Boiler flue gas waste-heat utilization system based on organic Rankine cycle

A boiler flue gas and Rankine cycle technology, which is applied to furnaces, waste heat treatment, furnace components, etc., can solve problems such as public reports on the control problem of the deep utilization system of boiler flue gas waste heat, and achieve simple structure and ensure stability. performance, ease of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

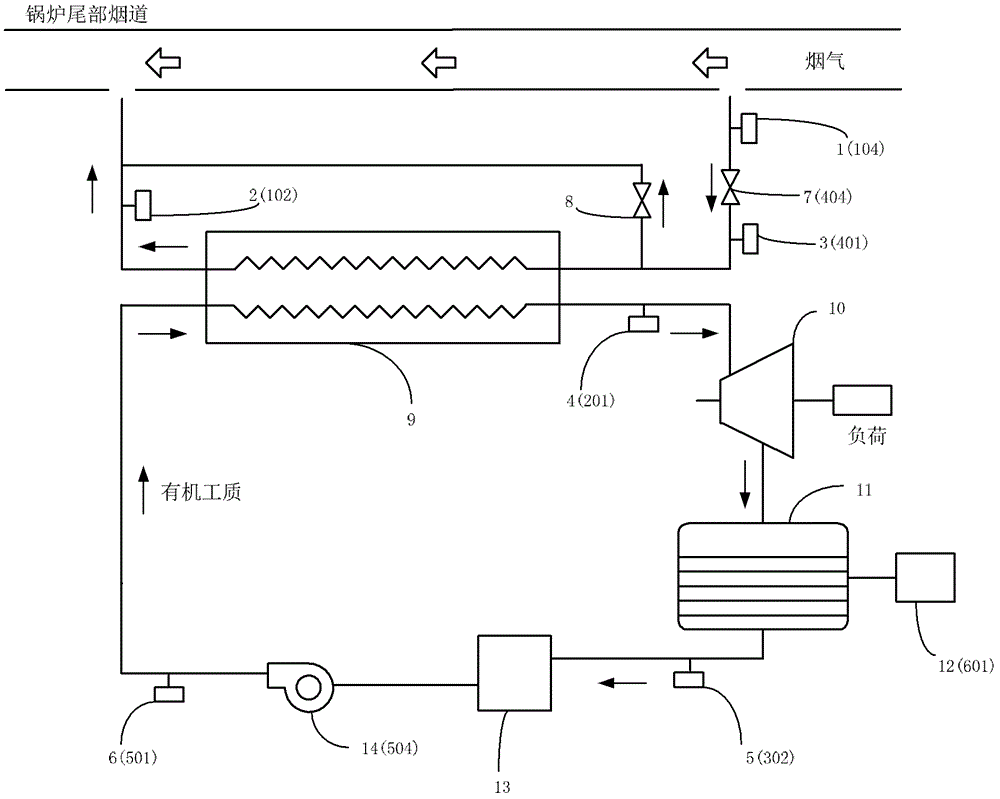

[0031] The production flow chart of the present invention is as figure 1 shown.

[0032] The present invention includes a first detection transmitter 1, a second detection transmitter 2, a third detection transmitter 3, a fourth detection transmitter 4, a fifth detection transmitter 5, and a sixth detection transmitter 6 , flue gas flow regulating valve 7, bypass regulating valve 8, evaporator 9, expander 10, condenser 11, fan 12, liquid receiver 13 and pump 14;

[0033] The inlet of the flue gas flow regulating valve 7 is connected to the boiler flue gas inlet; the outlet of the flue gas flow regulating valve 7 is respectively connected to the bypass regulating valve 8 and the evaporator 9; the bypass regulating val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com