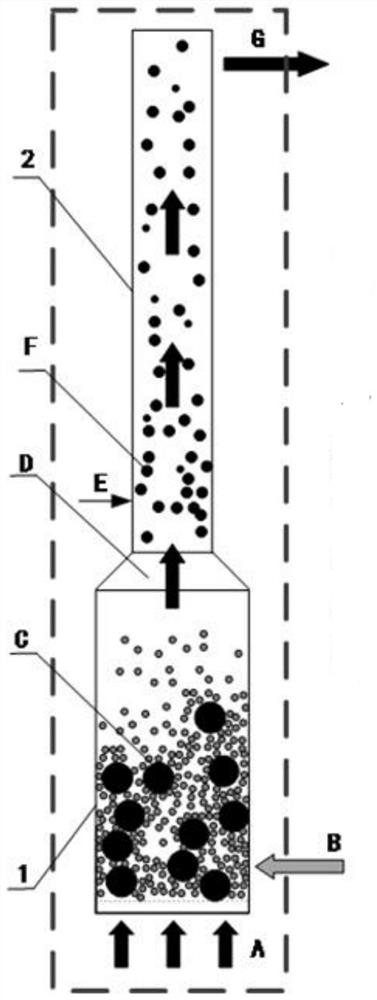

[0024] Refer to the following figure 1 To describe in detail the two-stage method for preparing methane gas from solid waste in this patent,

[0025] Such as figure 1 As shown, a two-stage method for preparing methane gas from solid waste according to an embodiment of the present invention is characterized in that it comprises the following steps:

[0026] Step 10) In the primary methanation zone 1 in the two-stage methanation reactor, the water vapor A as the fluidizing medium and the methanation agent is passed from the bottom of the primary methanation zone 1, and the solid as fuel Waste B and modified calcium-based ore catalyst C as a direct methanation catalyst pass through from the side of primary methanation zone 1. Under the action of water vapor A, solid waste B and modified calcium-based ore catalyst C The mixture moves upwards in a bubbling fluidized state, and undergoes a direct methanation reaction with water vapor A to obtain crude methane gas D.

[0027] In s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com