Grain drying system based on multi-fluid heat pipe

A drying system and multi-fluid technology, applied in drying, dryer, heating device and other directions, can solve the problems of not reaching the inlet air temperature of the dryer, waste of waste heat resources, and high exhaust air temperature, and achieve a reasonable structure. , the effect of reducing carbon emissions and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

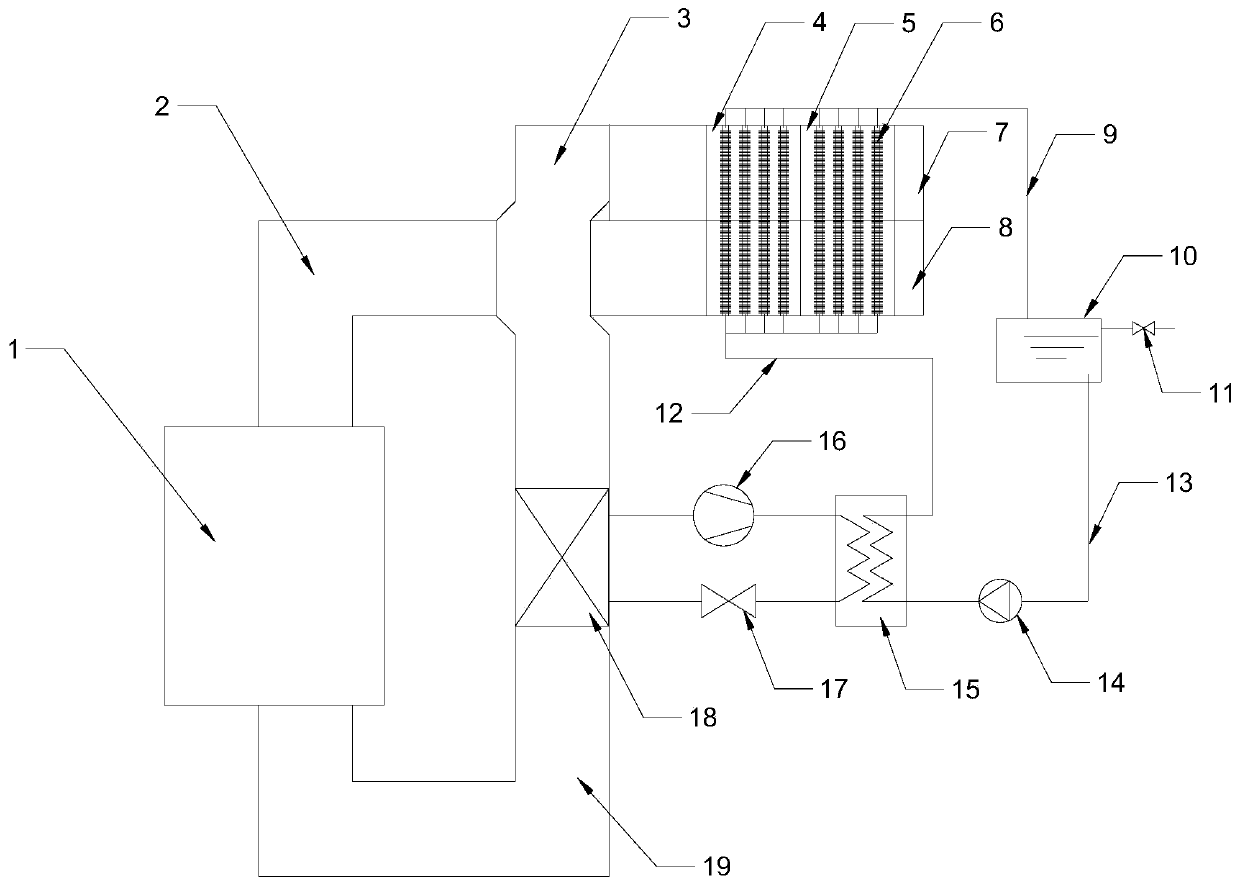

[0036] Embodiment 1: When the ambient temperature is 10 degrees, the exhaust air temperature of the grain dryer is usually higher than 35 degrees, and the air intake requirement for grain drying is not lower than 55 degrees. Through the first multi-fluid heat pipe exchange in the present invention The condensation end of the heat device 4 and the second multi-fluid heat pipe heat exchange device 5 releases heat to preheat the fresh air. After preheating, the temperature of the fresh air can usually reach 30 degrees, and then use the water source heat pump to heat the fresh air to above 60 degrees again. To meet the air inlet temperature requirements of the grain dryer;

