Biomass ash bag deduster

A technology of bag dust collector and biomass ash, which is applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., and can solve the problems of poor dust removal effect when replacing filter bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

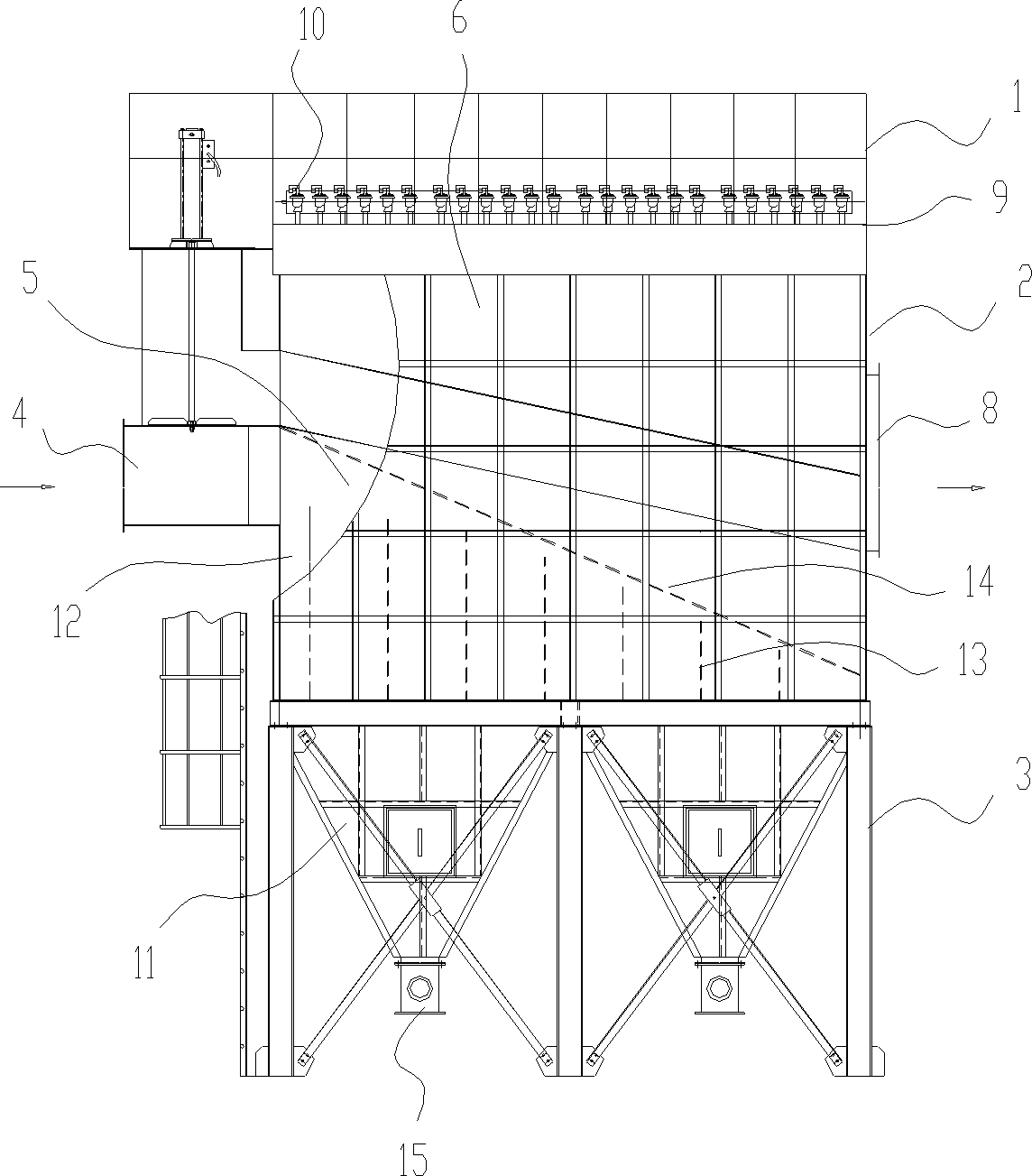

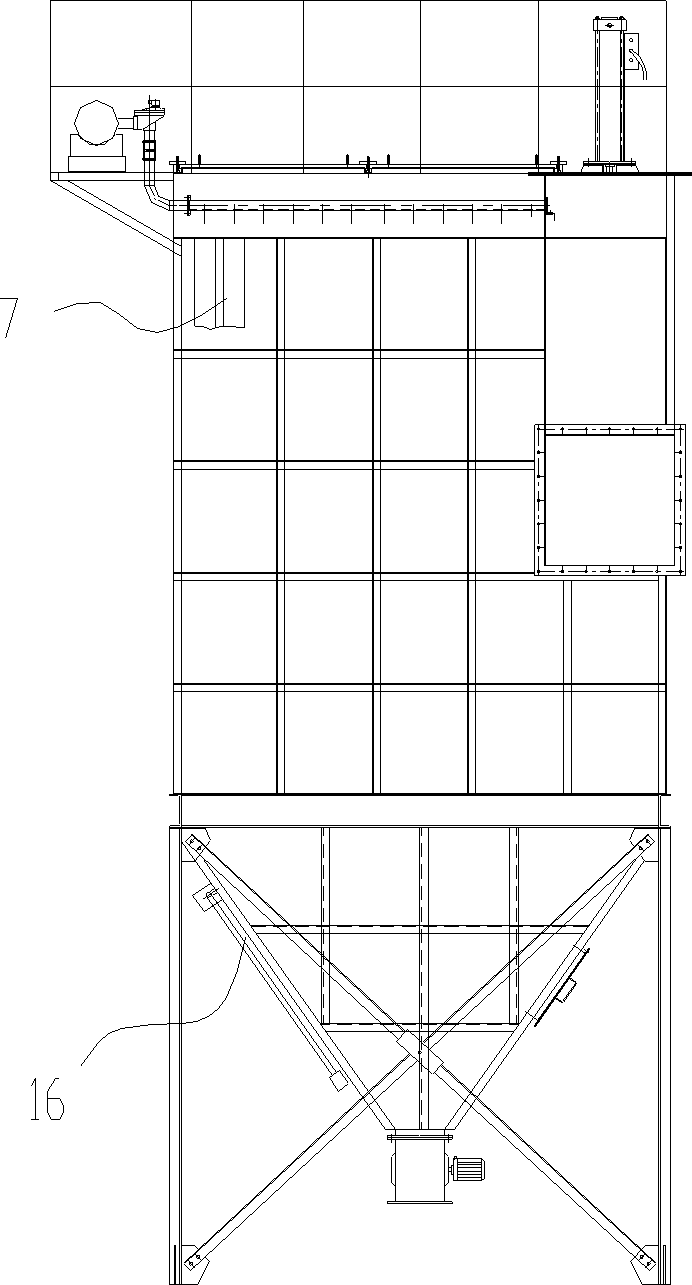

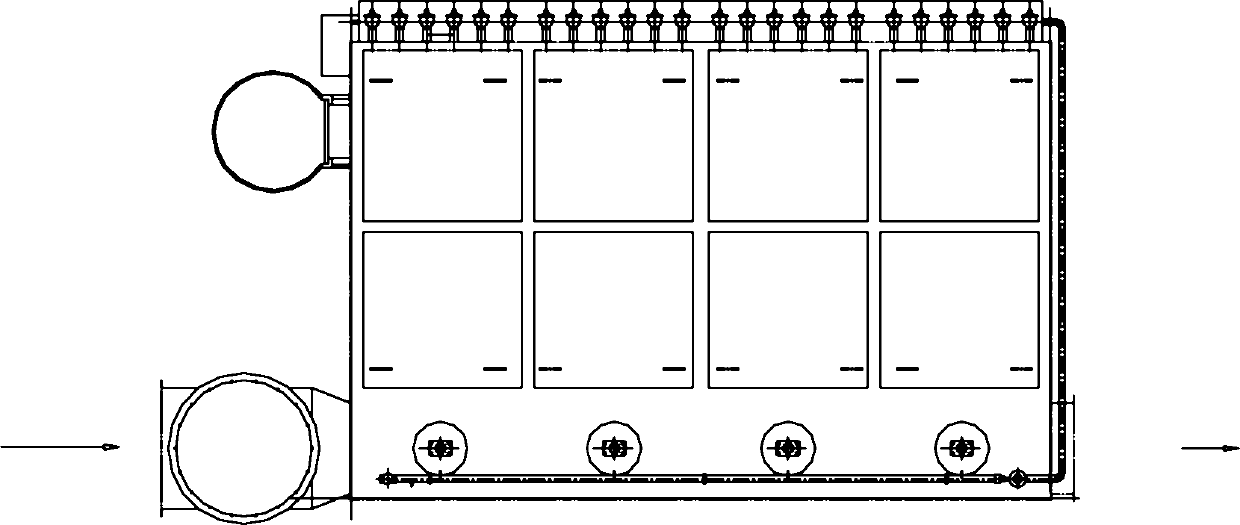

[0024] See Figure 1 to Figure 3 , The biomass dust bag type dust collector of this embodiment includes an upper box body 1, a middle box body 2 and a lower box body 3, wherein the middle box body 2 is provided with an air inlet channel 5 communicating with the dust-containing gas inlet 4, A plurality of bag cages 6 communicating with the air inlet channel 5 are separately arranged above the air inlet channel 5 in the middle box 2, and filter bags 7 are placed in each bag cage and each bag cage passes through an outlet valve (not shown in the figure) ) It communicates with the purified gas outlet 8 and communicates with a pulse valve 10 arranged in the upper box 1 through a nozzle 9 and an ash hopper 11 for discharging ash is provided in the lower box 3.

[0025] When dealing with combustion gas or high-temperature gas, incomplete combustion dust, sparks, combustible and explosive gases, etc. often enter the system. Some dusts have spontaneous combustion or chargeability. At the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com