Biomass-ash-residue brick as well as preparation method and application thereof

A biomass ash and ash slag technology, applied in the field of comprehensive treatment of solid waste and resource utilization, can solve the problems of restricting the development of biomass power generation, breaking the ecological chain of nutrient elements, occupying land resources, etc. Short processing cycle and good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

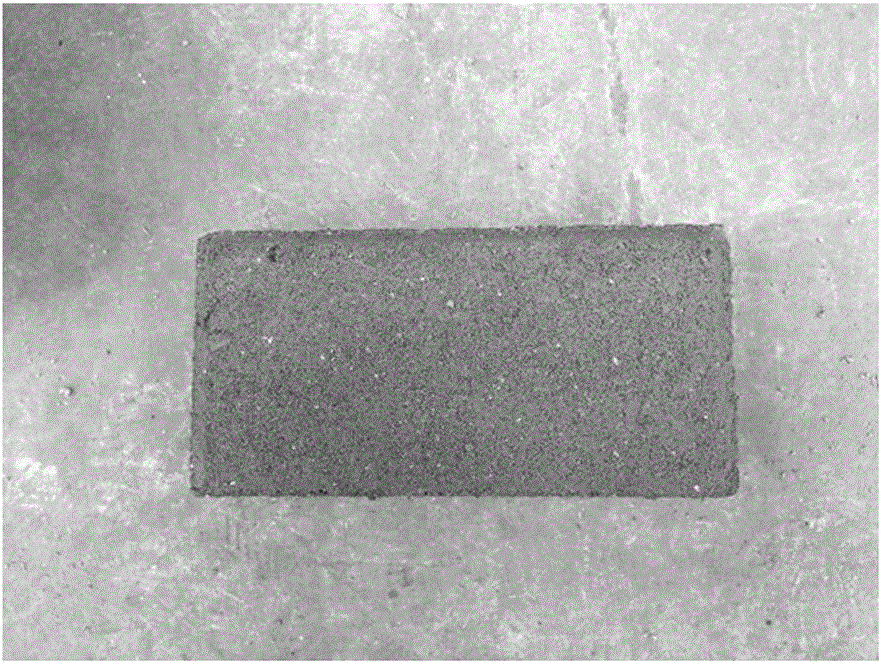

Image

Examples

Embodiment 1

[0031] A preparation method for biomass ash bricks, comprising the steps of:

[0032] (1) Sieve the biomass ash to obtain No. 2 (effective particle size 5-10mm) and No. 3 (effective particle size 0.5-0.8mm) biomass ash;

[0033] (2) Use tap water to clean the above two kinds of biomass ash and slag. After the first cleaning for 20 minutes, replace the tap water, and then wash after the second immersion for 10 minutes. The cleaned ash and slag are weathered and dried under natural conditions;

[0034] (3) Mix 7Kg of No. 2 ash, 3Kg of No. 3 ash and 3Kg of P.O 42.5 cement. Stir with a stirrer at a speed of 120 r / min for 3 minutes at room temperature, and add 3.9 L after stirring for 1 minute. of tap water, and then stirred at a speed of 70 r / min for 1.5 min to obtain a bottom material; meanwhile, mix 10Kg of No. 3 ash and 3Kg of P.O 42.5 cement evenly according to the same steps above to obtain a fabric;

[0035] (4) Place the mold on a vibrating table with an amplitude of 3 mm....

Embodiment 2

[0043] A preparation method for biomass ash bricks, comprising the steps of:

[0044] (1) Sieve the biomass ash to obtain No. 1 (effective particle size 10-30mm), No. 2 (effective particle size 5-10mm) and No. 3 (effective particle size 0.5-0.8mm) biomass material ash;

[0045] (2) Use tap water to clean the three kinds of biomass ash and slag. After the first cleaning for 20 minutes, replace the tap water, and then wash after the second immersion for 10 minutes. The cleaned ash and slag are weathered and dried under natural conditions;

[0046] (3) Mix 3Kg of No. 1 ash, 4Kg of No. 2 ash, 3Kg of No. 3 ash and 3Kg of P.O 42.5 cement, and stir for 3 minutes with a stirrer at a speed of 120 r / min at room temperature. When stirring for 1 minute, add 3.9 L of tap water, and then stir at a speed of 70 r / min for 1.5 minutes to obtain a base material; at the same time, mix 10Kg of No. 3 ash and 3Kg of P.O 42.5 cement according to the same steps as above to obtain a fabric;

[0047] ...

Embodiment 3

[0055] A preparation method for biomass ash bricks, comprising the steps of:

[0056] (1) Sieve the biomass ash to obtain No. 2 (effective particle size 5-10mm) and No. 3 (effective particle size 0.5-0.8mm) biomass ash;

[0057] (2) Use tap water to clean the three kinds of biomass ash and slag. After the first cleaning for 20 minutes, replace the tap water, and then wash after the second immersion for 10 minutes. The cleaned ash and slag are weathered and dried under natural conditions;

[0058] (3) Mix 7Kg of No. 2 ash, 3Kg of No. 3 ash and 3Kg of P.O 42.5 cement. Stir with a stirrer at a speed of 120r / min for 3 minutes at room temperature, and add 4.2 L of Tap water, and then stir at a speed of 70 r / min for 1.5 minutes to obtain a base material; meanwhile, mix 10Kg of No. 3 ash and 3Kg of P.O 42.5 cement evenly according to the same steps above to obtain a fabric;

[0059] (4) Place the mold on a vibrating table with an amplitude of 3 mm. The evenly mixed base material and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Average compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com