Embodiment 2

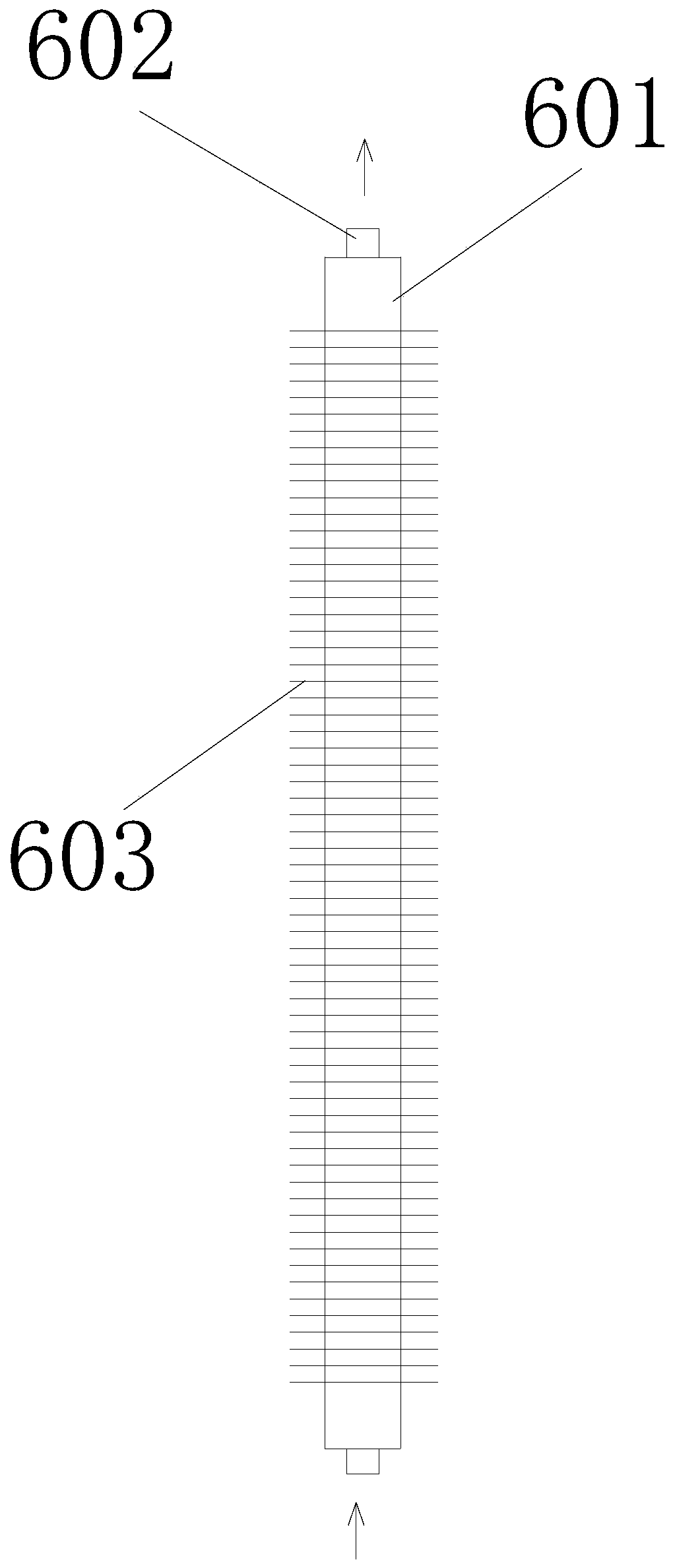

[0037] Embodiment 2: When the ambient temperature is 0 degrees, the exhaust air temperature of the grain dryer is usually higher than 35 degrees, passing through the condensation end of the first multi-fluid heat pipe heat exchange device 4 and the second multi-fluid heat pipe heat exchange device 5 in this system Inside, the condensing end of the multi-fluid sleeve heat pipe 6 releases heat to preheat the fresh air. The fresh air after preheating can usually reach 28 degrees, and then reheated to above 57 degrees by the water source heat pump to meet the requirements of the grain dryer. Inlet air temperature requirements;

Embodiment 3

[0038] Embodiment 3: When the ambient temperature is -5 degrees, the exhaust air temperature of the grain dryer is usually higher than 30 degrees, and the first multi-fluid heat pipe heat exchange device 4 and the second multi-fluid heat pipe heat exchange device 5 are passed through the condensing end. , the condensing end of the multi-fluid sleeve heat pipe 6 releases heat to preheat the fresh air. The preheated fresh air can usually reach 25 degrees, and then use the water source heat pump to reheat to more than 55 degrees to meet the requirements of the grain dryer. Inlet air temperature requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com