Method for analyzing melting characteristics of biomass ash

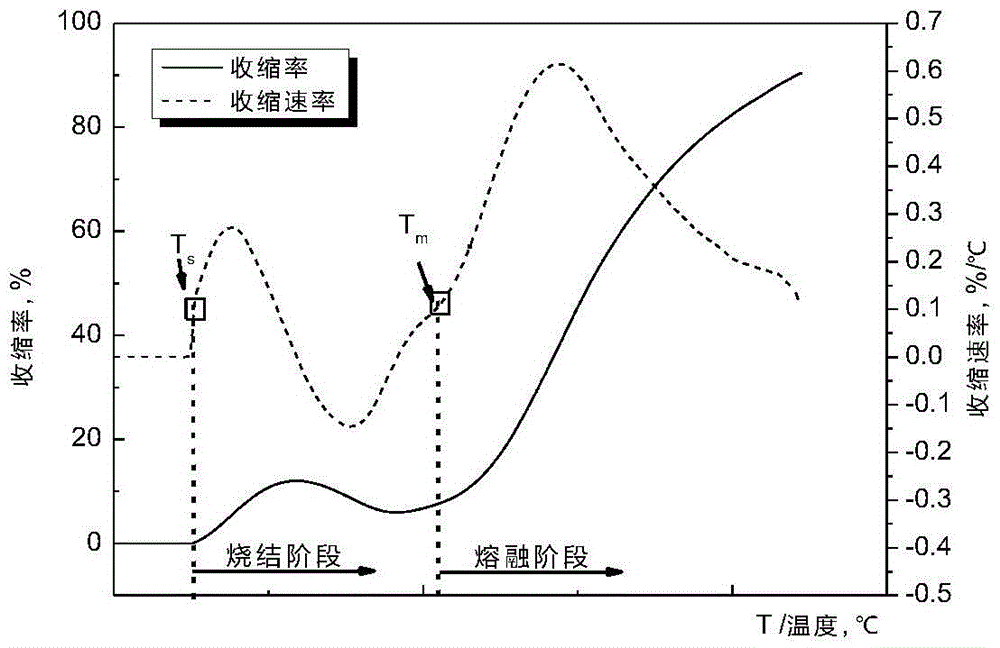

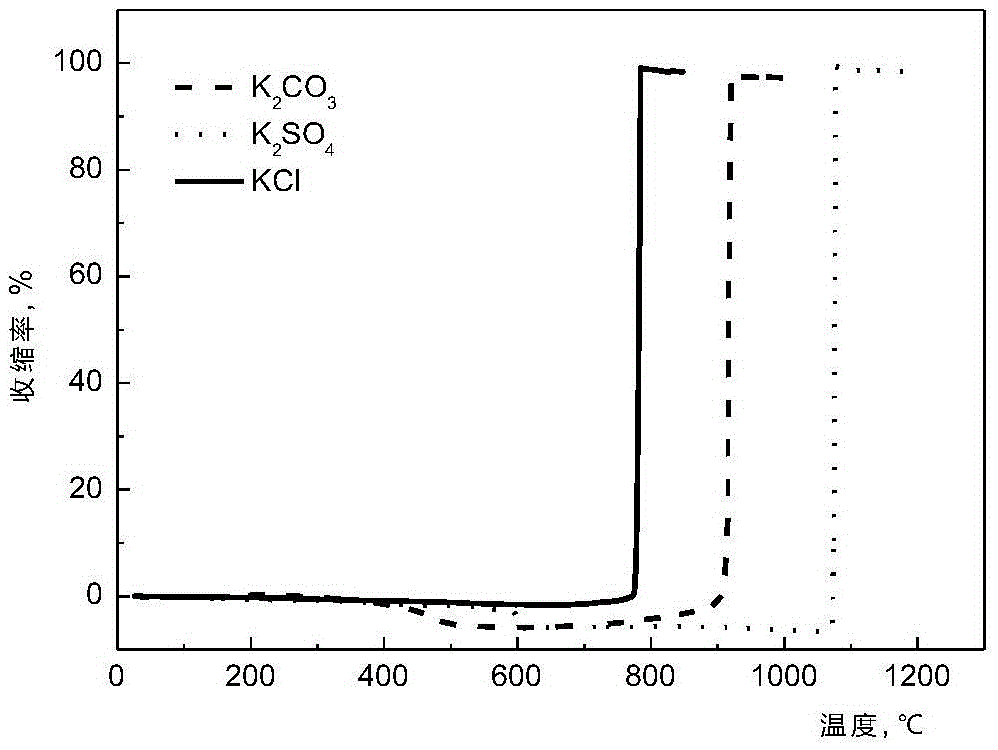

A technology of biomass ash and analysis method, which is applied in the investigation phase/state change, etc., can solve problems such as melting, coal ash melting characteristic evaluation index, and complex biomass ash content, and achieve good repeatability and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

