Heat transfer device and heating system

A heat exchange device and heating system technology, which is applied in the direction of fuel cell heat exchange, reactant parameter control, fuel cell additives, etc., can solve the problem of low utilization rate of waste heat from fuel cell tail gas, and improve the comprehensive utilization efficiency of energy. Easy to disassemble and improve the effect of turbulence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

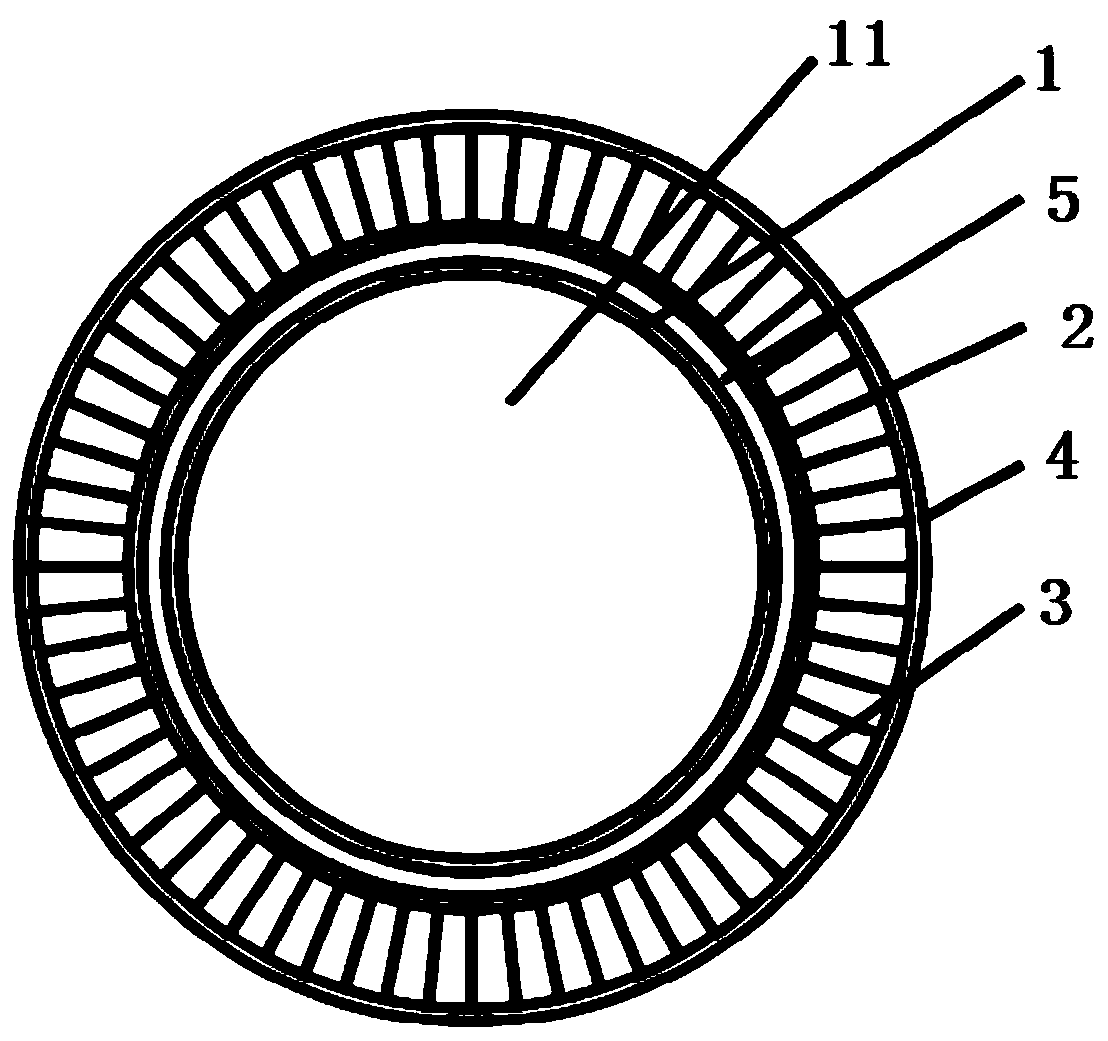

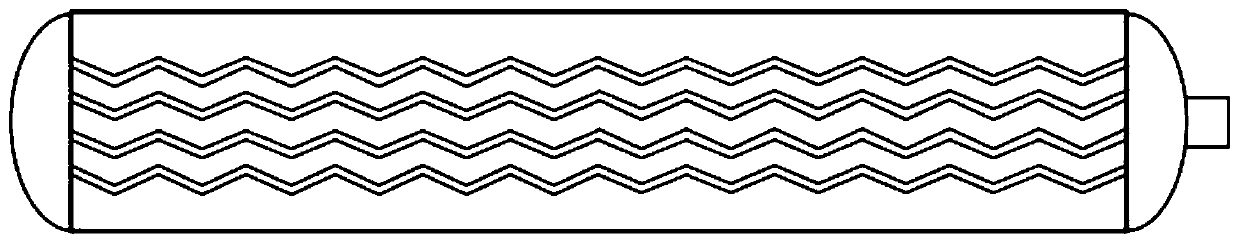

[0035] Such as figure 1 , 2 As shown, a heat exchange device is arranged outside the hydrogen storage tank 1, and inside the hydrogen storage tank 1 is a metal hydride reaction bed 11 capable of generating hydrogen, including an inner sleeve 2 arranged at a distance from the hydrogen storage tank, and the inner sleeve 2 The outer wall is provided with a plurality of fins 3 , and an outer sleeve 4 is arranged outside the fins 3 .

[0036] In this embodiment, the inner sleeve 2 and the outer sleeve 4 are cylindrical structures. In order to facilitate installation and disassembly, they can be set to a detachable structure. , card connection, etc., and then assemble the split type into an integral structure.

[0037] In this embodiment, the fins 3 are fins with a corrugated structure, and are arranged along the outer wall of the inner sleeve 2 along the circumferential direction. The outer surface of the hydrogen storage tank 1 is usually a smooth surface, and the outer surface ...

Embodiment 2

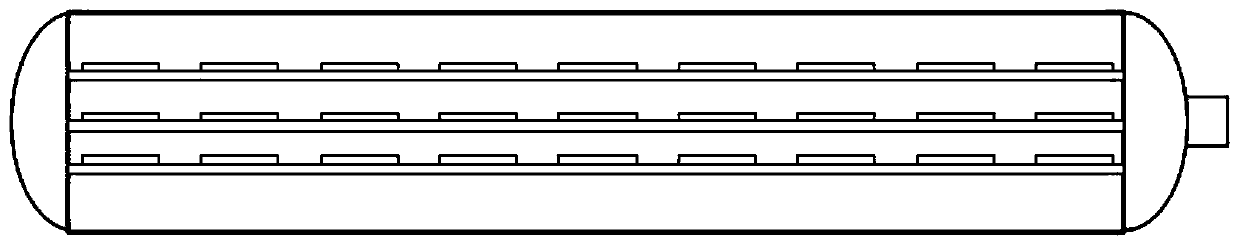

[0041] Such as image 3 As shown, the difference between this embodiment and the first embodiment lies in that the structure of the fins 3 is different.

[0042] The fins 3 in this embodiment are fins with a slit structure.

Embodiment 3

[0044] Such as Figure 4 As shown, the difference between this embodiment and the first embodiment lies in that the structure of the fins 3 is different.

[0045] The fins 3 in this embodiment are fins with a louver structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com