Step-heat-supplying oxygen-enrichment microwave ignition device

An ignition device and microwave ignition technology, applied in the field of ironmaking, can solve the problems of low oxygen content, reduce emissions and improve the effect of ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

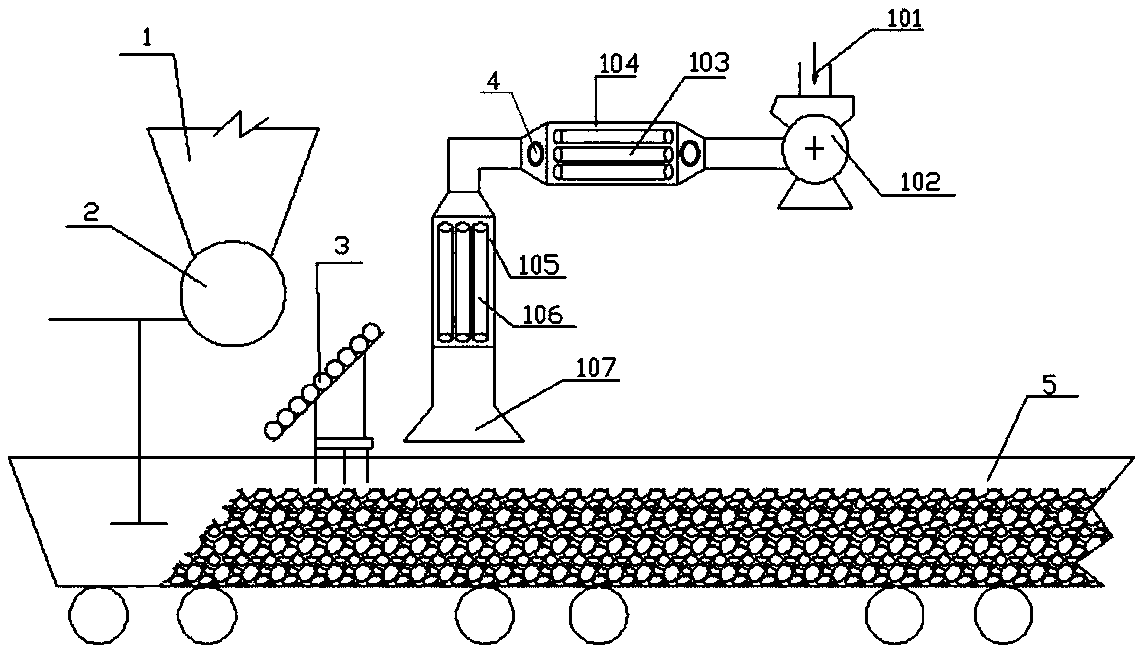

[0028] This embodiment provides a cascaded heating oxygen-enriched microwave ignition device, including a microwave heating zone 104 and an electric heating zone 105, wherein:

[0029] The microwave heating zone 104 includes a microwave generator and a ceramic tube 103 that can convert microwaves into heat energy under microwave radiation. The ceramic tube 103 is connected to the fan 102, and the auxiliary airflow 101 passes through the fan 102 and passes through the ceramic tube 103 to form a first-stage oxygen-enriched gas. Hot air: the first-level oxygen-enriched hot air is further heated through the electric heating zone 105 to generate a second-level oxygen-enriched hot air that reaches the temperature required for sintering ignition.

[0030] The electric heating area 105 is provided with an infrared emitting tube or a ceramic resistance rod, which is a ceramic resistance rod 106 in this embodiment. The ceramic tube 103 is a microwave high loss material such as silicon c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com