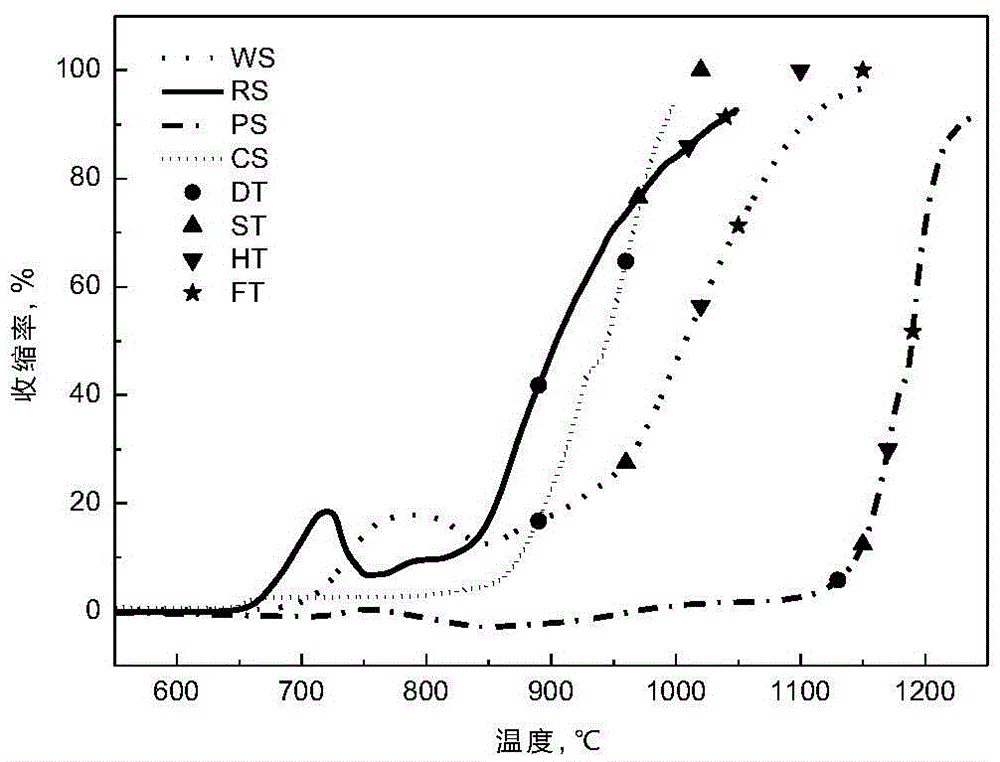

[0035] Embodiment 1 Utilizes thermomechanical analysis to measure the melting characteristics of corn stalk ash (see figure 2 -CS)

[0036] Corn stalks were used as raw materials, crushed and ground through a 1mm sieve; in a muffle furnace, the temperature was raised from room temperature to 250°C at a rate of 5°C / min and maintained for 1 hour, and then continued to rise from 250°C to 550°C and maintained 2hr, the gray sample was prepared; the gray sample was ground and sieved, and the particle size was less than 0.1mm; 50mg of the gray sample was taken for tableting, and put into the test room of the thermomechanical analyzer; Rise from room temperature to 550°C, and then continue to heat up to 1000°C / min at 5°C / min. By analyzing the melting curve, the characteristic temperature is obtained: the sintering characteristic temperature T of corn stalk ash s is 650°C, the characteristic temperature T of the melting stage of corn stalk ash m is 850°C. The characteristic temper...

Embodiment 2

[0037] Embodiment 2 Utilizes thermomechanical analysis to measure the melting characteristics of rice straw ash (see figure 2 -RS)

[0038] Using rice straw as raw material, it was crushed and ground through a 1mm sieve; in a muffle furnace, the temperature was raised from room temperature to 250°C at a rate of 4°C / min and kept for 40 minutes, and then continued to rise from 250°C to 550°C and Keep for 1.5hr to prepare ash sample; grind and sieve the ash sample, the particle size is less than 0.1mm; take 40mg ash sample for tableting, put it into the test room of the thermomechanical analyzer; The heating rate was increased from room temperature to 550°C, and then continued at 2°C / min to 1050°C / min. Through the analysis of the melting curve, the characteristic temperature is obtained: the sintering characteristic temperature T of rice straw ash s is 651°C, the characteristic temperature T of the melting stage of rice straw ash m It is 810°C. The characteristic temperature...

Embodiment 3

[0039] Embodiment 3 Utilizes thermomechanical analysis to measure the melting characteristics of peanut shell ash (see figure 2 -PS)

[0040] Use peanut shells as raw materials, crush and grind them through a 1mm sieve; raise the temperature from room temperature to 250°C at a rate of 6°C / min in a muffle furnace and keep it for 2 hours, then continue to rise from 250°C to 550°C and keep it 3hr to prepare ash sample; grind and sieve the ash sample, the particle size is less than 0.1mm; take 70mg ash sample for tableting, put it into the test room of the thermomechanical analyzer; Rise from room temperature to 550°C, and then continue to heat up to 1250°C / min at 6°C / min. Through the analysis of the melting curve, the characteristic temperature is obtained: the sintering characteristic temperature T of peanut shell ash s is 701°C, the characteristic temperature T of the melting stage of peanut shell ash m It is 865°C. The characteristic temperatures obtained by the pyramid m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com