Waste incineration fly ash molten salt heat treatment system

A technology of waste incineration fly ash, heat treatment system, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as corrosiveness, complex procedures, difficult separation, etc., to achieve good results and avoid fragmentation effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

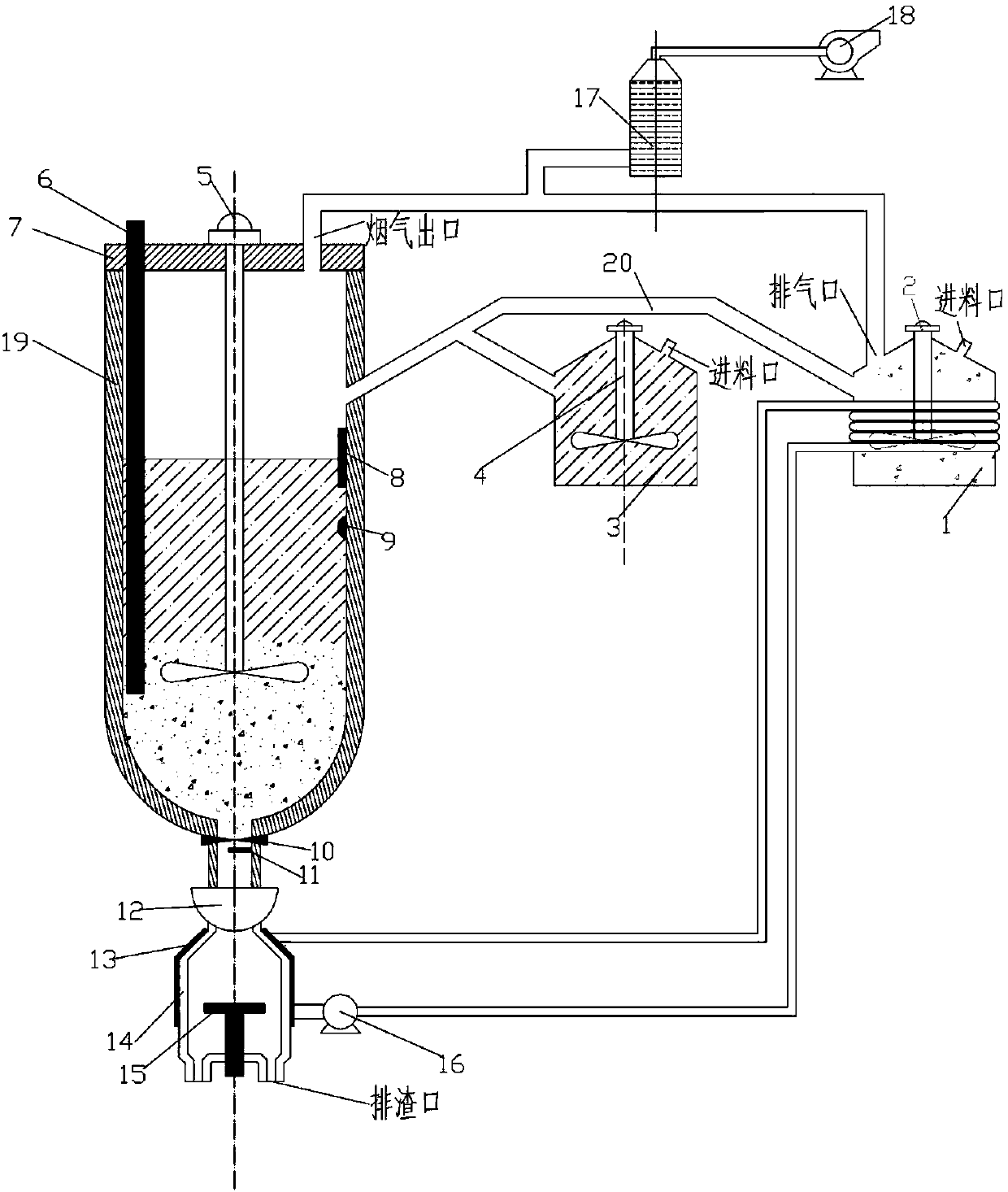

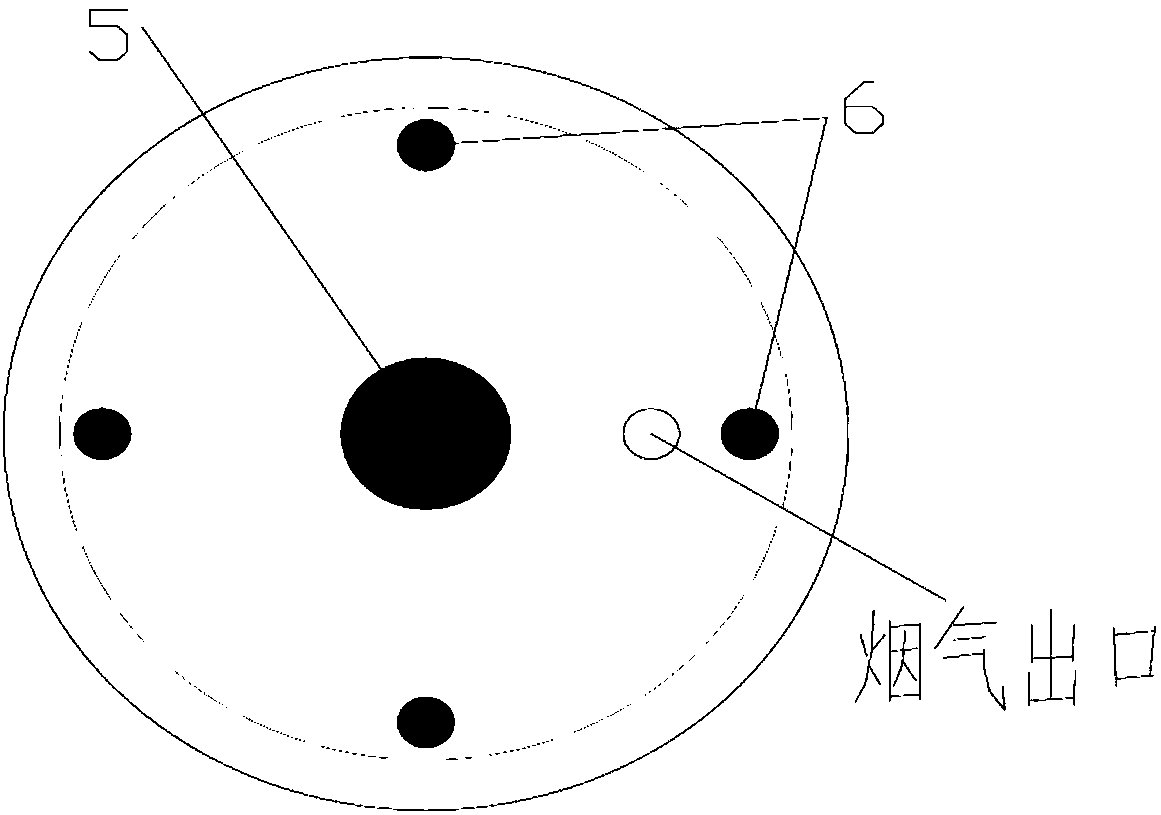

[0032] In order to clearly explain the technical problems solved by the patent of the present invention, the technical solutions adopted and the technical effects achieved, the following is combined with the attached figure 1 The embodiments of the patent of the present invention are described in detail. Apparently, the described embodiments only belong to a part of the present invention, but not all of the embodiments. Therefore, all other embodiments proposed by those skilled in the art without any creative work belong to the protection scope of the present invention.

[0033] The invention discloses a molten salt heat treatment system for waste incineration fly ash, which includes a raw material feeding system, a fly ash heat treatment system, a material discharge control system, a waste heat recovery system and a flue gas purification system.

[0034] The raw material feeding system includes a molten salt storage bin 3, a fly ash storage bin 1, and a feeding device 20. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com