Method for extracting protein and phytic acid from rapeseed meal

A technology of rapeseed cake and phytic acid, which is applied in the field of oil and vegetable protein processing engineering, can solve the problems of low protein and phytic acid yield and low protein purity, achieve high purity, reduce the amount of lye, and adapt to a wide range of raw materials sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

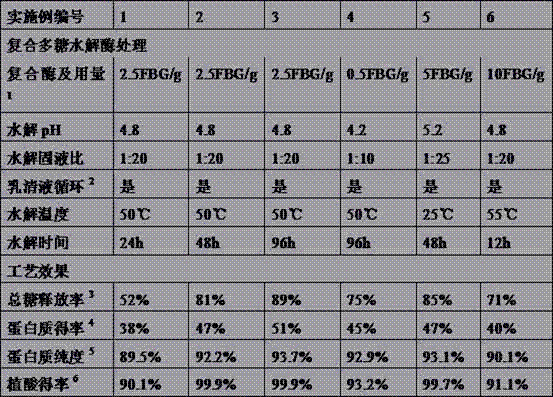

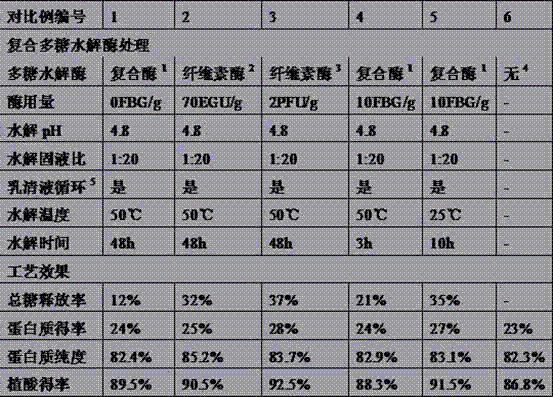

Embodiment 1-6

[0039] Using pre-extracted rapeseed meal with skin as raw material, the recycled whey liquid was used as the dispersion liquid, and sodium acetate-acetic acid was used as the buffer, and the complex polysaccharide hydrolase treatment was carried out under different conditions (see Table 1). Then adjust the pH value to 5.0 to carry out acid-liquid extraction. The operating conditions are extraction temperature 50°C, extraction time 180 minutes, and centrifugation at 2000×g for 20 minutes to implement solid-liquid separation to obtain hydrolyzed meal and phytic acid extract respectively. Then use alkaline solution to extract protein from the hydrolyzed meal, the operating conditions are: use NaOH solution containing 0.1mol / L EDTA, at pH 12.0 and 50°C, extract the hydrolyzed meal once with a solid-to-liquid ratio of 1:20, The extraction time was 30 minutes, the obtained alkaline extract was adjusted to pH 4.0, and solid-liquid separation was carried out by centrifugation at 2000×g...

Embodiment 7-9 and comparative example 7-9

[0064] Rapeseed low-temperature desolvated meal was used as raw material, firstly recycled whey liquid was used as dispersion liquid, and sodium citrate-citric acid was used as buffer agent, and Aspergillus ( Aspergillus aculeatus ) complex polysaccharide hydrolase produced by the strain and the use of Trichoderma ( Trichoderma reesei ) strain of cellulase produced by mixed enzymes (mass ratio 3:1) for treatment. The treatment conditions are: enzyme addition 2.5FBG / g, pH 4.5, temperature 40°C, solid-liquid ratio 1:25, treatment for 72h. Then pickling was carried out under different conditions (see Table 3), and solid-liquid separation was carried out by centrifugation at 5000×g for 10 minutes to obtain hydrolyzed meal and phytic acid extract respectively. Then use an alkaline solution to extract protein from the hydrolyzed meal. The operating conditions are: use NaOH solution containing 0.2mol / L sodium hexametaphosphate at pH 12.0 and 25°C to extract the hydrolyzed meal with...

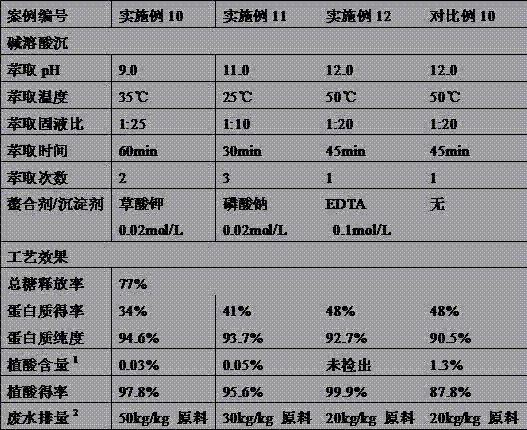

Embodiment 10-12 and comparative example 10

[0071] Rapeseed low-temperature pressed cake is used as raw material, firstly, recycled whey liquid is used as dispersion liquid, and sodium acetate-acetic acid is used as buffer agent, and Aspergillus ( Aspergillus aculeatus ) complex polysaccharide hydrolase produced by the strain and the use of Trichoderma ( Trichoderma viride ) strain of cellulase produced by mixed enzymes (mass ratio 1:1) for treatment. The treatment conditions are: enzyme addition 1FBG / g, pH 5.5, temperature 55°C, solid-liquid ratio 1:20, and treatment for 24 hours. Then, at pH 5.0 and temperature 25°C, acid wash for 180 minutes, settle for 6 hours to separate solid and liquid, and obtain hydrolyzed cake and phytic acid extract respectively. Then, various alkaline extraction conditions (see Table 4) were used to extract the protein, and the resulting alkaline extract was adjusted to pH 4.0 to precipitate the protein, and then centrifuged at 5000×g for 10 minutes to separate the solid and liquid to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com