Method for preparing concrete admixture by utilizing mixture of multiple biomasses

A biomass material and biomass technology, applied in the field of building materials, can solve the problems of difficult to eliminate the influence of concrete durability, ash slagging, low melting point of metal, etc., achieve significant social and economic benefits, and achieve efficient use, The effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

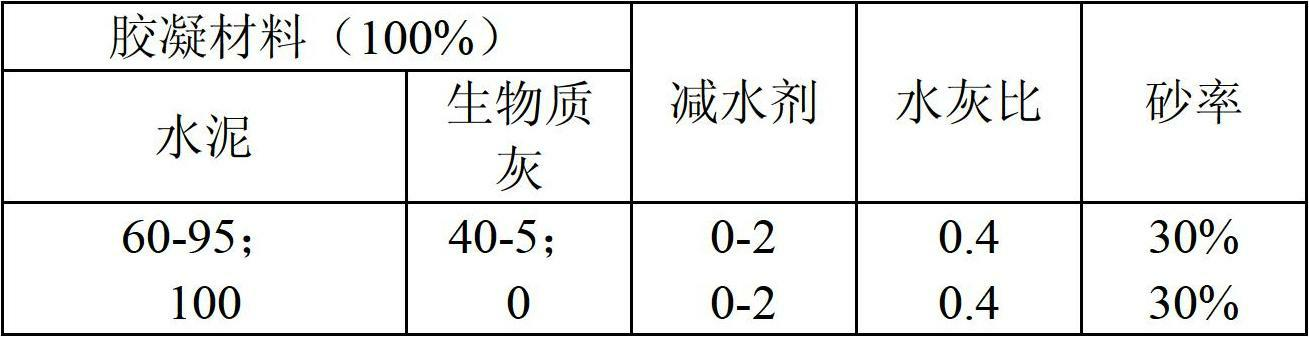

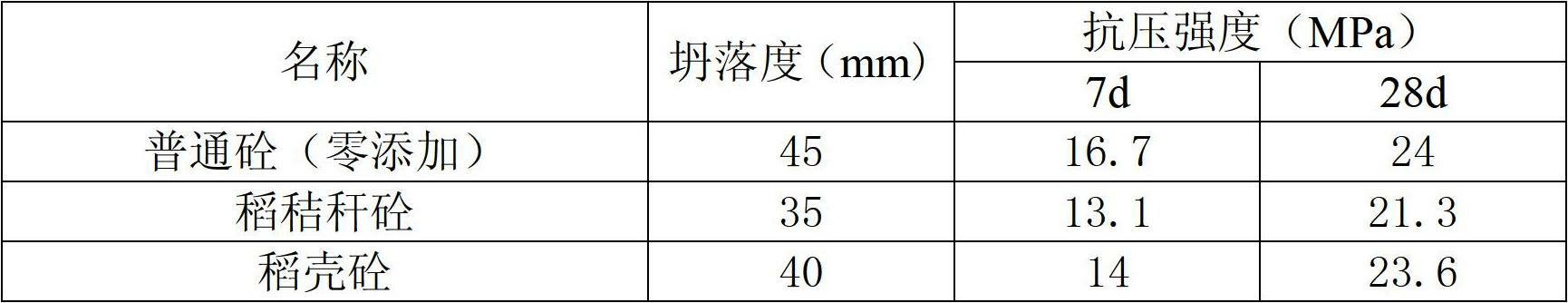

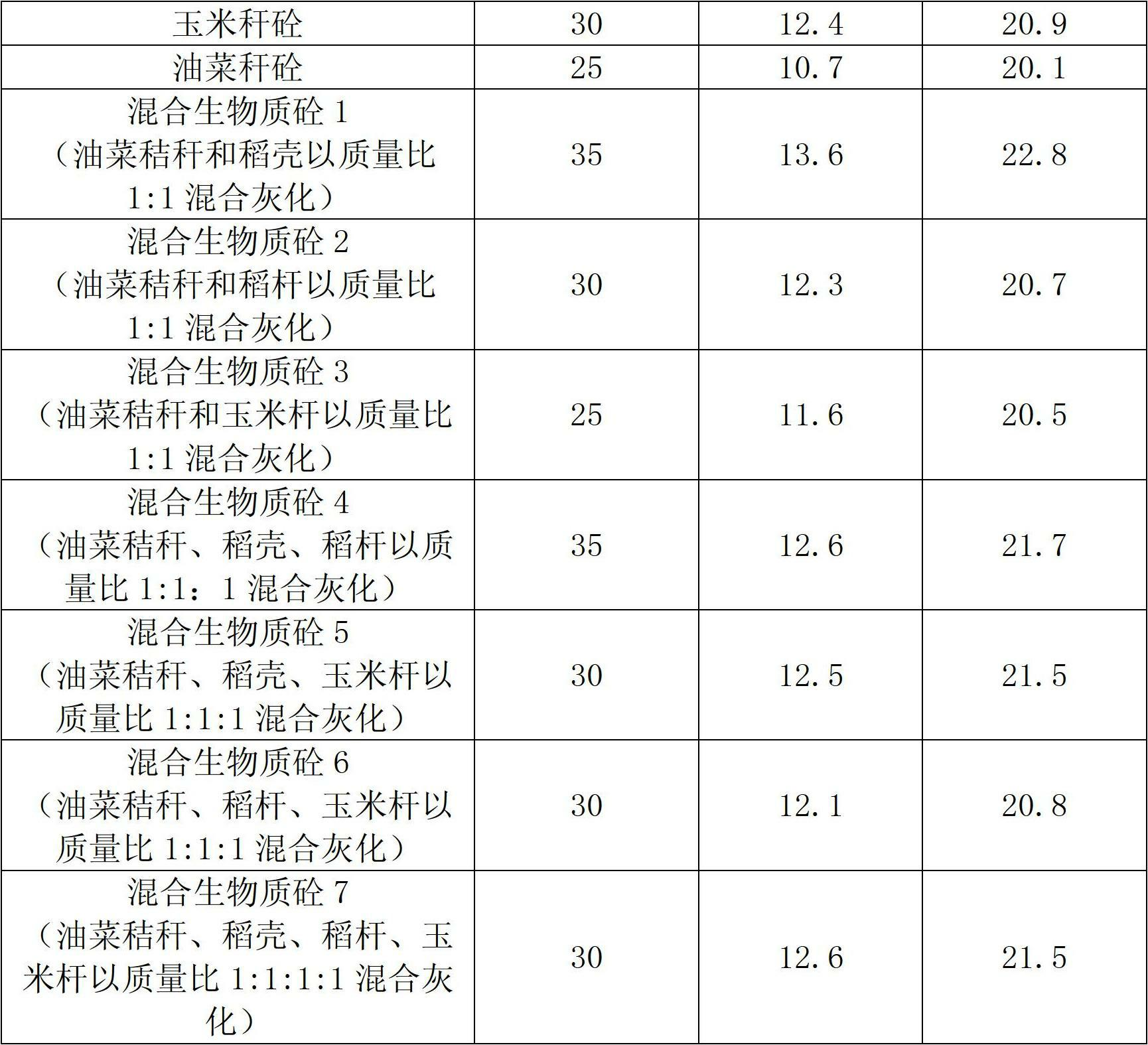

Method used

Image

Examples

Embodiment Construction

[0014] The following examples are intended to illustrate the present invention without further limiting the invention.

[0015] The inventor will use any single biomass of rice stalks, rice husks, corn stalks and rape stalks as an additional admixture, and if the ash content of any single biomass meets the requirements as a cement admixture, then any of the four The ash content must be satisfied after the mixed combustion of two or any three or four kinds of biomass, the reason is that the main chemical composition of the mixed biomass material, especially SiO 2 The content must be higher than the lowest SiO provided in a single biomass 2 content. In addition, ashing after mixing various raw materials will also improve various properties of ash, such as specific surface area and ash melting point. For example: experiments have shown that when rape straw is mixed with any one, two or three of rice straw, rice husk, and corn stalk in equal quantities, the specific surface area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com