An analytical method for the fusion properties of biomass ash

A technology of biomass ash and analysis method, applied in the investigation stage/state change and other directions, can solve the problems of melting, complex biomass ash content, evaluation index of coal ash melting characteristics, etc., and achieve the effect of good repeatability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

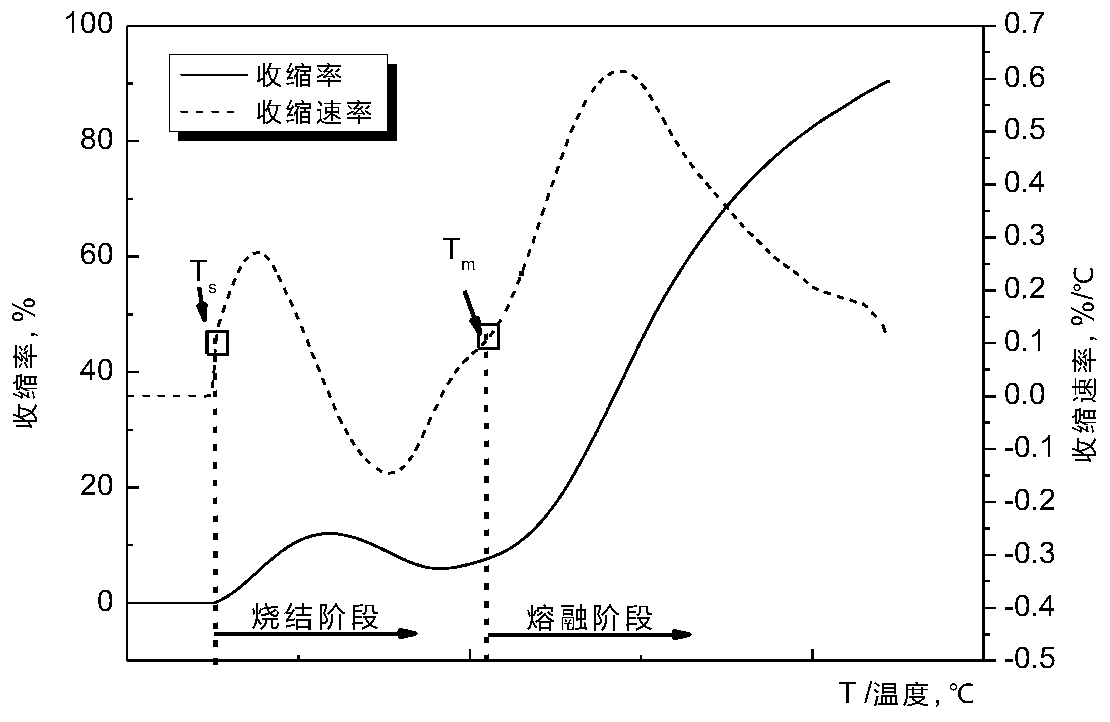

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

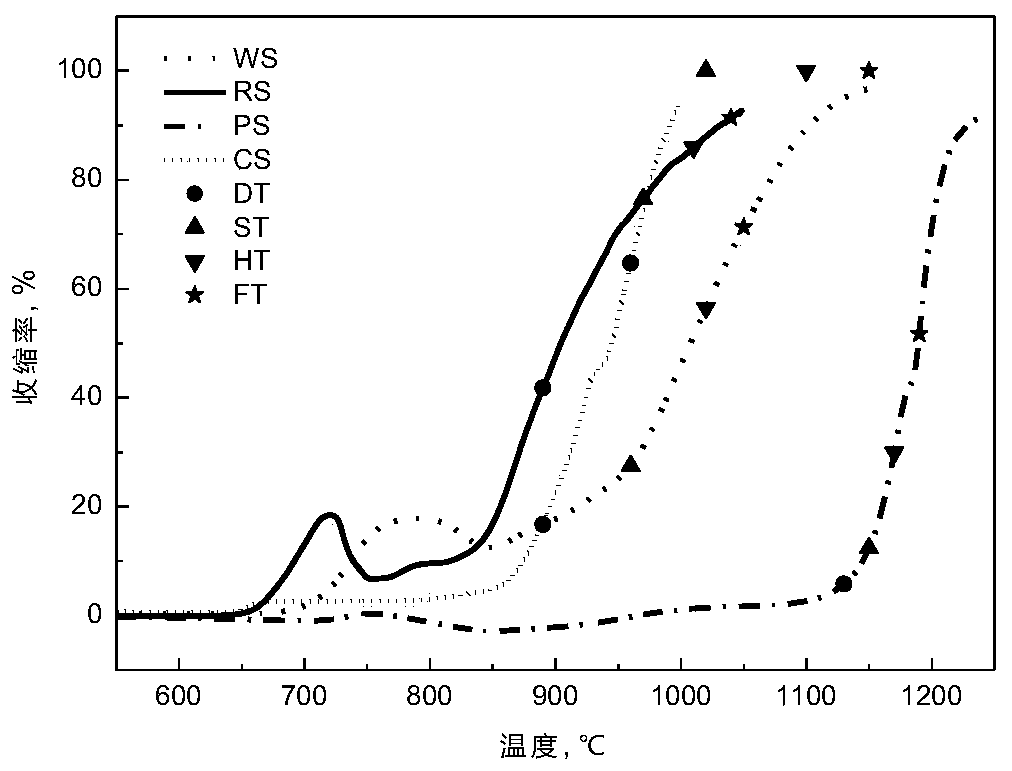

[0035] Embodiment 1 Utilizes thermomechanical analysis to measure the melting characteristics of corn stalk ash (see figure 2 -CS)

[0036] Corn stalks were used as raw materials, crushed and ground through a 1mm sieve; in a muffle furnace, the temperature was raised from room temperature to 250°C at a rate of 5°C / min and maintained for 1 hour, and then continued to rise from 250°C to 550°C and maintained 2hr, the gray sample was prepared; the gray sample was ground and sieved, and the particle size was less than 0.1mm; 50mg of the gray sample was taken for tableting, and put into the test room of the thermomechanical analyzer; Rise from room temperature to 550°C, and then continue to heat up to 1000°C / min at 5°C / min. By analyzing the melting curve, the characteristic temperature is obtained: the sintering characteristic temperature T of corn stalk ash s is 650°C, the characteristic temperature T of the melting stage of corn stalk ash m is 850°C. The characteristic temper...

Embodiment 2

[0037] Embodiment 2 Utilizes thermomechanical analysis to measure the melting characteristics of rice straw ash (see figure 2 -RS)

