Coal-fired power plant boiler biomass reburning denitration agent and preparation method thereof

A technology for coal-fired power plants and denitration agents, applied in separation methods, chemical instruments and methods, fuels, etc., can solve the problems of complex reburning fuel systems, high carbon content in fly ash, and high operating costs, and achieve simple preparation methods and denitrification High efficiency and improved utilization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

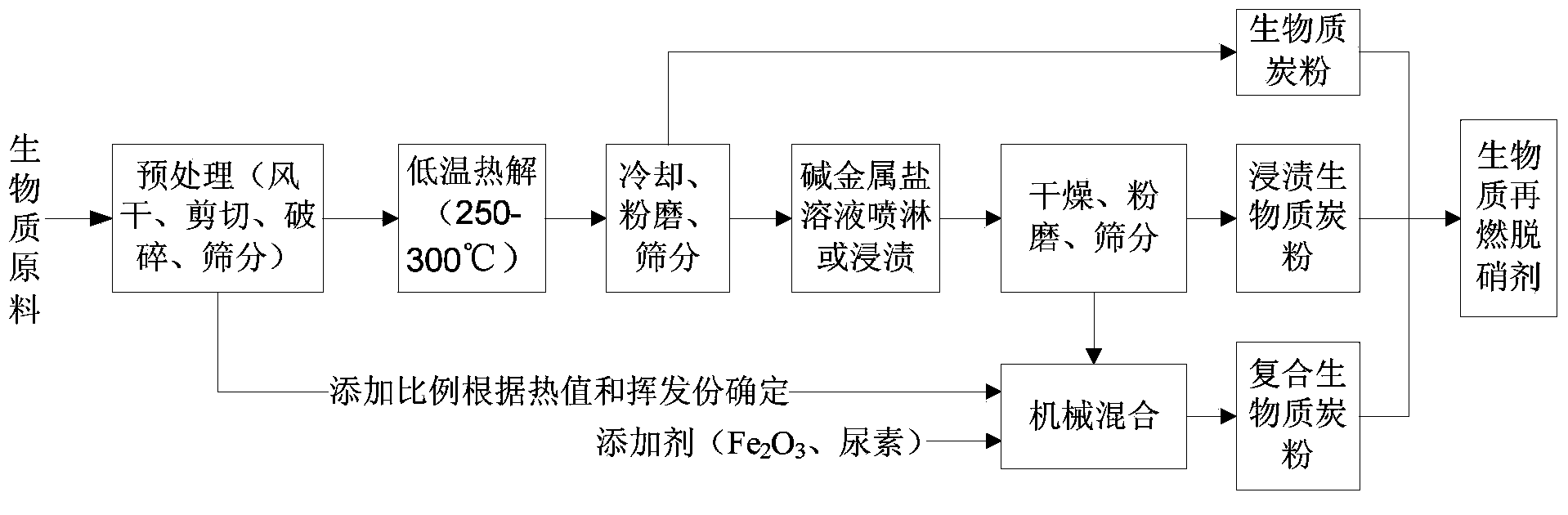

Method used

Image

Examples

Embodiment 1

[0034]In this embodiment, wood chips (SD) are used as raw materials, and after pretreatment processes such as air-drying, crushing, and screening, wood chips with a particle size of less than 5 cm are produced. Weigh about 250g of sawdust samples, put them quickly into a fixed-bed low-temperature pyrolysis carbonization device with a pyrolysis temperature of 250°C and continuous flow of nitrogen (flow rate: 5L / min), turn off the electric heater after pyrolysis for 20 minutes, and Cool down to room temperature. Sawdust charcoal powder (SD250) with a particle size of less than 0.5mm is obtained after crushing, grinding and sieving. Weigh 0.60g of analytically pure Fe with a particle size of less than 0.45mm 2 o 3 and 0.90g of analytically pure urea granules, mixed with 100g of wood chip charcoal powder (SD250) in turn, and mixed thoroughly to prepare wood chip charcoal powder with additives (SD250-UF), and put it into a reagent bottle for later use.

Embodiment 2

[0036] In this embodiment, wood chips (SD) are used as raw materials, and after pretreatment processes such as air-drying, crushing, and screening, wood chips with a particle size of less than 5 cm are produced. Weigh about 200g of sawdust samples, quickly put them into a fixed-bed low-temperature pyrolysis carbonization device with a pyrolysis temperature of 300°C and continuous flow of nitrogen (flow rate: 5L / min), turn off the electric heater after pyrolysis for 20min, and Cool to room temperature. Sawdust charcoal powder (SD300) with a particle size of less than 5mm is obtained after crushing, grinding and sieving.

[0037] Weigh 0.17g NaCl, 0.22g KCl and 0.16g Na 2 CO 3 Analytical pure particles, formulated separately as 5% NaCl, KCl and Na 2 CO 3 solution; the prepared NaCl, KCl and Na 2 CO 3 The solution was evenly sprayed on 100g of wood chip charcoal powder (SD300), and after being fully stirred, it was placed in an oven at 80°C to dry for 2 hours; the dried imp...

Embodiment 3

[0039] In this embodiment, bamboo (BB) is used as raw material, and after pretreatment processes such as air-drying, crushing and sieving, wood pellets with a particle size of less than 5 cm are produced. Weigh about 250g of bamboo samples, quickly put them into a spiral low-temperature pyrolysis carbonization device with a pyrolysis temperature of 275°C and continuous flow of nitrogen (flow rate: 8L / min), turn off the electric heater after pyrolysis for 20min, and Cool to room temperature. Bamboo charcoal powder (BB275) with a particle size of less than 0.5mm was obtained after crushing, grinding and sieving, and put into a reagent bottle for later use.

[0040] Weigh 0.10g NaCl and 0.13g KCl analytically pure particles, and prepare 5% NaCl and KCl solutions respectively; spray the prepared NaCl and KCl solutions evenly on 100g bamboo charcoal powder (BB275) in turn, and place them in the Dry in an oven at 80°C for 2 hours; spray the dried bamboo charcoal powder with 2.50g u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com