Preparation method for silicon dioxide/carbon compound and application to lithium/sodium ion batteries

A technology of carbon composites and silicon dioxide, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of low coulombic efficiency in the first week of metal oxides, unstable silicon and tin structures, and complicated processing processes, and achieve The preparation method is simple and easy to operate, the cost is low, and the effect of wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of method using rice husk as raw material to prepare silicon dioxide / carbon compound, comprises the following steps:

[0037] A: Weigh 5g of rice husks, pass through a grinder, and grade and grind until the particle size is 0.8mm;

[0038] B: Put the crushed rice husk obtained in step A into an alumina crucible, and put the alumina crucible containing the rice husk

[0039] The crucible was placed in a tube furnace, heat-treated at 900°C under a nitrogen atmosphere for 4 hours, and then cooled down to room temperature with the furnace;

[0040] C: The product obtained in step B was washed 3 times with deionized water, centrifuged, and the solid obtained by centrifugation was

[0041] The body was dried in a vacuum oven at 80°C for 6 hours to obtain a silica / carbon composite.

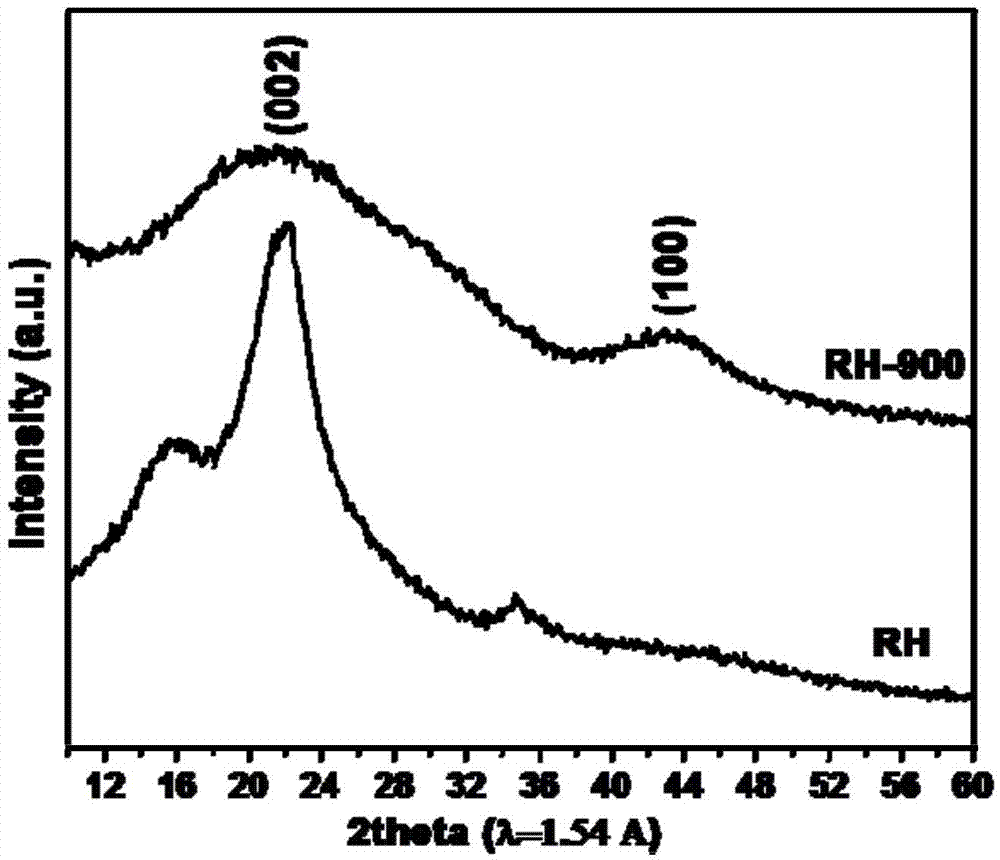

[0042] figure 1For the X-ray diffraction (XRD) pattern of the silica / carbon composite prepared in Example 1, wherein, RH is the untreated rice husk, and RH-900 is the bismuth obtained by...

Embodiment 2

[0052] A kind of method using rice husk as raw material to prepare silicon dioxide / carbon compound, comprises the following steps:

[0053] A: Weigh 5g of rice husk, pass through a mill, and grade and grind to a particle size of 0.8mm.

[0054] The rice husk particles and the KOH solid are mixed in a ratio of 1:3 in mass ratio;

[0055] B: Put the rice husk particles obtained after the treatment in step A into an alumina crucible, and put the rice husk particles

[0056] The alumina crucible was placed in a tube furnace, heat treated at 800°C under a nitrogen atmosphere for 4 hours, and then cooled with the furnace

[0057] to room temperature;

[0058] C: The product obtained in step B was washed 3 times with deionized water, centrifuged, and the solid obtained by centrifugation was

[0059] The body was dried in a vacuum oven at 80°C for 10 h to obtain a silica / carbon composite.

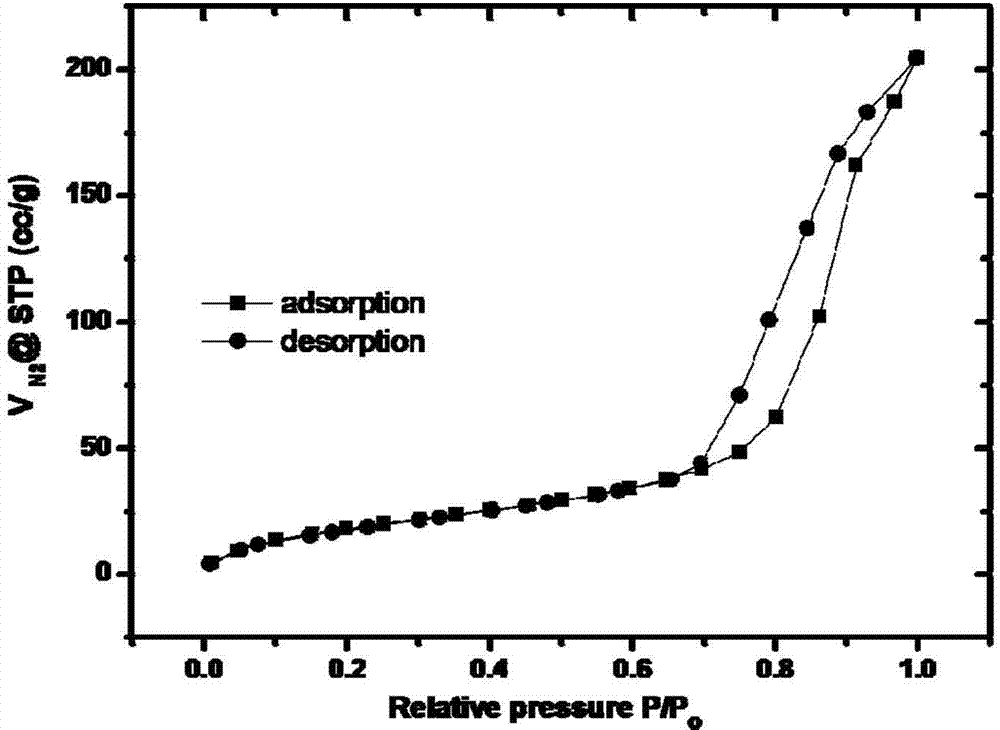

[0060] Figure 9 Be the N of the silica / carbon composite prepared in Example 2 of the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com