Gas boiler system

A gas-fired boiler and flue gas technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of low efficiency, difficulty in popularization and use, increased investment and operating costs, etc., and achieve the effect of cost saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

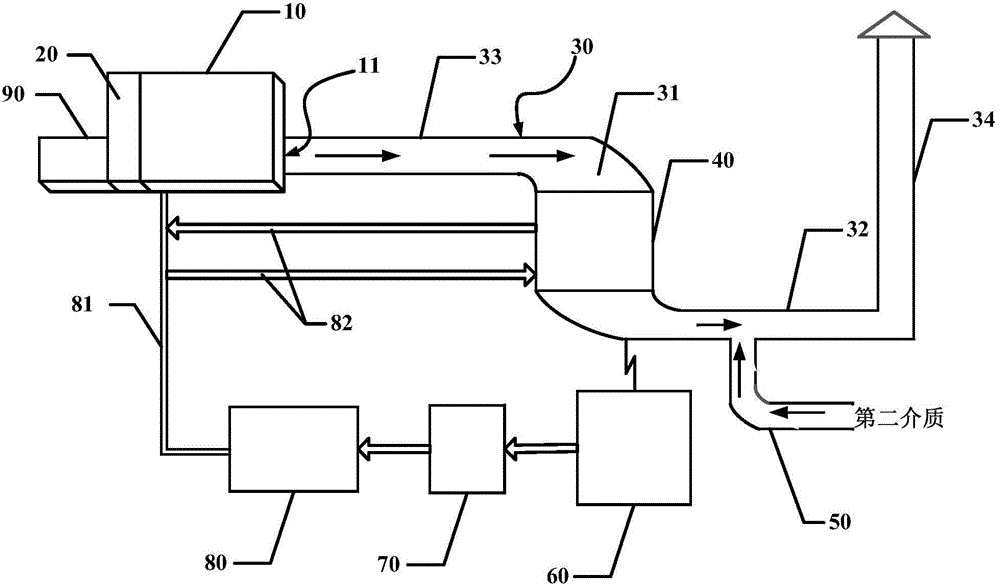

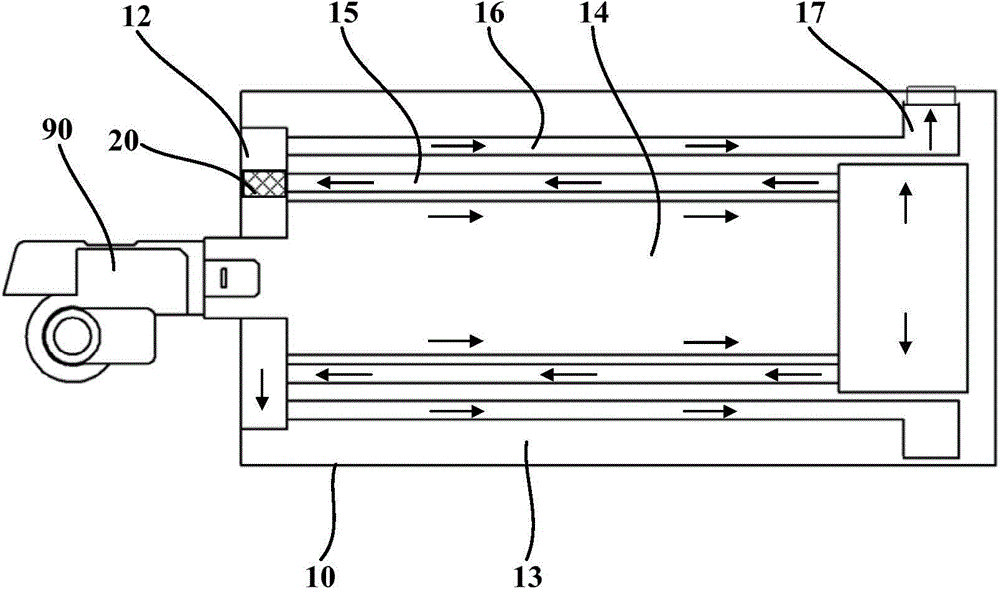

[0022] figure 1 It is a schematic structural diagram of a gas boiler system according to an embodiment of the present invention. Such as figure 1 As shown, the gas boiler system of the embodiment of the present invention may generally include a furnace body 10, a catalytic reactor 20, a flue gas discharge pipeline 30, a flue gas waste heat utilization device 40 arranged in the flue gas discharge pipeline, and The flue gas recooling device 50 in the flue gas discharge pipeline and located downstream of the flue gas waste heat utilization device 40.

[0023] The furnace body 10 has a flue gas discharge port 11 for discharging combustion flue gas. The catalytic reactor 20 is arranged in the furnace body 10 to promote the NO in the flue gas to be oxidized to NO before being discharged from the flue gas outlet 11 2 . The flue gas discharge pipe 30 is arranged outside the furnace body 10 and connected to the flue gas outlet 11 of the furnace body 10 for receiving the flue gas discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com