[0038] Using rice straw as raw material, it was crushed and ground through a 1mm sieve; in a muffle furnace, the temperature was raised from room temperature to 250°C at a rate of 4°C / min and kept for 40 minutes, and then continued to rise from 250°C to 550°C and Keep for 1.5hr to prepare ash sample; grind and sieve the ash sample, the particle size is less than 0.1mm; take 40mg ash sample for tableting, put it into the test room of the thermomechanical analyzer; The heating rate was increased from room temperature to 550°C, and then continued at 2°C / min to 1050°C / min. Through the analysis of the melting curve, the characteristic temperature is obtained: the sintering characteristic temperature T of rice straw ash s is 651°C, the characteristic temperature T of the melting stage of rice straw ash m It is 810°C. The characteristic temperature...

Embodiment 3

[0039] Embodiment 3 Utilizes thermomechanical analysis to measure the melting characteristics of peanut shell ash (see figure 2 -PS)

[0040] Use peanut shells as raw materials, crush and grind them through a 1mm sieve; raise the temperature from room temperature to 250°C at a rate of 6°C / min in a muffle furnace and keep it for 2 hours, then continue to rise from 250°C to 550°C and keep it 3hr to prepare ash sample; grind and sieve the ash sample, the particle size is less than 0.1mm; take 70mg ash sample for tableting, put it into the test room of the thermomechanical analyzer; Rise from room temperature to 550°C, and then continue to heat up to 1250°C / min at 6°C / min. Through the analysis of the melting curve, the characteristic temperature is obtained: the sintering characteristic temperature T of peanut shell ash s is 701°C, the characteristic temperature T of the melting stage of peanut shell ash m It is 865°C. The characteristic temperatures obtained by the pyramid m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com