Device and method for treating pharmaceutical tail water

A tail water and water treatment technology, applied in water/sewage treatment, natural water treatment, water treatment parameter control, etc., can solve problems such as poor biodegradability, oxidative degradation of organic matter, toxicity of intermediate products, etc., to avoid secondary pollution , Improve the contact effect, strengthen the effect of degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] In the present invention, there is no special limitation on the source of the second catalyst, which can be prepared by using commercially available products or preparation methods well known to those skilled in the art. In the present invention, the preparation of the second catalyst preferably includes the following steps: immersing the carrier in a manganese nitrate solution, drying and calcining to obtain the second catalyst. In the present invention, the mass concentration of the manganese nitrate solution is preferably 5-10%, more preferably 6-8%. In the present invention, the soaking time is preferably 18-30 hours, more preferably 20-25 hours, and most preferably 22-23 hours. In the present invention, the drying is preferably room temperature evaporation. In the present invention, the calcination temperature is preferably 320-360°C, more preferably 330-350°C, most preferably 340°C; the calcination time is preferably 4-6 hours, more preferably 5 hours.

[0055] ...

Embodiment 1

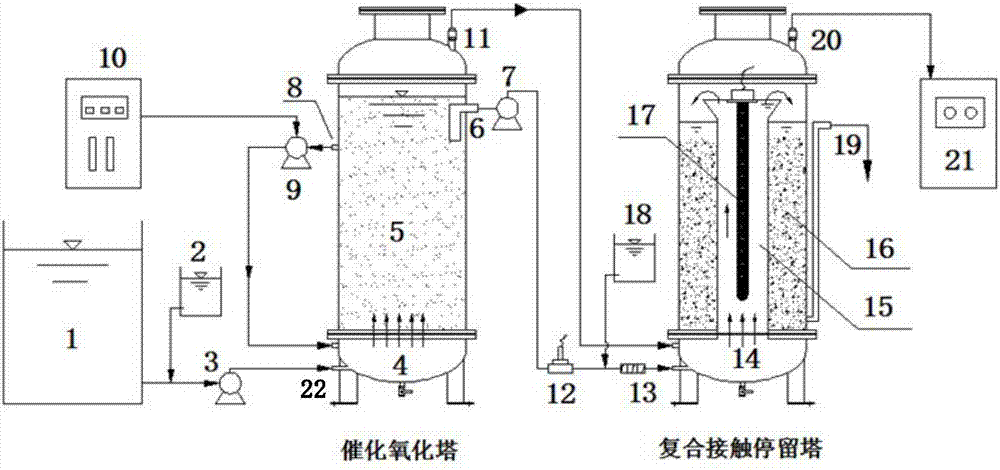

[0083] This embodiment provides a pharmaceutical tail water heterogeneous catalytic ozonation advanced treatment device such as figure 1As shown, it includes: a catalytic oxidation tower, a first water distribution area is provided at the bottom of the catalytic oxidation tower, a water inlet is provided in the first water distribution area; a catalytic reaction area is provided above the first water distribution area , the first catalyst powder is placed in the catalytic reaction zone; a first orifice plate is set between the first water distribution zone and the catalytic reaction zone. The height ratio of the first water distribution area to the catalytic reaction area is 1:9; a return pipe is communicated with the upper part of the catalytic reaction area, and the return pipe is also communicated with the first water distribution area, which is suitable for Return part of the water in the catalytic reactor to the first water distribution area, a dissolved air pump is provi...

Embodiment 2

[0086] The pharmaceutical tail water discharged from the secondary biochemical treatment process of a park is treated by using the multi-phase catalytic ozone oxidation advanced treatment device for pharmaceutical tail water described in Example 1. The water quality of the waste water is: COD, 140-160mg / L; BOD 5 , 18~20mg / L, pH value is 7.2~7.5, SS is 25mg / L. The concentration of berberine in the pharmaceutical tail water is 12mg / L.

[0087] The processing method specifically includes the following steps:

[0088] (1) The pH of the pharmaceutical tail water flowing out of the adjustment tank is adjusted to 8.0, and the ozone oxidation efficiency is the highest under this pH, and the water pump is pumped into the first water distribution area at the bottom of the catalytic oxidation tower through the water inlet, and the pharmaceutical tail water The inflow of water is 0.25t / h; the pharmaceutical tail water is mixed with the water returned by the return pipe and ozone gas in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com